Contents

Manufacturing Insight: Large Cnc Mill

Manufacturing Insight: Large CNC Milling Capabilities at Honyo Prototype

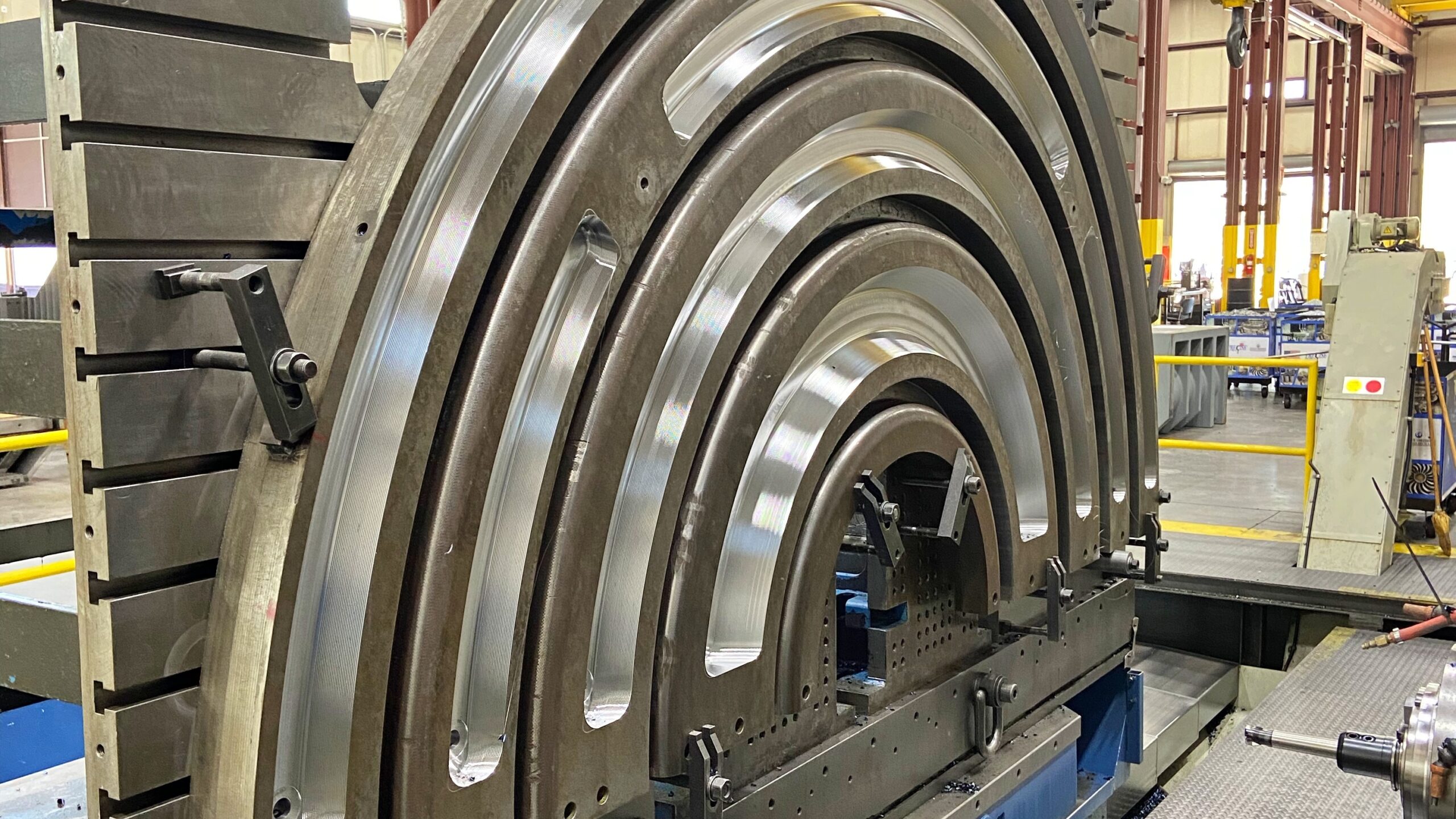

Large-format CNC milling represents a critical capability for industries demanding precision-engineered components beyond standard machine envelopes. At Shenzhen Honyo Prototype, we specialize in machining complex, oversized parts where dimensional stability, tight tolerances, and material integrity are non-negotiable. Our large CNC mills address the unique challenges of scaling up production—such as thermal drift, tool deflection, and fixturing complexity—without compromising the accuracy expected in high-value sectors like aerospace, energy, and heavy machinery. Unlike conventional machining centers, these systems integrate reinforced structural designs, advanced thermal compensation, and high-torque spindles to maintain repeatability across extended work zones. This ensures that parts exceeding 1,500 mm in critical dimensions achieve micron-level precision, eliminating costly rework and assembly delays.

Honyo Prototype operates a dedicated large-mill facility featuring dual-pallet horizontal and vertical machining centers, each engineered for uninterrupted production of monolithic structures. Our equipment portfolio includes machines with work envelopes exceeding 2,000 mm in length, supported by 4th/5th axis integration for complex geometries. Crucially, we implement proprietary fixturing protocols and in-process probing to counteract gravitational sag and vibration in thin-walled or asymmetric components. This methodology, combined with real-time tool wear monitoring, delivers consistent ±0.010 mm tolerances on features up to 2,500 kg, directly translating to reduced scrap rates and accelerated time-to-assembly for our clients.

The technical specifications below reflect our core large-milling infrastructure, validated through ISO 9001-certified processes:

| Parameter | Specification | Industry Relevance |

|————————-|———————————–|———————————————|

| Max Work Envelope | 2,000 x 1,000 x 800 mm (LxWxH) | Accommodates full-scale aerospace brackets |

| Spindle Speed/Torque | 12,000 RPM / 350 Nm (continuous) | Optimized for titanium and Inconel alloys |

| Positioning Accuracy | ±0.005 mm over full travel | Meets AS9100 aerospace standards |

| Control System | Fanuc 31i-B with AI thermal comp | Compensates for ambient temperature shifts |

Our approach extends beyond hardware. Honyo’s engineering team collaborates with clients during DFM (Design for Manufacturing) to optimize part geometry for large-scale milling, minimizing material waste and cycle times. We leverage high-efficiency roughing strategies and adaptive finishing paths to reduce machining time by up to 30% compared to conventional programming—particularly vital for expensive alloys like 7075-T6 aluminum or duplex stainless steels. Furthermore, our facility maintains strict environmental controls (20±1°C) to stabilize thermal conditions, a prerequisite for holding tight tolerances on multi-day operations.

For OEMs developing next-generation infrastructure or transportation systems, Honyo Prototype delivers more than machining; we provide a scalable manufacturing partner capable of bridging prototyping and low-volume production. By integrating large CNC milling with our in-house CMM validation and material certification, we ensure every component meets stringent regulatory requirements while accelerating project timelines. This capability positions Honyo as the strategic choice for engineers confronting the dimensional and precision demands of modern industrial innovation.

Technical Capabilities

Large CNC Milling Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our advanced large-format CNC milling systems are engineered to deliver precision, versatility, and efficiency for complex, high-integrity components across aerospace, industrial equipment, energy, and defense sectors. Our facility is equipped with high-torque, multi-axis CNC machining centers capable of handling workpieces up to 2,500 mm × 1,200 mm × 1,000 mm (X×Y×Z), enabling the production of large-scale prototypes and low-volume production runs with exceptional accuracy.

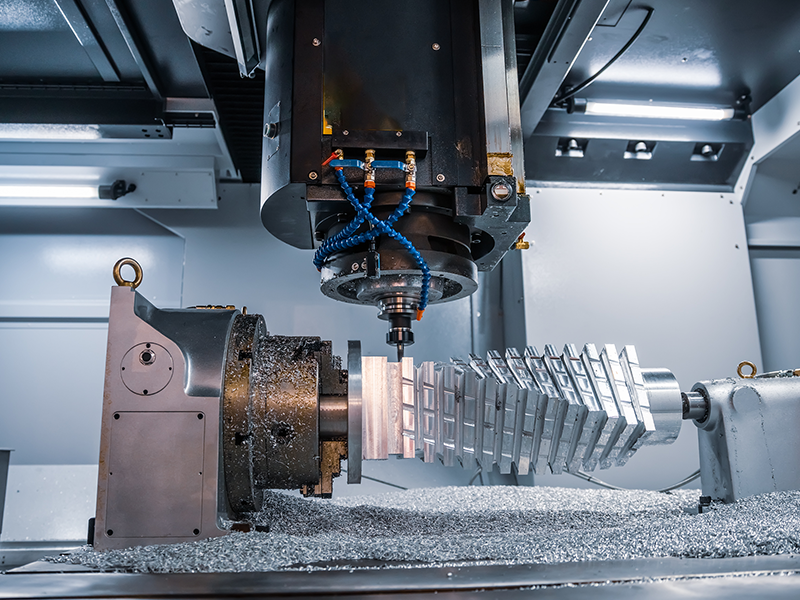

Our machining capabilities span 3-axis, 4-axis, and 5-axis milling processes, allowing for complex geometry creation, reduced setup cycles, and superior surface finishes. The integration of 5-axis simultaneous machining ensures optimal tool access and precision for intricate contours and deep cavities, minimizing the need for secondary operations. In addition to milling, we offer precision CNC turning for cylindrical and rotational components, supporting bar stock diameters up to Ø400 mm with live tooling for mill-turn hybrid operations.

A core strength of our large CNC milling services is our ability to maintain tight tolerances consistently across large part volumes. Our machines are calibrated daily and operate within controlled thermal environments to ensure dimensional stability. We utilize high-rigidity spindles with speeds up to 24,000 RPM and advanced tool monitoring systems to optimize cut quality and prolong tool life. All programs are verified using industry-leading CAM simulation software to prevent collisions and ensure process reliability.

We support a broad range of engineering materials, including aluminum alloys (e.g., 6061, 7075), stainless steels (303, 304, 316), alloy steels (4140, 4340), titanium (Grade 5, Ti-6Al-4V), brass, copper, and high-performance plastics such as PEEK, PTFE, and ULTEM. Material certifications and traceability are available upon request, and our team collaborates closely with clients during material selection to balance performance, machinability, and cost.

The table below outlines our standard tolerance capabilities and supported materials:

| Feature | Specification |

|——–|—————|

| Maximum Work Envelope (Milling) | 2,500 mm × 1,200 mm × 1,000 mm |

| Axis Configuration | 3-axis, 4-axis (indexed), 5-axis (simultaneous) |

| Turning Capacity | Up to Ø400 mm diameter, 1,000 mm length |

| Standard Tolerance (Machining) | ±0.025 mm |

| Tight Tolerance Capability | ±0.005 mm (with process control and inspection) |

| Surface Finish (Typical) | Ra 1.6 μm (standard), down to Ra 0.4 μm (polished/controlled) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.008 mm |

| Repeatability | ±0.005 mm |

| Material Category | Examples | Notes |

|——————|———|——-|

| Aluminum Alloys | 6061, 7075, 2024 | High strength-to-weight, excellent machinability |

| Stainless Steels | 303, 304, 316, 17-4PH | Corrosion resistant, ideal for harsh environments |

| Alloy Steels | 4140, 4340 | High toughness, suitable for load-bearing parts |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | High strength, low density, excellent for aerospace |

| Brass & Copper | C36000, C11000 | Good conductivity, decorative and functional uses |

| Engineering Plastics | PEEK, PTFE, ULTEM, Nylon | Lightweight, chemical resistant, non-conductive |

All large CNC machined parts undergo rigorous quality inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to ensure compliance with engineering specifications. Shenzhen Honyo Prototype combines scale, precision, and technical expertise to deliver mission-critical components with fast turnaround and full process transparency.

From CAD to Part: The Process

From CAD to Precision Part: Large CNC Milling Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our large CNC milling production process is engineered for precision, efficiency, and reliability on complex, oversized components. We streamline the journey from your initial CAD model to the finished physical part through a rigorously defined three-stage workflow: AI-Powered Quoting, Expert Design for Manufacturability (DFM) Review, and Optimized Production Execution. This integrated approach minimizes risk and ensures optimal outcomes for demanding large-part applications.

The process initiates with our proprietary AI Quote Engine. Upon receipt of your 3D CAD model (STEP, IGES, or native formats accepted), the system performs an instant, multi-faceted analysis. It accurately calculates material volume, assesses geometric complexity including deep cavities and thin walls, identifies critical tolerances, and evaluates required fixture strategies specific to large-scale machining. This generates a highly precise cost estimate and lead time within minutes, providing immediate project visibility while flagging potential high-risk features for immediate engineering attention. This speed and accuracy eliminate traditional quoting bottlenecks.

Following quote acceptance, your design undergoes a mandatory DFM review by our senior manufacturing engineering team. This is not a passive check; it’s an active collaboration. Engineers scrutinize the model specifically for large-part challenges: verifying structural stability during machining to prevent deflection, assessing optimal material block sizing to minimize waste on expensive alloys, confirming achievable tolerances across extended dimensions, and proposing strategic feature modifications. Common recommendations include adjusting internal radii for standard tool access, optimizing wall thickness for rigidity, or suggesting phased machining sequences. Client approval of the DFM report is required before production, ensuring alignment and preventing costly revisions later.

Production leverages our specialized large-format CNC milling capabilities. Parts are meticulously fixtured using modular tombstone systems or custom-designed bases to ensure stability across the entire work envelope. Machining employs optimized, verified toolpaths generated in Mastercam, prioritizing material removal rate while maintaining surface finish and dimensional accuracy. Our large mills utilize high-torque spindles and robust construction to handle the significant forces involved in machining large aluminum, steel, or titanium billets. In-process inspections via coordinate measuring machines (CMM) or on-machine probing validate critical features at defined stages, guaranteeing conformance before final finishing and deburring.

The table below outlines key specifications of our primary large CNC milling platforms, essential for handling your most demanding projects.

| Machine Parameter | Typical Range for Large Mills | Significance for Large Parts |

| :———————- | :—————————- | :———————————————– |

| Max Work Envelope (X) | 2000 mm – 5000 mm | Accommodates substantial part footprints |

| Max Work Envelope (Y) | 1000 mm – 2500 mm | Supports wide components |

| Max Work Envelope (Z) | 800 mm – 1500 mm | Enables deep cavity machining |

| Spindle Power | 22 kW – 50 kW | Delivers torque for aggressive metal removal |

| Rapid Traverse (X/Y/Z) | 30 m/min – 45 m/min | Reduces non-cutting time on large travel moves |

| Positioning Accuracy | ≤ ±0.005 mm | Critical for maintaining tolerances over scale |

This proven workflow – from AI-driven quoting through proactive DFM to precision large-scale production – ensures Honyo Prototype delivers complex, high-integrity machined parts on time and to exacting specifications, establishing us as a trusted partner for demanding large-component manufacturing.

Start Your Project

Start Your Large CNC Mill Project with Precision and Confidence

When it comes to manufacturing high-precision components at scale, large CNC milling plays a critical role in delivering parts with tight tolerances, superior surface finishes, and complex geometries. At Shenzhen Honyo Prototype, we specialize in advanced CNC machining services tailored to meet the demands of industries ranging from aerospace and automotive to industrial equipment and medical devices. Our state-of-the-art large-format CNC milling capabilities ensure that even the most intricate designs are produced with unmatched accuracy and repeatability.

Large CNC milling allows for the machining of oversized components that standard machines cannot accommodate. Whether your project involves aluminum, stainless steel, titanium, or engineering plastics, our multi-axis milling centers are equipped to handle workpieces up to 2000 mm in length with micron-level precision. We combine cutting-edge technology with expert programming and setup to minimize cycle times and reduce production costs—without compromising on quality.

Our manufacturing process begins with a thorough review of your design files. We support a wide range of CAD formats, including STEP, IGES, SolidWorks, and DXF, and our engineering team performs a comprehensive Design for Manufacturability (DFM) analysis to identify potential improvements in material selection, tool access, and feature optimization. This proactive approach helps eliminate costly revisions and accelerates time-to-market.

Once your design is finalized, we move swiftly into production using high-rigidity machines with dynamic tool compensation and real-time monitoring systems. Our skilled machinists oversee every stage, ensuring consistent part quality across both prototypes and low-to-mid volume production runs. All finished components undergo rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy and compliance with your specifications.

Below are key specifications for our large CNC milling capabilities:

| Parameter | Specification |

|—————————-|———————————————-|

| Maximum Work Envelope | 2000 mm × 1000 mm × 800 mm |

| Spindle Speed | Up to 12,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (e.g., PEEK, Delrin) |

| Axis Configuration | 3-axis, 4-axis, and 5-axis milling |

| Tolerances | Standard: ±0.025 mm; Tight: ±0.005 mm |

| Surface Finishes | As-machined, Deburred, Bead-blasted, Anodized (Type II & III), Powder Coating |

Partnering with Shenzhen Honyo Prototype means gaining access to a reliable, responsive, and technically proficient manufacturing partner committed to your project’s success. We understand the urgency of prototyping and production timelines, which is why we offer rapid quoting and fast turnaround without sacrificing precision.

Ready to bring your next large-scale CNC milled component to life? Contact Susan Leo today at info@hy-proto.com. Share your design files and project requirements, and we’ll provide a detailed quote, DFM feedback, and a clear production timeline—fast and hassle-free. Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.