Contents

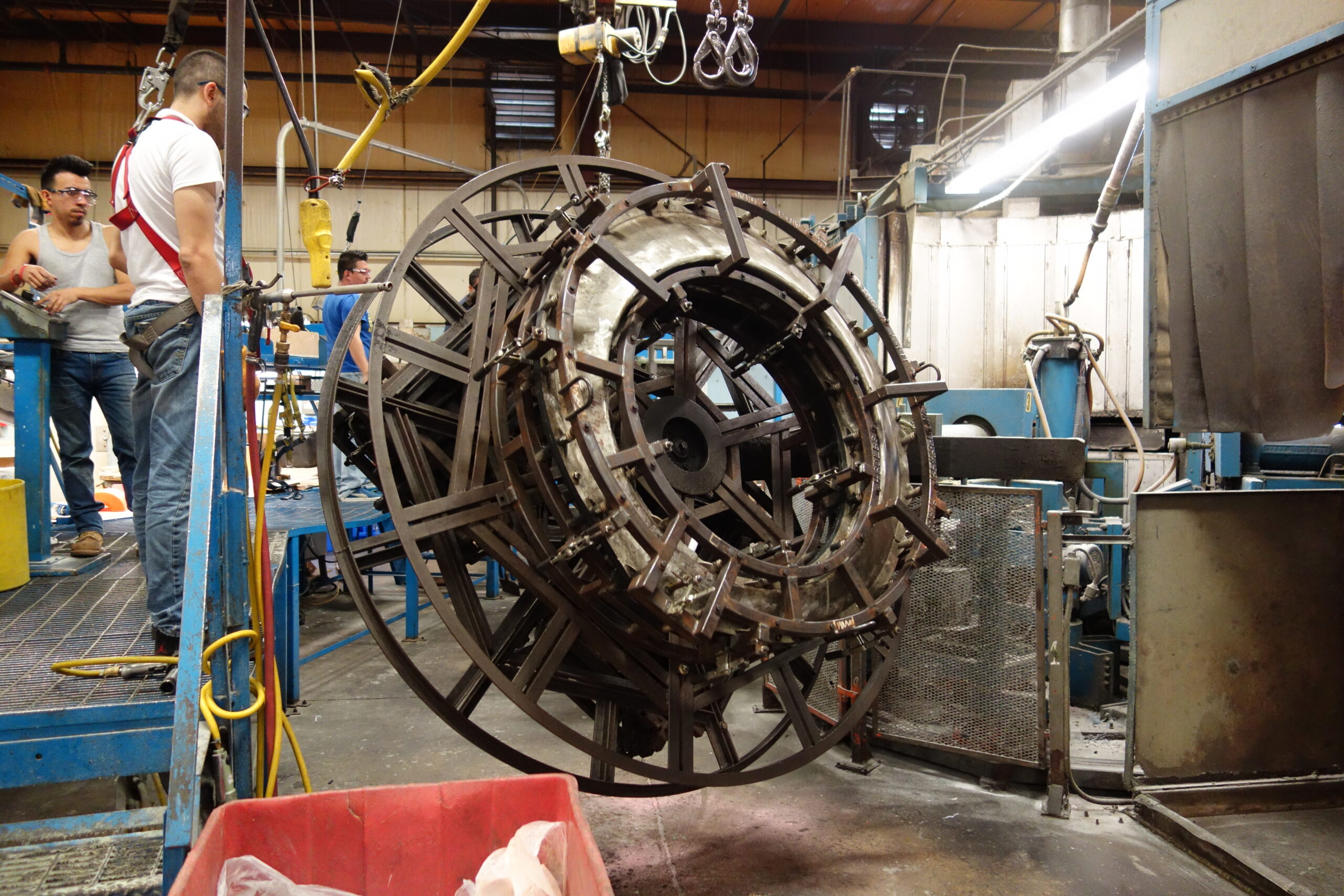

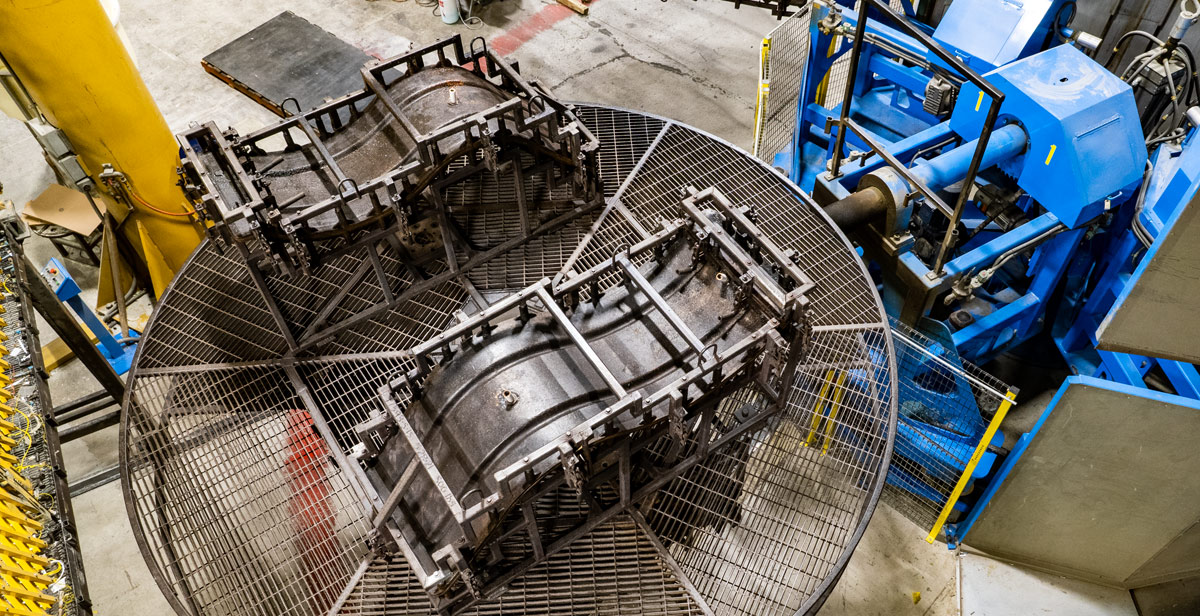

Manufacturing Insight: Rotational Molding Machine

Rotational Molding: Precision Prototyping for Complex Geometries

Rotational molding (rotomolding) is a critical thermoplastic processing technique uniquely suited for producing seamless, hollow, one-piece parts with complex geometries and uniform wall thickness. Unlike injection molding, which relies on high pressure, rotomolding uses low-pressure gravity distribution of polymer powder within a heated, bi-axially rotating mold. This process eliminates internal stresses, weld lines, and the need for expensive multi-part tooling, making it exceptionally cost-effective for low-to-medium volume prototyping and end-use production of large components. At Shenzhen Honyo Prototype, we leverage this technology to bridge design validation and functional testing gaps where traditional methods fall short.

Process Fundamentals and Strategic Advantages

The rotomolding cycle involves four key phases: mold loading with polymer powder, biaxial rotation within a heated oven for melting and coating, controlled cooling to solidify the part, and demolding. This slow, thermal-driven process accommodates intricate undercuts, integrated textures, and oversized parts—often exceeding 1.5 meters in dimension—that would be prohibitively expensive or impossible via injection molding. Material versatility is a cornerstone advantage; our facility specializes in polyethylenes (LDPE, HDPE, LLDPE), polypropylene, and select thermoplastic elastomers (TPEs), enabling prototypes with UV resistance, chemical stability, or impact toughness for rigorous field testing. Crucially, rotomolding’s low tooling costs (using cast aluminum or machined composites) allow rapid iteration. Design modifications can be implemented in days, not weeks, accelerating your product development timeline without sacrificing structural integrity.

Honyo Prototype’s Rotomolding Capabilities

Shenzhen Honyo Prototype integrates industrial-scale rotomolding within our rapid tooling ecosystem, specifically optimized for engineering-grade prototypes and pilot runs. Our dedicated rotomolding line features CNC-controlled ovens and precision arm systems, ensuring repeatable thermal profiles and wall consistency down to ±0.5mm tolerance. We prioritize speed-to-part without compromising quality, leveraging in-house aluminum tool fabrication to reduce lead times by 40% compared to steel alternatives. Below are key operational specifications:

| Parameter | Specification | Relevance for Prototyping |

|————————-|—————————————-|—————————————–|

| Max Mold Cavity Size | 1500 x 1000 x 800 mm | Supports large-scale industrial parts |

| Typical Wall Thickness | 3–12 mm (adjustable per design) | Enables functional stress testing |

| Cycle Time Range | 15–45 minutes | Facilitates rapid design iterations |

| Material Compatibility | PE (all grades), PP, TPE | Validates material performance early |

| Tooling Lead Time | 7–10 days (aluminum) | Cuts development cycle by weeks |

Why Partner with Honyo?

For engineering teams facing challenges with oversized assemblies, watertight enclosures, or ergonomic consumer products, Honyo’s rotomolding service delivers production-intent prototypes with real-world performance data. Our process expertise ensures minimal distortion during cooling and precise replication of surface finishes—from matte textures to Class A surfaces—critical for user trials and investor demonstrations. By combining rotomolding with our rapid CNC tooling and DFM analysis, we eliminate the traditional trade-off between speed and fidelity. Contact Honyo Prototype to integrate rotomolding into your development workflow and transform complex design concepts into validated, manufacturable solutions.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision rotational molding solutions tailored for rapid tooling and low-to-medium volume production. Our rotational molding machines are engineered to support rapid prototyping and functional testing, with a focus on delivering T1 samples within 7 days from mold approval. This accelerated timeline is made possible through in-house mold fabrication, automated processing controls, and streamlined post-production validation. Our capabilities are optimized for both steel and aluminum molds, allowing flexibility in tool life, thermal response, and part complexity.

Our rotational molding process excels in producing hollow, seamless plastic components with uniform wall thickness and excellent structural integrity. The process is ideal for large, geometrically complex parts such as tanks, enclosures, automotive components, and recreational equipment. We utilize a biaxial rotation system that ensures even material distribution during heating, followed by controlled cooling to minimize warpage and residual stress. Machine ovens are calibrated for precise temperature gradients, and rotational speeds are programmable to match part geometry and material behavior.

Mold materials are selected based on production volume, detail requirements, and thermal efficiency. Aluminum molds offer faster cycle times and are ideal for prototyping and short runs due to their high thermal conductivity and ease of machining. Steel molds, typically fabricated from P20 or 4140 alloy steel, provide superior durability and surface finish for long-term production. Both mold types are CNC-machined in-house with tight process control, ensuring dimensional accuracy and consistent part replication.

We support a wide range of engineering-grade thermoplastics, including polyethylene (HDPE, LDPE, LLDPE), polypropylene (PP), nylon, and PVC. Material selection is guided by mechanical performance, chemical resistance, UV stability, and regulatory compliance. All materials are pre-compounded and loaded as fine powders to ensure optimal flow and fusion during rotation.

The following table outlines key tolerances and compatible materials for our rotational molding process:

| Parameter | Standard Tolerance | Notes |

|——————————-|——————–|——-|

| Linear Dimensions (up to 500 mm) | ±0.5 mm | Increases by 0.1 mm per additional 300 mm |

| Wall Thickness | ±10% of nominal | Uniformity optimized via rotational speed and cycle profiling |

| Draft Angles | 1°–3° | Required for part ejection; depends on surface finish |

| Surface Finish | As-molded (MT-11xx), Textured, Polished | Custom textures available |

| Part Size Range | Up to 2000 x 1200 x 1000 mm | Maximum chamber capacity |

| Mold Material Options | Aluminum (6061, 7075), Steel (P20, 4140) | Steel recommended for >1,000 cycles |

| Lead Time (T1 Sample) | 7 days | From finalized CAD and material approval |

| Compatible Materials | HDPE, LDPE, LLDPE, PP, Nylon, PVC | FDA, UV-stabilized, and flame-retardant grades available |

At Shenzhen Honyo Prototype, we integrate advanced process monitoring with rigorous quality inspection to ensure every T1 sample meets functional and dimensional requirements. Our technical team collaborates closely with clients during design for manufacturability (DFM) to optimize part geometry, minimize cycle time, and ensure rapid iteration. With a focus on speed, accuracy, and material versatility, our rotational molding services support fast-to-market development cycles across industrial, medical, and consumer sectors.

From CAD to Part: The Process

Rotational Molding Production Workflow: From CAD to Final Part

Rotational molding delivers seamless, stress-free hollow parts ideal for prototypes and low-volume production. At Shenzhen Honyo Prototype, our streamlined workflow ensures precision and speed, transforming your CAD model into a finished component through three critical phases: AI Quote, DFM optimization, and controlled production.

The process initiates with the AI Quote phase. Clients submit CAD files (STP/IGS formats preferred) via our secure portal. Honyo’s proprietary AI engine instantly analyzes geometry, wall thickness distribution, draft angles, and material compatibility. This automated assessment generates a preliminary cost estimate and timeline within 2 hours, highlighting potential manufacturability risks such as excessive thin sections or undercuts incompatible with rotomolding’s biaxial rotation. Early cost transparency allows rapid project validation without engineering resource commitment.

Following quote acceptance, the DFM (Design for Manufacturability) phase commences. Honyo’s senior engineers conduct a collaborative review, focusing on optimizing cavity design, venting, and parting lines to eliminate air traps and ensure uniform material distribution. Critical considerations include: adjusting radii to prevent stress concentration, verifying adequate draft for mold release, and specifying optimal wall thickness tolerances (±15% typical). We provide actionable feedback within 24 hours, often suggesting minor geometry tweaks that prevent costly iterations during tooling. This phase minimizes post-tooling rework and accelerates time-to-market.

Upon DFM sign-off, Production begins with rapid tool fabrication. Honyo utilizes aluminum or mild steel molds, CNC-machined to ±0.1mm accuracy for prototype fidelity. The mold is mounted on a biaxial rotational arm, preheated, and charged with precisely measured powdered polyethylene (PE) or polypropylene (PP). Key process parameters are strictly controlled:

| Parameter | Typical Range | Critical Impact |

|——————–|———————|——————————————|

| Oven Temperature | 300–400°C | Material sintering and fusion quality |

| Rotation Speed | 4–15 RPM (biaxial) | Wall thickness uniformity |

| Cycle Time | 15–45 minutes | Throughput efficiency |

| Coolant Temp | 15–25°C | Dimensional stability and surface finish |

The mold rotates slowly in two axes while heating, ensuring even polymer coating. After fusion, controlled cooling solidifies the part without warpage. Demolding yields a stress-relieved prototype with consistent wall thickness and excellent surface detail. All parts undergo first-article inspection against CAD, verifying critical dimensions and material properties before shipment.

Honyo’s integrated workflow—powered by AI-driven quoting, expert DFM collaboration, and tightly monitored production—ensures your rotational molding project achieves target quality in as few as 7 days. This approach eliminates guesswork, reduces cost escalation, and delivers production-ready prototypes that validate design intent with manufacturing reality.

Start Your Project

Start Your Rotational Molding Project with Honyo Prototype – Precision, Speed, and Expert Support

At Shenzhen Honyo Prototype, we specialize in rapid tooling and injection molding solutions engineered for speed, precision, and cost-efficiency. If you’re exploring rotational molding as a manufacturing method for your next project, our team is ready to guide you from concept to production with unmatched technical expertise and responsive service. Rotational molding—also known as rotomolding—is ideal for producing large, hollow, durable plastic parts with consistent wall thickness and minimal material waste. Whether you’re developing prototypes or preparing for low- to mid-volume production, our rotational molding capabilities are designed to meet your project’s unique demands.

Our advanced rotational molding machines support a wide range of thermoplastic materials, including polyethylene (PE), cross-linked polyethylene (XLPE), and specialty polymers, allowing for flexibility in chemical resistance, UV stability, impact strength, and surface finish. We utilize programmable oven and cooling cycles, precision clamping systems, and multi-axis rotational arms to ensure uniform part quality and repeatability. With tooling lead times reduced by up to 50% through our rapid tooling processes, Honyo Prototype accelerates your time-to-market without compromising on performance.

We understand that every rotational molding project begins with specific requirements—part geometry, material selection, production volume, and surface texture. That’s why we offer personalized engineering consultations to assess your design for manufacturability, recommend optimal process parameters, and support mold design validation. Our in-house team handles mold fabrication, machine setup, and initial sample production, ensuring seamless transition from CAD model to physical part.

Below are key specifications of our rotational molding capabilities:

| Parameter | Specification |

|——————————|———————————————–|

| Maximum Mold Size | 2000 mm × 1500 mm × 1000 mm |

| Maximum Part Weight | 150 kg |

| Material Compatibility | LDPE, HDPE, MDPE, XLPE, PP, PA, PVC (limited) |

| Wall Thickness Range | 2 mm – 20 mm (adjustable) |

| Oven Temperature Range | Up to 400°C (programmable) |

| Cooling Method | Forced air and mist cooling |

| Axis Rotation Speed (RPM) | 0–20 (independent control for each axis) |

| Cycle Time Range | 15–60 minutes (depending on part size) |

| Tooling Lead Time | 10–20 days (rapid steel or aluminum molds) |

From medical enclosures and industrial tanks to automotive components and recreational products, our rotational molding service delivers high-quality, stress-free parts with excellent impact resistance and long service life. We also provide post-processing options such as trimming, drilling, UV coating, and assembly integration.

Ready to move forward? Contact Susan Leo, our Project Engineering Manager, to discuss your rotational molding requirements. We offer free design reviews, material recommendations, and project feasibility assessments to ensure your concept is production-ready.

Email Susan Leo at info@hy-proto.com to start your project today. At Honyo Prototype, we don’t just manufacture parts—we partner in innovation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.