Contents

Manufacturing Insight: Forced Cnc

Manufacturing Insight: Advanced 5-Axis CNC Machining at Honyo Prototype

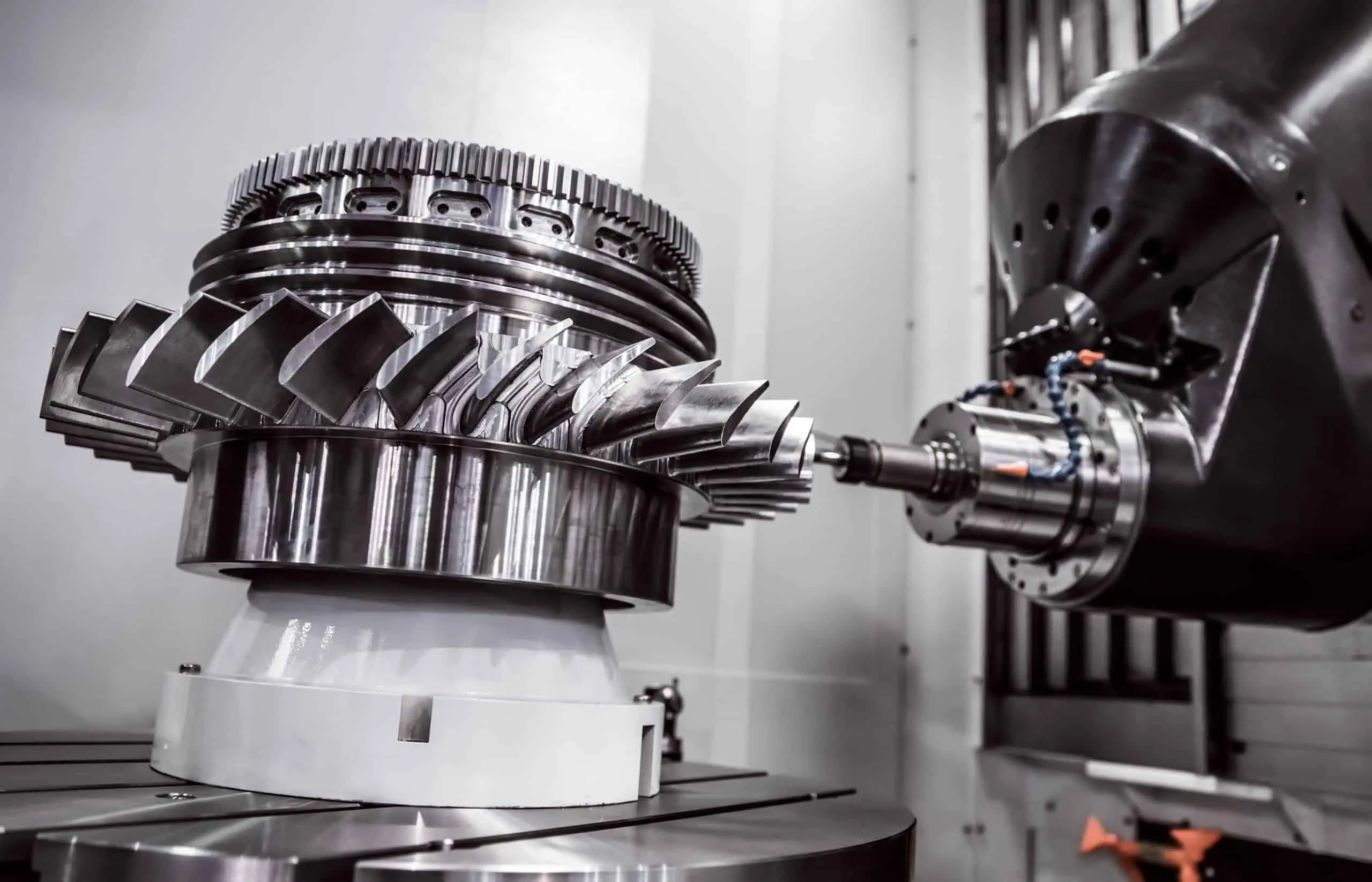

Shenzhen Honyo Prototype leverages advanced 5-axis CNC machining as a cornerstone technology for producing complex, high-precision prototypes and low-volume production parts. This capability transcends traditional 3-axis limitations by enabling simultaneous movement along five axes (X, Y, Z, plus two rotational axes, typically A and B). The core advantage lies in the ability to machine intricate geometries—such as organic contours, deep cavities, undercuts, and multi-faceted features—in a single setup. This eliminates the need for multiple repositionings, significantly reducing cumulative error, fixture complexity, and overall lead time while enhancing part accuracy and surface finish. For industries demanding rapid iteration on sophisticated designs—medical devices, aerospace components, robotics, and consumer electronics—5-axis machining is not merely beneficial; it is often essential to realize functional prototypes that accurately validate final production intent.

At Honyo, our investment in state-of-the-art 5-axis machining centers from leading manufacturers ensures we meet the stringent demands of modern prototyping. Our fleet is optimized for both speed and micron-level precision, handling a wide spectrum of engineering materials including aluminum alloys (e.g., 6061, 7075), stainless steels (e.g., 303, 316), titanium (e.g., Ti-6Al-4V), engineering plastics (e.g., PEEK, Delrin), and magnesium. We prioritize process stability through rigorous machine calibration, advanced toolpath simulation, and experienced programming using Mastercam and Fusion 360. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase, specifically evaluating how 5-axis capabilities can simplify part geometry, reduce component count, and accelerate time-to-test without sacrificing critical tolerances.

The measurable impact of our 5-axis capability is evident in reduced part handling and accelerated throughput. Complex components that might require 3-4 setups on a 3-axis machine are routinely completed in one. This directly translates to faster prototype delivery, often cutting lead times by 30-50% compared to multi-setup alternatives, while simultaneously improving geometric accuracy and surface quality. Our commitment to precision is validated through in-process probing and post-machining inspection using calibrated CMMs and optical comparators, ensuring every part meets specified GD&T requirements.

Honyo Prototype 5-Axis CNC Core Specifications

| Parameter | Specification Range | Capability Impact |

| :——————— | :—————————— | :—————————————– |

| Machine Travel (X/Y/Z) | 500mm – 1000mm / 400mm – 800mm / 400mm – 600mm | Accommodates diverse part sizes from small precision components to larger assemblies |

| Positioning Accuracy | ≤ ±0.005 mm | Ensures critical feature alignment and dimensional integrity |

| Repeatability | ≤ ±0.003 mm | Guarantees consistent quality across prototypes and low-volume runs |

| Spindle Speed Range | 8,000 – 24,000 RPM | Optimizes material removal rates for metals and plastics |

| Tool Capacity | 24 – 40 tools | Minimizes non-cut time during complex operations |

| Typical Tolerance | ±0.025 mm (Standard) | Meets common prototype requirements; tighter tolerances achievable |

| Surface Finish (Ra) | 0.8 µm – 3.2 µm (as machined) | Delivers near-net-shape quality, reducing post-processing needs |

Honyo Prototype’s mastery of 5-axis CNC machining delivers a decisive advantage: transforming complex design concepts into physically accurate, functionally validated prototypes faster and with greater fidelity than conventional methods allow. This capability is fundamental to our mission of accelerating your product development cycle while maintaining uncompromising quality standards. Partner with Honyo to leverage precision 5-axis technology for your most challenging prototyping requirements.

Technical Capabilities

Technical Capabilities: Advanced CNC Machining at Shenzhen Honyo Prototype

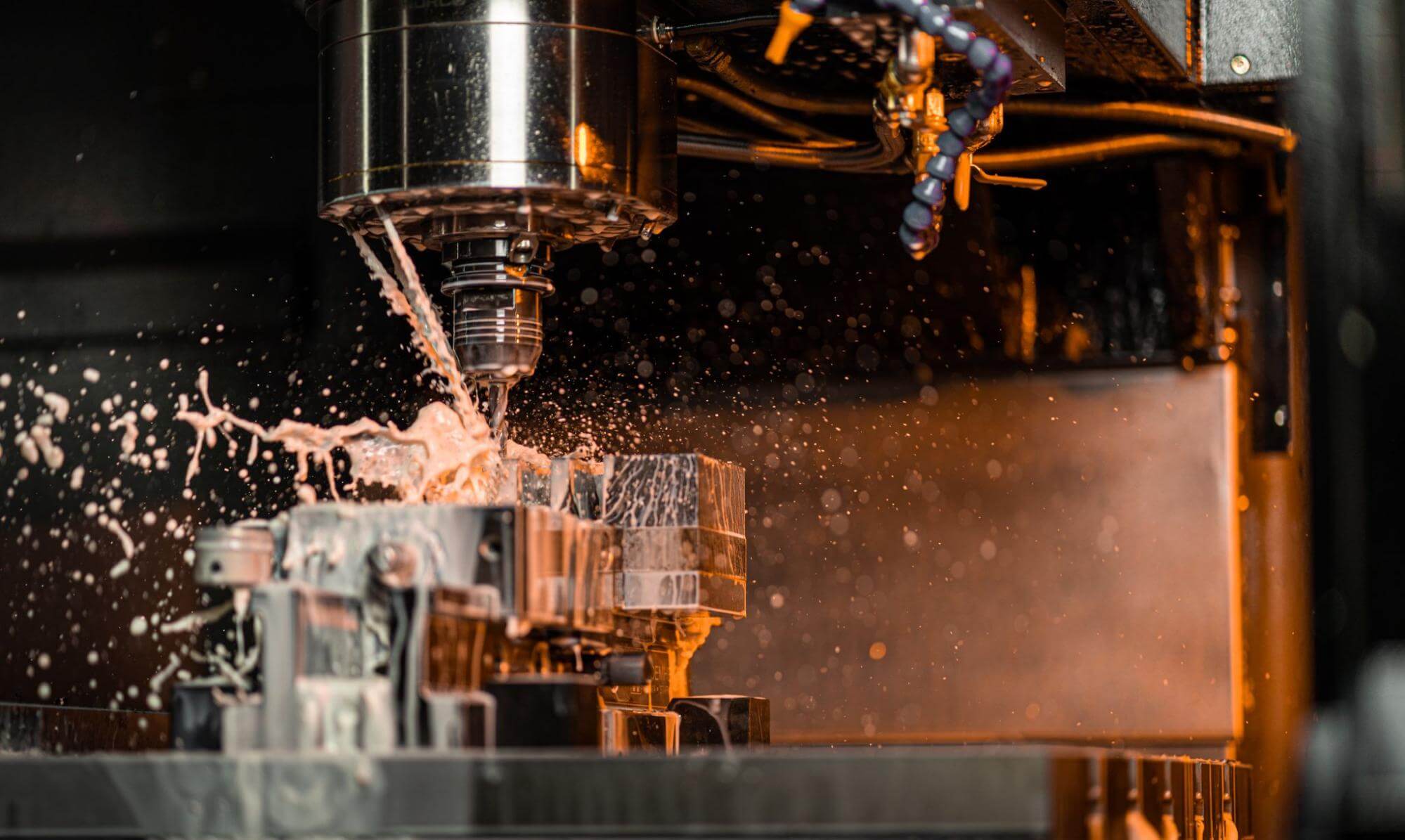

At Shenzhen Honyo Prototype, our forced CNC machining services are engineered to deliver precision, repeatability, and high efficiency across complex part geometries. Leveraging state-of-the-art 3-axis, 4-axis, and 5-axis milling centers alongside advanced CNC turning systems, we support rapid prototyping and low-to-mid volume production for industries demanding tight tolerances and superior surface finishes. Our integrated manufacturing ecosystem ensures seamless transitions from design to finished component, maintaining strict quality control throughout.

Our 3-axis milling platforms are optimized for prismatic and planar geometries, providing high-speed material removal and excellent dimensional accuracy. When rotational features or undercuts are required, our 4-axis CNC machines introduce indexed rotary motion (A-axis), enabling efficient machining of complex profiles without manual repositioning. For the most intricate components—such as aerospace impellers, medical instrument housings, or ergonomic industrial parts—our 5-axis simultaneous milling systems offer full contouring capabilities with dynamic tool orientation, minimizing setup次数 and enhancing geometric precision.

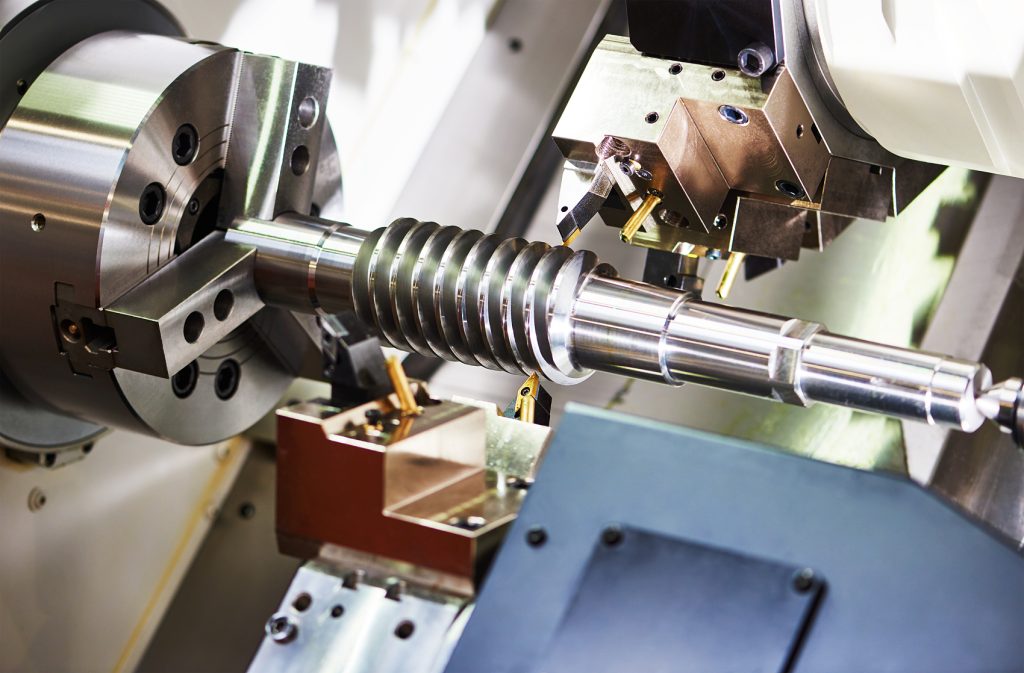

Complementing our milling capabilities, our CNC turning centers support both standard and multi-axis turning operations, including live tooling for mill-turn hybrid parts. This allows us to produce fully finished rotational components in a single setup, reducing lead times and improving concentricity. Materials range from standard aluminum and steel alloys to high-performance engineering plastics and exotic metals, all processed under climate-controlled conditions to ensure thermal stability and repeatability.

Tight tolerance machining is a core competency at Honyo. We routinely hold tolerances down to ±0.005 mm (±0.0002″) on critical features, supported by in-process probing, laser tool measurement, and post-machining inspection using calibrated CMMs and optical comparators. Our quality management system adheres to ISO 9001 standards, ensuring traceability and consistency across all production batches.

The following table outlines our standard tolerance capabilities and compatible materials across machining platforms:

| Machining Type | Typical Tolerance (Linear) | Positional Tolerance | Surface Finish (Ra) | Common Materials |

|———————-|—————————-|———————–|———————-|——————|

| 3-Axis Milling | ±0.01 mm | ±0.01 mm | 1.6 – 3.2 µm | Aluminum 6061, 7075; Steel 1045, 4140; Stainless 303, 316; POM, PC, PEEK |

| 4-Axis Milling | ±0.01 mm | ±0.01 mm | 1.6 – 3.2 µm | Same as above, plus titanium alloys (Grade 2, 5) |

| 5-Axis Milling | ±0.005 mm | ±0.008 mm | 0.8 – 1.6 µm | Aluminum, stainless steel, titanium, Inconel 718, PEEK |

| CNC Turning | ±0.01 mm | ±0.01 mm | 1.6 – 3.2 µm | Aluminum, brass, steel, stainless, PTFE, Nylon |

| Tight Tolerance Machining | ±0.005 mm (down to ±0.002 mm on request) | ±0.005 mm | 0.8 µm (achievable) | All above materials, including hardened steels (up to 60 HRC) |

All processes are supported by advanced CAM programming using Siemens NX and Mastercam, ensuring optimized toolpaths and minimized cycle times. At Shenzhen Honyo Prototype, we combine technical expertise with cutting-edge equipment to deliver CNC-machined parts that meet the most stringent engineering requirements.

From CAD to Part: The Process

From CAD to Finished Part: The Honyo Prototype CNC Production Workflow

At Shenzhen Honyo Prototype, our CNC machining process is engineered for precision, speed, and reliability, transforming digital designs into high-fidelity physical prototypes and low-volume production parts. This structured workflow ensures optimal outcomes while minimizing delays and costs, leveraging advanced technology at every stage.

AI-Powered Quoting System

The journey begins when a client submits their CAD file through our secure portal. Our proprietary AI quoting engine instantly analyzes the geometry, material specifications, and requested tolerances. This system cross-references Honyo’s extensive machining database, accounting for machine capabilities, tooling requirements, material waste factors, and historical production data. Within minutes, clients receive a detailed, transparent quote outlining cost, lead time, and any initial observations. This rapid assessment eliminates traditional quoting bottlenecks, allowing projects to move swiftly into the engineering phase while setting clear expectations.

Comprehensive Design for Manufacturability (DFM) Review

Following quote acceptance, Honyo’s engineering team conducts a rigorous DFM analysis. This is not a passive checklist but an active collaboration. Senior engineers scrutinize the CAD model for potential manufacturability challenges: identifying thin walls prone to deflection, excessive undercuts requiring complex fixtures, non-optimal hole depths, or surface finish requirements exceeding practical machining limits. We proactively suggest design modifications—such as adjusting fillet radii, simplifying geometry, or recommending alternative materials—to enhance part integrity, reduce machining time, and lower costs, all while preserving the client’s functional intent. Client feedback on these suggestions is integrated before finalizing the production plan, ensuring alignment and preventing costly revisions later.

Precision CNC Machining & Quality Assurance

With an approved DFM report, the job enters production. Our state-of-the-art CNC fleet, including 3-axis vertical mills, 4-axis indexers, and 5-axis simultaneous machining centers, is programmed using CAM software. Critical toolpaths are simulated offline to verify collision avoidance and optimize cycle times. Machining occurs under strict environmental controls, with automated tool measurement ensuring dimensional accuracy. Throughout the process, in-process inspections using calibrated CMMs and optical comparators verify critical features against the original CAD model. Final parts undergo 100% dimensional inspection per the client’s drawing, with full material certification and a detailed inspection report provided. This closed-loop process guarantees parts meet the stringent requirements essential for functional prototyping and pre-production validation.

Key Production Specifications

| Parameter | Standard Capability | High-Precision Capability |

| :—————– | :———————— | :———————— |

| Tolerance | ±0.025 mm | ±0.005 mm |

| Surface Finish | 3.2 µm Ra (Machined) | 0.8 µm Ra (Polished) |

| Max Work Envelope | 1000 x 600 x 500 mm | 500 x 400 x 300 mm |

| Common Materials | Aluminum 6061/7075, SS304/316, POM, PEEK, ABS | Titanium Grade 5, Inconel 718, Ceramics |

This integrated workflow—from AI-driven quoting through collaborative DFM to tightly controlled production—embodies Honyo Prototype’s commitment to delivering CNC-machined parts that are right the first time, accelerating our clients’ product development cycles without compromising on quality or technical rigor.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision CNC machining, the foundation of success lies in early collaboration between design and manufacturing teams. At Shenzhen Honyo Prototype, we specialize in transforming complex designs into high-accuracy, fully functional prototypes and low-volume production parts. Our advanced CNC machining capabilities support a wide range of materials, tight tolerances, and complex geometries—ensuring your project meets both performance and timeline requirements from the outset.

We understand that every engineering challenge is unique. Whether you’re developing aerospace components, medical devices, or industrial equipment, our team brings decades of experience in forced CNC processes—where precision, repeatability, and material integrity are non-negotiable. Our facility in Shenzhen is equipped with 3-axis, 4-axis, and 5-axis CNC machining centers, allowing us to handle everything from simple milled parts to intricate, multi-faceted components with minimal setup changes.

To begin your project, simply share your design files—preferably in STEP, IGES, or native CAD formats—along with any specific requirements such as material type, surface finish, tolerances, or quantity. Our engineering team will conduct a comprehensive Design for Manufacturability (DFM) review to identify potential optimizations, reduce lead time, and avoid common pitfalls before machining begins. This proactive approach not only enhances quality but also reduces costs and accelerates time-to-market.

We support a broad range of engineering materials including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), titanium, brass, copper, and high-performance plastics such as PEEK, Delrin, and Polycarbonate. Whether you need a single prototype or a batch of 100+ precision-machined parts, our scalable processes ensure consistency across all production volumes.

Below is an overview of our standard CNC machining capabilities:

| Parameter | Specification |

|—————————-|———————————————-|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 600 x 500 mm (5-axis) |

| Minimum Feature Size | 0.5 mm (internal radii) |

| Standard Tolerance | ±0.05 mm (can achieve ±0.01 mm on request) |

| Surface Finish | As-machined, bead-blasted, anodized, plated |

| Lead Time | 5–10 business days (varies by complexity) |

| Supported File Formats | STEP, IGES, X_T, SLDPRT, DWG, DXF |

All parts undergo rigorous in-process and final inspections using coordinate measuring machines (CMM) and optical comparators, ensuring compliance with your specifications. We also provide full traceability and inspection reports upon request—critical for regulated industries.

Your project deserves more than just machining—it requires partnership, precision, and responsiveness. Contact Susan Leo today at info@hy-proto.com to initiate your CNC machining project. Include your CAD files and requirements, and receive a detailed quote with DFM feedback within 24 hours. At Shenzhen Honyo Prototype, we don’t just manufacture parts—we engineer solutions.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.