Contents

Manufacturing Insight: Cnc Knurling Tool

Manufacturing Insight: CNC Knurling Tool Capabilities at Shenzhen Honyo Prototype

Precision knurling is a critical roll-forming process in CNC machining that creates controlled, repetitive patterns on cylindrical surfaces to enhance grip, aesthetics, or assembly functionality. Unlike manual knurling, CNC-controlled knurling ensures exceptional repeatability, dimensional accuracy, and surface consistency across high-mix production runs—particularly vital for aerospace components, medical devices, and industrial tooling where human error is unacceptable. At Shenzhen Honyo Prototype, we leverage advanced CNC Swiss-type and milling machines with synchronized live tooling to execute complex knurl profiles—including straight, diagonal, and diamond patterns—with micron-level precision. Our process eliminates common pitfalls like pattern slippage, inconsistent depth, or material burring by dynamically adjusting feed rates, spindle synchronization, and tool pressure based on real-time material feedback.

Honyo’s expertise lies in optimizing knurling for challenging materials, including hardened steels (up to 60 HRC), titanium alloys, and engineered plastics, where thermal deformation and tool wear typically compromise quality. We utilize carbide-tipped knurling tools with precision-ground teeth and proprietary coatings to extend tool life by 40% compared to standard tooling, reducing downtime and cost per part. Crucially, our engineers program adaptive depth-of-cut strategies to prevent material pull-out in thin-walled components—a frequent issue in prototype-stage manufacturing. All knurling operations undergo in-process CMM verification to maintain ±0.02 mm tolerance on pitch and profile depth, ensuring compliance with ISO 22028 and ASTM D2466 standards.

Our integrated approach begins with DFM analysis to validate knurl geometry feasibility, followed by custom toolpath simulation to avoid collisions in multi-axis setups. For low-volume prototypes or high-volume production, Honyo guarantees first-article approval within 72 hours, supported by material traceability documentation and surface roughness reports (Ra 0.8–3.2 μm). This capability is especially valuable for clients iterating ergonomic handles, threaded fasteners, or optical instrument barrels requiring tactile precision.

Key technical specifications for Honyo’s CNC knurling services are summarized below:

| Parameter | Capability | Application Impact |

|——————–|————————————-|—————————————-|

| Material Range | Aluminum, Stainless Steel, Titanium, Plastics, Brass | Supports medical, aerospace, and consumer prototypes |

| Tolerance | ±0.02 mm on pitch/profile depth | Ensures consistent grip force and assembly fit |

| Max. Knurl Diameter| 120 mm | Accommodates large-scale industrial components |

| Pattern Types | Straight, Diamond, Diagonal, Custom | Enables brand-specific texture design |

| Surface Finish (Ra)| 0.8–3.2 μm | Meets functional and aesthetic requirements |

Shenzhen Honyo Prototype bridges the gap between rapid prototyping and serial production through our mastery of CNC knurling. By combining rigid process controls with material science expertise, we transform intricate knurling requirements from design challenge into repeatable manufacturing outcome. Contact our engineering team to discuss complex geometries or stringent regulatory needs—we deliver precision-engineered texture solutions without compromising lead times.

Technical Capabilities

CNC Knurling Tool Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC knurling operations are integrated within advanced multi-axis machining platforms, enabling precise texture replication and functional grip enhancement on cylindrical and flat surfaces. Our capabilities span 3-axis, 4-axis, and 5-axis milling systems, as well as high-precision CNC turning centers, ensuring versatility in producing knurled features across complex geometries. We specialize in tight-tolerance knurling for critical components used in aerospace, medical devices, automotive, and industrial equipment sectors.

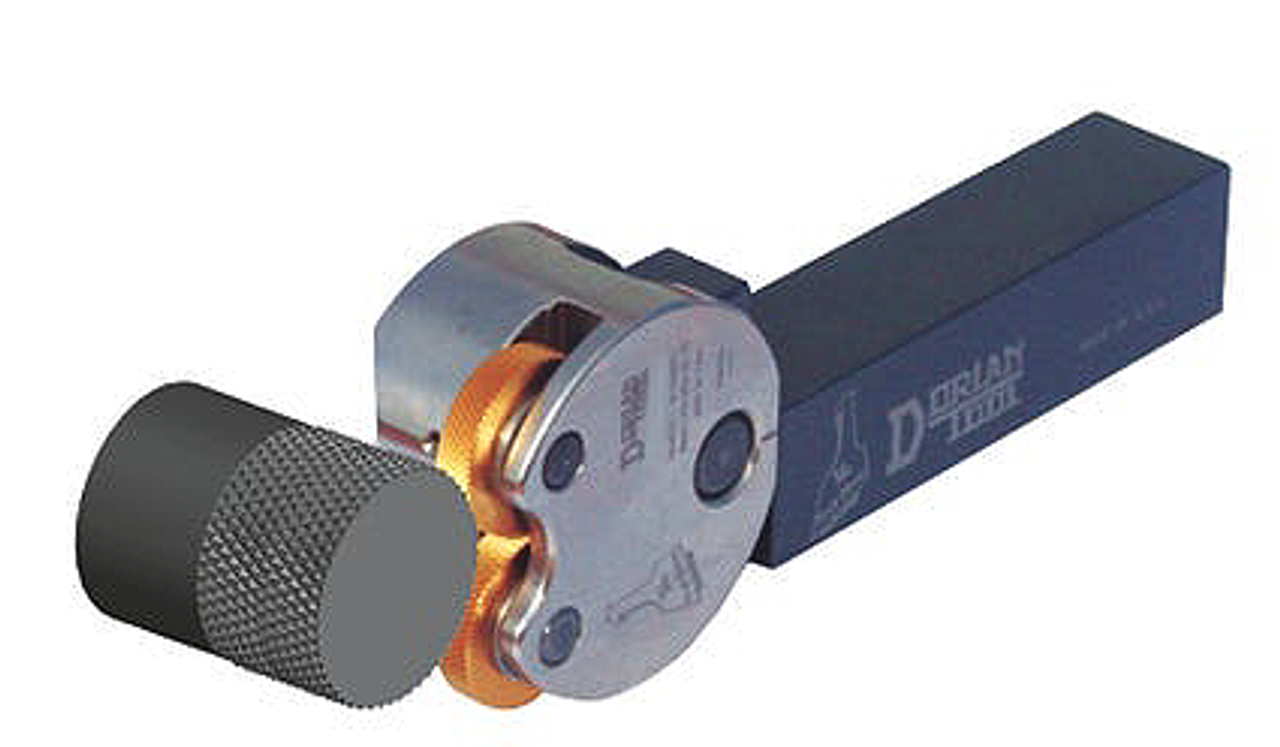

Our CNC knurling tools are engineered for accuracy and repeatability, supporting both straight, diagonal, and diamond pattern generation with controlled pitch and depth. Utilizing rigid toolholding systems and synchronized spindle control, we achieve consistent knurl profiles without slippage or material deformation. The process is performed under real-time tool path verification, minimizing runout and ensuring conformity to print specifications.

We support a wide range of materials, from soft aluminum alloys to hardened steels and exotic alloys, adjusting feed rates, spindle speeds, and engagement strategies to maintain surface integrity. Our tooling inventory includes high-speed steel (HSS) and carbide-tipped knurling tools, selected based on material hardness and required pattern definition. Each operation is backed by in-process inspection and final CMM validation to confirm dimensional compliance.

Tolerances are maintained within strict limits, with typical knurling depth tolerances reaching ±0.02 mm and positional accuracy of ±0.01 mm on critical diameters. For high-volume or mission-critical parts, we implement SPC (Statistical Process Control) monitoring to ensure long-term consistency.

Below is a summary of our standard knurling capabilities and material compatibility:

| Parameter | Specification |

|—————————-|——————————————————————————-|

| Machine Platforms | 3-Axis, 4-Axis, 5-Axis CNC Milling; CNC Turning (Swiss and Chucker Lathes) |

| Knurl Patterns | Straight, Diagonal (Left/Right), Diamond (Cross) |

| Standard Pitches | 0.5 mm to 2.0 mm (metric), 14 to 40 TPI (imperial) |

| Knurling Diameter Range | Ø3 mm to Ø120 mm (milling); Ø2 mm to Ø80 mm (turning) |

| Depth Tolerance | ±0.02 mm |

| Positional Tolerance | ±0.01 mm |

| Surface Finish (Ra) | 1.6 – 3.2 µm (typical), adjustable per requirement |

| Lead Time (Prototype) | 3–7 days, depending on complexity and material availability |

| Material Category | Compatible Materials |

|—————————-|——————————————————————————-|

| Aluminum Alloys | 6061, 7075, 2024, 5052 |

| Steels | 1018, 4140, 4340, Stainless 303, 304, 316, 17-4 PH |

| Exotic Alloys | Inconel 718, Titanium Grade 5 (Ti-6Al-4V), Monel, Hastelloy |

| Brass & Copper Alloys | C36000 (Free-Cutting Brass), C11000 (Electrolytic Tough Pitch Copper) |

| Plastics | Acetal (POM), Nylon, PEEK, Polycarbonate (for low-pressure knurling) |

Shenzhen Honyo Prototype combines advanced CNC infrastructure with deep process expertise to deliver knurling solutions that meet demanding functional and aesthetic requirements. Our engineering team collaborates directly with clients to optimize knurl design for manufacturability, ensuring seamless integration into end-use applications.

From CAD to Part: The Process

CNC Knurling Tool Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC knurling tool manufacturing process is engineered for precision, efficiency, and seamless integration from initial concept to functional prototype. This structured workflow ensures optimal part quality while minimizing lead times and non-conformance risks. The process begins with an AI-driven quotation phase, transitions through rigorous Design for Manufacturability (DFM) analysis, and culminates in controlled production execution.

The AI Quote Phase initiates upon receipt of the client’s CAD model and technical specifications. Our proprietary AI engine rapidly analyzes the 3D geometry, material requirements, and surface finish criteria to generate an accurate, data-backed quotation within hours. This system cross-references historical machining data, current machine availability, and material costs to provide transparent pricing and realistic lead time estimates. Crucially, the AI performs an initial geometric sanity check, flagging potential issues like undercuts incompatible with standard knurling operations or wall thicknesses below our process capability before human engineering review commences. This early validation prevents quoting on fundamentally unmanufacturable designs.

Subsequently, the project enters the Critical DFM Analysis Stage. Our senior manufacturing engineers conduct a detailed, hands-on review focusing specifically on knurling feasibility. We assess the part’s geometry for adequate gripping surfaces, verify the specified knurl pattern (straight, diagonal, or diamond) aligns with functional requirements and standard tooling, and evaluate the base material’s suitability for cold forming. Key considerations include the minimum recommended root diameter to prevent part deformation, the required knurl depth relative to wall thickness, and the impact of adjacent features on tool access. We collaborate directly with the client to propose actionable optimizations—such as slight diameter adjustments or pattern modifications—that enhance manufacturability without compromising the design intent, significantly reducing scrap rates and post-processing needs.

The validated design then progresses to Controlled Production Execution. CNC turning centers are precisely programmed using the final CAD/CAM data. Knurling is performed as a dedicated operation using specialized hardened steel knurling tools mounted in live tooling or dedicated knurling holders. Process parameters are meticulously selected based on the specific material and pattern:

| Parameter | Typical Range for Steel/Aluminum | Critical Influence |

| :—————– | :——————————- | :——————————- |

| Knurl Pitch | 0.5mm – 1.5mm | Pattern density, grip strength |

| Axial Feed Rate | 0.1 – 0.3 mm/rev | Pattern definition, tool wear |

| Spindle RPM | 80 – 250 RPM | Surface finish, chatter control |

| Radial Pressure | 1.5 – 3.0 kN | Knurl depth, material flow |

| Coolant/Lubrication| High-pressure soluble oil | Heat dissipation, chip control |

Throughout machining, in-process inspections verify critical knurl dimensions and surface integrity against the original CAD model. Final parts undergo 100% visual inspection for pattern consistency and absence of burrs, with critical diameters and knurl depths measured using calibrated optical comparators or CMMs where specified. This closed-loop workflow, integrating intelligent quoting, expert DFM, and tightly controlled production, guarantees knurling tools that meet Honyo’s stringent quality standards and the client’s exact functional requirements.

Start Your Project

Start Your Project with Precision CNC Knurling Tools from Shenzhen Honyo Prototype

When it comes to high-precision CNC machining, the quality of each tool in your process directly impacts the performance, durability, and finish of your final product. At Shenzhen Honyo Prototype, we specialize in manufacturing premium CNC knurling tools engineered for consistency, accuracy, and extended tool life. Whether you’re producing industrial components, automotive parts, or precision instruments, our knurling solutions ensure optimal grip, aesthetics, and functional performance on cylindrical surfaces.

Our CNC knurling tools are designed and built using advanced manufacturing techniques and high-grade materials to meet the rigorous demands of modern machining environments. Each tool undergoes strict quality control and precision calibration to deliver repeatable results across high-volume production runs. We understand that knurling is more than just surface texturing—it’s a critical process that influences ergonomics, assembly efficiency, and product reliability.

To ensure seamless integration into your existing CNC workflows, we offer customizable knurling profiles, pitch options, and mounting configurations. Whether you require straight, diagonal, or diamond patterns, our engineering team works closely with you to match your exact specifications. Our tools are compatible with a wide range of CNC lathes and turning centers, supporting both imperial and metric standards.

We also provide technical consultation to help you select the optimal knurling method—form-cut knurling or cut knurling—based on your material type, spindle speed, feed rate, and desired surface finish. This tailored approach minimizes tool wear, reduces cycle time, and enhances surface integrity.

To support your prototyping and production needs, we maintain fast turnaround times without compromising on precision. From initial design review to final delivery, our team ensures transparency and responsiveness at every stage.

Below are key specifications for our standard CNC knurling tools:

| Parameter | Specification |

|————————-|—————————————-|

| Tool Material | High-Speed Steel (HSS) or Tungsten Carbide |

| Shank Diameter | 12 mm, 16 mm, 20 mm (custom options available) |

| Knurl Type | Straight, Diagonal, Diamond (Custom) |

| Pitch Range | 0.5 mm to 2.0 mm |

| Mounting Style | ER Collet, Round Shank, Square Shank |

| Applicable Machines | CNC Lathes, Swiss-type, Turning Centers |

| Standard Coating | TiN, TiCN (optional) |

| Tolerance | ±0.02 mm |

At Shenzhen Honyo Prototype, we are committed to empowering manufacturers with reliable, high-performance tooling solutions. Our expertise in CNC machining and precision tool fabrication ensures that your knurling operations run smoothly and efficiently.

Ready to start your project? Contact Susan Leo today at info@hy-proto.com for technical support, custom tooling quotes, or sample requests. Let us help you achieve superior knurling results with tools built to perform.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.