Contents

Manufacturing Insight: Cnc Laser Wood

CNC Laser Wood Machining: Precision Fabrication for Prototyping and Production

CNC laser cutting and engraving represent a cornerstone technology for rapid, high-precision wood fabrication at Shenzhen Honyo Prototype. This non-contact process utilizes a focused, computer-controlled laser beam to vaporize material along programmed paths, enabling the creation of intricate 2D and 2.5D parts from diverse wood substrates with exceptional repeatability. Unlike traditional mechanical routing, laser machining eliminates tool deflection and mechanical stress on delicate wood grains, significantly reducing the risk of splintering or warping while achieving superior edge quality. This makes it indispensable for applications demanding fine detail, complex geometries, and tight tolerances within tight development cycles, from architectural models and exhibition displays to functional prototypes and limited-run consumer products.

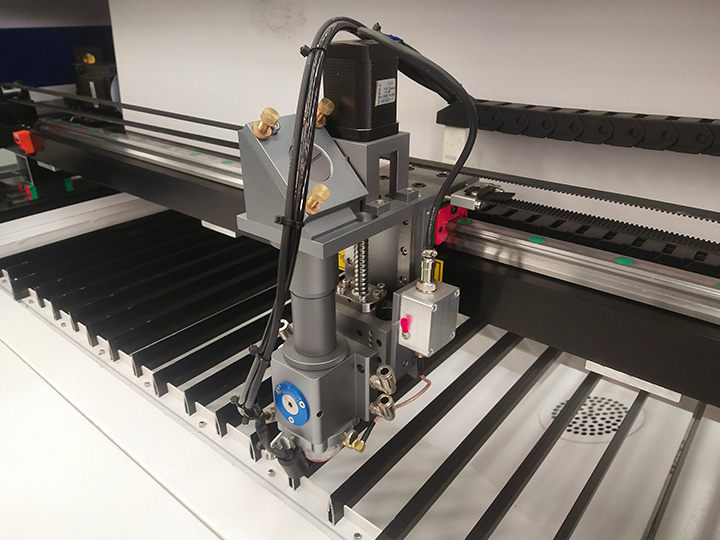

Honyo leverages state-of-the-art CO2 laser systems calibrated specifically for optimal wood processing. Our engineering expertise ensures minimal heat-affected zones, preventing excessive charring or discoloration common with less refined setups. We specialize in handling a wide range of wood types, including Baltic Birch plywood, MDF, solid hardwoods like walnut and cherry, and sustainable alternatives such as bamboo. Critical to our process is rigorous material certification and environmental conditioning within our climate-controlled facility, ensuring dimensional stability and consistent cut quality batch after batch. Our integrated workflow, from CAD file receipt through nesting optimization, laser processing, and optional post-finishing like edge sanding or light sealing, is designed for speed without compromising on the precision requirements of engineering prototypes and low-volume production.

The following table outlines key technical specifications achievable with Honyo’s CNC laser wood machining capabilities:

| Parameter | Capability Range | Notes |

| :—————– | :———————————– | :————————————- |

| Material Thickness | 0.8 mm to 12.0 mm | Optimal results typically 1.5-9.0 mm |

| Positional Accuracy | ±0.1 mm | Verified per ISO 2768-mK standard |

| Minimum Feature | 0.5 mm (internal corners/holes) | Depends on material density & thickness|

| Surface Finish | Smooth, minimal char (post-clean optional) | Varies slightly by wood species |

| Max Work Area | 1200 mm x 900 mm | Standard machine envelope |

Our commitment extends beyond mere cutting. Honyo engineers provide proactive Design for Manufacturability (DFM) feedback during the quotation phase, identifying potential issues like kerf compensation needs, unsupported features, or material suitability early to prevent delays. We understand that wood’s natural variability requires adaptive process parameters; our technicians dynamically adjust power, speed, and pulse frequency based on real-time material response monitoring. This granular control, combined with our ISO 9001-certified quality management system, ensures every part meets stringent dimensional and aesthetic criteria. For projects requiring rapid iteration or seamless transition from prototype to small-batch production, Honyo’s CNC laser wood machining delivers the accuracy, material versatility, and responsive engineering support essential for bringing intricate wooden components to life efficiently. Partner with us for precision-engineered wood solutions where detail and reliability are non-negotiable.

Technical Capabilities

CNC Laser Wood Machining – Technical Capabilities

Shenzhen Honyo Prototype specializes in precision CNC laser machining for wood-based materials, combining advanced multi-axis technology with strict quality control to deliver high-accuracy prototypes and low-volume production components. Our capabilities in 3-axis, 4-axis, and 5-axis CNC milling, complemented by precision turning and laser cutting, allow for complex geometries, intricate detailing, and consistent repeatability in wood and engineered wood products. Whether for architectural models, furniture prototypes, or custom signage, our manufacturing processes are optimized for dimensional accuracy, surface finish, and material integrity.

Our CNC laser systems are calibrated for high-speed cutting and engraving on a range of wood substrates, including natural hardwoods, plywood, MDF, and bamboo. The integration of multi-axis motion control enables undercuts, 3D contouring, and seamless edge detailing—features typically challenging with conventional routing. The laser’s non-contact method minimizes material deformation and tool wear, ensuring clean cuts and tight tolerance compliance across batches.

Tight tolerance machining is a core strength at Honyo Prototype. We maintain standard dimensional tolerances of ±0.1 mm for linear features and ±0.05 mm for critical interfaces, with the ability to achieve ±0.03 mm when required. These tolerances are consistently upheld through in-process inspections, automated calibration, and environmental controls that mitigate thermal expansion effects during machining.

Below is a detailed specification table outlining our standard capabilities for CNC laser wood machining:

| Parameter | Specification |

|——————————|——————————————————————————-|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling, CNC Turning, Laser Cutting & Engraving |

| Material Compatibility | Natural Wood (Beech, Walnut, Oak), Plywood, MDF, Bamboo, Acrylic (wood-like finishes) |

| Max Work Envelope | 1200 x 600 x 200 mm (47” x 23.6” x 7.9”) |

| Laser Power | 130W CO₂ Laser (adjustable for depth and kerf control) |

| Positioning Accuracy | ±0.02 mm |

| Standard Tolerance | ±0.1 mm (general), ±0.05 mm (precision features) |

| Tight Tolerance Capability | ±0.03 mm (achievable under controlled conditions) |

| Surface Finish | Ra 3.2–6.3 µm (laser cut), Ra 1.6–3.2 µm (milled) |

| Minimum Feature Size | 0.5 mm (laser engraving), 2 mm (internal radii for milling) |

| Lead Time | 3–7 days (depending on complexity and finishing requirements) |

All CNC laser wood projects undergo rigorous first-article inspection and are supported by digital documentation, including inspection reports and as-machined dimensional data. Our engineering team collaborates directly with clients to optimize designs for manufacturability, ensuring that grain orientation, moisture content, and structural integrity are considered during process planning.

At Shenzhen Honyo Prototype, we combine technical precision with material expertise to deliver CNC-machined wood components that meet the demanding requirements of industrial design, architectural modeling, and high-end consumer products.

From CAD to Part: The Process

CNC Laser Wood Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC laser cutting process for wood transforms digital designs into precise physical components through a rigorously defined workflow. This structured approach ensures optimal quality, material efficiency, and cost-effectiveness for B2B clients requiring rapid prototyping or low-volume production. The journey begins with the client’s CAD file and progresses seamlessly through three critical phases: AI-Powered Quoting, Design for Manufacturability (DFM) review, and controlled Production execution.

The initial phase leverages our proprietary AI quoting engine. Upon secure upload of the client’s 2D vector CAD file (DXF or DWG format preferred), the system performs an instant geometric analysis. It calculates material utilization, estimates cutting path length, factors in machine setup time, and applies real-time material cost data specific to the requested wood grade. Crucially, the AI identifies potential red flags such as excessively small internal features prone to charring or geometries violating minimum bend radii for wood. This delivers a highly accurate, transparent cost estimate and lead time within minutes, enabling rapid project validation before commitment. Client feedback on the quote triggers immediate iteration if needed.

Following quote acceptance, the DFM phase becomes paramount. Our senior manufacturing engineers conduct a detailed technical review, focusing specifically on wood’s unique properties. We verify material suitability against the design’s structural and aesthetic requirements, considering factors like grain direction, natural defects, and moisture content. Key adjustments often include implementing precise kerf compensation (typically 0.1-0.2mm for wood) to ensure dimensional accuracy, optimizing part nesting to minimize waste of valuable sheet material, and strategically placing micro-tabs to prevent small features from falling into the laser bed during cutting. We also assess cut sequence to minimize thermal stress and potential warping. Client collaboration during this stage is essential to resolve any conflicts between design intent and manufacturability constraints, preventing costly rework later.

Material selection is critical for laser processing. The following table outlines common wood options and their key processing parameters at Honyo:

| Wood Type | Typical Thickness Range (mm) | Max Power Setting (%) | Key Considerations |

| :————– | :————————— | :——————– | :————————————- |

| Birch Plywood | 1.5 – 12.0 | 70-85 | Excellent edge quality; minimal charring; consistent layers |

| MDF (Low-Density)| 3.0 – 18.0 | 60-75 | Smooth cut edges; higher smoke output; requires robust extraction |

| Solid Walnut | 3.0 – 10.0 | 65-80 | Beautiful finish; risk of flame on thicker pieces; grain variation |

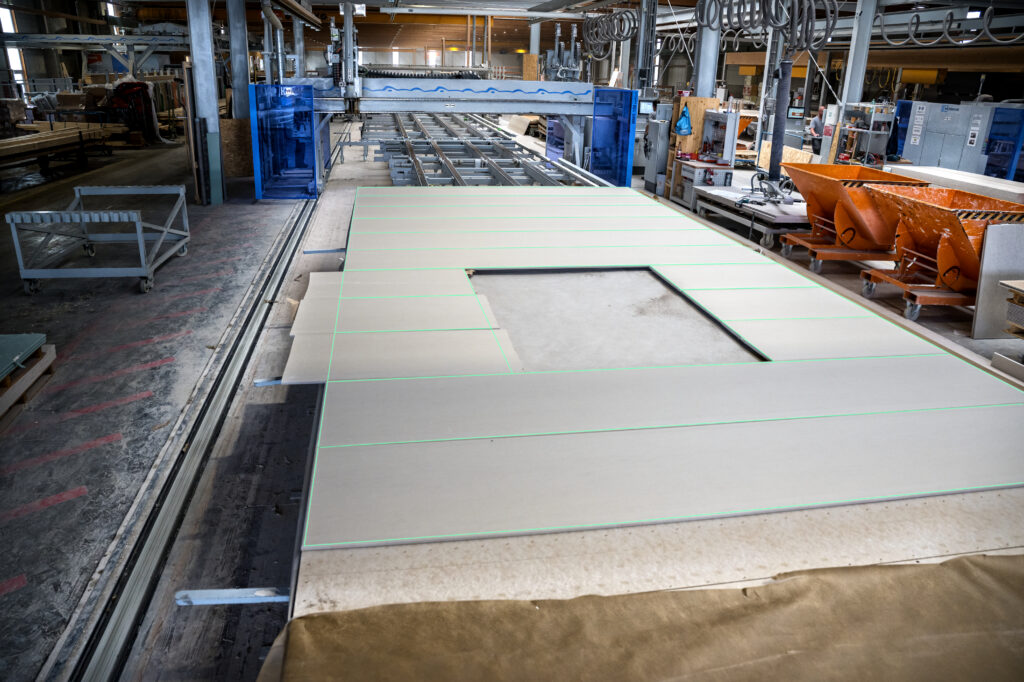

Production commences only after DFM sign-off. The approved CAD file is converted into optimized machine code (G-code). Material is carefully loaded, leveled, and secured on the laser bed. Parameters—laser power, pulse frequency, cutting speed, and assist gas (typically compressed air for wood)—are meticulously set based on the validated DFM plan and the specific wood type/thickness. Real-time monitoring ensures consistent cut quality and immediate intervention if issues like excessive smoke or flame occur. Post-processing includes careful part removal, deburring of any minor slag, thorough cleaning to remove residual soot, and a final dimensional and visual inspection against the original CAD model before shipment. This integrated workflow, from AI insight through expert DFM to precision production, guarantees that Honyo delivers dimensionally accurate, clean-edged wood components meeting stringent B2B prototyping and production demands.

Start Your Project

Start Your CNC Laser Wood Project with Precision and Expertise

When it comes to producing high-quality prototypes or custom parts using CNC laser cutting in wood, precision, material understanding, and technical expertise are paramount. At Shenzhen Honyo Prototype, we specialize in advanced CNC machining services tailored to meet the exacting demands of engineers, designers, and product developers across industries. Our state-of-the-art laser systems, combined with decades of manufacturing experience, ensure your wood-based designs are translated into flawless physical components—on time and to specification.

Whether you’re developing architectural models, intricate signage, furniture prototypes, or precision enclosures, our CNC laser wood service delivers clean cuts, tight tolerances, and excellent edge quality. We work with a variety of wood types, including plywood, MDF, solid hardwoods, and bamboo, ensuring compatibility with your functional and aesthetic requirements. Our laser systems offer high positional accuracy and dynamic control, enabling the production of complex geometries that traditional machining methods cannot achieve.

We understand that every project begins with a concept. That’s why our engineering team collaborates closely with clients from the initial design phase through to final delivery. We review your CAD files, provide design for manufacturability (DFM) feedback, and recommend optimal wood materials and thicknesses to ensure structural integrity and dimensional accuracy. Our facility supports sheet sizes up to 1200 x 600 mm, with laser power options calibrated for both delicate detailing and rapid cutting of thicker substrates.

To maintain consistency and quality, all parts undergo rigorous inspection, including visual checks for charring or edge imperfections and dimensional verification using calibrated measuring tools. We also offer post-processing services such as sanding, edge finishing, engraving, and optional clear coating to enhance durability and appearance.

Below are the key technical specifications for our CNC laser wood machining service:

| Parameter | Specification |

|—————————-|————————————————|

| Material Types | Plywood, MDF, Balsa, Basswood, Bamboo, Hardwood |

| Maximum Sheet Size | 1200 mm × 600 mm |

| Wood Thickness Range | 1 mm – 18 mm |

| Laser Power Options | 60W, 80W, 100W CO₂ Lasers |

| Positional Accuracy | ±0.1 mm |

| Minimum Feature Size | 0.5 mm (dependent on material and design) |

| Lead Time (Standard) | 3–5 working days |

| Finishing Options | Natural, Sanded, Engraved, Clear-Coated |

Starting your project is simple. Share your design files in DXF, DWG, or STEP format, along with your material preferences and quantity requirements. Our team will respond with a detailed quote, DFM analysis, and production timeline within 24 hours.

For immediate assistance, contact Susan Leo at info@hy-proto.com. As your dedicated project engineer, Susan will guide you through every step—from material selection to final delivery—ensuring your CNC laser wood components meet the highest standards of quality and precision. At Shenzhen Honyo Prototype, we don’t just manufacture parts; we help bring innovative ideas to life. Reach out today and start your next project with confidence.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.