Contents

Manufacturing Insight: Cnc Lathe Projects

Manufacturing Insight: CNC Lathe Projects at Honyo Prototype

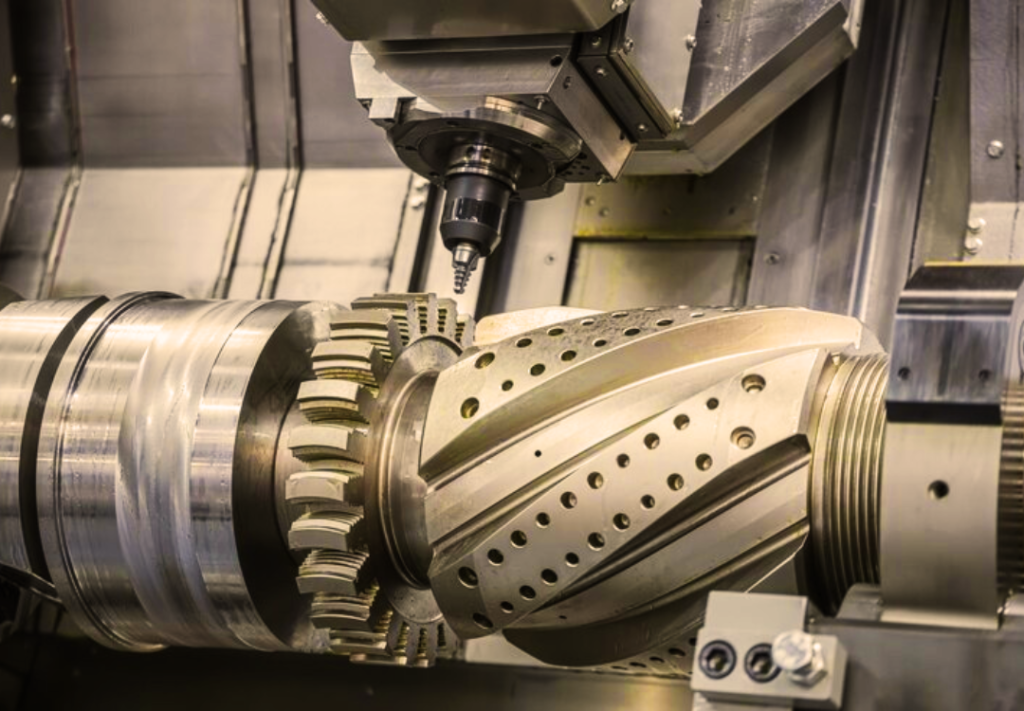

CNC turning remains a cornerstone of precision metal and plastic component production, particularly for geometries requiring rotational symmetry. Unlike milling, which removes material from a stationary workpiece, CNC lathes rotate the stock against cutting tools, enabling efficient creation of shafts, bushings, fittings, and complex contoured features with exceptional repeatability. This process excels in producing high-tolerance cylindrical parts at significant speeds, minimizing material waste while maintaining structural integrity. At Shenzhen Honyo Prototype, we leverage advanced CNC lathe technology to transform engineering concepts into functional prototypes and low-volume production runs, serving industries where precision and rapid iteration are non-negotiable, including medical devices, aerospace, and automation.

Our facility utilizes a strategic fleet of modern CNC lathes, balancing automation capabilities with hands-on engineering oversight. We prioritize machine rigidity, thermal stability, and tool-path optimization to achieve micron-level accuracy consistently. All lathes are maintained under strict ISO 9001 protocols, with regular calibration using laser interferometers to ensure geometric precision across the entire work envelope. This foundation allows us to meet demanding specifications while accommodating tight project timelines inherent in prototype development.

Honyo Prototype’s lathe capabilities are engineered for versatility without compromising precision. The table below outlines our core equipment specifications for standard turning projects.

| Parameter | Specification Range |

|————————–|—————————|

| Maximum Turning Diameter | 200 mm |

| Maximum Turning Length | 500 mm |

| Spindle Speed Range | 50 – 6,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Typical Materials | Aluminum, Steel, Stainless, Brass, Plastics (PEEK, Acetal) |

Material selection directly impacts machining strategy and final part performance. We work closely with clients during the Design for Manufacturability (DFM) phase to optimize geometry for turnability, minimizing setups and secondary operations. For instance, features like undercuts or eccentric profiles may necessitate live tooling or sub-spindle operations, which our multi-axis lathes execute seamlessly. Our engineers analyze CAD models to identify potential stress points, thin walls, or challenging tolerances early, proposing adjustments that preserve function while enhancing manufacturability.

Quality assurance is integrated at every stage. Post-machining, parts undergo rigorous inspection using calibrated CMMs, optical comparators, and surface roughness testers. Critical dimensions are verified against first-article inspection reports, with full traceability maintained for all production batches. This disciplined approach ensures that prototypes function as intended during testing and that transition to volume production is seamless. For clients requiring accelerated development cycles, our Shenzhen-based facility supports rapid iteration, often delivering precision-turned components within 5-7 business days from approved CAD data.

By combining robust machinery, material expertise, and proactive engineering collaboration, Honyo Prototype delivers CNC lathe solutions where precision, speed, and reliability converge. We transform complex rotational geometries from concept to reality, ensuring your prototype performs exactly as designed.

Technical Capabilities

CNC Lathe Projects – Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC lathe solutions tailored for complex, high-integrity components across aerospace, medical, automotive, and industrial sectors. Our advanced 3, 4, and 5-axis CNC turning centers integrate live tooling and sub-spindle functionality to perform simultaneous milling, drilling, tapping, and contouring operations in a single setup. This multi-axis capability significantly enhances geometric complexity handling while minimizing part handling errors and cycle times.

Our CNC turning systems support both bar-fed and chucking configurations, accommodating a broad size range from Ø3 mm to Ø320 mm in diameter and lengths up to 1,000 mm. We specialize in high-precision turning with the capacity to hold tight tolerances down to ±0.002 mm on critical dimensions. Surface finishes as fine as Ra 0.4 µm are routinely achieved, with optional polishing and micro-finishing available for specialized applications.

The integration of Y-axis milling on 4 and 5-axis turning centers allows off-center feature machining such as slots, flats, and cross-holes with exceptional positional accuracy. This hybrid turning-milling functionality enables complete part fabrication—often eliminating the need for secondary operations. Additionally, our automated part catchers and robotic loading systems support high-volume production runs with consistent quality and minimal downtime.

We maintain strict process control through in-process probing, tool length compensation, and post-process CMM inspection, ensuring full traceability and compliance with ISO 9001:2015 standards. All CNC programs are verified using simulation software to prevent collisions and optimize toolpaths for efficiency and accuracy.

Material versatility is a core strength of our CNC lathe operations. We machine a comprehensive range of metals and engineering plastics, including aluminum, stainless steel, titanium, brass, PEEK, and PTFE. Each material is processed using optimized cutting parameters and tooling strategies to maintain dimensional stability and surface integrity.

The following table outlines our standard tolerance and material capabilities:

| Feature | Specification |

|——–|—————|

| Axis Configuration | 3-Axis (X, Z, C), 4-Axis (X, Z, C, Y), 5-Axis (X, Y, Z, B, C) |

| Maximum Work Envelope | Ø320 mm × 1,000 mm |

| Minimum Feature Size | Ø3 mm |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.002 mm (tight tolerance), ±0.01 mm (standard) |

| Surface Roughness | Ra 0.4 µm to Ra 3.2 µm (adjustable per requirement) |

| Spindle Speed | Up to 12,000 rpm (depending on machine model) |

| Tooling Capacity | Up to 12 live tools per station |

| Material Category | Examples | Notes |

|——————|———|——-|

| Aluminum | 6061, 7075, 2024 | High machinability, ideal for prototypes and lightweight parts |

| Stainless Steel | 303, 304, 316, 17-4 PH | Corrosion-resistant; suitable for medical and food-grade applications |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | High strength-to-density ratio; used in aerospace and medical implants |

| Brass | C3604, C3850 | Excellent for threaded components and electrical connectors |

| Engineering Plastics | PEEK, PTFE, Delrin, Nylon | Low friction, chemical resistance, non-conductive properties |

Shenzhen Honyo Prototype combines advanced machinery, rigorous quality control, and material expertise to deliver CNC lathe projects that meet the most demanding technical specifications.

From CAD to Part: The Process

CNC Lathe Production Workflow: From CAD to Precision Component

At Shenzhen Honyo Prototype, our CNC lathe production process is engineered for efficiency, accuracy, and seamless client collaboration. We transform your digital CAD model into a high-integrity physical component through a rigorously defined workflow: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution. This structured approach minimizes risk, optimizes lead times, and ensures first-time-right manufacturing.

The workflow initiates upon receipt of your native CAD file (STEP, IGES, or native formats preferred). Our proprietary AI Quoting Engine performs an immediate, multi-faceted analysis. It automatically identifies geometric complexity, material utilization, required tooling paths, and potential fixture challenges. Crucially, it cross-references this data against our real-time machine availability, tooling inventory, and historical process performance metrics. This generates a highly accurate initial quote within hours, not days, detailing estimated cost, lead time, and critical process parameters. The AI output forms the technical foundation for all subsequent stages, eliminating manual interpretation errors common in traditional quoting.

Following client approval of the quote, the project enters the mandatory Design for Manufacturability (DFM) Review. Our senior manufacturing engineers conduct a deep technical assessment, focusing on optimizing the design for CNC lathe capabilities while preserving functional intent. We identify and collaboratively resolve potential manufacturability hurdles before metal is cut. Key considerations include geometric feasibility, tolerance stack-ups, surface finish requirements, and material suitability. Proactive DFM collaboration prevents costly revisions and delays during production. Common critical parameters addressed during this phase include:

| Critical Parameter | Honyo Standard Capability | Recommended for Optimal Efficiency |

| :———————— | :———————— | :——————————— |

| Minimum Wall Thickness | 0.5mm | ≥ 0.8mm |

| Minimum Hole Diameter | Ø0.8mm | ≥ Ø1.5mm |

| Maximum Aspect Ratio (OD) | 15:1 | ≤ 10:1 |

| Standard Tolerance (±) | 0.01mm | 0.02mm – 0.05mm |

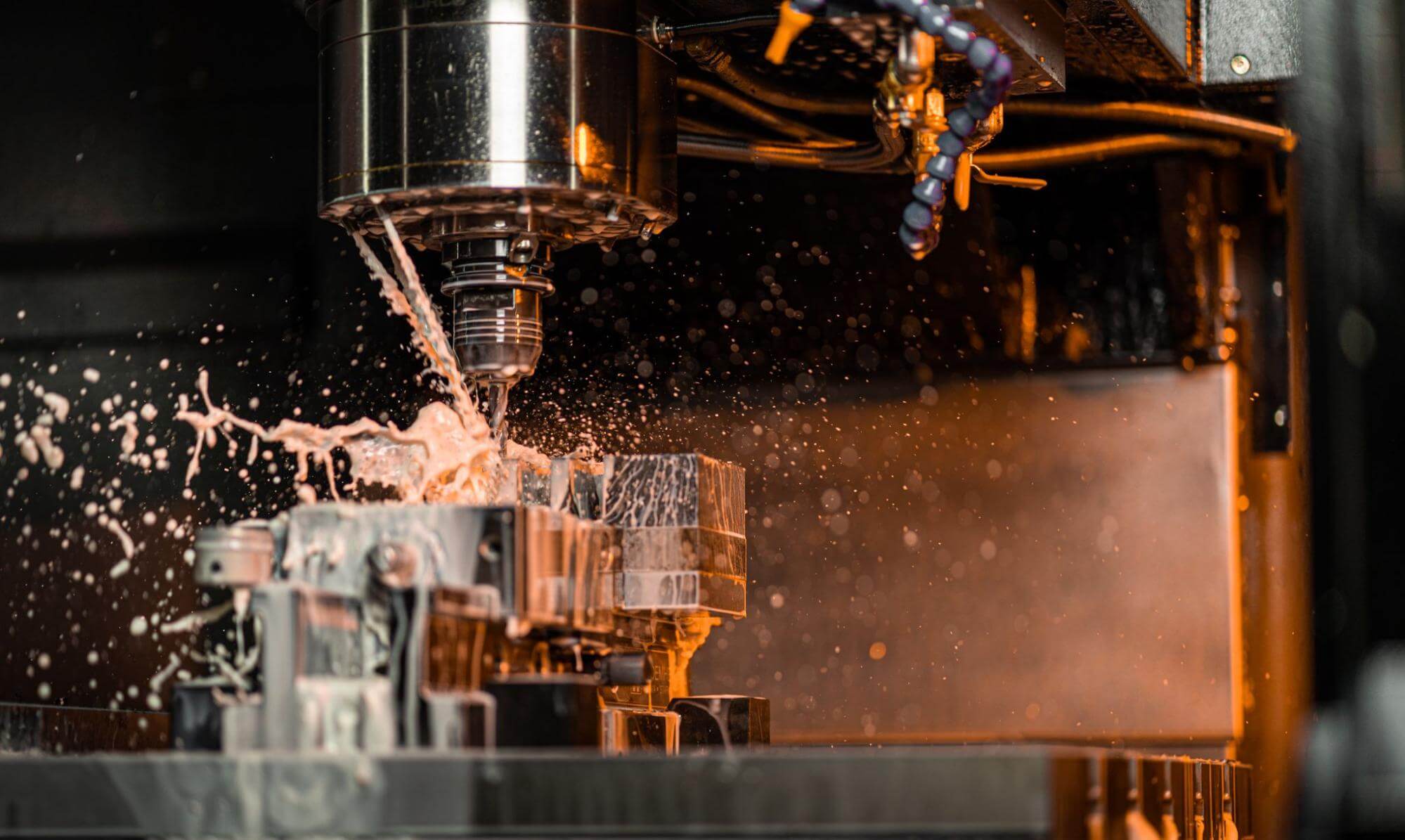

Upon DFM sign-off, the project advances to Precision Production. Our CNC lathe programmers generate optimized G-code using Mastercam and Siemens NX CAM, leveraging the insights from the DFM phase. Production occurs on our modern Swiss-type and multi-axis turning centers (including live tooling capabilities), equipped with high-precision spindles and automated bar feeders. Each operation undergoes rigorous in-process inspection using calibrated CMMs and vision systems at defined checkpoints, verifying critical dimensions against the original CAD model and approved DFM modifications. Final inspection provides full dimensional certification per ISO 2768-mK or client-specified standards, accompanied by material certification and process documentation. This closed-loop process ensures every component meets the stringent quality and precision demands of industries like medical devices, aerospace, and advanced automation, delivering on-time, specification-compliant parts with minimal client rework.

Start Your Project

Start Your CNC Lathe Project with Precision and Confidence

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services tailored to meet the demands of engineers, product designers, and manufacturing teams across industries. Whether you’re developing a functional prototype, a bridge production batch, or a full-scale manufacturing run, our CNC lathe capabilities ensure tight tolerances, superior surface finishes, and rapid turnaround times. Our state-of-the-art equipment, combined with expert programming and quality control, allows us to deliver machined components that meet exact design specifications—every time.

Our CNC turning services support a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics. With multi-axis lathes and live tooling options, we handle complex geometries and intricate features that standard machines cannot achieve. From simple shafts to complex turned components with undercuts, threads, and cross-holes, we bring your designs to life with precision and consistency.

We understand that every project begins with a vision. That’s why our engineering team works closely with clients during the initial stages to review designs for manufacturability, suggest material optimizations, and identify potential cost-saving opportunities. Our goal is not just to produce parts—but to help you refine your concept into a manufacturable, high-performance solution.

When you partner with Honyo Prototype, you gain access to a seamless workflow from quote to delivery. Our online submission system allows you to upload CAD files in minutes, and our team provides detailed feedback and pricing within 12 hours. All parts undergo strict in-process and final inspections using calibrated measurement tools, including CMM and optical comparators, ensuring compliance with ISO 9001 standards.

Below is an overview of our standard CNC lathe capabilities:

| Specification | Detail |

|—————|——–|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 600 mm |

| Spindle Speed | Up to 5,000 RPM |

| Tolerances | ±0.005 mm (typical) |

| Supported Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass (C3604), Titanium, PEEK, Delrin |

| Secondary Operations | Milling, threading, knurling, drilling, tapping, surface finishing |

| Quality Standards | ISO 9001:2015 compliant, First Article Inspection (FAI) available |

Starting your project is simple. Just send your 3D model or technical drawing to our manufacturing team for a fast, no-obligation quote. We support STEP, IGES, DWG, DXF, and PDF formats.

Contact Susan Leo today at info@hy-proto.com to begin your CNC lathe project. With her extensive experience in technical sales and project coordination, Susan will ensure your requirements are fully understood and matched with the right manufacturing solution. At Honyo Prototype, we don’t just machine parts—we build partnerships that drive innovation forward.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.