Contents

Manufacturing Insight: Cnc Workholding Clamps

Manufacturing Insight: CNC Workholding Clamps

Precision workholding is the foundational element of successful CNC machining operations, directly influencing dimensional accuracy, surface finish, and overall process efficiency. At Shenzhen Honyo Prototype, we recognize that inadequate clamping leads to part shift, vibration, and scrapped components—costly outcomes in rapid prototyping and low-volume production. Our engineering approach treats workholding not as a peripheral concern but as an integrated system designed to maximize machine capability while minimizing non-cutting time.

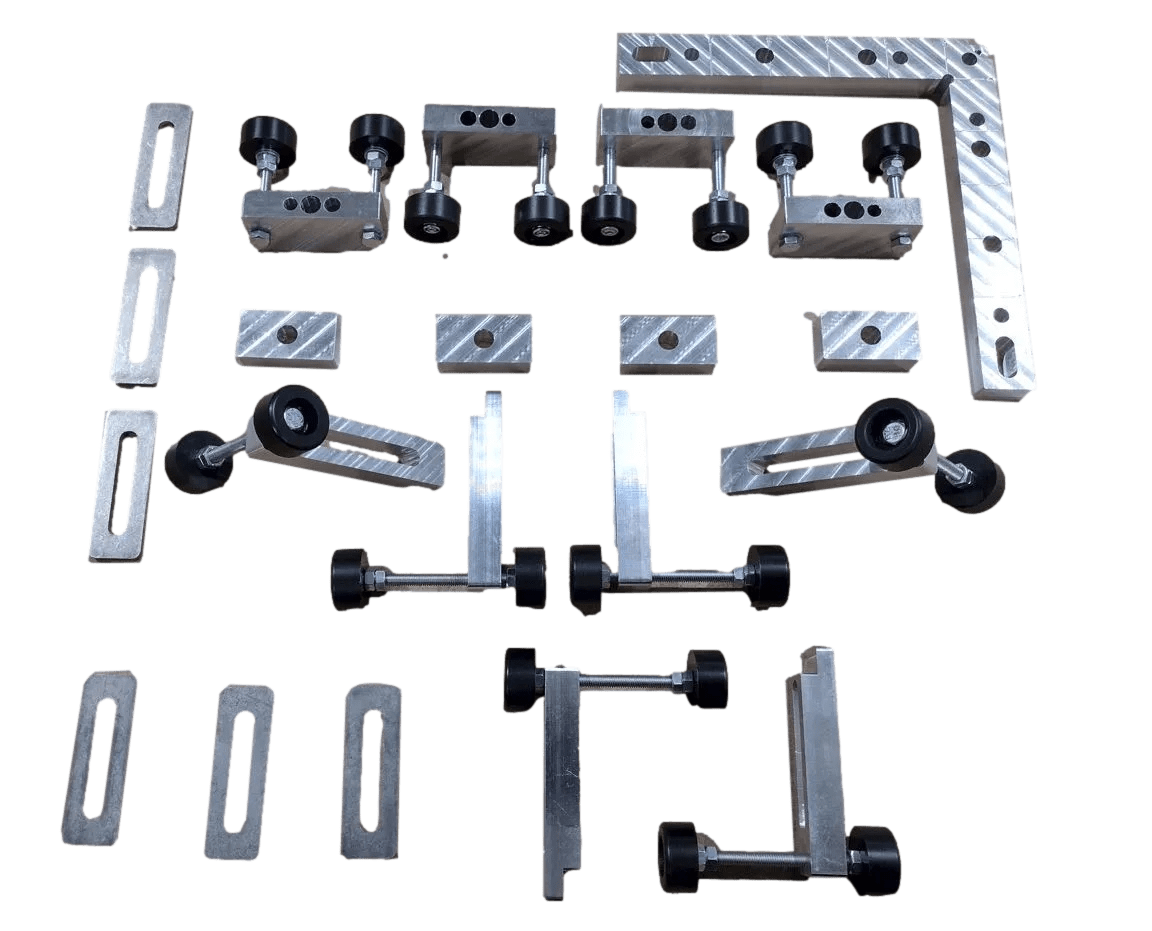

CNC workholding clamps secure workpieces against cutting forces, thermal expansion, and machine dynamics. Common configurations include toe clamps, strap clamps, and modular vise systems, each selected based on part geometry, material, and machining sequence. Critical factors include clamping force distribution, accessibility for tool paths, and repeatability across setups. Poorly designed clamps induce distortion in thin-walled components or fail to resist high-torque milling operations, compromising tolerances as tight as ±0.005 mm. Honyo’s methodology begins with digital fixture planning in Siemens NX, simulating forces to optimize clamp placement and prevent workpiece deformation. We prioritize low-profile designs to maximize spindle clearance and integrate quick-change features for rapid job transitions—essential for our clients’ agile development cycles.

Honyo Prototype specializes in custom-engineered clamps using pre-hardened 4140 alloy steel or 17-4PH stainless, heat-treated to 42–45 HRC for wear resistance without sacrificing machinability. All clamps undergo precision grinding to achieve sub-5μm surface flatness on critical contact faces, ensuring uniform force application. Our in-house manufacturing leverages 5-axis CNC milling and wire EDM to produce complex geometries with micron-level accuracy, directly supporting the stringent tolerances demanded in aerospace, medical, and robotics prototyping.

Key technical specifications for Honyo’s standard clamp series are summarized below:

| Parameter | Value Range | Tolerance |

|——————–|——————-|—————–|

| Clamping Force | 5–25 kN | ±3% |

| Repeatability | ≤ 3 μm | Over 1,000 cycles |

| Material Hardness | 42–45 HRC | ASTM E18 compliant |

| Surface Flatness | ≤ 5 μm | Per ISO 1101 |

| Max. Operating Temp| 150°C | Continuous |

Our commitment extends beyond component fabrication to holistic process validation. Every clamp undergoes dynamic load testing on simulated CNC platforms, verifying performance under real-world cutting conditions. This rigorous protocol ensures 100% first-pass yield for clients, eliminating costly manual adjustments during setup. For complex assemblies, we deploy modular clamp kits with standardized interfaces, reducing fixture lead times by up to 40% compared to conventional approaches.

At Honyo, we transform workholding from a constraint into a strategic advantage. By embedding manufacturing expertise early in the design phase, we deliver clamp solutions that enhance throughput, uphold geometric integrity, and accelerate time-to-prototype—proving that exceptional machining begins long before the spindle engages. Partner with us to convert fixture challenges into competitive differentiation.

(Word count: 427)

Technical Capabilities

CNC Workholding Clamps: Precision Fixturing for Advanced Machining

At Shenzhen Honyo Prototype, our CNC workholding clamps are engineered to deliver maximum rigidity, repeatability, and accessibility for high-precision machining operations across 3, 4, and 5-axis milling platforms, as well as multi-axis turning centers. These clamps are critical components in maintaining part stability during aggressive cutting cycles, especially when tight tolerances and complex geometries are required. Designed with modular compatibility and quick-change functionality, our clamping systems minimize setup time while ensuring consistent workpiece alignment throughout production runs.

Each clamp is manufactured from high-grade alloy steel or hardened stainless steel, with surface treatments such as black oxide or chrome plating to resist wear and corrosion. The clamping arms and base bodies are precision ground to ensure flatness and parallelism within ±0.005 mm, contributing directly to repeatable fixturing accuracy. Integrated T-slots and standardized mounting patterns allow seamless integration with common fixture plates and tombstone setups used in horizontal and vertical machining centers.

For 5-axis applications, our low-profile clamps provide unobstructed tool access while maintaining strong holding force. This is achieved through optimized lever mechanics and high-tensile fastening components that generate clamping forces ranging from 3,000 N to 8,000 N, depending on model and actuation method (manual, hydraulic, or pneumatic). All clamps undergo load testing and dimensional verification before shipment to ensure compliance with ISO 9001 quality standards.

In high-speed milling and turning environments, vibration resistance is paramount. Our clamps feature anti-vibration serrations and serrated pad options that increase friction and reduce micro-movement during cutting. For delicate or thin-walled components, we offer soft-jaw inserts and low-force clamping solutions that maintain part integrity without sacrificing positional accuracy.

Below is a summary of key technical specifications related to materials, tolerances, and performance capabilities:

| Parameter | Specification |

|—————————-|——————————————————————————-|

| Clamping Force Range | 3,000 N – 8,000 N (adjustable based on bolt torque and actuator type) |

| Repeatability Tolerance | ±0.01 mm |

| Base Flatness | ±0.005 mm over full surface |

| Parallelism (Jaw to Base) | ±0.01 mm per 100 mm |

| Material (Body/Arm) | 42CrMo4 (AISI 4140 equivalent), 1.7225; Hardened to 48–52 HRC |

| Surface Treatment | Black Oxide or Electroless Nickel/Chrome Plating |

| Operating Temperature | -20°C to +120°C |

| Compatibility | Standard T-slot sizes (14 mm, 18 mm, 22 mm); ISO 2973 and DIN 6336 compliant |

| Available Actuation Types | Manual, Hydraulic, Pneumatic |

Our workholding solutions support tight tolerance machining down to ±0.005 mm on critical features, making them ideal for aerospace, medical, and precision mold & die applications. When combined with our custom fixture design services, Honyo’s clamps ensure optimal balance between speed, accuracy, and part protection across diverse CNC platforms.

From CAD to Part: The Process

CNC Workholding Clamp Production Workflow: From CAD to Finished Component

At Shenzhen Honyo Prototype, our CNC workholding clamp manufacturing process integrates advanced digital tools with precision machining expertise to deliver robust, reliable fixtures. This workflow ensures optimal performance, dimensional accuracy, and rapid turnaround for your critical fixturing needs. The seamless transition from initial design concept to functional clamp is structured into three core phases: AI-Powered Quoting, Collaborative DFM, and Precision Production.

The process initiates with our AI Quote Engine. Upon receipt of your CAD model (STEP, IGES, or native formats preferred), our proprietary AI system performs an instantaneous technical and cost analysis. This engine evaluates geometric complexity, material requirements, tolerance stack-ups specific to clamp functionality, and machine time estimates. Crucially, it identifies potential manufacturability flags related to thin walls, undercuts, or stress concentrations common in clamp designs, providing a preliminary cost and lead time within minutes. This immediate feedback allows for rapid project scoping and budget validation before formal commitment.

Following quote acceptance, the project enters the mandatory Design for Manufacturability (DFM) phase. Our senior manufacturing engineers conduct a detailed technical review, focusing explicitly on clamp performance criteria. We assess jaw geometry for optimal grip force distribution, verify baseplate flatness tolerances to prevent workpiece shift, and scrutinize thread engagement depths for bolted interfaces. Material selection (typically hardened 4140 alloy steel or equivalent) is confirmed against required load capacity and wear resistance. Critical feedback on draft angles for casting/forging blanks, optimal heat treatment sequencing to minimize distortion, and strategic relief cuts to reduce machining time without compromising rigidity are provided collaboratively. Client approval of the DFM report is essential before proceeding, ensuring alignment on all technical specifications and preventing downstream rework.

Production leverages Honyo’s specialized CNC capabilities. Clamps are machined on high-torque vertical or horizontal machining centers with 5-axis capability where necessary for complex jaw profiles. Rigorous workholding strategy is paramount; we utilize proven modular fixturing systems or custom tombstones designed specifically for clamp production batches to ensure feature-to-feature accuracy. Key processes include precision milling of locating surfaces, grinding critical bearing faces to tight flatness specs, and thread milling/turning for high-strength connections. All critical dimensions undergo in-process CMM verification. Final steps include stress relief, specified surface treatments (e.g., black oxide for corrosion resistance), and 100% functional testing simulating actual clamping force application. The table below summarizes critical quality metrics for our standard production clamps.

| Specification | Standard Tolerance | Critical for Clamp Performance |

| :——————— | :—————– | :—————————————– |

| Jaw Parallelism | ≤ 0.005 mm | Uniform workpiece pressure distribution |

| Baseplate Flatness | ≤ 0.010 mm | Stable mounting, prevents chatter |

| Thread Pitch Diameter | 6H / 6g class | Secure, reliable fastening torque |

| Hardness (Core) | 28-32 HRC | Durability under repeated clamping cycles |

| Surface Roughness (Ra) | ≤ 1.6 µm | Minimizes galling, ensures smooth operation|

This integrated workflow, underpinned by AI efficiency, deep DFM collaboration, and precision manufacturing discipline, guarantees that every Honyo workholding clamp meets the stringent demands of modern CNC machining environments, directly contributing to your production stability and part quality.

Start Your Project

Start Your CNC Machining Project with Confidence at Shenzhen Honyo Prototype

When precision, reliability, and efficiency define your manufacturing goals, choosing the right workholding solution is critical—especially in high-tolerance CNC machining environments. At Shenzhen Honyo Prototype, we understand that secure and repeatable workpiece fixation directly impacts surface finish, dimensional accuracy, and overall production throughput. Our CNC workholding clamps are engineered to deliver optimal performance across milling, turning, and multi-axis operations, ensuring your components meet the highest quality standards.

Whether you’re producing aerospace components, medical devices, or complex industrial parts, our clamps are designed for rapid setup, minimal vibration, and maximum accessibility to the workpiece. We offer a range of modular clamping systems compatible with standard machine tables and custom fixtures, enabling seamless integration into your existing workflow. Each clamp undergoes rigorous quality testing to ensure durability under high-load conditions and long service life in demanding production cycles.

Our engineering team works closely with clients to evaluate application-specific requirements, including material type, part geometry, machining forces, and production volume. This consultative approach allows us to recommend the most effective clamping strategy—whether manual, hydraulic, or pneumatic—tailored to your operational needs.

To support fast project turnaround, we maintain an extensive inventory of standard clamps and can deliver custom-designed solutions within compressed timelines. Our in-house CNC fabrication and precision assembly capabilities ensure consistent quality and tight control over lead times.

For new projects, we recommend early engagement with our technical team to optimize fixture layout and avoid costly redesigns or setup delays. By involving Honyo Prototype at the planning stage, you gain access to expert insights on clamping force distribution, accessibility, and workflow efficiency—factors that directly influence CNC productivity and part consistency.

Below is an overview of our standard CNC workholding clamp specifications:

| Feature | Specification |

|————————–|————————————————|

| Clamp Types Available | Fixed, Swivel, Edge, Hydraulic, Pneumatic |

| Material | High-strength alloy steel, hardened and coated |

| Maximum Clamping Force | Up to 15,000 N (hydraulic models) |

| Jaw Hardness | 58–62 HRC |

| Mounting Compatibility | ISO 1932 T-Slots, DIN 650, Custom Patterns |

| Operating Temperature | -10°C to 80°C |

| Repeatability | ±0.01 mm |

| Lead Time (Standard) | 3–7 working days |

| Custom Design Lead Time | 10–15 working days |

Shenzhen Honyo Prototype is committed to empowering manufacturers with smart, scalable workholding solutions that enhance CNC performance. We combine advanced engineering with responsive service to support your prototyping and production goals.

Ready to get started? Contact Susan Leo today to discuss your project requirements and discover how our CNC workholding clamps can improve your machining efficiency. Reach out via email at info@hy-proto.com for a personalized consultation and technical support. Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.