Contents

Manufacturing Insight: Automotive Metal Fabrication

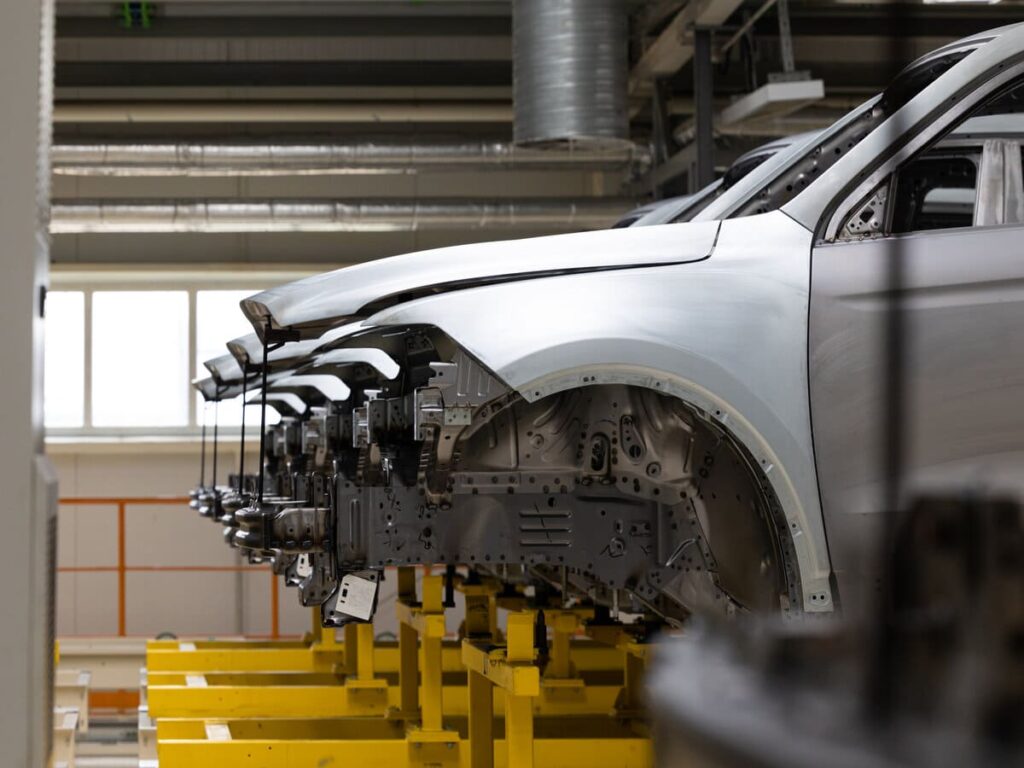

Automotive Metal Fabrication: Precision Engineering for Modern Vehicle Systems

Automotive metal fabrication represents a critical discipline where advanced material science converges with stringent manufacturing precision to produce components essential for vehicle performance, safety, and efficiency. Modern automotive demands—driven by lightweighting initiatives, electrification, and enhanced structural integrity—require fabrication processes capable of handling complex geometries, high-strength alloys, and uncompromising quality standards. From intricate battery enclosures and structural subframes to precision brackets and chassis components, the ability to transform sheet metal into functionally reliable parts directly impacts vehicle dynamics, occupant protection, and production viability. Shenzhen Honyo Prototype leverages deep industry expertise and advanced manufacturing infrastructure to meet these exacting automotive requirements, providing OEMs and Tier suppliers with scalable solutions from rapid prototyping through low-to-mid volume production.

Our core capabilities encompass a comprehensive suite of sheet metal processes optimized for automotive applications. We specialize in working with advanced materials including ultra-high-strength steel (UHSS), aluminum alloys (6061-T6, 5052, 7075), and tailored blanks, ensuring compatibility with evolving vehicle architectures. Precision laser cutting, multi-axis CNC bending, robotic welding (MIG/TIG), and sophisticated assembly techniques form the backbone of our production flow. Critical to automotive success is our rigorous adherence to geometric dimensioning and tolerancing (GD&T) standards and robust process validation protocols. The following table outlines key technical specifications achievable within our automotive-focused production environment:

| Process Capability | Typical Tolerance Range | Supported Materials | Maximum Work Envelope |

| :———————– | :———————- | :————————————– | :————————– |

| Fiber Laser Cutting | ±0.05 mm | Steel (up to 12mm), Aluminum (up to 8mm) | 3000 x 1500 mm |

| CNC Press Brake Forming | ±0.05° angular, ±0.1 mm | UHSS, Aluminum, Stainless Steel | 4000 x 300 ton capacity |

| Robotic MIG/TIG Welding | ±0.2 mm positional | Steel, Aluminum, Dissimilar Metals | Component-dependent |

| Surface Finishing | Ra 0.8 – 3.2 μm | All fabricated metals | Full part coverage |

Honyo Prototype differentiates itself through integrated engineering support and agile manufacturing systems designed for the automotive sector’s fast-paced development cycles. Our team conducts proactive Design for Manufacturability (DFM) analysis early in the prototyping phase, identifying potential fabrication challenges and material conflicts before tooling commitment. This is complemented by our ISO 9001 and IATF 16949 certified quality management system, featuring comprehensive in-process inspection (CMM, vision systems), material traceability, and rigorous First Article Inspection (FAI) reporting per PPAP requirements. We understand that automotive components demand more than dimensional accuracy; they require consistent mechanical properties, fatigue resistance, and corrosion performance. Our process controls and material testing protocols ensure every fabricated part meets the structural and longevity demands of modern vehicles, whether for initial concept validation, pre-production builds, or specialized low-volume production runs. Partner with Honyo to transform complex automotive metal designs into high-integrity, production-ready components with speed and precision.

Technical Capabilities

Automotive Metal Fabrication Technical Capabilities

Shenzhen Honyo Prototype delivers precision sheet metal fabrication services tailored to the demanding requirements of the automotive industry. Our advanced manufacturing capabilities in laser cutting, bending, and welding ensure high repeatability, structural integrity, and dimensional accuracy across prototyping and low-to-mid volume production runs. We specialize in processing a wide range of metals commonly used in automotive applications, including cold-rolled steel (CRS), stainless steel, aluminum alloys, and galvanized materials. Each process is supported by strict quality control protocols and in-line metrology to meet automotive OEM standards.

Laser Cutting

Our fiber laser cutting systems provide high-speed, burr-free cutting with minimal heat-affected zones, ideal for complex geometries and tight-tolerance components. With a maximum cutting area of 1500 mm × 3000 mm and power up to 4 kW, we handle sheet thicknesses from 0.5 mm to 25 mm depending on material type. This capability supports the fabrication of brackets, housings, chassis components, and structural reinforcements with clean edge quality suitable for subsequent forming or welding operations.

Press Brake Forming (Bending)

We utilize CNC-controlled press brakes equipped with automatic tool changers and precision backgauging systems to achieve consistent bend angles and tight angular tolerances. Our forming capacity supports sheet lengths up to 3 meters and thicknesses up to 16 mm, depending on material strength. Advanced offline programming with 3D bending simulation ensures first-time accuracy and reduced setup times. This capability is critical for producing complex enclosures, mounting frames, and structural supports used in electric vehicles and conventional automotive platforms.

Welding and Joining

Honyo Prototype offers MIG, TIG, and spot welding processes compliant with automotive structural standards. Our certified welders follow approved Welding Procedure Specifications (WPS) to ensure joint integrity, penetration, and cosmetic quality. Robotic welding cells are deployed for repeatable production runs, while manual TIG welding is used for prototypes and high-precision assemblies. Post-weld treatments such as grinding, polishing, and dimensional stress-relief annealing are available upon request.

The following table outlines key process capabilities and tolerances for automotive sheet metal fabrication:

| Process | Material Types | Thickness Range (mm) | Typical Tolerance | Max Work Envelope (mm) |

|——————|————————————|———————-|————————–|————————|

| Laser Cutting | CRS, Stainless Steel, Aluminum, Galvanized | 0.5 – 25 | ±0.1 mm (dimensional) | 1500 × 3000 |

| CNC Bending | CRS, Stainless Steel, Aluminum | 0.8 – 16 | ±0.2° angular, ±0.2 mm | 3000 (length) |

| MIG/TIG Welding | CRS, Stainless Steel, Aluminum | 1.0 – 20 | ±0.5 mm (assembly) | 2000 × 1500 × 800 |

| Spot Welding | CRS, Galvanized Steel | 0.8 – 3.0 | ±1.0 mm (pitch accuracy) | 1200 × 800 |

All fabricated components undergo first-article inspection and in-process quality checks using CMM, optical comparators, and weld penetration testing where applicable. Shenzhen Honyo Prototype is equipped to support full vehicle subsystem fabrication, from concept validation to pre-production builds, ensuring technical readiness for automotive integration.

From CAD to Part: The Process

From CAD to Finished Component: Automotive Sheet Metal Fabrication Workflow

At Shenzhen Honyo Prototype, our automotive sheet metal fabrication process is engineered for precision, efficiency, and adherence to stringent industry standards. We execute a seamless transition from digital design to certified physical part through a rigorously defined workflow: AI-Powered Quoting, Engineering-Driven DFM, and Integrated Production. This structured approach ensures manufacturability, cost-effectiveness, and on-time delivery for critical automotive applications.

AI-Powered Quoting System

The process initiates upon receipt of the customer’s 3D CAD model and technical specifications. Our proprietary AI quoting engine rapidly analyzes the geometry, material requirements, tolerances, and surface finish criteria. It cross-references this data against real-time machine capabilities, material costs, labor rates, and historical production data to generate an accurate, detailed cost estimate and lead time projection within hours. This initial AI assessment provides immediate transparency, highlighting potential high-cost features early and enabling swift project validation before engineering resources are committed. The output is a formal quotation package detailing scope, pricing breakdown, and preliminary timeline.

Engineering-Driven Design for Manufacturability (DFM)

Following quotation approval, the project enters the critical DFM phase led by our senior manufacturing engineering team. This is not a superficial review but a deep technical collaboration. Engineers scrutinize the CAD model against our specific sheet metal fabrication capabilities, focusing on bend radii relative to material thickness, minimum flange lengths, hole placement relative to bends, and weld accessibility. We proactively identify features that could cause tooling conflicts, excessive secondary operations, or quality risks under automotive vibration and stress conditions. Recommendations for geometric optimization—such as adjusting bend sequences, modifying cutouts, or suggesting alternative fastening methods—are provided to the client with clear technical justification. This collaborative refinement, often completed within 1-2 business days, is essential for achieving first-time-right production, minimizing waste, and ensuring the part meets automotive durability requirements. Formal DFM sign-off is mandatory before production release.

Integrated Production Execution

With DFM validation complete, the approved design moves seamlessly into production. Our integrated manufacturing cell manages the entire sequence: precision laser or turret punching cuts the flat pattern; CNC press brakes execute complex, multi-stage bending with in-process metrology verifying critical angles; robotic or skilled manual welding assembles subcomponents per AWS D1.1 standards; followed by finishing processes like powder coating or anodizing as specified. Throughout fabrication, our MES system enforces strict material traceability (lot/batch tracking) and real-time quality checkpoints aligned with IATF 16949 protocols. Final inspection utilizes CMMs and optical comparators against the original CAD model and client drawings, generating comprehensive First Article Inspection (FAI) reports per AS9102 or customer-specific formats. The result is a fully documented, automotive-grade metal component ready for validation and integration.

Material selection is paramount for automotive performance. Key specifications we routinely certify include:

| Material Grade | Typical Thickness Range (mm) | Tensile Strength (MPa) | Key Automotive Application | Corrosion Resistance |

| :——————- | :————————— | :——————— | :——————————- | :——————- |

| 5052-H32 Aluminum | 0.8 – 6.0 | 228 | Fuel tanks, brackets, housings | Excellent |

| 304 Stainless Steel | 0.5 – 4.0 | 515 | Exhaust components, fasteners | Very Good |

| DC04 / SPCC Steel | 0.5 – 3.0 | 270-500 | Structural brackets, chassis | Fair (Requires coat) |

| 6061-T6 Aluminum | 1.0 – 10.0 | 310 | Suspension arms, high-strength | Good |

This disciplined workflow—from intelligent quoting through rigorous DFM to traceable production—ensures Shenzhen Honyo Prototype delivers automotive sheet metal components that consistently meet the exacting demands of performance, reliability, and compliance.

Start Your Project

Start Your Automotive Metal Fabrication Project with Confidence

When it comes to automotive metal fabrication, precision, durability, and performance are non-negotiable. At Shenzhen Honyo Prototype, we specialize in high-quality sheet metal fabrication tailored specifically for the automotive industry. Whether you’re developing a prototype for a new vehicle component, upgrading an existing design, or scaling production for aftermarket parts, our advanced manufacturing capabilities ensure your vision becomes a reality—on time and to exact specifications.

Our expertise spans laser cutting, CNC punching, precision bending, robotic welding, and custom finishing—all performed in-house using state-of-the-art equipment and quality-controlled processes. We work with a wide range of materials including cold-rolled steel, aluminum alloys, stainless steel, and galvanized sheet metal, ensuring optimal performance under demanding automotive conditions. From concept to final part, we support every stage of development with engineering consultation, DFM analysis, and rapid turnaround times.

We understand that automotive components require strict adherence to dimensional tolerances, structural integrity, and surface quality. That’s why every project at Honyo Prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and visual QA protocols to ensure compliance with ISO 9001 standards. Our team collaborates closely with engineers, designers, and OEMs to deliver parts that meet both functional and aesthetic requirements.

To help you get started, we’ve outlined our standard fabrication capabilities in the table below:

| Specification | Capability |

|—————————-|——————————————-|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Max. Sheet Size | 1500 mm × 3000 mm |

| Tolerance (General) | ±0.1 mm |

| Tolerance (Laser Cutting) | ±0.05 mm |

| Bend Tolerance | ±0.2° angular, ±0.1 mm linear |

| Welding Types | MIG, TIG, Spot, Robotic Welding |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Brushing, Galvanizing |

| Lead Time (Prototypes) | 5–7 working days |

| Lead Time (Production) | 10–15 working days (volume-dependent) |

| Certifications | ISO 9001:2015, RoHS Compliant |

No matter the complexity of your design or the urgency of your timeline, Shenzhen Honyo Prototype is equipped to deliver. Our engineering team is available to review your CAD files, provide design feedback, and recommend cost-saving optimizations before production begins.

Ready to move forward? The next step is simple. Contact Susan Leo, our dedicated project coordinator, to discuss your automotive fabrication needs. She will guide you through the quoting process, answer technical questions, and ensure your project is in expert hands from day one.

Email Susan Leo at info@hy-proto.com with your drawings, specifications, and project requirements. Include any preferred materials, quantities, and target deadlines so we can provide an accurate, detailed quote promptly. For time-sensitive projects, please indicate your required delivery date—we prioritize responsiveness without compromising quality.

At Honyo Prototype, we don’t just fabricate metal—we build partnerships that drive innovation in automotive manufacturing. Start your project today and experience the difference precision engineering makes.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.