Contents

Manufacturing Insight: Cnc Machine Working

Manufacturing Insight: CNC Machine Working at Honyo Prototype

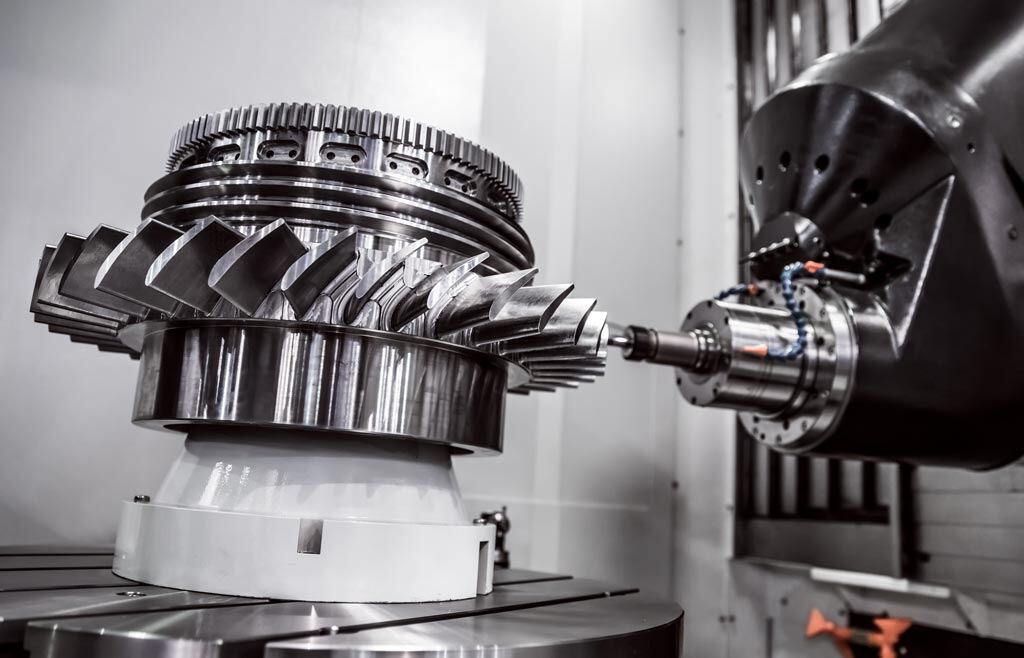

Computer Numerical Control (CNC) machining remains the cornerstone of precision manufacturing for rapid prototyping and low-to-mid volume production. At Shenzhen Honyo Prototype, we leverage advanced CNC technology to transform digital designs into high-fidelity physical components with exceptional accuracy, repeatability, and material integrity. Our process utilizes subtractive methods where computer-guided cutting tools remove material from solid stock—ensuring complex geometries, tight tolerances, and superior surface finishes are achieved consistently. This capability is critical for industries demanding rigorous validation of form, fit, and function early in product development cycles, including aerospace, medical devices, and consumer electronics.

Honyo Prototype operates a comprehensive CNC fleet, integrating 3-axis, 4-axis, and 5-axis milling centers alongside precision turning centers. This strategic mix enables us to handle everything from simple brackets to intricate organic shapes requiring multi-angle access without manual repositioning. Our machines are maintained to ISO 9001:2015 standards and supported by in-house tool calibration systems, ensuring dimensional stability across all production runs. We prioritize material versatility, routinely machining metals such as aluminum 6061-T6, stainless steel 304/316, titanium Ti-6Al-4V, and brass, alongside engineering plastics including PEEK, Delrin, and polycarbonate. Each material undergoes strict incoming inspection to verify grade compliance and structural homogeneity before processing.

The technical specifications underpinning our CNC operations are designed for uncompromising quality. Key performance metrics are summarized below:

| Parameter | Capability | Industry Standard Context |

|————————-|——————————–|—————————|

| Positional Accuracy | ±0.005 mm | Exceeds typical ±0.01 mm |

| Repeatability | ±0.002 mm | Critical for batch consistency |

| Max Work Envelope | 1000 x 600 x 500 mm (Milling) | Accommodates mid-size assemblies |

| Surface Finish (Ra) | 0.8 µm (as-machined) | Meets stringent cosmetic requirements |

| Lead Time (Prototype) | 3–7 days | Accelerates time-to-test |

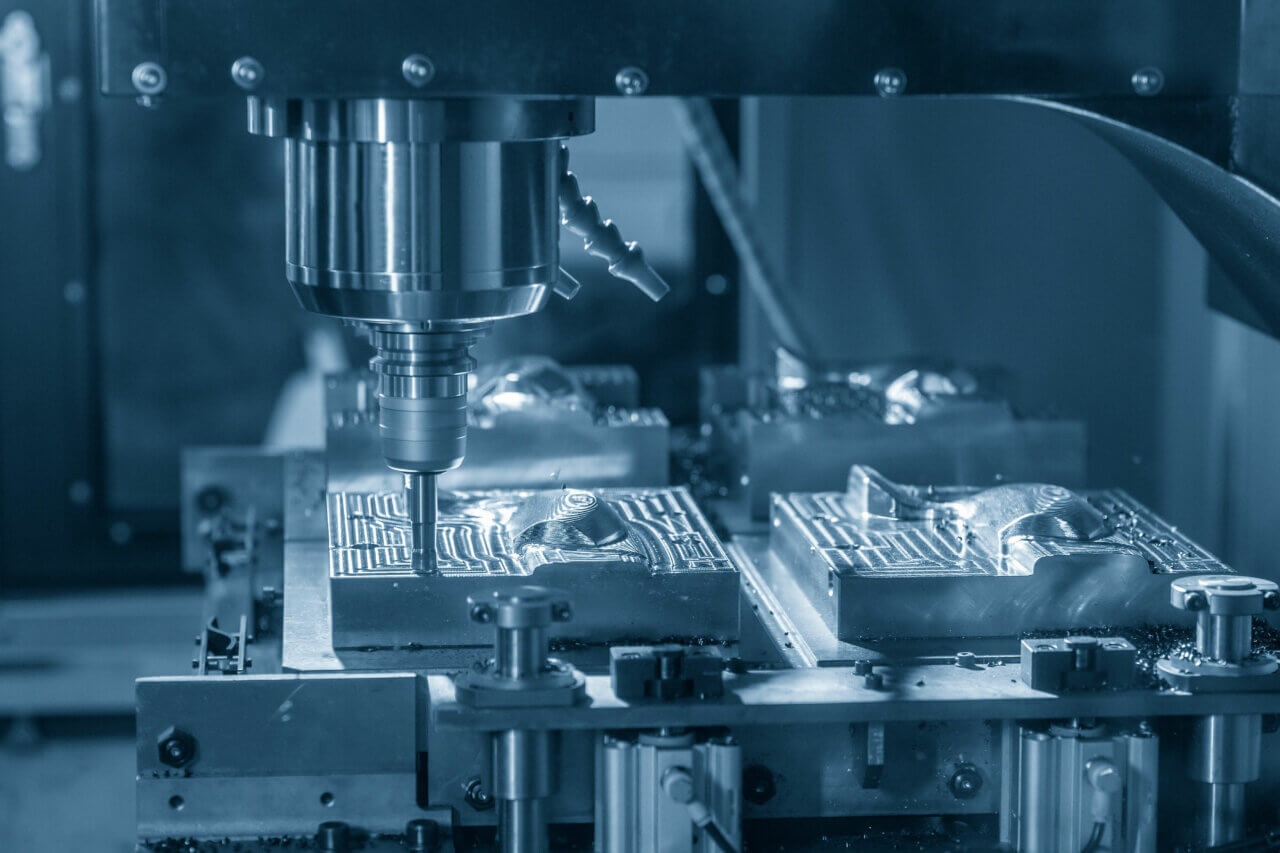

Quality assurance is embedded at every stage. Our engineers employ real-time in-process probing to verify critical features during machining, minimizing scrap and rework. Post-processing, components undergo CMM (Coordinate Measuring Machine) validation against original CAD models, with full inspection reports provided. This data-driven approach ensures that every part meets Honyo’s zero-defect philosophy while adhering to client-specified GD&T callouts.

Beyond technical execution, Honyo Prototype distinguishes itself through collaborative engineering support. Our manufacturing team engages early in the design phase to identify potential manufacturability improvements—suggesting optimized toolpaths, material substitutions, or feature modifications that reduce cost without sacrificing performance. This proactive partnership mitigates downstream risks and accelerates project timelines. For global clients requiring rapid iteration, our Shenzhen-based facility offers seamless integration with digital workflows, including instant DFM feedback and cloud-based production tracking. By combining cutting-edge CNC infrastructure with deep process expertise, Honyo Prototype delivers precision-machined components that reliably bridge the gap between concept and commercialization.

Technical Capabilities

CNC Machine Working – Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining services tailored for rapid prototyping and low-to-mid volume production. Our advanced machining center is equipped with high-performance 3-axis, 4-axis, and 5-axis CNC milling machines, as well as multi-axis CNC turning centers. These capabilities enable us to produce complex geometries, tight-tolerance components, and functional prototypes across a wide range of engineering materials.

Our 3-axis milling systems are ideal for prismatic parts with straightforward geometries, offering high-speed material removal and excellent surface finishes. For more complex components requiring machining from multiple angles, our 4-axis and 5-axis CNC milling platforms provide enhanced flexibility. The addition of rotary axes allows for single-setup machining of intricate contours, undercuts, and organic shapes—common in aerospace, medical, and robotics applications. This reduces cumulative tolerance stack-up and improves part accuracy while minimizing lead time.

In addition to milling, our CNC turning capabilities support the production of cylindrical and symmetric components with precision diametrical control. Equipped with live tooling, our turning centers can perform mill-turn operations, enabling the completion of complex parts in one setup—such as shafts with cross-drilled holes or keyways.

Tight tolerance machining is a core competency at Honyo Prototype. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, with typical production tolerances held at ±0.025 mm (±0.001″). Our quality assurance process includes first-article inspection, in-process checks, and final verification using CMM, optical comparators, and precision metrology tools, ensuring compliance with engineering specifications.

The following table outlines standard tolerance capabilities and compatible materials for our CNC machining services:

| Operation | Standard Tolerance | Tight Tolerance | Typical Materials |

|—————–|——————–|—————–|——————-|

| 3-Axis Milling | ±0.025 mm | ±0.005 mm | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (1018, 4140), Titanium (Grade 5), Brass (C360), Plastics (ABS, PC, POM, PEEK, Nylon) |

| 4-Axis Milling | ±0.025 mm | ±0.008 mm | Aluminum (6061, 7075), Stainless Steel (304, 316), Brass, PEEK, PC |

| 5-Axis Milling | ±0.025 mm | ±0.005 mm | Aluminum, Titanium, Stainless Steel, Inconel, PEEK, Delrin |

| CNC Turning | ±0.025 mm | ±0.010 mm | Aluminum, Stainless Steel, Brass, Steel, Plastics |

| Mill-Turn | ±0.025 mm | ±0.010 mm | Aluminum, Stainless Steel, Titanium, Brass |

All materials are sourced to meet international standards and are inspected upon receipt. We support both standard and exotic materials, with stock often maintained for fast-turn projects.

At Honyo Prototype, our technical expertise, rigorous quality control, and advanced CNC infrastructure ensure reliable, repeatable, and high-precision machining outcomes for demanding industrial applications.

From CAD to Part: The Process

From CAD to Precision Part: Honyo Prototype’s CNC Production Workflow

At Shenzhen Honyo Prototype, our CNC machining process transforms digital designs into high-precision components through a seamless, integrated workflow. This systematic approach ensures manufacturability, cost efficiency, and on-time delivery for complex prototypes and low-volume production runs. The journey begins with AI-powered quoting and culminates in rigorous quality validation, all managed within our Shenzhen facility.

AI-Powered Quoting and Feasibility Assessment

Upon receiving a CAD file (STEP, IGES, or native formats), our proprietary AI quoting system performs an instant geometric and material analysis. This tool evaluates feature complexity, raw material requirements, and machine time estimates while cross-referencing real-time shop floor data. The output is a detailed quote with delivery timelines and preliminary cost breakdowns within 2 business hours. Crucially, the AI flags potential manufacturability risks—such as thin walls below 0.5mm or deep cavities exceeding aspect ratios of 10:1—enabling proactive dialogue before order confirmation.

DFM Optimization and Engineering Collaboration

Following quote acceptance, our manufacturing engineers conduct a formal Design for Manufacturability (DFM) review. This phase involves direct collaboration with the client to refine geometries that challenge standard CNC capabilities. We identify opportunities to reduce setups (e.g., modifying undercuts for 3-axis accessibility), suggest material substitutions for improved machinability, and optimize tolerances to avoid unnecessary grinding or secondary operations. All DFM recommendations are documented in a shared report, with client approval required before programming commences. This step typically reduces production lead time by 15–25% and eliminates costly revisions.

Precision Production and Quality Assurance

With finalized CAD/CAM files, parts enter production on our certified CNC equipment. Toolpaths are validated via simulation to prevent collisions, followed by first-article inspection against the original CAD model. Each component undergoes in-process checks for critical dimensions, with final verification using CMM, optical comparators, or surface roughness testers per ISO 2768 standards. Below are key capabilities enabling this precision:

| Parameter | Capability Range | Standard Tolerance |

|——————–|——————————–|——————–|

| Machine Types | 3-axis, 4-axis, 5-axis milling | ±0.005 mm |

| Max Work Envelope | 1,200 x 800 x 650 mm | — |

| Spindle Speed | Up to 24,000 RPM | — |

| Surface Finish | Ra 0.8 µm (as-machined) | Ra 1.6 µm typical |

| Materials | Metals, Engineering Plastics | — |

The entire workflow—from CAD upload to shipped part—is tracked in our MES, providing clients with real-time progress updates. By embedding AI analysis, collaborative DFM, and closed-loop quality control, Honyo Prototype delivers CNC-machined components that meet exacting functional and dimensional requirements, minimizing time-to-market for innovative engineering projects. This integrated methodology underscores our commitment to being a strategic manufacturing partner, not just a job shop.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision manufacturing, CNC machining remains one of the most reliable and versatile methods for producing high-quality prototypes and end-use parts. At Shenzhen Honyo Prototype, we specialize in delivering CNC machining services that combine advanced technology, expert engineering, and strict quality control to meet the demanding requirements of industries ranging from aerospace and medical devices to consumer electronics and automotive systems. Whether you’re developing a single prototype or preparing for low-volume production, our team is ready to support your project from concept to completion.

Our state-of-the-art CNC machining center is equipped with multi-axis milling and turning machines capable of handling complex geometries with tight tolerances down to ±0.005 mm. We work with a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics such as PEEK, ABS, and polycarbonate. This flexibility allows us to tailor the manufacturing process to your specific functional and environmental requirements.

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients during the initial design phase to optimize part geometry, select appropriate materials, and identify cost-saving opportunities without compromising performance. Our design for manufacturability (DFM) analysis ensures that your components are not only precise but also efficient to produce, reducing lead times and minimizing waste.

Once your design is finalized, our digital workflow enables rapid quoting, quick setup, and real-time progress tracking. Typical lead times range from 3 to 10 business days, depending on complexity and volume, with express options available for urgent requirements. All parts undergo rigorous in-process and final inspections using coordinate measuring machines (CMM) and optical comparators to ensure compliance with your specifications.

To ensure transparency and consistency, we provide full documentation, including inspection reports, material certifications, and as-built dimensional data. Our quality management system is aligned with ISO 9001 standards, reflecting our commitment to excellence in every project.

Below is an overview of our standard CNC machining capabilities:

| Feature | Specification |

|—————————-|———————————————-|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning |

| Tolerance | ±0.005 mm standard |

| Materials | Aluminum, steel, stainless steel, brass, titanium, PEEK, ABS, PC, and more |

| Maximum Work Envelope | 1200 x 600 x 500 mm (milling), Ø300 x 600 mm (turning) |

| Surface Finishes | As machined, anodizing, powder coating, plating, polishing |

| Lead Time | 3–10 days (standard), expedited options available |

| Quality Standards | ISO 9001 compliant, full inspection reports |

Starting your project with Honyo Prototype is simple. If you have a design ready or need engineering support, we encourage you to reach out today. Susan Leo, our dedicated project coordinator, is available to assist with quotations, technical questions, and project planning. Contact Susan Leo at info@hy-proto.com to begin the conversation. Let us help you turn your ideas into precision-engineered reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.