Contents

Manufacturing Insight: Ceramic 3D Printing Services

Manufacturing Insight: Ceramic 3D Printing Services

Ceramic 3D printing represents a transformative capability for producing complex, high-performance components unattainable through traditional molding or machining. At Shenzhen Honyo Prototype, we leverage advanced vat photopolymerization (SLA/DLP) techniques to fabricate precision ceramic parts with exceptional geometric freedom, thermal stability, and chemical resistance. This technology is critical for industries demanding biocompatible medical implants, intricate aerospace components, or durable industrial tooling where conventional methods fail. Unlike polymer or metal additive processes, ceramic printing requires meticulous control over multiple stages: green-state printing, debinding, and high-temperature sintering. Each phase demands deep material science expertise to mitigate challenges like shrinkage, warpage, and microcracking, ensuring final parts meet stringent functional requirements.

Honyo’s ceramic 3D printing service integrates proprietary process optimization with industrial-grade equipment to deliver production-ready components. Our workflow begins with material selection from a curated portfolio of alumina, zirconia, and silica-based slurries, each engineered for specific mechanical and thermal properties. During printing, we maintain sub-50μm layer resolution to achieve fine features and smooth surface finishes, minimizing post-processing needs. The critical sintering phase—where parts densify and achieve final material properties—is executed in controlled atmosphere furnaces with AI-driven thermal profiling. This reduces dimensional deviation to ±0.5% and ensures consistent density (>99% theoretical), directly impacting part reliability in demanding applications.

Our technical capabilities are structured to support rapid prototyping and low-volume production with rigorous quality assurance. The table below outlines key specifications for our standard ceramic printing service:

| Parameter | Specification |

|————————-|—————————————-|

| Supported Materials | Alumina (Al₂O₃), Zirconia (ZrO₂), Silica |

| Layer Resolution | 25–50 μm |

| Build Volume | 50 x 50 x 100 mm (standard) |

| As-Printed Tolerance | ±0.1 mm |

| Sintered Tolerance | ±0.5% of linear dimension |

| Surface Roughness (Ra) | < 5 μm (post-sintering) |

| Minimum Feature Size | 150 μm |

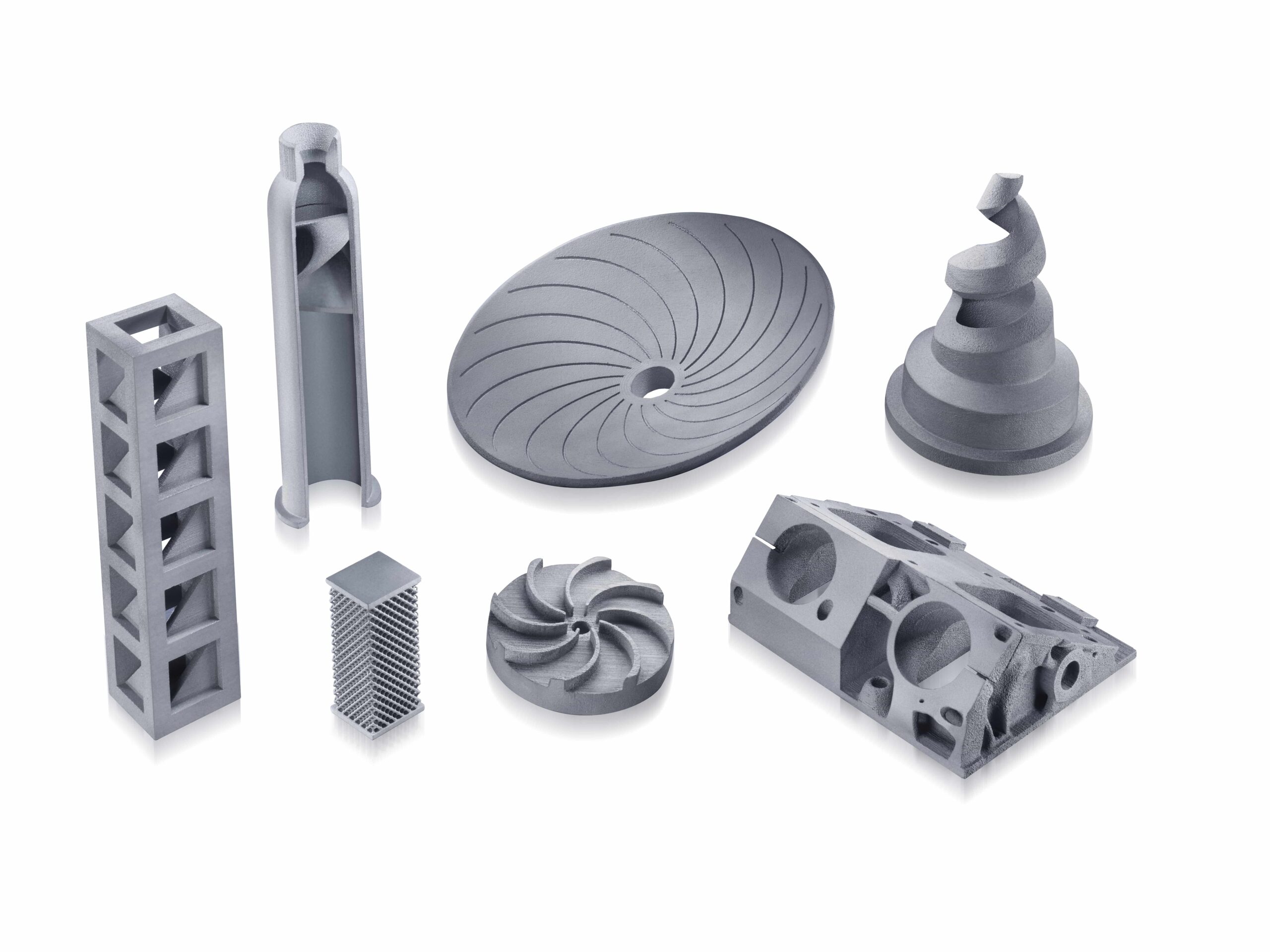

Honyo’s engineering team collaborates closely with clients during design for additive manufacturing (DfAM) reviews, identifying potential failure points like unsupported overhangs or stress concentrations early in the process. We implement in-process monitoring for layer adhesion and slurry viscosity, coupled with post-sintering CT scanning for internal defect validation. This end-to-end control enables us to consistently achieve >95% first-pass yield rates on complex geometries—such as lattice structures, microfluidic channels, or thin-walled enclosures—that would be impossible to manufacture conventionally.

For manufacturers seeking to accelerate innovation in high-temperature, corrosive, or wear-intensive environments, Honyo Prototype delivers not just parts, but validated solutions. Our ceramic 3D printing service bridges the gap between conceptual design and functional deployment, ensuring components meet exacting industry standards while reducing time-to-market by up to 70% compared to traditional tooling. Partner with us to transform material limitations into competitive advantages.

Technical Capabilities

Shenzhen Honyo Prototype offers advanced ceramic 3D printing services tailored for industrial applications requiring high thermal stability, chemical resistance, and mechanical performance under extreme conditions. Our expertise spans multiple additive manufacturing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS), adapted for ceramic materials and ceramic-composite systems. Each process is optimized to deliver precision, repeatability, and scalability for prototyping and low-volume production.

Our ceramic SLA process utilizes photosensitive ceramic-loaded resins to produce highly detailed components with excellent surface finish. This method is ideal for intricate geometries and complex internal features common in aerospace, medical, and electronics industries. Parts are thermally post-processed to burn out the polymer matrix and fully densify the ceramic structure, resulting in components with near-theoretical density and superior mechanical properties.

For applications requiring enhanced strength and thermal resilience, we employ modified SLS and MJF platforms capable of processing ceramic-filled polymer powders. These technologies allow rapid fabrication of functional prototypes and end-use parts with good dimensional accuracy and mechanical robustness. Post-processing through debinding and sintering enhances the ceramic content and structural integrity, enabling performance in high-temperature environments.

DMLS, while traditionally used for metals, is leveraged in our facility for printing metal-ceramic composites and fully dense ceramic parts via specialized process parameters and hybrid feedstock materials. This approach supports the production of wear-resistant, thermally conductive components suitable for demanding industrial environments.

All ceramic 3D printing processes at Honyo are supported by in-house material characterization, thermal analysis, and metrology to ensure compliance with industry standards. We work closely with clients to select the optimal combination of material, process, and post-treatment to meet functional requirements.

The following table summarizes the technical specifications, achievable tolerances, and compatible materials for each ceramic 3D printing technology offered:

| Technology | Material Options | Layer Thickness | Typical Tolerance | Surface Roughness (Ra) | Post-Processing Required |

|———-|————————————–|—————–|——————-|————————-|—————————-|

| SLA | Alumina, Zirconia, Silica-loaded resin | 25–100 μm | ±0.1% (min ±0.05 mm) | 0.8–1.6 μm | Yes (Debinding, Sintering) |

| SLS | Ceramic-filled nylon (e.g., PA11/Al₂O₃) | 80–120 μm | ±0.3% (min ±0.2 mm) | 3.0–5.0 μm | Yes (Debinding, Sintering) |

| MJF | Ceramic-reinforced polyamide | 80 μm | ±0.3% (min ±0.2 mm) | 2.5–4.0 μm | Yes (Debinding, Sintering) |

| DMLS | SiC, Al₂O₃-TiC composites, ZrO₂-based alloys | 20–50 μm | ±0.1 mm | 5.0–10.0 μm | Yes (HIP, Annealing, Machining) |

All processes are supported by full traceability, first-article inspection reports, and optional ISO 9001-compliant quality documentation. Shenzhen Honyo Prototype is equipped to handle complex ceramic components from design validation through to serial production, ensuring technical performance and manufacturability across industries.

From CAD to Part: The Process

Ceramic 3D Printing Production Workflow: From CAD to Final Part

Shenzhen Honyo Prototype delivers high-precision ceramic components through a rigorously controlled additive manufacturing process. Our workflow, optimized for industrial applications, ensures dimensional accuracy, material integrity, and on-time delivery. The journey from initial concept to functional part is systematically managed across three critical phases: AI-Driven Quoting, Comprehensive Design for Manufacturing (DFM), and Precision Production.

The process initiates upon receipt of a client’s CAD file. Our proprietary AI quoting engine rapidly analyzes the geometry, material requirements (e.g., Alumina, Zirconia, Silica), and requested quantity. This system instantly generates a detailed quote encompassing production cost, lead time, and preliminary feasibility assessment. The AI leverages our extensive database of material properties and historical build data to provide accurate estimates, eliminating lengthy manual quoting delays and enabling rapid project initiation for time-sensitive industrial programs.

Following quote acceptance, the CAD model undergoes rigorous Design for Manufacturing (DFM) review by our senior ceramic engineering team. This phase is paramount for ceramic success, as material behavior during printing and sintering differs significantly from metals or polymers. Engineers scrutinize wall thicknesses, overhang angles, feature resolution, and internal channel complexity. Critical attention is paid to sintering-induced shrinkage (typically 15-25%) and potential warpage. Support structure requirements for the specific ceramic slurry and printing technology (SLA or DLP) are meticulously planned. The DFM report provides actionable feedback and optimization suggestions to the client, ensuring the design is manufacturable to target tolerances and eliminating costly iterations or failures during production. Client collaboration at this stage is essential for optimal outcomes.

Approved designs move to production. The CAD file is sliced into layers, and the build parameters are finalized based on the DFM analysis and material grade. Printing occurs in a controlled environment using high-resolution ceramic-loaded photopolymer resins. Post-print, parts undergo a multi-stage cleaning process to remove uncured resin. The critical debinding phase slowly removes the polymer binder via thermal or chemical methods, requiring precise control to prevent cracking. Finally, parts are sintered in high-temperature furnaces under specific atmospheres. Sintering parameters are strictly managed according to the ceramic material to achieve full density and the required mechanical properties. Key sintering parameters for common materials are maintained as follows:

| Material | Typical Sintering Temp (°C) | Avg. Linear Shrinkage | As-Sintered Tolerance (mm) |

| :———— | :————————– | :——————– | :————————- |

| Alumina (Al₂O₃) | 1550 – 1650 | 18% – 22% | ±0.1% (min ±0.05) |

| Zirconia (ZrO₂) | 1450 – 1550 | 20% – 25% | ±0.15% (min ±0.08) |

| Silica (SiO₂) | 1100 – 1250 | 15% – 18% | ±0.08% (min ±0.03) |

Post-sintering, parts may undergo precision grinding, lapping, or laser machining to achieve final critical dimensions and surface finishes. Each component undergoes stringent dimensional inspection and material verification against client specifications before shipment. This integrated workflow, combining AI efficiency, deep ceramic DFM expertise, and tightly controlled production, ensures Honyo Prototype consistently delivers mission-critical ceramic components meeting the highest industrial standards.

Start Your Project

Start Your Ceramic 3D Printing Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in advanced ceramic 3D printing services tailored for industrial applications where precision, thermal stability, and chemical resistance are non-negotiable. Whether you’re developing components for aerospace, medical devices, electronics, or high-temperature tooling, our manufacturing expertise ensures your design transitions seamlessly from concept to functional prototype or end-use part.

Ceramic 3D printing offers unmatched advantages over traditional forming methods—complex geometries, internal channels, lattice structures, and rapid iteration cycles are all achievable without the need for molds or extensive post-processing. At Honyo Prototype, we leverage state-of-the-art binder jetting and stereolithography (SLA) technologies to deliver high-density, fully sintered ceramic parts with excellent surface finish and dimensional accuracy.

Our engineering team works closely with clients from the earliest stages of design to ensure manufacturability, material compatibility, and performance under real-world conditions. We support a range of technical ceramics including alumina (Al₂O₃), zirconia (ZrO₂), silicon carbide (SiC), and silicon nitride (Si₃N₄), each offering unique properties suited to extreme environments.

To begin your project, simply reach out to Susan Leo, our dedicated manufacturing solutions coordinator. Susan will guide you through the onboarding process, from file submission and material selection to lead time estimation and quality assurance protocols. We accept STEP, IGES, STL, and native CAD formats, and our team performs a comprehensive Design for Additive Manufacturing (DfAM) review to optimize your part for printability and performance.

We understand that industrial timelines are demanding. That’s why we offer rapid turnaround times without compromising quality—typical lead times range from 5 to 12 business days depending on geometry, size, and finishing requirements.

Below are key specifications for our ceramic 3D printing capabilities:

| Parameter | Capability |

|—————————-|————————————————-|

| Printing Technologies | Binder Jetting, Ceramic SLA |

| Standard Materials | Alumina (95%, 99.5%), Zirconia (3Y-TZP), SiC, Si₃N₄ |

| Layer Resolution | 50–100 μm |

| Build Envelope | Up to 250 × 250 × 200 mm |

| Dimensional Accuracy | ±0.3% (with minimum ±0.1 mm) |

| Surface Roughness (as printed) | Ra 3.2–6.3 μm |

| Post-Processing Options | Debinding, Sintering, CNC Machining, Polishing |

| Minimum Feature Size | 0.5 mm (walls), 1.0 mm (pins) |

All parts undergo rigorous in-process inspections and final quality verification using coordinate measuring machines (CMM) and optical profilometry to ensure compliance with ISO 9001 standards.

Partner with Honyo Prototype to unlock the full potential of ceramic additive manufacturing. Contact Susan Leo today at info@hy-proto.com to submit your design files and receive a personalized project assessment. Let’s turn your most demanding ceramic component concepts into reality—faster, smarter, and with uncompromised quality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.