Contents

Manufacturing Insight: Cnc Mill For Steel

Precision Steel Machining: CNC Milling Capabilities at Honyo Prototype

Steel remains a cornerstone material for demanding industrial applications due to its exceptional strength, durability, and wear resistance. Successfully machining complex geometries in steel, however, presents significant technical challenges distinct from softer metals or plastics. Achieving tight tolerances, superior surface finishes, and structural integrity requires specialized CNC milling technology, rigorous process control, and deep metallurgical understanding. At Shenzhen Honyo Prototype, we leverage advanced CNC milling centers specifically optimized for the rigors of steel fabrication, enabling us to deliver high-precision components for aerospace, automotive, tooling, and industrial machinery sectors where performance under stress is non-negotiable.

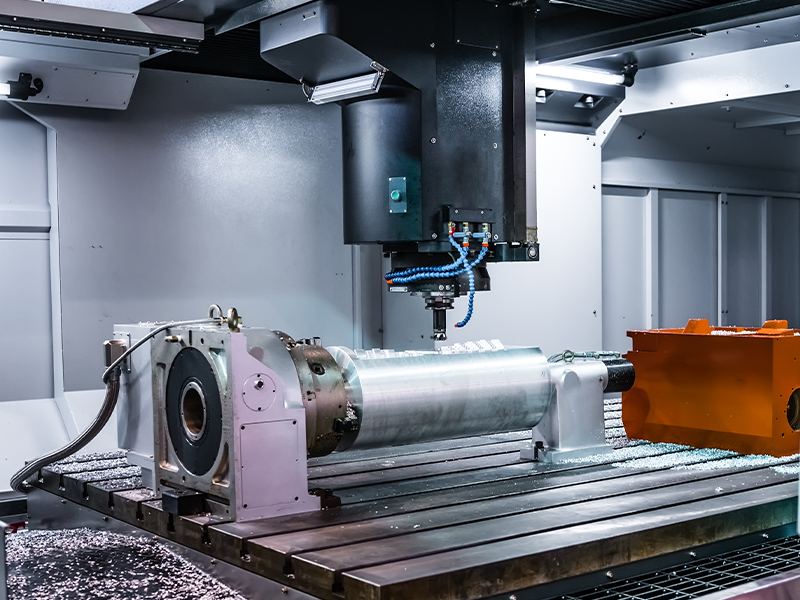

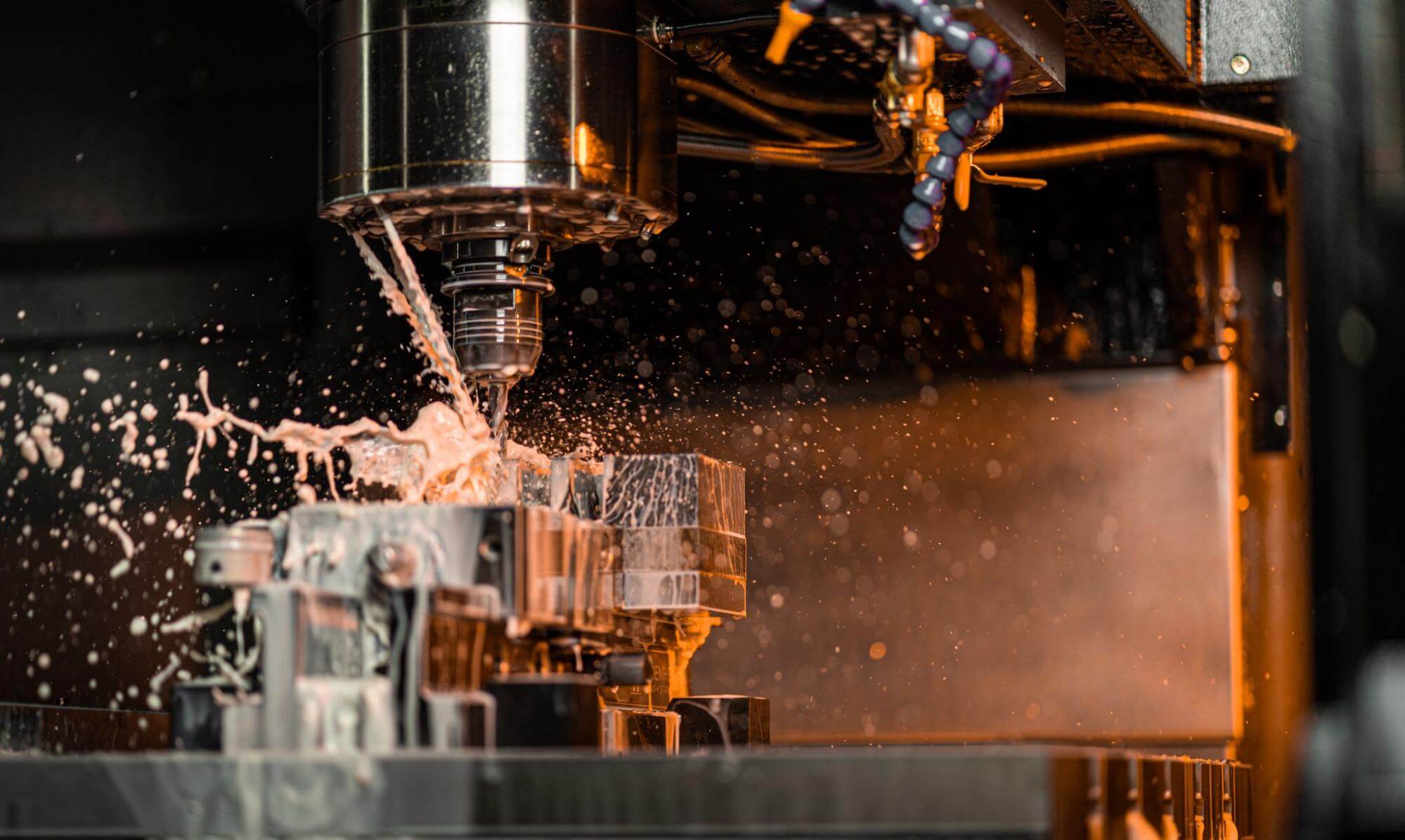

Milling steel effectively demands overcoming inherent material properties. Its high hardness and strength lead to substantial cutting forces, significant heat generation at the tool-workpiece interface, and accelerated tool wear. Inadequate process parameters can result in work hardening, poor surface integrity, dimensional inaccuracies, or catastrophic tool failure. Success hinges on selecting the correct tool geometry and substrate, precise coolant application, optimal spindle speeds and feed rates tailored to the specific steel grade, and robust machine rigidity to dampen vibrations. Honyo Prototype addresses these challenges through a dedicated steel machining workflow. Our facility utilizes state-of-the-art vertical and 5-axis CNC milling centers featuring high-torque spindles, thermal compensation systems, and reinforced cast iron frames essential for maintaining accuracy during prolonged, high-force steel cutting operations.

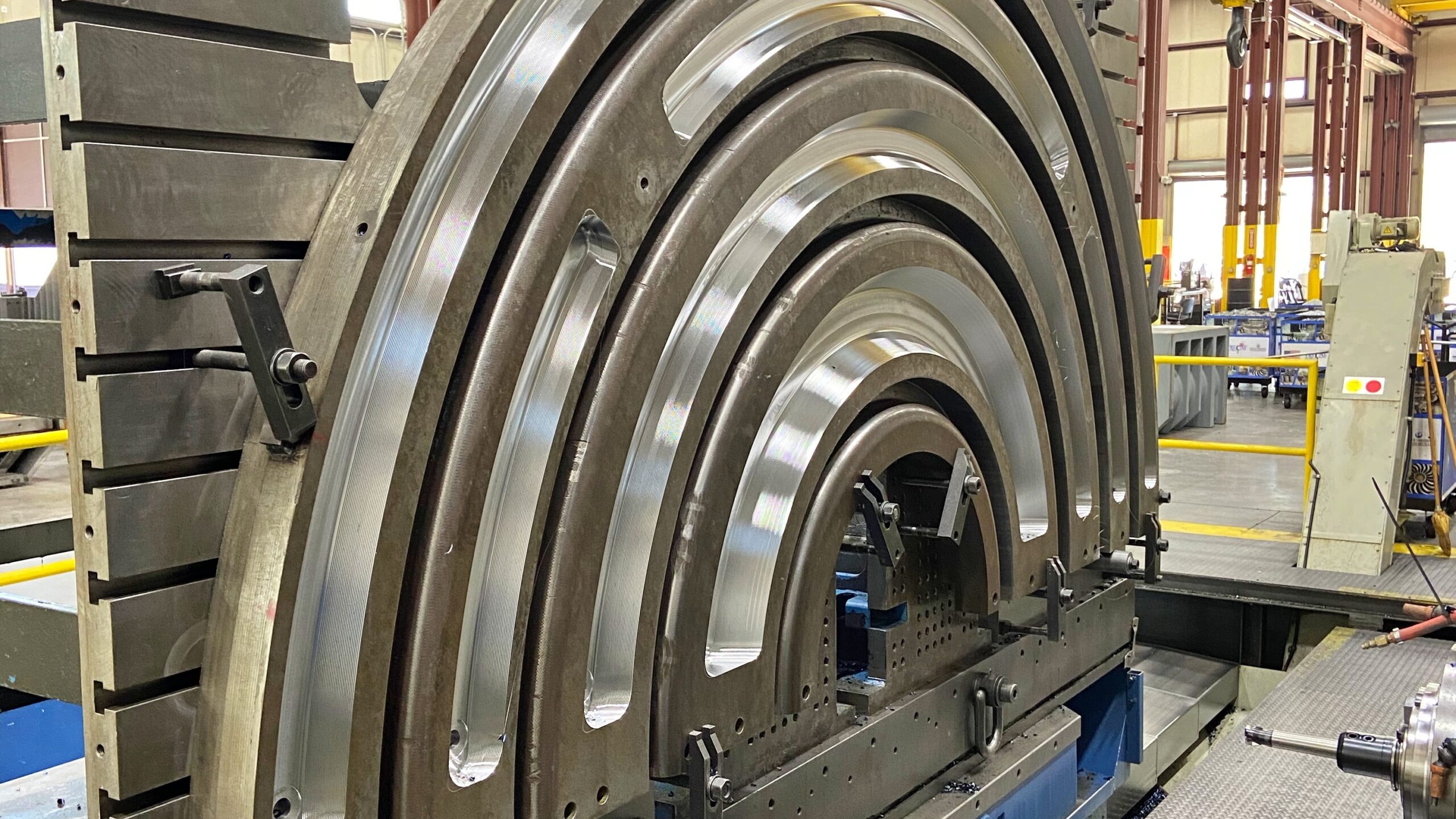

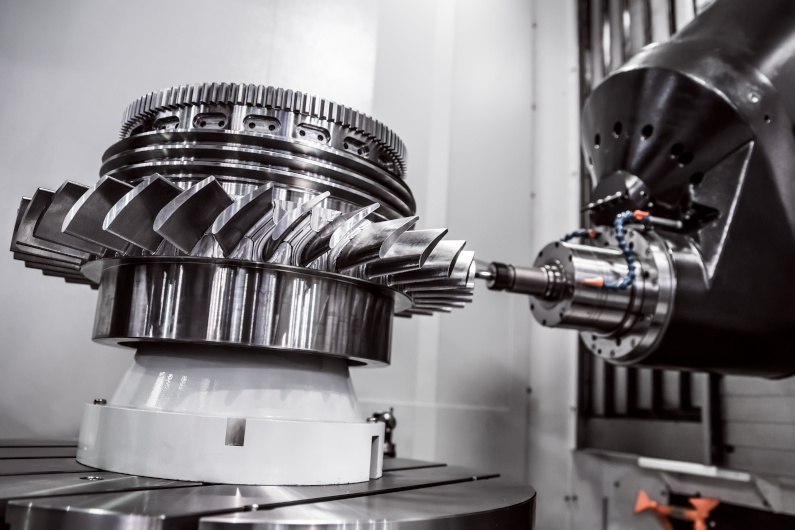

Our core steel machining capabilities are underpinned by precision equipment and stringent process protocols. We routinely machine a wide range of steel alloys, including stainless steels (304, 316, 17-4 PH), tool steels (D2, A2, H13), and carbon/alloy steels (1018, 4140, 4340), handling complexities from simple brackets to intricate hydraulic manifolds and structural components. Critical to our success is the integration of advanced toolpath strategies within our CAM software, utilizing techniques like high-efficiency milling (HEM) to manage heat and extend tool life while maintaining productivity. Rigorous in-process inspection using coordinate measuring machines (CMMs) and surface roughness testers ensures dimensional conformity and surface quality meet exacting specifications throughout the manufacturing cycle.

The following table outlines key specifications of our primary steel-machining CNC mills:

| Parameter | Specification | Significance for Steel Machining |

| :—————– | :——————————– | :——————————————— |

| Machine Platform | Haas VF-3 / DMG MORI CTX beta 1250 | High rigidity, thermal stability, proven reliability |

| Spindle Power | 15 kW (20 HP) / 22 kW (30 HP) | Sustains cutting forces for deep slots & heavy stock removal |

| Positioning Accuracy | ±0.005 mm (0.0002″) | Ensures tight tolerances on critical features |

| Repeatability | ±0.002 mm (0.00008″) | Guarantees consistency across production runs |

| Max Work Envelope | 1067 x 508 x 508 mm / Ø400 x 400 mm | Accommodates medium-sized industrial components |

| Tool Magazine | 30-Tool ATC | Enables complex multi-operation setups without manual intervention |

| Coolant System | High-Pressure Through-Spindle (1000 PSI) | Effectively evacuates chips and controls heat in deep cavities |

Beyond the machine, Honyo Prototype’s value lies in our engineering expertise. Our manufacturing engineers possess deep knowledge of steel metallurgy and its interaction with cutting processes. We collaborate closely with clients during the Design for Manufacturability (DFM) phase to identify potential issues early, recommend optimal steel grades for the application, and suggest geometric refinements that enhance machinability without compromising function. This proactive approach, combined with our advanced equipment and disciplined quality systems, ensures that every steel component we produce meets the highest standards of precision, reliability, and performance demanded by critical industrial applications. Partner with Honyo Prototype for steel CNC milling where uncompromising quality is essential.

Technical Capabilities

CNC Milling Capabilities for Steel at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our advanced CNC milling infrastructure is engineered specifically to handle the demanding requirements of steel machining. We specialize in high-precision 3-axis, 4-axis, and 5-axis milling operations, enabling us to produce complex geometries with superior accuracy and surface finish. Our multi-axis capabilities allow for reduced setup times, improved part consistency, and the ability to machine intricate features in a single operation—critical for prototyping and low-to-medium volume production runs.

Our CNC mills are equipped with high-torque spindles, rigid tooling systems, and adaptive control technology to maintain performance under the high cutting forces associated with steel materials. We process a wide range of steel alloys, including carbon steels, alloy steels, tool steels, and stainless steels such as 304, 316, 4140, and 4340. Each machine is maintained to strict calibration standards and operates under controlled environmental conditions to ensure thermal stability and dimensional accuracy.

In addition to milling, we integrate precision CNC turning for cylindrical steel components, supporting both bar-fed and chucked operations. This hybrid approach allows us to deliver complete-machined parts with minimal lead time and high repeatability. Our turning centers are capable of handling diameters up to 300 mm and lengths up to 600 mm, with live tooling options for mill-turn complexity.

Tight tolerance machining is a core competency. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, with surface finishes as fine as Ra 0.8 μm (32 μin) achievable through optimized tool paths and post-process finishing techniques. Our quality control system includes CMM inspection, optical comparators, and digital micrometry, ensuring every steel component meets stringent GD&T requirements.

Below is an overview of our typical machining capabilities and achievable tolerances for steel components:

| Parameter | Specification |

|——————————-|————-|

| Axis Configuration | 3-axis, 4-axis, 5-axis milling; CNC turning with live tooling |

| Maximum Work Envelope (mm) | 1000 × 700 × 600 (XYZ) for 5-axis; Ø300 × 600 mm for turning |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed options available) |

| Tool Capacity | Up to 30-tool automatic tool changer |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Finish (typical) | Ra 1.6 – 3.2 μm; down to Ra 0.8 μm with finishing passes |

| Steel Material Type | Common Grades Processed | Typical Tolerance Range |

|——————————-|——————————-|————————–|

| Carbon Steel | 1018, 1045 | ±0.010 mm |

| Alloy Steel | 4140, 4340 | ±0.008 mm |

| Tool Steel | A2, D2, H13 | ±0.008 mm |

| Stainless Steel | 303, 304, 316, 17-4 PH | ±0.005 mm |

All steel parts undergo rigorous in-process and final inspection, with full traceability and material certification available upon request. Shenzhen Honyo Prototype combines technical expertise, state-of-the-art equipment, and a commitment to precision to deliver reliable, high-performance steel components for aerospace, automotive, medical, and industrial applications.

From CAD to Part: The Process

CNC Milling Production Process: Steel Components from CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC milling workflow for steel components is engineered for precision, efficiency, and guaranteed manufacturability. We execute a rigorous three-phase sequence—AI Quote, DFM Analysis, and Production—to transform client CAD data into high-integrity steel parts, minimizing risk and maximizing value.

The process initiates with our proprietary AI-Powered Quoting Engine. Upon receiving the client’s 3D CAD model (STEP, IGES, or native formats), the system automatically analyzes geometric complexity, material requirements (specifying grades like 304SS, 4140, or 1045), critical tolerances (±0.005mm typical), and surface finish demands. It calculates precise machine time, material consumption, and fixture requirements, generating a detailed quote with lead time and cost breakdown within hours. This phase ensures initial feasibility assessment against our HAAS VF-2SS and DMG MORI 5-axis milling capabilities before human engineering review.

Subsequent to quote acceptance, Comprehensive DFM Analysis becomes paramount. Our senior manufacturing engineers conduct a deep dive into the design, focusing explicitly on steel’s unique challenges: work hardening, thermal conductivity, and chip evacuation. We verify tool access, optimize wall thicknesses to prevent chatter, assess hole depth-to-diameter ratios, and validate tolerance stack-ups. Crucially, we identify potential stress concentrations and recommend geometry modifications to enhance machinability without compromising function. This collaborative review with the client resolves ambiguities and ensures the design is optimized for efficient, high-yield steel machining. Key steel-specific parameters addressed include:

| Parameter | Typical Value for Steel | Purpose |

|——————–|——————————-|——————————————|

| Spindle Speed | 500 – 3500 RPM | Balances tool life & material removal rate |

| Feed Rate | 100 – 800 mm/min | Manages chip load & surface finish |

| Coolant | High-Pressure Soluble Oil | Controls heat, evacuates chips, extends tool life |

| Tool Material | Carbide with TiAlN Coating | Resists abrasion & heat in steel |

Only after DFM sign-off does Controlled Production commence. The approved CAD model drives CAM programming (using Mastercam and Fusion 360), generating optimized toolpaths with precise stepovers and depths of cut tailored to the steel grade. Rigorous setup occurs on the selected CNC mill, employing custom soft jaws or modular fixturing to ensure absolute part stability—a critical factor for vibration-sensitive steel operations. Production utilizes premium carbide tooling with specialized geometries for steel, coupled with through-spindle coolant delivery. In-process inspections via Renishaw probes verify critical dimensions after roughing and semi-finishing stages. Final parts undergo full CMM validation against the original CAD, with comprehensive first-article inspection reports provided. Throughout, our process control system logs machine parameters and inspection data, ensuring traceability and enabling continuous improvement for future steel projects. This disciplined workflow guarantees Honyo delivers dimensionally accurate, structurally sound steel components meeting the most demanding industrial specifications.

Start Your Project

Start Your Steel CNC Milling Project with Honyo Prototype

When it comes to precision manufacturing in steel, CNC milling stands as one of the most reliable and accurate methods available. At Shenzhen Honyo Prototype, we specialize in high-precision CNC milling services tailored specifically for steel components, ensuring your parts meet exact design specifications and industry standards. Whether you’re developing prototypes for aerospace applications, industrial tooling, or high-strength mechanical components, our advanced CNC milling capabilities deliver consistent quality, tight tolerances, and rapid turnaround times.

Our facility in Shenzhen is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling machines, allowing us to handle complex geometries and multi-faceted designs with ease. We work with a wide range of steel alloys, including stainless steel (303, 304, 316), tool steel (D2, A2, O1), and carbon steel (1018, 1045), ensuring material compatibility for your application. Each part undergoes rigorous quality control, including dimensional inspection using coordinate measuring machines (CMM), surface finish verification, and material certification upon request.

Below are the key technical specifications for our CNC milling services for steel:

| Parameter | Specification |

|—————————-|————————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 mm × 600 mm × 500 mm |

| Tolerance | ±0.005 mm (standard), down to ±0.002 mm (tight) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.4 µm (polished) |

| Material Options – Steel | Stainless (303/304/316), Tool Steel (D2/A2/O1), Carbon Steel (1018/1045) |

| Lead Time | 3–7 days (prototypes), 7–12 days (production) |

| Secondary Operations | Deburring, anodizing, plating, heat treatment, passivation |

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients from the initial design phase through final production. Our DFM (Design for Manufacturability) analysis helps optimize your part for cost-efficiency and performance, minimizing material waste and machining time without compromising strength or accuracy.

Whether you’re producing a single prototype or scaling up to low-volume production, Honyo Prototype offers scalable solutions with full traceability and documentation. Our ISO 9001-certified processes ensure every steel component is manufactured to the highest quality standards.

Ready to bring your steel CNC milled part to life?

Contact Susan Leo today to discuss your project requirements. With expert guidance and responsive support, we’ll help you select the right materials, finishes, and machining strategies for optimal results.

Email: info@hy-proto.com

Contact Person: Susan Leo

Company: Shenzhen Honyo Prototype

Let’s turn your design into a precision-engineered reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.