Contents

Manufacturing Insight: Cnc Milling Aluminum

Manufacturing Insight: Precision CNC Milling of Aluminum for Rapid Prototyping

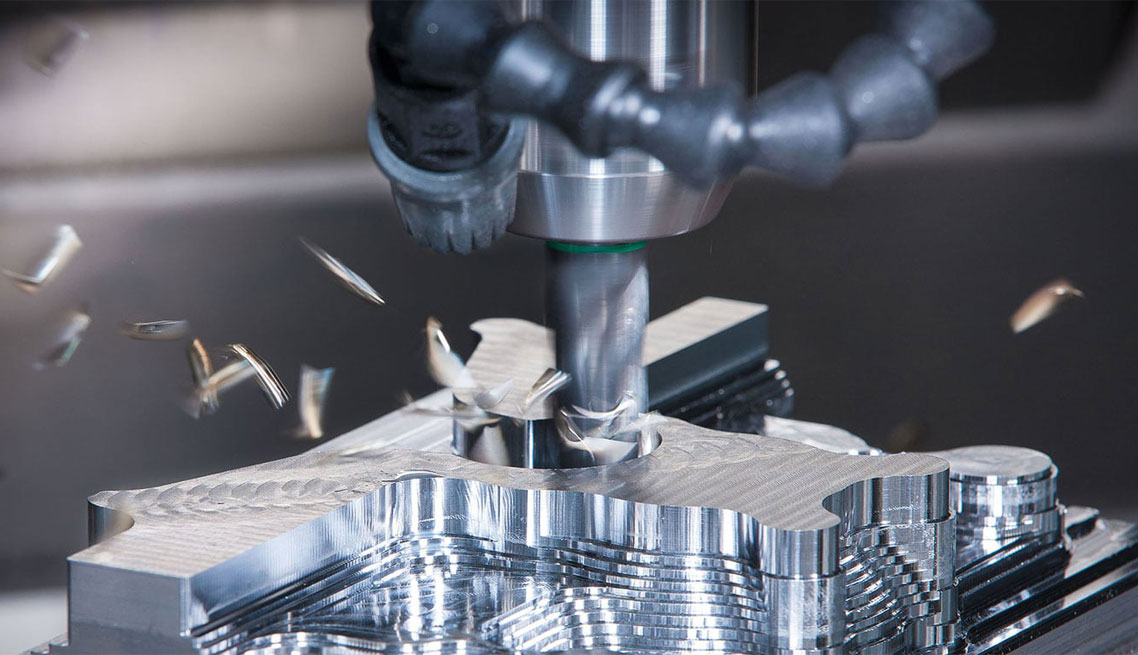

Aluminum remains the dominant material choice for functional prototypes and low-volume production due to its exceptional strength-to-weight ratio, thermal conductivity, and machinability. At Shenzhen Honyo Prototype, we leverage advanced CNC milling technology to transform aluminum billets into high-integrity components with tight tolerances and superior surface finishes. Our process addresses critical challenges inherent in aluminum machining—including chip evacuation, thermal deformation, and work hardening—through optimized toolpaths, specialized tooling, and stringent environmental controls. This ensures dimensional stability and repeatability, even for complex geometries requiring multi-axis operations.

Honyo’s manufacturing ecosystem integrates 3-, 4-, and 5-axis milling centers with automated tool changers and high-precision probing systems. Our engineers prioritize material-specific strategies: using sharp, polished carbide cutters with high helix angles to minimize built-up edge, applying through-spindle coolant for thermal management, and implementing adaptive clearing cycles to reduce cycle times by up to 25% compared to conventional roughing. All operations occur in climate-controlled facilities (±1°C stability) to eliminate thermal drift, a critical factor for achieving micron-level accuracy in aluminum.

Below are key technical capabilities for aluminum CNC milling at Honyo Prototype:

| Parameter | Typical Capability | High-Precision Capability |

|————————–|————————–|—————————|

| Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Finish (Ra) | 1.6 μm | 0.8 μm |

| Max. Work Envelope | 1000 x 600 x 500 mm | 600 x 400 x 300 mm |

| Lead Time (Prototype) | 3–5 working days | 5–7 working days |

| Supported Aluminum Alloys| 6061, 7075, 2024, 5052 | 6061-T6, 7075-T6, ADC12 |

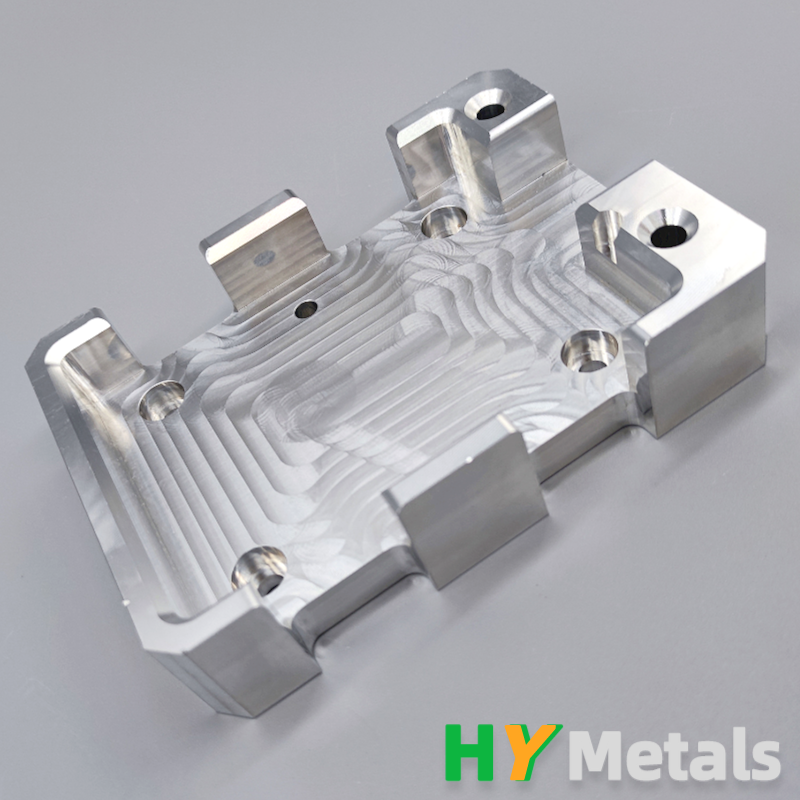

Our expertise spans aerospace brackets, medical housings, and automotive thermal management components, where material integrity directly impacts performance validation. For instance, we routinely machine thin-walled aluminum enclosures (0.5 mm walls) with flatness tolerances of 0.02 mm using vacuum-assisted workholding to prevent deflection. Post-machining, in-house coordinate measuring machines (CMM) validate critical features against GD&T callouts, with full inspection reports provided.

Honyo Prototype’s Shenzhen-based facility capitalizes on regional supply chain agility while maintaining ISO 9001-certified quality systems. We collaborate with clients during DFM analysis to optimize part geometry for machinability—recommending draft angles, uniform wall thicknesses, and strategic feature consolidation to minimize setups and reduce costs. By combining technical rigor with responsive manufacturing, we deliver aluminum prototypes that accurately simulate end-part performance, accelerating time-to-test for engineering teams worldwide. Partner with us to transform your aluminum component designs into precision-engineered realities.

Technical Capabilities

Shenzhen Honyo Prototype specializes in high-precision CNC milling of aluminum components, serving industries that demand reliability, repeatability, and strict adherence to engineering specifications. Our advanced machining capabilities include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to produce complex geometries with exceptional surface finishes and dimensional accuracy. We focus on low-to-medium volume production and rapid prototyping, ensuring fast turnaround without compromising quality.

Our 5-axis CNC milling centers allow for simultaneous multi-axis movement, reducing setup time and improving part accuracy by minimizing repositioning. This capability is ideal for intricate aluminum components used in aerospace, medical devices, automation, and consumer electronics. The integration of high-speed spindles and rigid tooling systems ensures superior cut quality and tight tolerance control across all part features. For simpler geometries, our 3-axis and 4-axis platforms provide cost-effective and efficient solutions with consistent results.

CNC turning complements our milling services, enabling the production of cylindrical aluminum parts with precise outer and inner diameters, threads, and grooves. Combined with live tooling, our turning centers support mill-turn operations, allowing us to complete complex parts in a single setup.

Tight tolerance machining is a core strength at Honyo Prototype. We routinely hold tolerances down to ±0.005 mm on critical dimensions, supported by in-process inspections and final verification using coordinate measuring machines (CMM) and optical comparators. Our quality management system ensures compliance with ISO 9001 standards, providing traceability and consistency across all production runs.

We work primarily with aerospace-grade and industrial aluminum alloys, selected for their strength-to-weight ratio, machinability, and corrosion resistance. Material certifications are available upon request, and we support both customer-supplied and vendor-sourced materials.

The following table outlines our standard capabilities and achievable tolerances across different machining processes:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|——————————-|———————-|———————-|———————-|———————-|

| Max Work Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 | 700 × 500 × 400 | Ø300 × 500 length |

| Positional Tolerance | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm |

| Feature-to-Feature Tolerance | ±0.015 mm | ±0.012 mm | ±0.008 mm | ±0.015 mm |

| Surface Finish (Ra) | 3.2 – 1.6 μm | 3.2 – 1.6 μm | 1.6 – 0.8 μm | 1.6 – 0.8 μm |

| Typical Lead Time | 5–7 days | 6–8 days | 7–10 days | 5–7 days |

| Common Aluminum Alloys | 6061-T6, 7075-T6, 2024-T3, 5052, 6082-T6, 7050-T7451 |

|——————————-|——————————————————–|

| Secondary Operations | Deburring, Anodizing (Type II & III), Bead Blasting, Laser Marking, Passivation |

At Shenzhen Honyo Prototype, our expertise in CNC milling aluminum is backed by precision equipment, skilled programming using advanced CAM software, and a commitment to engineering excellence. We deliver components that meet the most demanding technical requirements, supporting innovation and performance across high-tech industries.

From CAD to Part: The Process

CNC Milling Aluminum: Production Process Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our CNC milling process for aluminum components is engineered for precision, speed, and reliability, transforming client CAD models into high-quality physical parts through a rigorously defined sequence. This workflow ensures optimal manufacturability and minimizes lead time, critical for prototype and low-volume production demands.

The process initiates with our proprietary AI-powered quoting system. Upon receiving a client’s 3D CAD model (STEP, IGES, or native formats), the AI engine rapidly analyzes geometric complexity, material requirements (primarily 6061-T6 or 7075-T6 aluminum), and specified tolerances. It cross-references this data against our extensive machining center capabilities, tooling library, and real-time shop floor scheduling. Crucially, this stage is not fully automated; our senior manufacturing engineers perform an immediate manual review of the AI assessment. This human oversight validates the feasibility, identifies potential high-risk features the AI might flag conservatively, and ensures the quote accurately reflects the true production effort and timeline, typically providing clients with a detailed quotation within 4-8 business hours.

Following client approval, the Design for Manufacturability (DFM) review becomes paramount. Our engineering team conducts a meticulous analysis focused specifically on aluminum’s properties. We assess wall thicknesses to prevent chatter and deflection, verify hole depths against standard drill capabilities, evaluate internal corner radii for tool access, and scrutinize tolerance callouts against practical milling capabilities. We proactively engage clients to suggest minor, non-functional geometry adjustments – such as adding modest radii to sharp internal corners or relaxing non-critical tolerances – that significantly enhance machinability, reduce cycle time, and lower costs without compromising the part’s function. This collaborative DFM step is essential for avoiding production delays and ensuring first-article success.

Production commences only after DFM sign-off. Programmers generate optimized CNC toolpaths using Mastercam, leveraging high-speed machining (HSM) strategies tailored for aluminum’s machinability. Tool selection prioritizes sharp, polished solid carbide end mills with specialized aluminum coatings (e.g., ZrN) and high helix angles to evacuate chips efficiently and minimize burring. Machining typically occurs on our HAAS VF-2SS or DMG MORI 5-axis vertical machining centers, utilizing flood coolant for thermal control and chip evacuation. Operations progress systematically from roughing (high material removal rates) through semi-finishing to final precision finishing passes. In-process inspections using Renishaw probes verify critical features mid-run, while final First Article Inspection (FAI) reports, including CMM data for GD&T, are provided per client requirements. Our standard lead time from approved DFM to shipped part is 3-5 business days for typical aluminum prototypes.

Key aluminum milling capabilities achievable within this workflow are summarized below:

| Parameter | Typical Capability (Aluminum 6061-T6/7075-T6) | Notes |

| :—————– | :——————————————– | :————————————- |

| Standard Tolerance | ±0.05 mm | Tighter tolerances (±0.0125 mm) achievable with grinding or specialized finishing |

| Surface Finish (Ra)| 1.6 – 3.2 μm | Fine finishes (<0.8 μm Ra) possible with dedicated polishing passes |

| Min. Wall Thickness | 0.8 mm | Dependent on feature height; taller walls require increased thickness |

| Max. Part Size | 500 x 400 x 300 mm (3+2 Axis) | Larger parts accommodated via multi-setup or 5-axis |

| Lead Time | 3-5 Business Days | From DFM approval; excludes shipping |

This integrated AI Quote → DFM → Production workflow, underpinned by experienced engineering judgment and state-of-the-art equipment, ensures Honyo Prototype delivers dimensionally accurate, functionally sound aluminum prototypes and bridge production parts with exceptional speed and reliability.

Start Your Project

Start Your CNC Milling Aluminum Project with Honyo Prototype

When it comes to precision CNC milling of aluminum prototypes and production parts, Shenzhen Honyo Prototype delivers unmatched accuracy, speed, and technical expertise. Whether you’re developing aerospace components, medical devices, or industrial machinery, our advanced 3-axis, 4-axis, and 5-axis CNC milling capabilities ensure your design is manufactured to exact specifications. With strict adherence to GD&T standards, tight tolerances down to ±0.005 mm, and rapid turnaround times, we support engineers and product developers from concept to final part.

Our facility in Shenzhen is equipped with state-of-the-art CNC machines, high-speed spindles, and automated tool changers that handle complex geometries with ease. We specialize in milling a wide range of aluminum alloys, including 6061, 7075, 2024, and 5052, each selected for specific mechanical properties such as strength-to-weight ratio, corrosion resistance, and machinability. From single prototypes to low-volume production runs, our team optimizes every step of the process to reduce lead times and maintain consistency across batches.

At Honyo Prototype, we understand that clear communication and technical collaboration are critical to project success. Our engineering team performs a full design for manufacturability (DFM) review on every submitted file, providing actionable feedback to improve part functionality, reduce costs, and accelerate production. We support STEP, IGES, DWG, DXF, and native CAD formats from all major design platforms.

To ensure material integrity and surface quality, we employ precision cutting tools, optimized coolant systems, and in-process inspection using coordinate measuring machines (CMM). Surface finishes range from standard machined (3.2 μm) to fine polishing (<0.8 μm), with optional post-processing including anodizing, powder coating, bead blasting, and laser engraving.

We invite you to start your next CNC milling project with confidence. Share your design files and requirements with Susan Leo, our dedicated manufacturing engineer, who will guide you through quoting, material selection, and production planning. With responsive communication, competitive pricing, and a commitment to on-time delivery, Honyo Prototype is your trusted partner in precision aluminum machining.

| Specification | Detail |

|—————|——–|

| Material Options | Aluminum 6061, 7075, 2024, 5052 |

| Tolerance | ±0.005 mm standard |

| Axis Capabilities | 3-axis, 4-axis, 5-axis milling |

| Max Work Envelope | 1200 × 600 × 500 mm |

| Surface Finish | 3.2 μm (standard), down to 0.8 μm (precision) |

| Lead Time | As fast as 3–5 days for prototypes |

| File Formats Accepted | STEP, IGES, DWG, DXF, SLDPRT, IPT, CATIA, NX |

Contact Susan Leo today at info@hy-proto.com to submit your design and receive a detailed quote within 4 business hours. Let Honyo Prototype bring your aluminum components to life with precision, reliability, and expert support.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.