Contents

Manufacturing Insight: Cnc Screw Machine

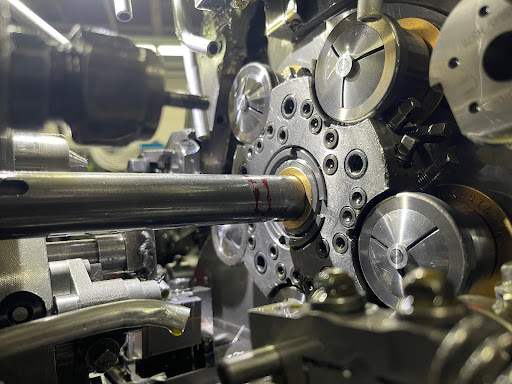

Precision CNC Screw Machine Capabilities at Honyo Prototype

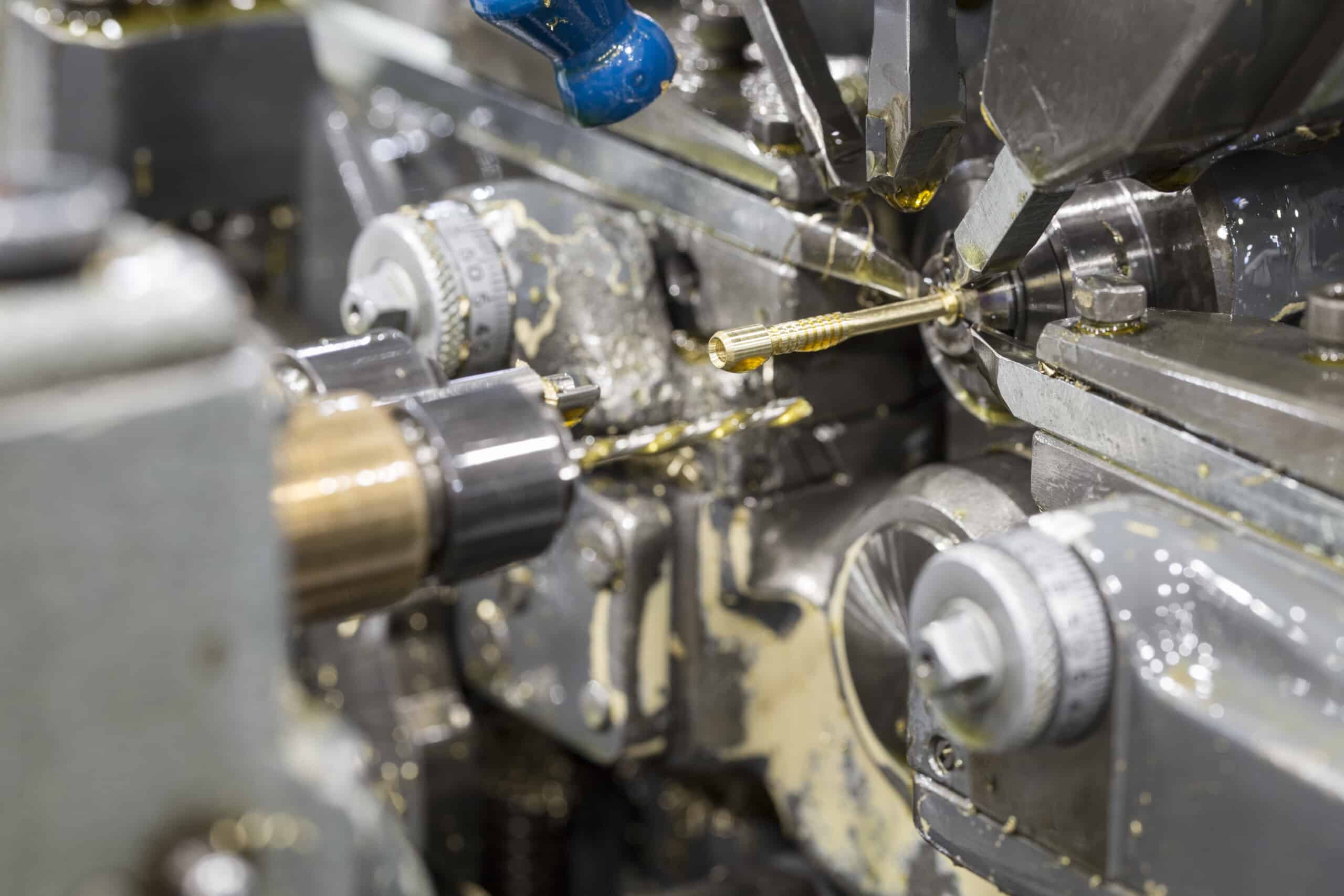

Honyo Prototype delivers industry-leading CNC screw machine services engineered for the exacting demands of high-precision, high-volume component manufacturing. Our advanced Swiss-type CNC lathes and multi-axis turning centers excel in producing complex, small-diameter parts—including screws, pins, bushings, and micro-machined components—with tolerances consistently held to ±0.0002″ (5 microns). Leveraging state-of-the-art Mori Seiki and Tsugami platforms, we machine challenging materials such as stainless steel (303, 316, 17-4 PH), titanium, brass, aluminum, and engineered plastics with exceptional repeatability and surface finish integrity.

Our integrated manufacturing ecosystem supports end-to-end production, from rapid prototyping to full-scale volume runs, with in-house secondary operations including threading, knurling, cross-hole drilling, and precision grinding. This holistic approach eliminates supply chain dependencies while ensuring stringent adherence to AS9100 and ISO 9001 quality standards. For engineering teams requiring accelerated development cycles, Honyo’s Online Instant Quote system provides validated cost and lead time estimates within minutes—directly inputting CAD files and specifications to bypass traditional quotation delays.

Engineers and procurement specialists leverage this digital workflow to de-risk project timelines and optimize budget planning without compromising on the metallurgical or geometric precision essential for aerospace, medical, and industrial applications. Request your instant quote today to experience Honyo’s fusion of precision machining expertise and operational agility.

Technical Capabilities

CNC screw machines are precision manufacturing systems designed for high-volume production of small to medium-sized turned and milled components. While traditionally used for simple bar-fed turning operations, modern CNC screw machines have evolved to incorporate multi-axis milling, turning, and advanced control systems to achieve tight tolerances and complex geometries. These machines are commonly used in industries such as aerospace, medical, and automotive where precision and repeatability are critical.

The following table outlines the key technical specifications relevant to CNC screw machines with capabilities in 3/4/5-axis milling, turning, and tight-tolerance machining across common engineering materials.

| Specification | Detail |

|---|---|

| Machining Axes | Modern CNC screw machines support up to 5-axis simultaneous machining (X, Y, Z linear axes + A and B rotary axes), enabling complex contouring and multi-sided operations without manual re-fixturing. Some models integrate sub-spindles and live tooling for combined turning and milling. |

| Spindle Speed | Up to 12,000 RPM (standard); high-speed models reach 20,000+ RPM for fine finishing and small-tool applications in aluminum and plastics. |

| Bar Capacity | Typically 1/2″ to 2″ (12–50 mm) diameter bar stock, depending on machine size and model. Larger models support extended bar feeding for continuous operation. |

| Positioning Accuracy | ±0.0001″ (±2.5 µm) with high-resolution encoders and thermal compensation systems. |

| Repeatability | ±0.00005″ (±1.3 µm) under stable environmental conditions, essential for tight-tolerance production. |

| Tolerance Range | Capable of holding tolerances as tight as ±0.0002″ (±5 µm) on critical dimensions, especially in diameter, concentricity, and feature location. |

| Feed Rate | Up to 1,500 inches per minute (ipm) on linear axes, supporting both high-speed roughing and fine finishing. |

| Control System | Fanuc, Siemens, or Mitsubishi CNC controls with advanced programming support (G-code, conversational, CAD/CAM integration). |

| Tooling Capacity | 8–24 station tool turrets with optional live tooling for cross-drilling, tapping, and milling operations. |

| Materials Processed | Optimized for aluminum (6061, 7075), steel (1018, 4140, stainless 303/316), engineering plastics (ABS, Nylon 6/66), and brass. Each material requires specific tooling and cutting parameters. |

| Aluminum Machining | High-speed cutting with carbide tools; excellent surface finish and chip evacuation. Typical tolerance: ±0.0002″. |

| Steel Machining | Lower spindle speeds and higher torque; suitable for hardened and stainless steels. Tight tolerances maintained with rigid tooling and coolant-through spindles. |

| ABS & Nylon Machining | Low cutting forces and optimized feed rates to prevent melting or deformation. Coolant or air blast used instead of liquid coolant. Dimensional stability monitored due to material hygroscopy. |

| Coolant System | Through-spindle coolant (up to 1,000 psi) for chip control and tool life; optional mist or air cooling for plastics. |

| Automation Compatibility | Designed for integration with bar feeders, gantry loaders, and robotic part handling for lights-out manufacturing. |

These specifications reflect the advanced capabilities of modern CNC screw machines in producing high-precision, complex components from a wide range of materials while maintaining tight dimensional control and surface quality.

From CAD to Part: The Process

Honyo Prototype CNC Screw Machine Process Overview

Honyo Prototype utilizes a streamlined, technology-driven workflow for CNC screw machine (Swiss-type lathe) production, designed to accelerate prototyping and low-volume manufacturing while ensuring precision and cost efficiency. Our process eliminates traditional bottlenecks through integrated digital tools and engineering expertise.

Upload CAD

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure customer portal. The system validates file integrity and geometric complexity, automatically categorizing the part for Swiss-type machining suitability. This step includes metadata capture for material specifications, tolerances, and surface finish requirements, ensuring all critical parameters are preserved for downstream processing.

AI-Powered Quoting

Uploaded CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, feature density, and dimensional tolerances against our Swiss machine capabilities. The system cross-references real-time material costs, machine availability, and labor rates to generate a detailed quote within 2 business hours. Quotes include machine time estimates, material utilization metrics, and a preliminary risk assessment for challenging features. Clients receive transparent cost breakdowns with options for material substitutions or tolerance adjustments to optimize value.

Engineering-Validated DFM

Following quote acceptance, Honyo’s manufacturing engineers perform a rigorous Design for Manufacturability (DFM) review. While the AI system flags initial concerns (e.g., non-standard thread pitches, thin-wall instability, or undercut limitations), our engineers apply domain-specific knowledge to refine the process. Key DFM actions include:

Optimizing part orientation to minimize secondary operations

Recommending tolerance relaxations for non-critical features

Validating chip control strategies for exotic alloys

Simulating toolpath collisions using CAM software

A formal DFM report with actionable recommendations is shared within 24 hours, requiring client sign-off before production. This phase typically reduces lead times by 15–30% by resolving manufacturability issues upfront.

Precision Production

Approved designs move to our CNC Swiss screw machine fleet, featuring multi-axis Tsugami and Tornos platforms with live tooling and sub-spindles. Production adheres to the following protocol:

| Parameter | Specification | Control Method |

|---|---|---|

| Material | Stainless steel, brass, titanium, alloys | Certified mill certs + in-house PMI |

| Tolerances | ±0.0002″ (5µm) on critical features | In-process CMM verification |

| Surface Finish | Ra 0.8µm standard; Ra 0.4µm achievable | Profilometer validation |

| Lot Traceability | Full serial-numbered part tracking | Barcoded work orders |

Each run includes first-article inspection (FAI) per AS9102 standards, with real-time SPC monitoring of critical dimensions. Complex geometries leverage our Y-axis milling capabilities for integrated milling/drilling operations, eliminating secondary setups.

Guaranteed Delivery

Completed parts undergo final cleaning, deburring, and 100% functional inspection against client specifications. All deliverables include:

Dimensional inspection reports (PDF/Excel)

Material certification documentation

Packaging compliant with ESD-sensitive or medical requirements

Standard lead time is 5–7 business days from DFM approval, with expedited 72-hour options for urgent prototypes. Parts ship globally via DHL/FedEx with real-time tracking, and our logistics team provides proactive delivery notifications. Honyo maintains a 99.2% on-time delivery rate for CNC screw machine projects, backed by our process-locked quality management system (ISO 9001:2015 certified).

This integrated workflow ensures clients receive production-ready precision components with minimal iteration, leveraging automation for speed while retaining engineering oversight for uncompromised quality.

Start Your Project

Looking for precision CNC screw machine services? Contact Susan Leo at info@hy-proto.com to discuss your project requirements. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers high-accuracy components for demanding applications.

Our factory is located in Shenzhen, a leading hub for precision machining, enabling fast turnaround and efficient production for both prototypes and volume orders.

Let’s connect to explore how we can support your manufacturing needs. Reach out today via email for a quick response and competitive pricing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.