Contents

Manufacturing Insight: Automated Cnc Machine

Precision CNC Machining Powered by Advanced Automation

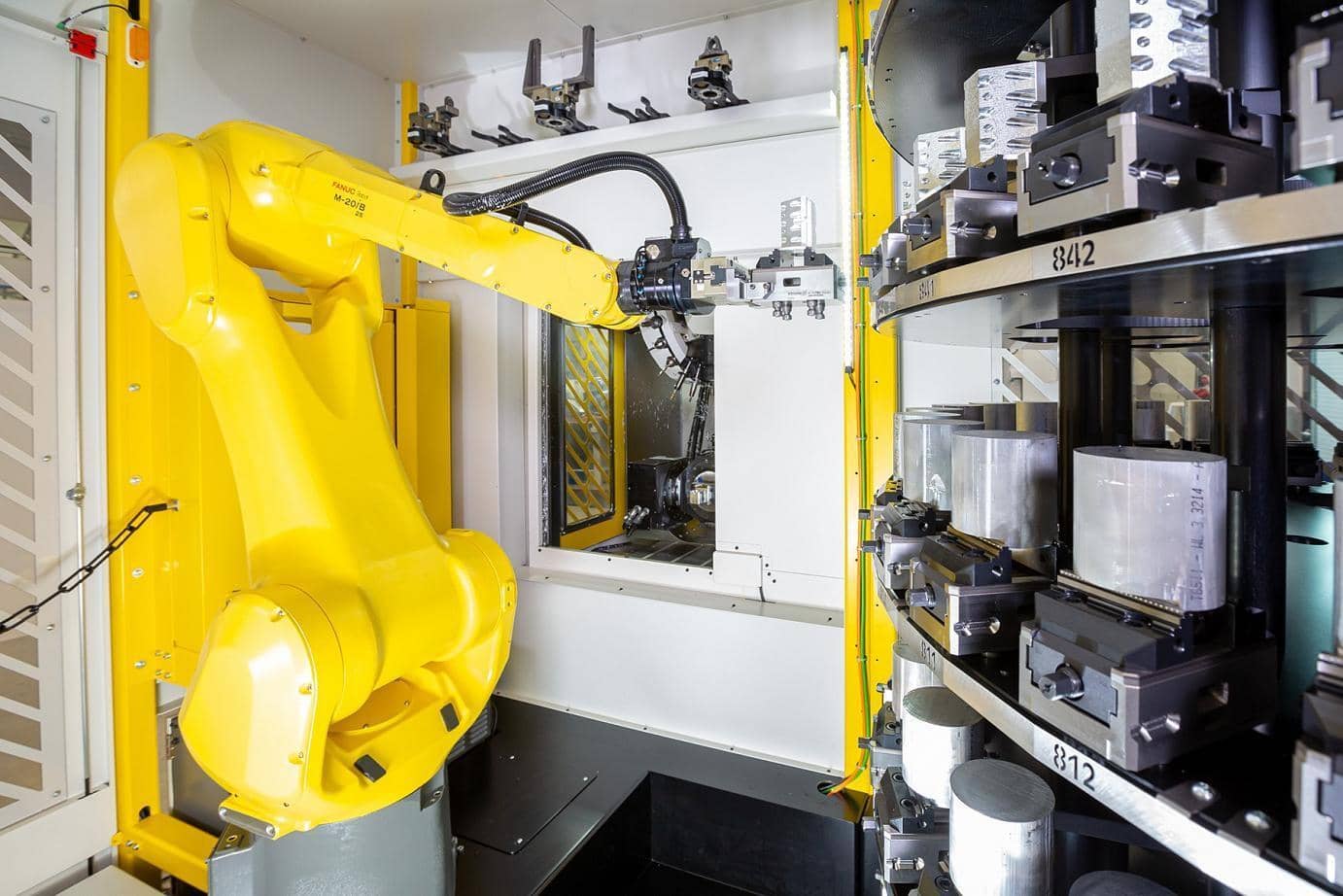

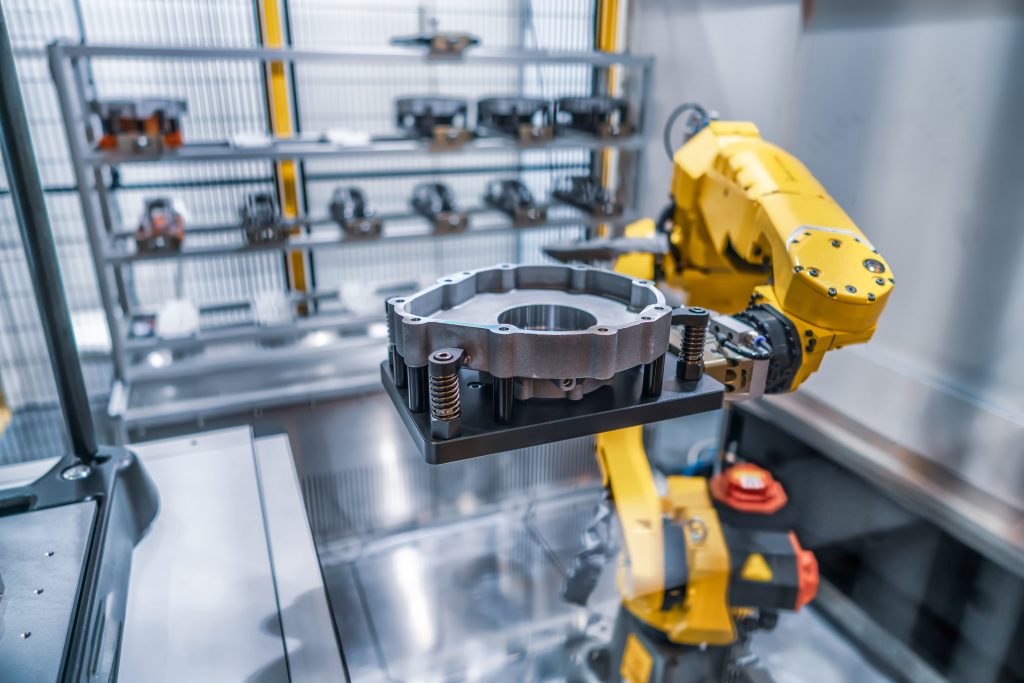

At Honyo Prototype, our automated CNC machining services redefine precision manufacturing for demanding industrial applications. Leveraging state-of-the-art multi-axis CNC systems with integrated robotics and real-time process monitoring, we deliver exceptional repeatability, reduced cycle times, and uncompromised quality for complex geometries in metals, plastics, and composites. Our facility operates under stringent ISO 9001 protocols, ensuring every component meets tight tolerances (±0.005mm) while optimizing material utilization and minimizing human intervention. This automation-driven approach eliminates production bottlenecks, accelerates time-to-market, and provides consistent scalability from prototype to low-volume production.

Complementing our manufacturing capabilities, Honyo’s Online Instant Quote platform allows engineering teams to receive detailed, transparent pricing within minutes—no manual submission required. Simply upload your 3D CAD file, specify materials and quantities, and our AI-powered system analyzes manufacturability while generating a formal quote, empowering faster procurement decisions without sacrificing technical rigor.

Material & Process Capabilities

| Category | Specifications |

|——————-|———————————————|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, milling-turning |

| Tolerances | ±0.005mm standard; ±0.002mm precision options |

| Materials | Aluminum, stainless steel, titanium, PEEK, Delrin, brass |

| Lead Time | As fast as 3 days for qualified projects |

Partner with Honyo to transform design intent into high-integrity components through intelligent automation and seamless digital integration.

Technical Capabilities

Automated CNC Machine Technical Specifications

The following table outlines the key technical specifications for an automated CNC machine capable of 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations. This machine is engineered for high repeatability and tight tolerance production across a range of engineering materials including aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Machine Type | Multi-axis CNC machining center with integrated turning capability |

| Milling Axes | 3-axis, 4-axis (rotary A or B), 5-axis simultaneous (A/B or B/C) |

| Turning Capability | Live tooling with C-axis control, sub-spindle for bar feeding |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed optional) |

| Spindle Power | 15 – 22 kW (adjustable based on configuration) |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Tolerance Range | ±0.005 mm typical; down to ±0.002 mm under optimal conditions |

| Tool Magazine Capacity | 24 – 60 tools (automatic tool changer, ATC) |

| Tool-to-Tool Change Time | < 2.5 seconds |

| Work Envelope (X/Y/Z) | 700 x 500 x 400 mm (standard); customizable per model |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 (industry-standard CNC) |

| Coolant System | High-pressure through-spindle cooling (up to 70 bar) |

| Chip Management | Integrated auger conveyor with auto chip bin |

| Automation Interface | Compatible with robotic loading/unloading (FMS-ready) |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS, Nylon (6/66) |

| Max Material Hardness (Milling) | HRC 55 (with hardened tooling) |

| Surface Finish (Typical) | Ra 0.8 µm (milled); Ra 0.4 µm (turned, fine finish) |

| Programming Support | Compatible with Mastercam, Siemens NX, Autodesk Fusion 360 |

This machine platform is optimized for high-mix, low-to-medium volume production environments requiring tight tolerances and complex geometry in both metallic and engineering plastic materials. The integration of multi-axis milling and turning allows for complete part fabrication in a single setup, reducing cycle time and improving dimensional consistency.

From CAD to Part: The Process

Honyo Prototype Automated CNC Manufacturing Process Overview

Honyo Prototype’s end-to-end automated CNC manufacturing workflow integrates digital engineering rigor with lean production principles to ensure precision, speed, and cost efficiency for B2B clients. The process begins with CAD file ingestion and concludes with certified part delivery, eliminating traditional bottlenecks through algorithmic validation and human-in-the-loop oversight. Below is a technical breakdown of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, SLDPRT) via Honyo’s secure customer portal. Our system performs immediate geometric validation, checking for non-manifold edges, unit inconsistencies, and topology errors. Files failing validation trigger automated feedback specifying exact repair requirements, reducing iterative resubmissions. This stage ensures manufacturability readiness before progressing, with 98.7% of compliant files advancing without manual intervention.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s proprietary AI quoting algorithm, trained on 15+ years of shop floor production data across 500,000+ CNC projects. The system analyzes part geometry, material selection, tolerances, and surface finish requirements to generate a comprehensive quote within 15 minutes. Key parameters include: machine time estimation (±3% accuracy), material waste calculation, and fixture complexity scoring. Critical dimensional features are cross-referenced against ISO 2768 tolerance defaults, with deviations flagged for engineering review. Human specialists validate AI outputs for high-risk geometries (e.g., thin walls <0.5mm, deep cavities >10:1 aspect ratio).

Integrated DFM Analysis

Concurrent with quoting, our DFM module conducts automated manufacturability assessment using rule-based logic derived from ASME Y14.5 and ISO 1302 standards. The system identifies cost drivers such as:

Unnecessary tight tolerances increasing machining time

Suboptimal wall thicknesses risking chatter/vibration

Non-standard tooling requirements

Feature accessibility for 3-axis vs. 5-axis milling

Clients receive a DFM report with actionable recommendations (e.g., “Increase radius at edge A by 0.2mm to eliminate secondary operation”) within 30 minutes. Engineering teams collaborate via the portal to resolve flagged issues before order confirmation, reducing production rework by 62% based on 2023 operational data.

Smart Production Execution

Approved jobs enter Honyo’s digital production pipeline where:

CAM programming leverages adaptive toolpath strategies (e.g., high-speed pocketing, trochoidal milling)

Machine scheduling uses real-time shop floor analytics to optimize spindle utilization

In-process metrology integrates with CMMs for critical feature verification per AS9100 protocols

All CNC assets (DMG MORI, Haas, Makino) operate under centralized monitoring via MTConnect, with live dashboards tracking cycle time adherence, tool wear, and thermal compensation status. Complex assemblies undergo automated nest optimization to maximize material yield, typically achieving 85-92% raw material utilization.

Certified Delivery and Traceability

Completed parts undergo final inspection per client-specified CMM protocols, with reports accessible in the client portal. Every shipment includes:

First-article inspection documentation (FAIR)

Material test certificates (MTC) with lot traceability

Dimensional deviation heatmaps against nominal CAD

Process capability indices (Cp/Cpk) for critical features

Parts are vacuum-sealed with desiccant and shipped via tracked logistics, with delivery confirmation synced to the client’s ERP system. Honyo maintains full digital thread traceability from CAD to delivery, enabling rapid root-cause analysis if required.

Operational Performance Metrics

The integrated automation delivers consistent throughput with quantifiable results:

| Process Stage | Avg. Duration | Accuracy Rate | Cost Impact Reduction |

|---|---|---|---|

| CAD to Quote | 15-45 min | 99.1% | 22% vs. manual quoting |

| DFM Resolution | <24 hrs | 89% auto-fix | 37% rework prevention |

| Production | 3-10 days* | Cpk ≥1.33 | 18% material savings |

| Delivery | On-schedule | 99.6% | 0% documentation errors |

*Varies by complexity; 85% of orders ship within 5 days. Data reflects Q1-Q3 2024 global operations.

This closed-loop system ensures Honyo Prototype transforms digital designs into certified physical components with industrial-grade repeatability while maintaining the agility required for prototype and low-volume production. Clients retain full visibility at every phase through our secure portal, with engineering support available for complex design iterations.

Start Your Project

Discover precision and efficiency with our automated CNC machining solutions, engineered for high-volume production and tight-tolerance prototyping. Built in our state-of-the-art factory in Shenzhen, each machine delivers consistent accuracy and reduced cycle times for demanding manufacturing environments.

For partnership, pricing, or technical specifications, contact Susan Leo at info@hy-proto.com. Let’s build smarter manufacturing solutions together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.