Contents

Manufacturing Insight: Lost Wax Casting Molds

Precision Lost Wax Casting Molds: Accelerated Through Honyo’s Integrated Rapid Tooling & Molding

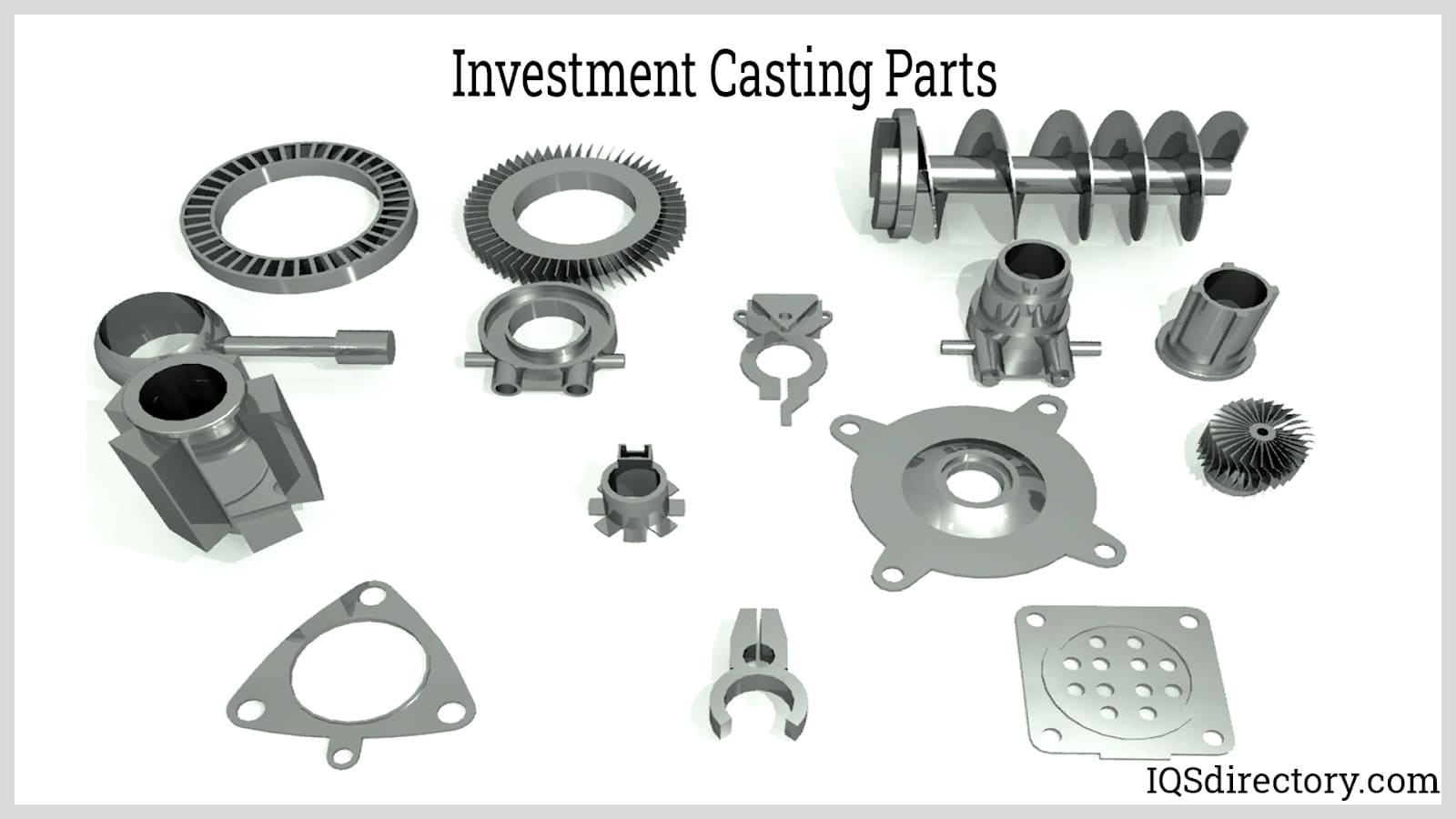

Lost wax casting, or investment casting, remains the definitive manufacturing process for producing complex, high-integrity metal components with exceptional surface finish and dimensional accuracy. Achieving optimal results, however, hinges critically on the precision and consistency of the wax pattern injection molding stage. Traditional approaches to creating the injection molds for these patterns often introduce significant lead times and cost barriers, particularly during the prototyping and low-to-mid volume production phases essential for product validation and market entry.

Honyo Prototype directly addresses these challenges by integrating advanced Rapid Tooling with high-precision Injection Molding specifically engineered for lost wax casting applications. We utilize state-of-the-art CNC machining and selective laser sintering (SLS) to fabricate robust, temperature-stable aluminum or steel injection molds for wax patterns in days, not weeks. This rapid mold fabrication capability, combined with our controlled injection molding processes using certified casting waxes, ensures pattern dimensional fidelity, repeatability, and surface quality that directly translate to superior final castings. Our engineering team collaborates closely with clients to optimize pattern geometry and gating for the casting process, minimizing iterations and accelerating the path from CAD model to validated metal part.

The efficiency of Honyo’s approach is demonstrated in the significant reduction of time and cost compared to conventional mold manufacturing methods. The table below illustrates the typical improvement:

| Process Phase | Traditional Approach | Honyo Prototype Rapid Tooling |

|---|---|---|

| Mold Design & Fabrication | 4-8+ Weeks | 5-10 Business Days |

| Initial Pattern Run | High Unit Cost | Reduced Unit Cost |

| Time to First Casting | 6-12+ Weeks | As Fast as 2 Weeks |

This integrated service eliminates the traditional bottleneck, enabling seamless transition from design validation through pilot production. To further streamline your project initiation, Honyo Prototype offers an Online Instant Quote system. Simply upload your CAD file for the wax pattern or final casting component, and receive a detailed, transparent cost and lead time estimate for both the rapid tooling and injection molding services within minutes, empowering faster decision-making and project acceleration.

Technical Capabilities

Lost wax casting molds, also known as investment casting molds, are precision tooling systems used to produce complex metal components through a process involving wax pattern replication, ceramic shell formation, dewaxing, and metal pouring. The mold itself—commonly referred to as a die or pattern die—is used to create wax or polymer patterns that replicate the final part geometry.

For rapid prototyping and T1 sample delivery within 7 days, mold material selection is critical to balance cycle life, thermal conductivity, dimensional accuracy, and lead time. Below are the technical specifications for molds used in lost wax casting, with a focus on aluminum and steel molds, while also referencing common pattern materials such as ABS and nylon.

| Parameter | Aluminum Molds (e.g., 6061-T6) | Steel Molds (e.g., H13, 420 SS) | ABS Patterns | Nylon (PA6/PA12) Patterns |

|---|---|---|---|---|

| Material Type | Aerospace-grade aluminum alloy | Tool steel or stainless steel | Thermoplastic (FDM/SLA) | Engineering thermoplastic (SLS/SLA) |

| Hardness | 95 HB | 48–52 HRC (H13) / 35–40 HRC (420 SS) | N/A | N/A |

| Thermal Conductivity | 167 W/m·K | 28–30 W/m·K (H13) | 0.19 W/m·K | 0.25 W/m·K |

| Machinability | Excellent – fast CNC machining | Moderate – slower machining, needs heat treatment | High (additive) | High (additive) |

| Tool Life (Cycles) | 1,000 – 5,000 cycles | 10,000 – 100,000+ cycles | Single-use (pattern) | Single-use (pattern) |

| Surface Finish (as machined) | 0.8 – 1.6 µm Ra | 0.4 – 0.8 µm Ra | 25 – 100 µm (as printed) | 20 – 50 µm (SLS) |

| Dimensional Accuracy | ±0.05 mm | ±0.02 mm | ±0.1 mm (SLA) / ±0.2 mm (FDM) | ±0.1 mm (SLS) |

| Lead Time (T1 Mold) | 5–7 days (ideal for fast turnaround) | 10–20 days | 2–3 days (for direct patterns) | 3–5 days |

| Typical Use Case | Prototypes, low-volume production | High-volume, high-precision runs | Rapid wax pattern replacement | Durable patterns for complex shapes |

| Coating / Treatment Options | Hard coat anodizing (optional) | Nitriding, PVD coating, polishing | Paint, sealant | Dyeing, sealing |

| Compatibility with Wax/Resin | Compatible with all injection waxes | Compatible with all injection waxes | Direct pattern – no wax needed | Direct pattern – no wax needed |

Notes on T1 Sample in 7 Days:

To achieve a T1 sample within 7 days using lost wax casting, aluminum molds are typically preferred due to their fast CNC machinability and shorter lead times. These molds can be designed and fabricated within 5–7 days, allowing for first-article wax pattern production and subsequent casting within the target timeline. For even faster iterations, direct 3D-printed patterns in ABS (SLA) or nylon (SLS) can bypass metal mold fabrication entirely, enabling T1 samples in as little as 3–5 days, depending on post-processing and foundry scheduling.

Steel molds, while more durable and dimensionally stable, require longer lead times due to machining complexity and heat treatment, making them less suitable for urgent T1 delivery unless pre-existing tooling is available.

ABS and nylon patterns are commonly used in rapid investment casting (e.g., 3D-printed patterns) for prototyping, eliminating the need for a physical mold in early stages. These polymer patterns are burned out during the shell firing process, just like wax.

For Honyo Prototype’s rapid-turn applications, aluminum tooling combined with automated pattern injection offers the optimal balance of speed, accuracy, and repeatability to meet 7-day T1 sample commitments.

From CAD to Part: The Process

Honyo Prototype delivers precision metal components through an integrated lost wax casting workflow designed for engineering accuracy and manufacturability. Our process begins with client-supplied CAD data and concludes with certified delivery, incorporating rigorous technical validation at each stage. Below is the complete sequence:

CAD Upload and Validation

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure portal. Our engineering team performs immediate geometric validation, checking for watertightness, minimum wall thickness compliance (typically ≥0.6mm for aluminum, ≥0.8mm for steel), and feature feasibility. Non-conforming files trigger automated feedback with specific error locations before proceeding.

AI-Powered Quoting System

Validated CAD data enters our proprietary AI quoting engine, which analyzes 15+ dimensional and topological parameters alongside material selection (e.g., Inconel 718, 316L stainless, aluminum A356). The system cross-references real-time material costs, labor rates, and historical production data to generate a technically grounded quote within 2 business hours. Critical outputs include estimated yield, gating system complexity rating, and preliminary cost drivers.

Engineering-Driven DFM Analysis

Upon quote acceptance, our manufacturing engineers conduct a formal Design for Manufacturing review. This phase addresses:

Thermal stress simulation to optimize gating and risering

Draft angle verification (minimum 1° for ceramic molds)

Shrinkage compensation application based on alloy-specific coefficients

Surface finish feasibility against ASTM B808 standards

Clients receive a DFM report with actionable recommendations, typically resolving 92% of potential defects before mold fabrication begins.

Mold Production and Casting

Approved designs proceed to physical production:

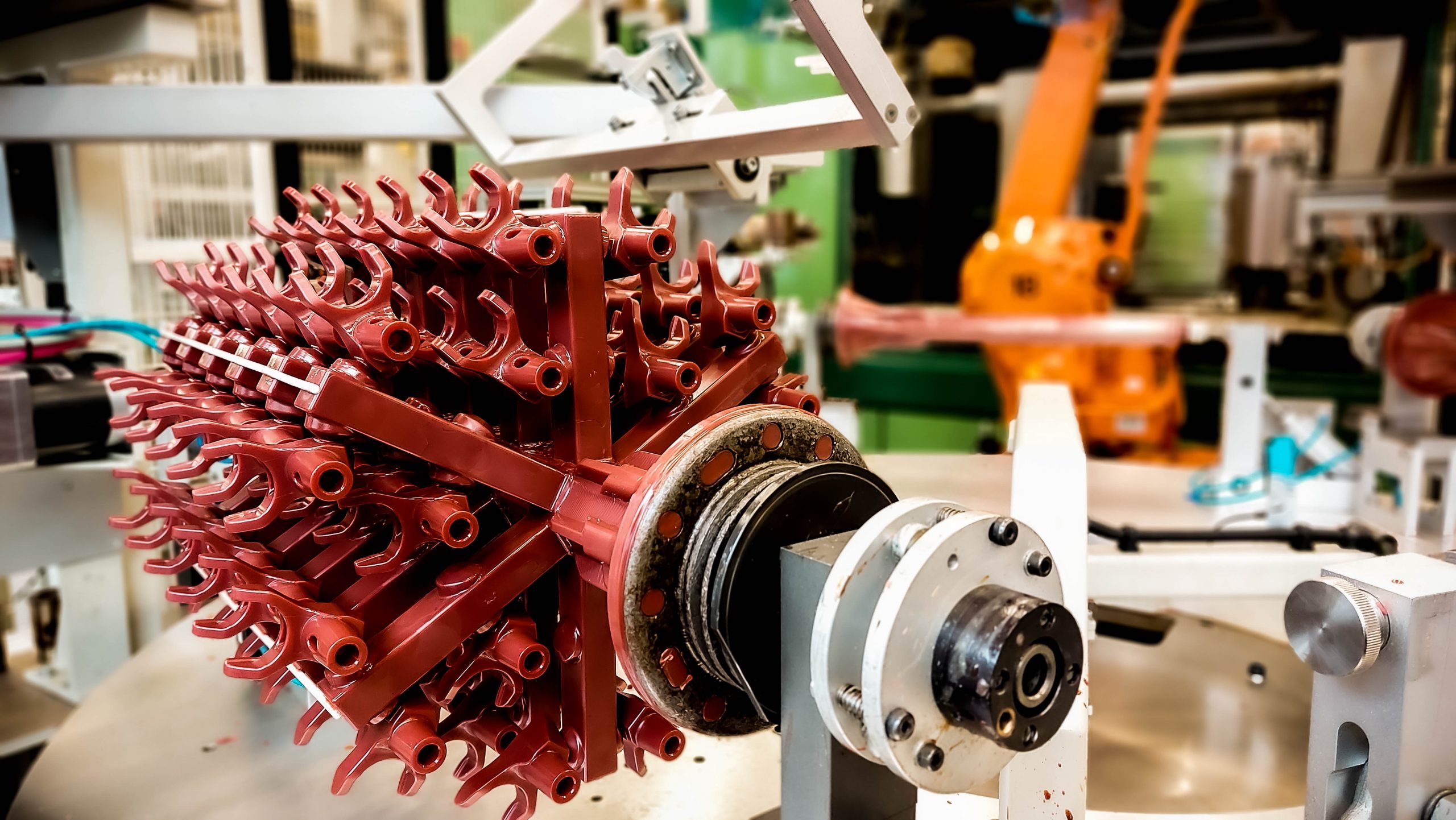

1. Wax Pattern Creation: Injection molding of precision wax patterns using tool steel dies (±0.05mm tolerance)

2. Ceramic Shell Building: Automated slurry dipping and stuccoing (8-12 layers) achieving 2-3mm shell thickness

3. Dewaxing and Firing: Steam autoclave dewaxing followed by 1000°C furnace firing

4. Metal Pouring: Vacuum-assisted or gravity pouring with melt chemistry verification (OES testing)

5. Shell Removal: Controlled hydro-blasting to prevent part damage

Finishing and Quality Control

All castings undergo standardized post-processing:

Gate removal via band sawing or thermal cutoff

Shot peening to 125-250 μin Ra surface finish

Dimensional inspection via CMM (reporting to ISO 2768-mK)

Material certification with traceable heat numbers

Optional NDT (RT/UT/PT) per client specifications

Delivery and Documentation

Final components ship in anti-corrosion packaging with full traceability documentation. Standard lead time from CAD approval is 18-22 business days for first articles. Rush services (12-day) are available for qualified geometries.

Production Timeline Summary

| Process Phase | Typical Duration | Key Outputs |

|—————|——————|————-|

| CAD to Quote | 0.5-2 business days | Validated geometry, cost breakdown |

| DFM Approval | 3-5 business days | Redline drawings, risk assessment |

| Mold Production | 8-10 business days | Ceramic shell molds, wax pattern tree |

| Casting & Finishing | 5-7 business days | Dimensional report, material certs |

| Total (Standard) | 18-22 business days | Shipment-ready components |

This closed-loop methodology ensures first-time quality while accommodating complex geometries up to 300mm in critical dimensions. All processes adhere to AS9100 and ISO 9001 standards, with metallurgical data archived for 10 years per aerospace requirements.

Start Your Project

For high-precision lost wax casting molds, contact Susan Leo at info@hy-proto.com. Our dedicated manufacturing facility in Shenzhen ensures tight tolerances, excellent surface finish, and fast turnaround for both prototypes and production runs.

We specialize in investment casting patterns and ceramic shell molding, supporting industries such as aerospace, medical, and industrial manufacturing.

Reach out today to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.