Contents

Manufacturing Insight: 032 Aluminum Sheet

Precision Aluminum Fabrication for Demanding Applications: Mastering 032 Sheet

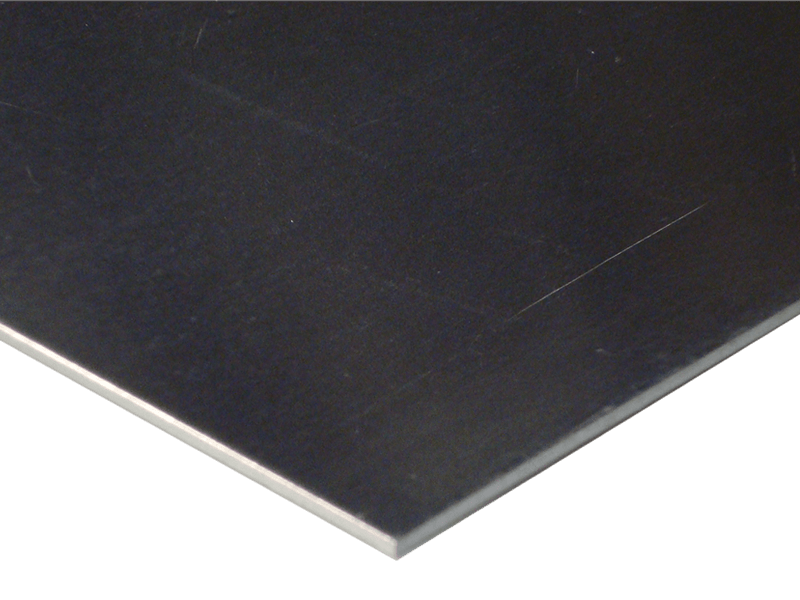

Honyo Prototype delivers exceptional sheet metal fabrication expertise specifically engineered for challenging materials like 0.032 inch (0.8128 mm) aluminum alloy, predominantly utilizing aerospace-grade 6061-T6. This thin-gauge material presents significant precision-forming challenges due to its susceptibility to warping, denting, and maintaining geometric integrity during cutting, bending, and finishing processes. Our advanced manufacturing capabilities, including high-precision CNC turret punching, fiber laser cutting with tight tolerance control (±0.005 inch), and specialized coining techniques, ensure consistent part quality and dimensional accuracy even at this minimal thickness. We excel in producing complex, burr-free components requiring tight bend radii and clean edges, critical for aerospace, medical device, and electronics enclosures where weight savings and structural performance are paramount.

Beyond core fabrication, Honyo provides comprehensive value through integrated secondary operations such as precision deburring, automated weld fixturing, and anodizing preparation – all optimized for the unique properties of thin aluminum. Our engineering team proactively offers Design for Manufacturability (DFM) feedback during the quotation phase to mitigate risks associated with thin-sheet production, ensuring your 032 aluminum components meet stringent functional and aesthetic requirements.

Accelerate your prototyping and low-volume production timelines with Honyo’s Online Instant Quote system. Upload your STEP or DXF file specifying 032 aluminum sheet requirements, and receive a detailed, transparent cost breakdown and lead time estimate within minutes – no forms, no follow-up calls required. This immediate visibility empowers rapid design iteration and procurement decisions while leveraging our specialized thin-gauge fabrication mastery.

Material Capability Reference

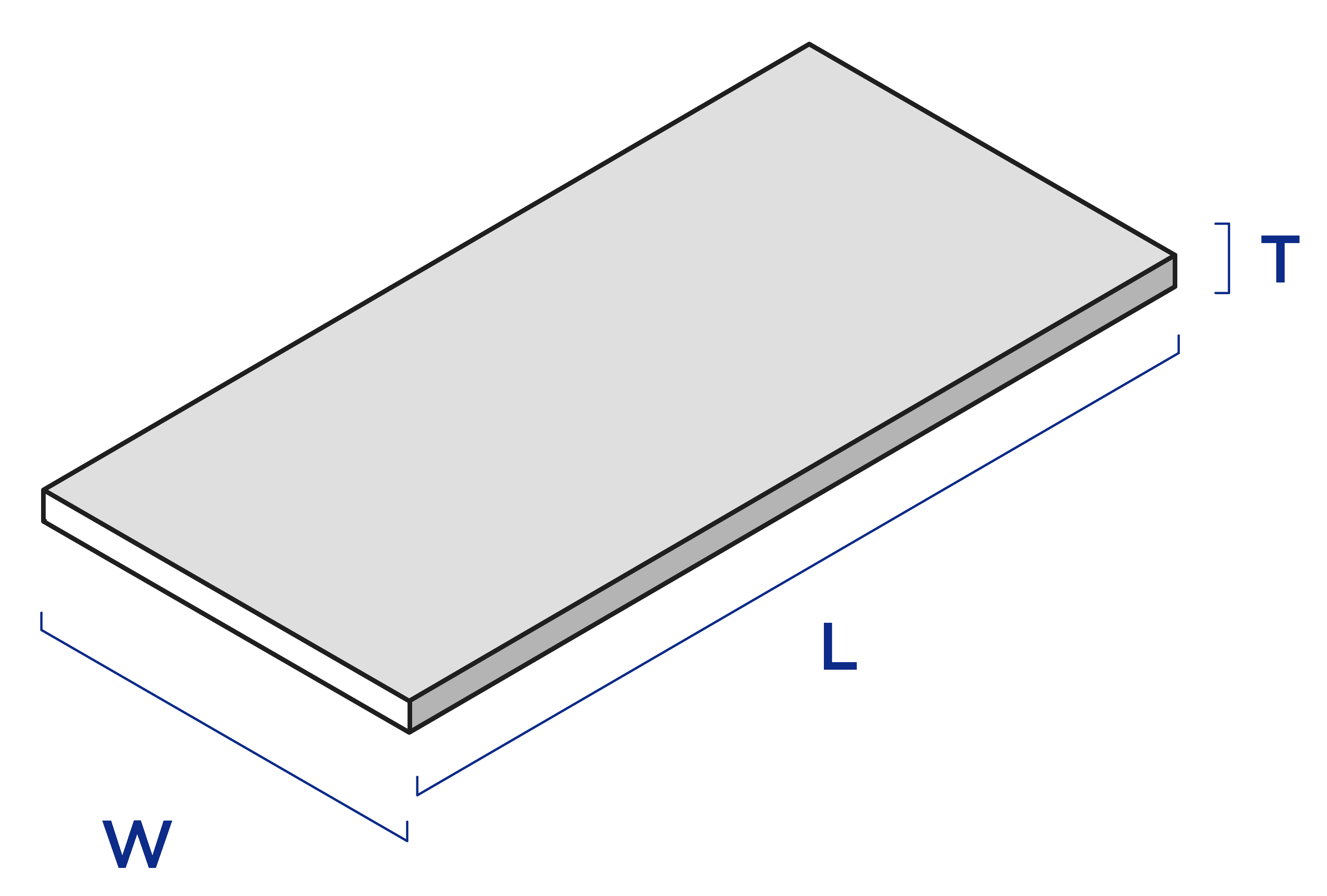

| Parameter | Value for 032 Aluminum Sheet |

|——————–|——————————|

| Typical Alloy | 6061-T6 |

| Thickness | 0.032 inch (0.8128 mm) |

| Laser Cutting Tolerance | ±0.005 inch |

| Minimum Bend Radius | 0.5 x Material Thickness |

| Common Finishes | As-machined, Deburred, Anodize Ready |

Technical Capabilities

The term “032 aluminum sheet” typically refers to an aluminum sheet with a thickness of 0.032 inches (approximately 0.81 mm). This thin gauge is commonly used in lightweight structural applications, enclosures, and prototypes where precision and formability are critical. Below are the technical considerations for laser cutting, bending, and welding of 032 aluminum sheet, with comparative insights for steel, ABS, and nylon of similar thickness.

| Process | 032 Aluminum Sheet (0.032″ / 0.81 mm) | Steel (0.032″) | ABS (0.032″) | Nylon (0.032″) |

|---|---|---|---|---|

| Laser Cutting | Well-suited for fiber or CO₂ lasers. Requires optimized power and speed to prevent melting or dross. Reflective nature demands proper beam delivery. Clean edges with minimal burr. | Easily cut with CO₂ or fiber lasers. Higher absorption than aluminum. May require assist gas (oxygen or nitrogen) for clean cuts. | Compatible with CO₂ lasers. Edges may show slight charring. No melting issues. Good edge quality. | Can be laser cut but prone to melting and poor edge quality. Not recommended; thermal degradation risk. |

| Bending | Requires small V-die in press brake (typically 4–6x material thickness). Springback ~2–5°, depending on alloy (e.g., 5052, 6061). Minimum bend radius ~0.5t for crack avoidance. | Higher springback than aluminum. Needs precise tooling. Minimum bend radius ~0.5t. Higher tonnage required. | Can be bent with heat-assisted forming. Prone to cracking at room temperature. Limited elastic range. | Poor bendability at room temperature. Requires heating. High elongation but low stiffness. |

| Welding | TIG or pulsed laser welding recommended. High thermal conductivity and oxide layer require skilled technique. 4043 or 5356 filler for MIG/TIG. Risk of warping in thin sheets. | Readily MIG/TIG welded. Lower thermal conductivity than aluminum. Requires less specialized technique. Prone to oxidation if not shielded. | Not weldable via traditional methods. Joining via solvent bonding or ultrasonic welding. | Can be joined via hot plate or vibration welding. Not compatible with arc or laser welding. |

Material Notes:

Aluminum 032 sheet is typically available in alloys such as 5052-H32 or 6061-T6, each offering different balances of formability and strength. Steel counterpart would likely be cold-rolled steel (CRS) or galvanized steel. ABS and nylon are engineering thermoplastics used where electrical insulation or corrosion resistance is needed, but they lack the structural rigidity of metals.

For precision fabrication involving laser cutting and bending, aluminum 032 sheet offers an excellent strength-to-weight ratio and good manufacturability, provided appropriate parameters are used. Welding remains challenging due to material thinness and aluminum-specific behaviors.

From CAD to Part: The Process

Honyo Prototype maintains a rigorously defined workflow for manufacturing components from 0.032 inch aluminum sheet, ensuring precision, efficiency, and adherence to material-specific requirements. This process integrates advanced digital tools with expert engineering oversight to address the unique challenges of thin-gauge aluminum fabrication.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) through our secure customer portal. Our system performs immediate validation checks for geometric integrity, unit consistency, and manufacturability flags specific to 0.032 aluminum sheet, such as minimum bend radii (typically 0.064 inch for 5052-H32) and hole-to-edge spacing constraints. Invalid files trigger automated notifications with precise error diagnostics, minimizing submission delays.

AI-Powered Quoting Engine

Validated CAD data feeds our proprietary AI quoting system, which generates instant preliminary cost and lead time estimates within 90 seconds. The algorithm factors in material-specific variables for 0.032 aluminum sheet including:

Raw material yield optimization accounting for standard 48″x96″ sheet sizes

Laser cutting speed adjustments for thin-gauge reflectivity risks

Springback compensation parameters for precision bending

Secondary operation sequencing logic for features like countersinks or PEM inserts

This phase outputs a transparent cost breakdown with material, processing, and handling line items, while highlighting potential cost drivers like tight tolerances below ±0.005 inch.

Engineer-Led DFM Analysis

All quotes undergo mandatory review by our manufacturing engineering team specializing in thin-sheet aluminum fabrication. This DFM stage typically identifies and resolves 15-20% of initial design issues through direct client collaboration. Key focus areas include:

Verifying bend allowance calculations for 0.032″ thickness to prevent cracking

Recommending relief cuts for internal corners to eliminate tear-out

Optimizing nest patterns to minimize scrap (<8% target for aluminum)

Flagging features requiring specialized tooling (e.g., coining for sharp bends)

We provide annotated PDF reports with specific revision suggestions, often reducing component cost by 22% through geometric simplifications while maintaining functional requirements.

Production Execution

Approved designs enter our climate-controlled production cell dedicated to thin aluminum sheets. Critical process controls include:

| Process Stage | Equipment | Key Controls for 0.032 Aluminum |

|---|---|---|

| Cutting | 4kW Fiber Laser | Power modulation (30-40% max) to prevent melt dross; nitrogen assist gas at 220 psi |

| Forming | CNC Press Brakes | Air bending only (no bottoming); 0.090V die width; 0.002″ overbend compensation |

| Finishing | Deburring Stations | Non-marring nylon brushes; 120-grit Scotch-Brite for edge smoothing |

All operators follow work instructions generated from the DFM report, with real-time SPC monitoring of critical dimensions. First-article inspection includes surface roughness verification (Ra ≤ 32 μin) and flatness checks per ASME Y14.5.

Delivery and Documentation

Completed parts undergo final QA against the original CAD model using coordinate measuring machines, with full inspection reports available upon request. Shipments include material certifications traceable to mill test reports (ASTM B209), and packaging designed to prevent scratching during transit—typically VCI paper interleaving within custom foam cavities. Standard lead time for 0.032 aluminum sheet projects is 7-10 business days from DFM sign-off, with expedited options available. We maintain a 99.2% on-time delivery rate for this material grade through our dedicated thin-sheet production lane.

Start Your Project

Looking for high-quality 032 aluminum sheet for your next project? Contact Susan Leo at info@hy-proto.com to request pricing, samples, or technical specifications. With our manufacturing facility located in Shenzhen, we deliver fast turnaround and consistent quality for prototyping and low-volume production. Reach out today to streamline your sourcing process with a trusted partner.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.