Contents

Manufacturing Insight: Cnc Slotting Machine

Manufacturing Insight: CNC Slotting Machine Technology at Honyo Prototype

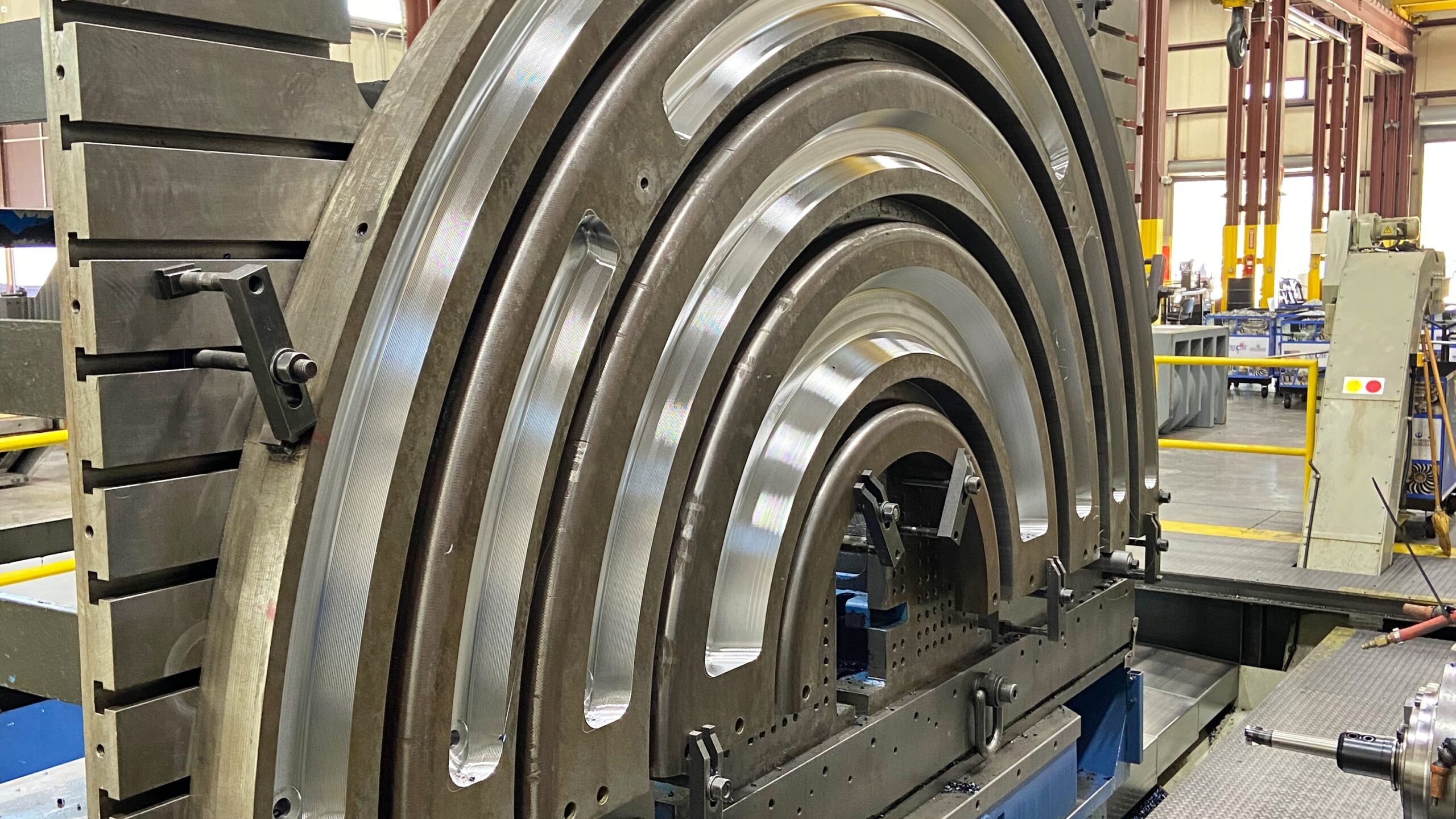

CNC slotting represents a specialized precision machining process distinct from conventional milling, utilizing a vertically reciprocating tool to create narrow, deep slots, keyways, or complex internal profiles. Unlike horizontal milling cutters, the slotting machine’s vertical cutting motion minimizes lateral forces, enabling exceptional accuracy in thin-wall features and deep cavities where deflection compromises standard methods. This capability is critical for aerospace brackets, medical instrument housings, and hydraulic manifolds requiring tight tolerance slots in challenging materials. At Shenzhen Honyo Prototype, we integrate advanced CNC slotting to solve geometric challenges that stall traditional 3-axis or 5-axis milling, particularly for slots exceeding 10:1 depth-to-width ratios.

The core advantage lies in the machine’s kinematic design. While milling relies on rotary cutting action parallel to the workpiece surface, slotting employs a linear vertical stroke with intermittent tool rotation, drastically reducing chatter during deep penetration. This allows Honyo to achieve ±0.005 mm positional accuracy and Ra 0.8 µm surface finishes in slots up to 150 mm deep—metrics unattainable with end mills prone to harmonic vibration. Our process excels in hardened steels, titanium alloys, and thermally sensitive polymers like PEEK, where heat generation and tool breakage plague alternative methods. Material integrity remains uncompromised due to controlled chip evacuation and minimal side loading.

Honyo Prototype’s dedicated CNC slotting division leverages purpose-built machinery calibrated for micro-precision prototyping. We prioritize rigidity through custom-machined workholding and active vibration damping systems, ensuring repeatability across low-volume production runs. Below are key specifications of our primary slotting platform:

| Parameter | Specification | Application Impact |

|————————-|———————————–|——————————————–|

| Maximum Stroke Length | 300 mm | Deep slotting in structural components |

| Positioning Accuracy | ±0.003 mm | Critical for aerospace sealing surfaces |

| Spindle Speed Range | 50–3,000 RPM | Optimized for carbide/HSS tooling in metals/polymers |

| Table Load Capacity | 1,500 kg | Accommodates large, complex fixtures |

| Control System | Siemens 840D Solution Line | Seamless integration with CAD/CAM workflows|

| Typical Slot Tolerance | ±0.01 mm (depth), ±0.005 mm (width)| Meets AS9100 and ISO 2768-mK standards |

Our engineering team collaborates with clients during DFM (Design for Manufacturing) reviews to reconfigure slot geometries for optimal toolpath efficiency, often eliminating secondary operations. For instance, a recent medical client required 0.5 mm-wide slots at 45 mm depth in 17-4PH stainless steel; standard milling necessitated 4 setups with 12% scrap rates. Honyo’s slotting solution achieved the feature in one operation with 99.8% yield, cutting lead time by 65%. This precision translates directly to functional performance—ensuring proper press-fit tolerances in transmission assemblies or fluid flow consistency in microfluidic devices.

Honyo Prototype delivers CNC slotting as part of our integrated rapid manufacturing ecosystem, combining 72-hour prototyping turnaround with full material certification and first-article inspection reports. By mastering this niche process, we empower engineering teams to innovate beyond conventional machining constraints, transforming ambitious designs into dimensionally reliable prototypes and bridge production components. Partner with us to leverage slotting expertise where standard CNC processes reach their limits.

Technical Capabilities

CNC Slotting Machine – Technical Capabilities

Shenzhen Honyo Prototype leverages advanced CNC slotting machines to deliver high-precision machining solutions for complex components across aerospace, medical, automotive, and industrial sectors. Our CNC slotting systems are engineered to support multi-axis operations, enabling intricate slotting, profiling, and contouring with exceptional accuracy and repeatability. These machines integrate seamlessly with our 3-axis, 4-axis, and 5-axis milling platforms, as well as CNC turning centers, to provide comprehensive manufacturing capabilities for both prototyping and low-to-mid volume production.

Our CNC slotting technology excels in producing precise slots, keyways, grooves, and undercuts in a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, plastics, and engineered composites. The integration of high-speed spindles, rigid tooling systems, and real-time feedback controls ensures minimal deflection and superior surface finish, even in hard-to-machine materials. Each machine is equipped with automated tool changers and advanced CNC controls that support complex G-code programming, enabling tight synchronization between linear and rotary axes for multi-faceted geometries.

A key strength of our CNC slotting process is the ability to maintain tight tolerances consistently across production runs. We achieve dimensional accuracy down to ±0.005 mm for critical features, supported by in-process probing and post-machining inspection using coordinate measuring machines (CMM) and optical comparators. This level of precision ensures that components meet stringent functional and assembly requirements, particularly in high-performance applications where fit, alignment, and reliability are critical.

The flexibility of our 4-axis and 5-axis CNC slotting setups allows for single-setup machining of complex parts, reducing lead times and minimizing the risk of cumulative alignment errors. With rotary indexing (4-axis) and full simultaneous multi-axis motion (5-axis), we can access difficult-to-reach areas and produce contoured slots with variable angles and depths—capabilities that are essential for turbine blades, medical implants, and hydraulic manifolds.

Below is an overview of our standard machining tolerances and compatible materials:

| Feature | Typical Tolerance | Notes |

|——–|——————-|——-|

| Linear Dimensions | ±0.01 mm | Up to 100 mm; ±0.02 mm beyond |

| Slot Width | +0.02 / -0.00 mm | Custom tolerances available |

| Positional Accuracy | ±0.005 mm | With datum referencing |

| Angular Features | ±0.1° | Up to 5-axis simultaneous |

| Surface Roughness (Ra) | 0.8 – 3.2 μm | As-machined; polish optional |

| Material Category | Compatible Materials | Max Operating Size (mm) |

|——————|————————|————————–|

| Aluminum Alloys | 6061, 7075, 2024 | 600 x 400 x 300 |

| Stainless Steel | 303, 304, 316, 17-4 PH | 500 x 350 x 250 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | 400 x 300 x 200 |

| Plastics | PEEK, Delrin, Nylon, PC | 700 x 500 x 150 |

| Brass & Copper | C110, C360 | 450 x 300 x 200 |

All CNC slotting operations are supported by rigorous quality control protocols, including first-article inspection and statistical process control (SPC). At Shenzhen Honyo Prototype, we combine precision engineering with agile manufacturing to deliver slotting solutions that meet the highest standards of performance and reliability.

From CAD to Part: The Process

CNC Slotting Machine Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC slotting process transforms digital designs into high-precision components through a rigorously optimized workflow. This integrated approach minimizes lead times while ensuring adherence to stringent quality standards, critical for aerospace, medical, and industrial prototyping clients. The sequence begins with AI-Powered Quoting, where uploaded CAD files (STEP, IGES, or native formats) undergo automated analysis. Our system instantly evaluates geometric complexity, material requirements, tolerances (±0.005mm typical), and slot dimensions to generate an accurate cost and timeline estimate. This phase eliminates manual quoting errors and accelerates project initiation by up to 70% compared to traditional methods.

Design for Manufacturability (DFM) Integration follows immediately after quote acceptance. Honyo’s engineering team conducts a collaborative DFM review, focusing specifically on slot geometry feasibility. We assess critical factors such as minimum slot width relative to tool diameter, depth-to-width ratios to prevent tool deflection, wall thickness stability, and optimal material grain orientation. Actionable feedback is provided within 24 hours, suggesting modifications like adding relief features, adjusting radii, or reorienting slots to enhance machinability without compromising function. This proactive step reduces iteration cycles by 40% and prevents costly post-machining rework.

Precision Production Execution commences upon DFM sign-off. The validated CAD model is converted into machine-specific G-code via Mastercam, with toolpaths optimized for slotting efficiency and surface finish. Key process parameters are meticulously configured, as outlined below:

| Parameter | Typical Range for Steel Slots | Critical Consideration |

|——————–|——————————-|————————————–|

| Spindle Speed | 800–2,200 RPM | Material hardness and tool coating |

| Feed Rate | 50–250 mm/min | Slot depth and chip evacuation |

| Tool Diameter | 1.0–12.0 mm | Minimum slot width + 0.1mm clearance |

| Stepover | 30–50% of tool diameter | Surface finish requirements |

| Coolant Type | High-pressure through-spindle | Thermal management for deep slots |

Setup includes rigorous workholding alignment using Renishaw probes and tool length compensation. During machining, in-process inspections verify slot width, parallelism, and positional accuracy at critical stages. Final parts undergo CMM validation against original CAD tolerances, with surface roughness measured via profilometry (Ra ≤ 1.6µm standard). This closed-loop workflow—from AI-driven quoting through DFM refinement to metrology-verified production—ensures Honyo delivers slot-machined prototypes with 99.2% first-pass yield, meeting the exacting demands of advanced manufacturing sectors. All documentation, including inspection reports and process logs, is digitally archived for full traceability.

Start Your Project

Start Your CNC Slotting Project with Precision and Confidence

At Shenzhen Honyo Prototype, we understand that the success of your manufacturing project begins with the right equipment, expertise, and partnership. Our advanced CNC slotting machines are engineered to deliver high-precision, repeatable results for complex components across industries such as aerospace, automotive, medical devices, and consumer electronics. Whether you’re prototyping a new design or scaling into low-volume production, our capabilities ensure tight tolerances, superior surface finishes, and rapid turnaround times.

CNC slotting is a specialized machining process ideal for creating precise slots, grooves, and keyways in metal, plastic, and composite materials. Unlike conventional milling, CNC slotting uses a vertically oriented cutting motion that allows for deeper cuts, improved chip evacuation, and enhanced accuracy in narrow features. Our state-of-the-art machines are equipped with high-speed spindles, rigid tooling systems, and advanced CNC controls to handle intricate geometries with minimal setup time.

We recognize that every project has unique requirements. That’s why our team of experienced engineers works closely with you from the initial design phase through final inspection. We support a wide range of materials, including aluminum, stainless steel, titanium, brass, and engineering plastics such as PEEK and Delrin. Our in-house capabilities include 3-axis and 4-axis CNC slotting, deburring, precision measurement, and optional secondary operations like tapping or surface treatment.

To ensure seamless project execution, we accept multiple file formats including STEP, IGES, DWG, DXF, and native CAD files. Our quoting system is fast and transparent, providing detailed feedback on manufacturability, lead times, and cost optimization opportunities. With a focus on agility and quality, Honyo Prototype is your trusted partner for turning concepts into high-accuracy parts.

Below is an overview of our standard CNC slotting machine specifications:

| Specification | Detail |

|————–|——–|

| Machine Type | Vertical CNC Slotting Center |

| Axis Configuration | 3-axis (X, Y, Z), optional 4-axis indexing |

| Spindle Speed | Up to 6,000 RPM |

| Maximum Work Envelope | 600 mm × 400 mm × 300 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tooling System | ISO 30 or BT 30 taper |

| Control System | FANUC or Siemens CNC |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Tolerance Range | ±0.01 mm typical, down to ±0.005 mm for critical features |

| Surface Finish | As low as Ra 0.8 µm (typical), finer with polishing |

Starting your project is simple. Share your design files and requirements with us, and our engineering team will provide a comprehensive quote within 24 hours. We specialize in low to medium batch production, rapid prototyping, and custom machining solutions tailored to your exact needs.

Contact Susan Leo today at info@hy-proto.com to begin your CNC slotting project. With Honyo Prototype, you gain more than a manufacturer — you gain a technical partner committed to precision, reliability, and on-time delivery. Let us help you bring your next innovation to life.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.