Contents

Manufacturing Insight: Cnc Carbon Fiber

Manufacturing Insight: CNC Carbon Fiber Machining

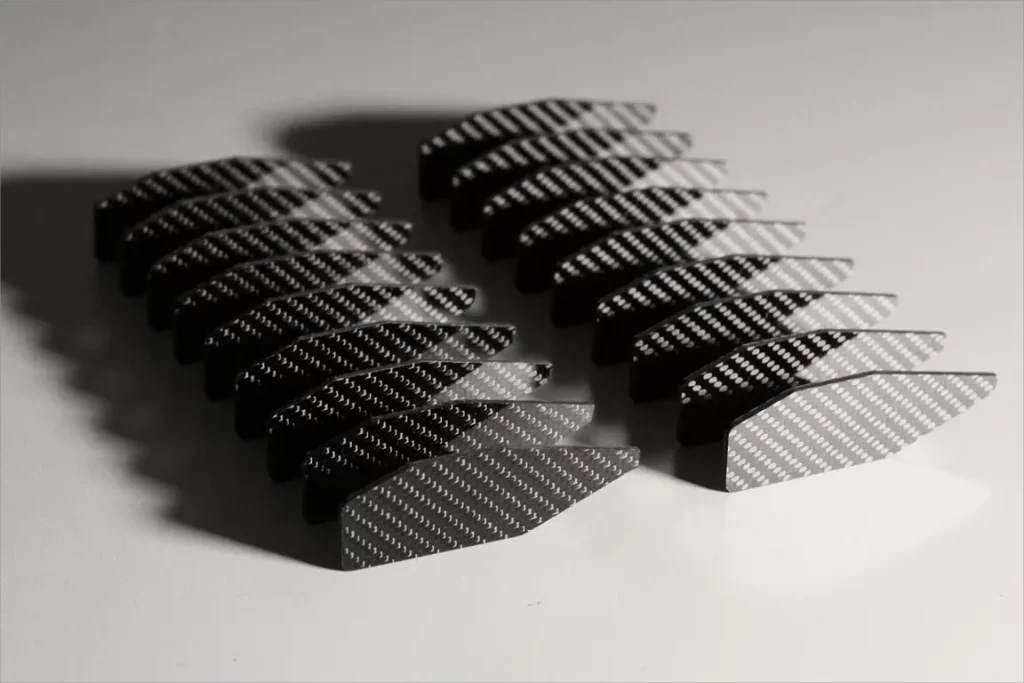

Carbon fiber reinforced polymer (CFRP) presents unique challenges and opportunities in precision CNC machining. Its exceptional strength-to-weight ratio and rigidity make it indispensable for aerospace, medical, and high-performance automotive prototypes. However, the abrasive nature of carbon fibers accelerates tool wear, while the layered composite structure risks delamination, fiber pull-out, and thermal damage during machining. Conventional metal-cutting parameters often fail, necessitating specialized strategies to maintain dimensional accuracy and surface integrity. At Shenzhen Honyo Prototype, we address these complexities through engineered processes that prioritize material preservation and micron-level precision.

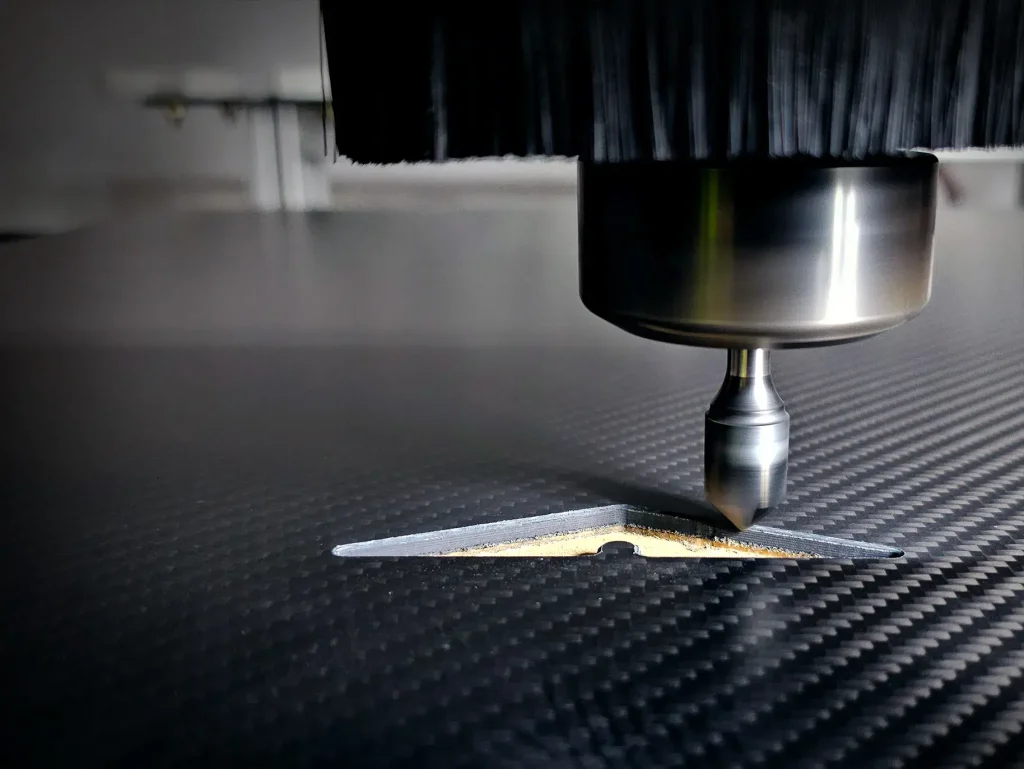

Our CNC carbon fiber workflow begins with proprietary toolpath optimization. High-speed machining (HSM) techniques combined with climb milling minimize lateral forces that cause fraying. We deploy diamond-coated or solid carbide tools with polished flutes to reduce heat generation and resin smearing, while maintaining aggressive chip evacuation to prevent re-cutting. Rigorous spindle speed and feed rate calibration—typically 15,000–24,000 RPM with feed rates of 500–1,200 mm/min—ensures clean cuts without compromising structural integrity. Crucially, our in-house material science team tailors parameters to each resin system (epoxy, vinyl ester, PEEK) and fiber orientation, avoiding the one-size-fits-all approach common in standard workshops.

Honyo’s capabilities extend beyond machining to holistic prototype validation. We integrate non-destructive testing (NDT) like ultrasonic scanning to detect subsurface defects pre- and post-machining, ensuring compliance with ASTM D7028 standards. Our 5-axis CNC centers, equipped with through-spindle coolant and high-precision probing, achieve tolerances down to ±0.025 mm on complex geometries. This is critical for assemblies where carbon fiber components interface with metal or additive-manufactured parts. Below are key specifications we support:

| Parameter | Capability Range | Notes |

|————————-|————————————–|—————————————-|

| Material Types | UD prepreg, woven fabric, CFRP tubes | Torayca T300/T700, Hexcel IM7, custom |

| Max Part Size | 1200 x 800 x 500 mm | 5-axis envelope |

| Tolerance | ±0.025 mm (standard) | ±0.01 mm achievable with inspection |

| Surface Finish (Ra) | 0.8–3.2 µm | As-machined; polishing available |

| Lead Time (Prototype) | 5–10 business days | Varies by complexity |

Unlike mass-production facilities, Honyo specializes in low-volume, high-mix prototyping where flexibility and rapid iteration are paramount. We collaborate with clients from DFM analysis through final inspection, identifying potential machining risks during the design phase—such as avoiding thin ribs prone to vibration-induced chatter. Our Shenzhen-based facility leverages real-time process monitoring to adjust parameters dynamically, reducing scrap rates by up to 35% compared to industry averages.

For engineering teams demanding carbon fiber prototypes that mirror production intent, Honyo delivers not just parts, but validated solutions. Our process ensures your design’s performance characteristics remain intact, turning material challenges into strategic advantages. Partner with us to transform complex carbon fiber concepts into flight-ready or production-bound prototypes, backed by ISO 9001-certified quality systems and 15+ years of composite machining expertise. Let’s engineer the future, one micron at a time.

Technical Capabilities

CNC Carbon Fiber Machining at Shenzhen Honyo Prototype

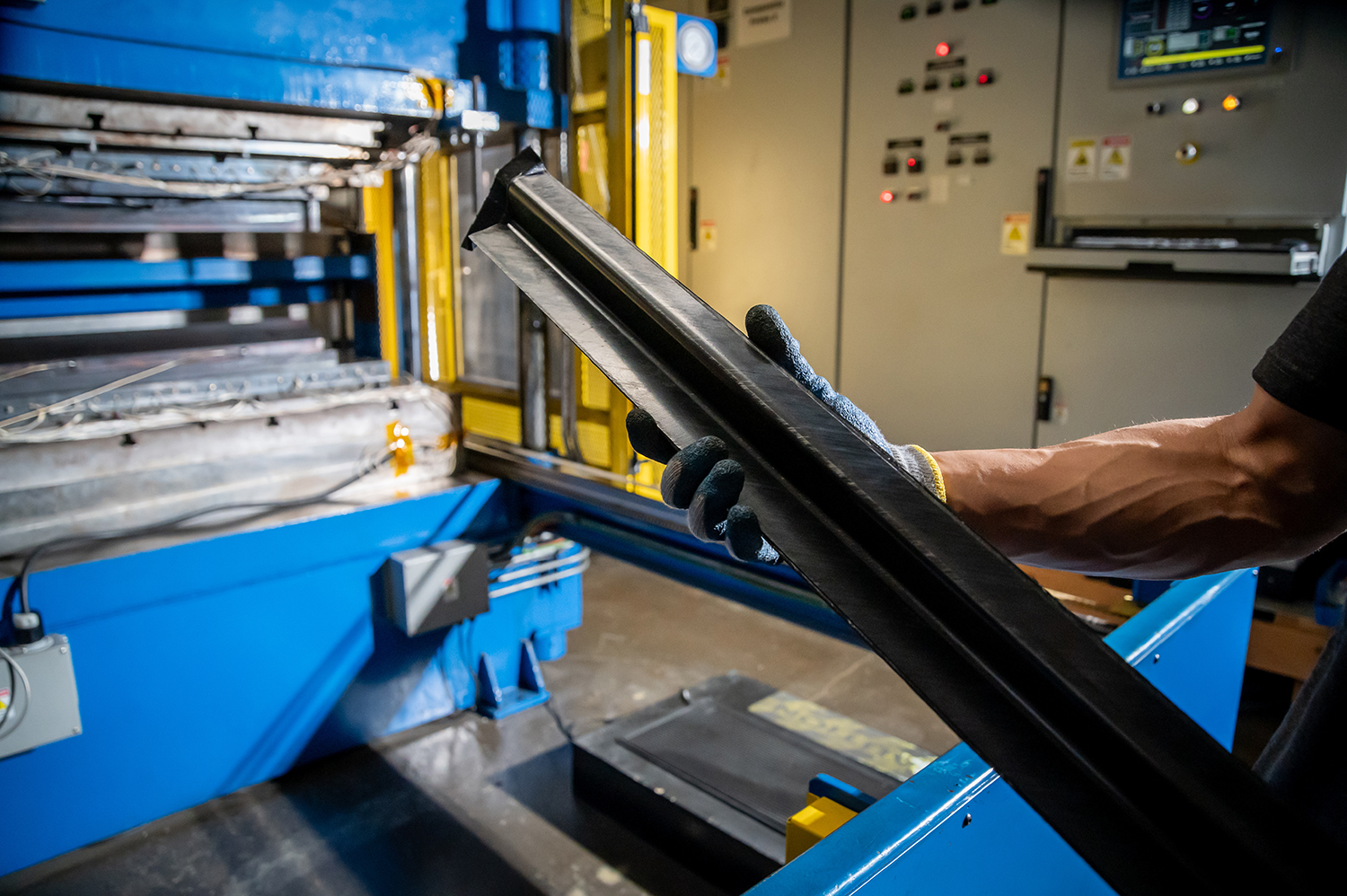

Shenzhen Honyo Prototype specializes in high-precision CNC machining of carbon fiber composites, delivering engineered solutions for aerospace, robotics, medical devices, and high-performance industrial applications. Our advanced 3-axis, 4-axis, and 5-axis CNC milling platforms are optimized for the unique challenges of carbon fiber-reinforced polymers (CFRP), ensuring dimensional accuracy, surface integrity, and structural performance. In addition to multi-axis milling, we offer CNC turning for cylindrical carbon fiber components, accommodating both solid and tubular geometries with consistent fiber alignment and minimal fraying.

Carbon fiber is inherently abrasive and anisotropic, requiring specialized toolpaths, diamond-coated or solid carbide tooling, and controlled feed rates to prevent delamination, fiber pull-out, and edge chipping. At Honyo Prototype, our manufacturing engineers employ adaptive machining strategies, including high-speed machining (HSM) and step-down profiling, to maintain material integrity while achieving tight tolerances. Our CNC systems are equipped with through-spindle coolant and dust extraction to manage heat and particulate, enhancing tool life and part cleanliness.

We support a range of carbon fiber material configurations, including unidirectional, woven, and hybrid laminates, with resin matrices such as epoxy, vinyl ester, and PEEK. Clients can choose from standard or custom fiber orientations to meet mechanical and thermal requirements. All parts undergo in-process inspection and final metrology using coordinate measuring machines (CMM) and optical comparators to verify compliance with design specifications.

The table below outlines our standard machining capabilities and achievable tolerances for CNC carbon fiber components.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|——————————-|———————-|———————-|———————-|———————-|

| Maximum Work Envelope (mm) | 1200 × 800 × 200 | 1200 × 800 × 200 | 800 × 600 × 150 | Ø200 × 300 length |

| Positional Tolerance | ±0.05 mm | ±0.05 mm | ±0.03 mm | ±0.05 mm |

| Feature-to-Feature Tolerance | ±0.10 mm | ±0.10 mm | ±0.05 mm | ±0.10 mm |

| Surface Roughness (Ra) | 3.2 – 6.3 µm | 3.2 – 6.3 µm | 1.6 – 3.2 µm | 1.6 – 3.2 µm |

| Minimum Wall Thickness | 0.8 mm | 0.8 mm | 0.6 mm | 1.0 mm |

| Standard Lead Time | 5–7 days | 6–8 days | 7–10 days | 5–7 days |

We maintain tight control over environmental conditions in our machining bays, including humidity and static management, to prevent resin brittleness and fiber misalignment during processing. All operators are trained in composite handling and non-destructive inspection techniques, ensuring that every component meets rigorous quality standards. Whether producing lightweight drone frames, robotic end-effectors, or precision medical enclosures, Honyo Prototype delivers carbon fiber parts with repeatable accuracy and superior surface finish. Our technical team collaborates with clients during DFM to optimize geometry, reduce machining risk, and accelerate time to market.

From CAD to Part: The Process

Shenzhen Honyo Prototype CNC Carbon Fiber Manufacturing Workflow: From CAD to Precision Component

Shenzhen Honyo Prototype executes precision CNC carbon fiber components through a rigorously controlled workflow designed to mitigate material-specific challenges and ensure first-time-right production. This integrated process spans initial quotation through final inspection, leveraging advanced technology and deep composite machining expertise to deliver complex prototypes and low-volume production parts efficiently.

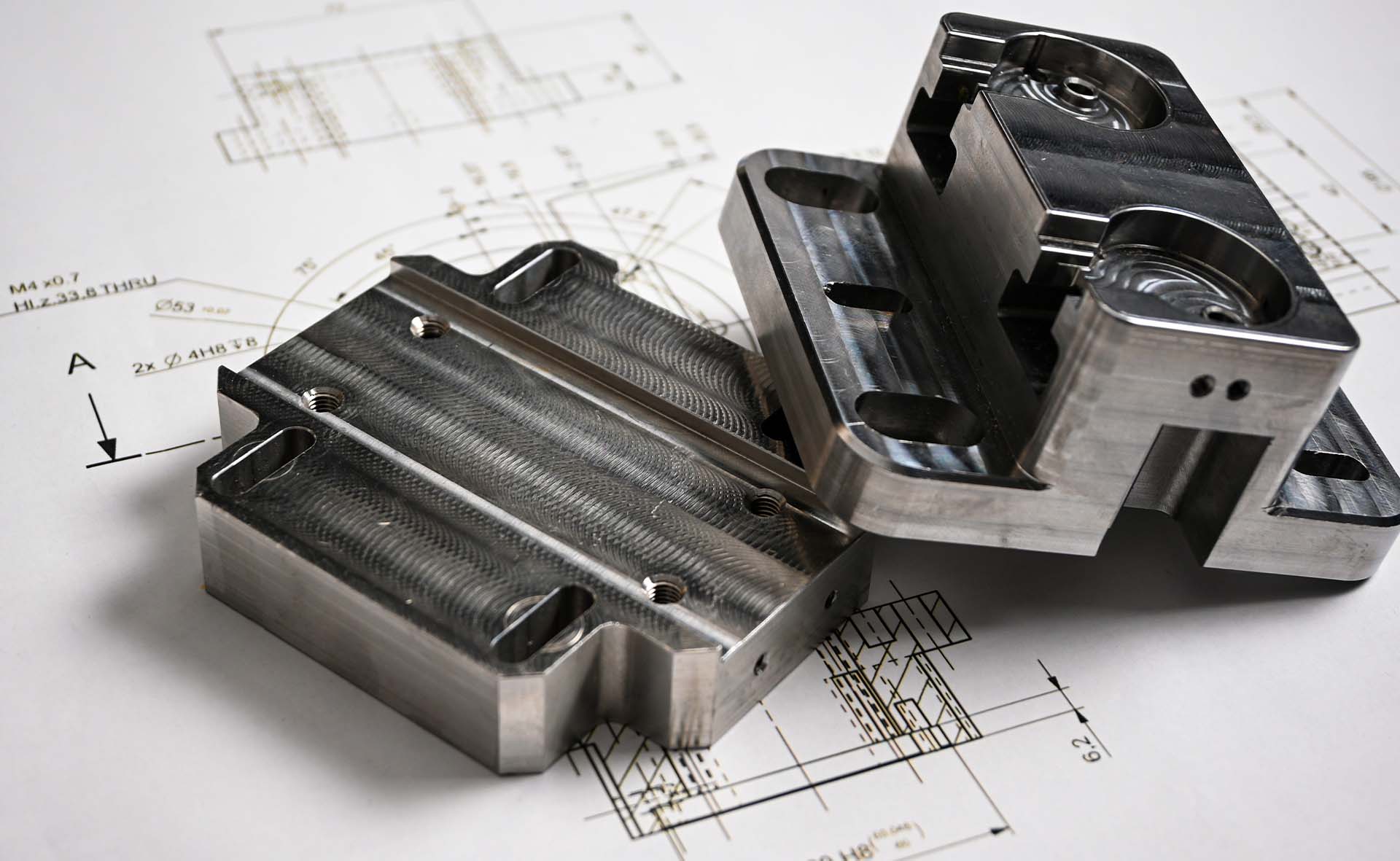

The workflow initiates with the AI-Powered Quotation System. Upon receipt of a client’s 3D CAD model, our proprietary AI engine performs an immediate preliminary manufacturability analysis. It identifies potential high-risk geometries for carbon fiber, such as thin walls prone to vibration-induced delamination, intricate internal features requiring specialized tooling, or tight tolerances challenging for the anisotropic material. Crucially, the AI quantifies material waste, estimates machine time considering slower feed rates and specialized toolpaths necessary for composites, and flags areas demanding engineering review. This generates a highly accurate, data-driven quote within minutes, setting realistic expectations and highlighting early opportunities for design optimization to reduce cost and lead time.

Following client approval, the project enters the critical Design for Manufacturability (DFM) Review phase. Honyo’s senior manufacturing engineers conduct a meticulous manual assessment, collaborating directly with the client. This step focuses explicitly on carbon fiber’s unique properties: verifying adequate support structures to prevent part movement during machining, assessing hole placement and size to avoid fraying or breakout, confirming wall thicknesses are sufficient for rigidity without inducing excessive heat buildup, and optimizing part orientation to minimize Z-axis depth and maximize stability. We provide actionable feedback, suggesting subtle design modifications like adding sacrificial tabs or adjusting radii, which significantly enhance yield and surface finish while maintaining functional intent. This proactive DFM collaboration prevents costly revisions and delays later in production.

The refined design then moves to Precision CNC Production. Machining carbon fiber requires stringent protocols distinct from metals. We employ rigid, high-precision 5-axis CNC centers equipped with high-frequency spindles and integrated vacuum dust extraction systems essential for operator safety and machine protection against conductive carbon dust. Tooling selection is paramount; diamond-coated or solid carbide end mills with specialized geometries for composites are used exclusively. Cutting parameters are meticulously controlled to minimize heat generation and prevent delamination or fiber pull-out. Key production parameters are strictly adhered to as outlined below.

| Parameter | Typical Range for Carbon Fiber | Critical Reason |

| :—————– | :—————————– | :———————————- |

| Spindle Speed | 12,000 – 18,000 RPM | Minimizes heat, prevents resin melt |

| Feed Rate | 100 – 300 mm/min | Reduces vibration, avoids fraying |

| Depth of Cut | ≤ 0.5 mm | Prevents delamination, ensures edge quality |

| Toolpath Strategy | Climb Milling, Constant Engagement | Reduces lateral forces, improves surface finish |

| Cooling | Dry Machining + Vacuum | Prevents resin clogging, ensures safety |

Throughout machining, in-process inspections verify critical dimensions and surface integrity. Final parts undergo comprehensive quality control, including CMM verification against the original CAD model and visual inspection for any surface imperfections. This seamless, expertise-driven workflow—from intelligent quoting through collaborative DFM to parameter-optimized production—ensures Shenzhen Honyo Prototype consistently delivers dimensionally accurate, high-quality carbon fiber components meeting the most demanding aerospace, medical, and robotics applications.

Start Your Project

Start Your CNC Carbon Fiber Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining of carbon fiber components for industries ranging from aerospace and automotive to medical and robotics. Our advanced manufacturing capabilities, combined with deep material expertise, enable us to deliver complex, durable, and lightweight carbon fiber parts that meet the most demanding engineering specifications. Whether you’re developing a prototype or scaling to low-volume production, we provide end-to-end support to bring your vision to life.

Carbon fiber is a challenging material to machine due to its abrasive nature and layered composite structure. However, our CNC machining processes are optimized specifically for carbon fiber reinforced polymers (CFRP), ensuring excellent dimensional accuracy, clean edge finishes, and minimal delamination. We use specialized diamond-coated cutting tools, high-speed spindles, and dust extraction systems to maintain part integrity and operator safety throughout production.

Our team works closely with engineers and product designers to review designs for manufacturability, suggest material grade selections, and optimize tool paths for performance and cost-efficiency. From 3-axis to 5-axis CNC routing, we handle intricate geometries and tight tolerances with confidence. All parts are inspected using precision metrology equipment to ensure compliance with your quality standards.

We support a wide range of carbon fiber materials, including unidirectional, woven, and prepreg composites, with various resin systems such as epoxy, vinyl ester, and phenolic. Whether your application requires high thermal resistance, EMI shielding, or structural rigidity, we tailor the material and machining process accordingly.

To get started, simply share your 3D model (STEP, IGES, or STL) and technical requirements with our engineering team. We offer rapid quoting, design feedback, and prototyping turnaround times as fast as 3–5 business days.

| Material Type | Tolerance | Max Part Size (mm) | Surface Finish (Ra) | Lead Time (Prototype) |

|————————-|———————|————————|————————-|—————————-|

| Woven Carbon Fiber | ±0.05 mm | 1000 × 600 × 200 | 1.6 – 3.2 µm | 3–5 days |

| Unidirectional CFRP | ±0.05 mm | 800 × 500 × 150 | 1.6 – 3.2 µm | 4–6 days |

| Prepreg Carbon Fiber | ±0.03 mm | 600 × 400 × 100 | 0.8 – 1.6 µm | 5–7 days |

| Hybrid CF/Nomex Core | ±0.1 mm | 1200 × 800 × 50 | 3.2 – 6.3 µm | 6–8 days |

All manufactured components undergo rigorous quality control, including first-article inspection reports (FAIR), dimensional verification, and visual defect screening. We are ISO 9001-certified and committed to delivering consistent, traceable results for every project.

Ready to move forward? Contact Susan Leo, our dedicated Project Manager, to discuss your CNC carbon fiber machining needs. We’re here to help you overcome material challenges, reduce development time, and achieve optimal part performance.

Susan Leo

Project Manager, CNC Machining Division

Shenzhen Honyo Prototype

Email: info@hy-proto.com

Send your design files today and receive a detailed technical evaluation and competitive quote within 24 hours. Let Honyo Prototype be your trusted partner in advanced composite manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.