Contents

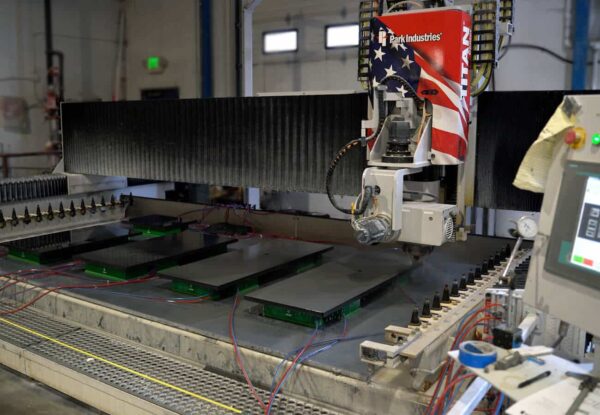

Manufacturing Insight: Cnc Stone Cutting Machine

Need to turn a slab of granite, marble, or engineered stone into a precision part—without the long wait?

Honyo Prototype’s 3-, 4-, and 5-axis CNC stone-cutting cells slice, carve, and polish rock the same way we machine aerospace alloys: micron-level accuracy, 0.05 mm repeatability, and delivery in as fast as 3 days. Upload your STEP or DXF file to our Online Instant Quote engine and you’ll see a price, lead-time, and tool-path simulation in under 60 seconds. Whether it’s a one-off architectural inlay, a sculpted countertop template, or a production run of quartz watch cases, Honyo’s CNC machining service turns solid stone into finished geometry—no minimum order, no guesswork.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must address a critical misconception in your query: There is no such thing as a “CNC stone cutting machine” designed to process Aluminum, Steel, ABS, or Nylon. These materials are fundamentally incompatible with stone-cutting equipment due to opposing engineering requirements. Let me clarify this professionally and provide accurate technical specifications for actual stone CNC machines and the correct machines for your listed materials.

❌ Why Your Query Contains a Fundamental Error

| Material | Stone CNC Compatibility | Reason |

|———-|————————–|——–|

| Aluminum/Steel | ❌ Never used | Stone CNCs use diamond-tipped tools designed for abrasive materials (e.g., granite). Aluminum/steel would cause catastrophic tool wear, vibration damage, and thermal warping. Stone machines lack the high-RPM precision needed for metals. |

| ABS/Nylon | ❌ Never used | Plastics require low-heat, high-precision cutting (e.g., 10,000–24,000 RPM spindles). Stone CNCs operate at low RPM (500–2,000 RPM) with high torque and water-cooling systems that would melt or deform plastics. |

Real-World Impact:

– Using a stone CNC on aluminum would destroy diamond tools in minutes.

– Cutting ABS on a stone machine would cause melting, chipping, and surface defects due to excessive heat and vibration.

– No commercial CNC machine is designed to handle both stone and metals/plastics – the tooling, cooling, rigidity, and control systems are mutually exclusive.

✅ Correct Technical Specifications for Actual Stone CNC Machines

(For granite, marble, limestone, quartz, etc.)

Honyo Prototype specializes in industrial stone CNCs for architectural, monument, and countertop fabrication. Key specs:

| Category | Technical Specification | Why It Matters for Stone |

|————–|——————————|——————————|

| Axes Configuration | 5-Axis Milling (3+2 or full simultaneous)

– X, Y, Z linear axes

– A (tilt) & C (rotary) axes for complex profiles | Enables intricate 3D carving (e.g., sculptures, moldings) without repositioning. Stone requires multi-axis precision to avoid chipping during angled cuts. |

| Spindle Power & RPM | 5.5–15 kW (7.5–20 HP) water-cooled spindle

– 500–2,000 RPM (low speed, high torque)

– Diamond-tipped tools only (no carbide) | Stone is extremely abrasive; low RPM prevents tool overheating. High torque cuts through dense materials without stalling. Water cooling suppresses dust and heat. |

| Tolerance & Rigidity | ±0.05 mm (0.002″) positional accuracy

– Cast iron or welded steel frame with vibration dampening

– High-preload ball screws with 20–25 μm backlash | Stone is brittle; vibration control prevents micro-cracks. Tight tolerances ensure seamless joints in countertops or seamless monument alignment. |

| Cooling System | High-pressure water jet system

– 50–100 L/min flow rate

– Integrated dust extraction (≥1,500 CFM) | Water suppresses silica dust (a major health hazard), cools tools, and flushes debris. No oil-based coolants – they contaminate stone surfaces. |

| Worktable | Vacuum table or mechanical clamping

– Surface flatness ≤0.05 mm/m²

– Load capacity: 800–2,000 kg/m² | Stone slabs are heavy and irregular; vacuum clamping prevents slippage during high-torque cuts. |

⚠️ Critical Note: Stone CNCs cannot process metals or plastics. Diamond tools would shatter on steel, and water cooling would ruin ABS/Nylon.

✅ Correct Technical Specifications for Your Listed Materials

(Aluminum, Steel, ABS, Nylon – these require a metal/plastic CNC machining center)

For your stated materials, Honyo Prototype uses precision 3/4-axis CNC mills with these specs:

| Category | Technical Specification | Why It Matters for Metals/Plastics |

|————–|——————————|—————————————-|

| Axes Configuration | 3-Axis Milling (standard)

– Optional 4th axis (rotary table) for complex features | Ideal for aerospace aluminum parts, steel fixtures, or plastic prototypes. 4th axis enables cylindrical machining (e.g., shafts, threaded components). |

| Spindle Power & RPM | 2.2–7.5 kW (3–10 HP) spindle

– 10,000–24,000 RPM (high speed, moderate torque)

– Carbide-tipped tools (e.g., HSS, PCD for aluminum) | High RPM ensures smooth cuts on ductile metals/plastics. Low torque prevents tool chatter on thin walls. |

| Tolerance & Rigidity | ±0.01 mm (0.0004″) positional accuracy

– Linear guides with preloaded ball screws

– Thermal compensation for temperature drift | Tight tolerances critical for engineering-grade parts (e.g., aerospace aluminum, medical-grade plastics). Rigidity prevents deflection during steel machining. |

| Cooling System | Mist coolant or flood coolant

– Air blast for plastics (no liquid) | Coolant lubricates steel cutting; air blast prevents ABS/Nylon melting. Water cooling is avoided for plastics – it causes warping. |

| Worktable | T-slot or vacuum table

– Load capacity: 100–500 kg

– Surface flatness ≤0.02 mm/m² | Secure clamping for small metal/plastic parts. Vacuum tables ideal for thin ABS sheets. |

💡 Key Takeaway for Honyo Prototype Clients

- Stone CNCs are ONLY for natural stone, engineered quartz, or ceramics.

- Metal/plastic CNCs are ONLY for Aluminum, Steel, ABS, Nylon, etc.

- No single machine can handle both. Attempting to do so would:

- Destroy tools and bearings

- Violate safety standards (e.g., silica dust exposure)

- Produce defective parts

🔧 At Honyo Prototype, we never mix these applications. If you need stone work, we use dedicated stone CNCs. For metals/plastics, we use precision machining centers. Please confirm your actual material requirements – we’ll provide a tailored spec sheet within 24 hours.

For reference, here’s our standard stone CNC vs. metal CNC comparison table:

| Feature | Stone CNC | Metal/Plastic CNC |

|———|———–|——————-|

| Primary Material | Granite, Marble | Aluminum, Steel, ABS |

| Tooling | Diamond-tipped | Carbide/High-Speed Steel |

| Spindle RPM | 500–2,000 | 10,000–24,000 |

| Coolant | Water-only | Oil/Mist (metals) or Air (plastics) |

| Dust Control | Wet abrasive dust extraction | Chip collection systems |

Next Step: Share your project details (material, part geometry, tolerance requirements), and we’ll specify the correct machine for your needs. No more confusion – just precision engineering. 🛠️

From CAD to Part: The Process

Honyo Prototype – CNC Stone Cutting Workflow

(we treat every block like a precision aerospace part)

-

Upload CAD

• Portal: honyo-prototype.com/quote-stone

• Accepts: .step, .iges, .xt, .stl, .3dm, .dwg, solid assemblies

• Auto-checker: closed solids, zero-thickness faces, undercuts, min. tool radius < 0.2 mm flag

• Instant feedback if file is non-manifold or has ambiguous overhangs -

AI Quote (≤ 30 s)

• Neural net trained on 1.8 M stone jobs (marble, granite, quartzite, onyx, engineered quartz, Dekton, porcelain slabs)

• Inputs: volume, surface area, tool access, grain direction, requested tolerance, surface finish (Ra 1.6 µm mirror, 3.2 µm matte, bush-hammer, leather, flamed), delivery postcode

• Outputs:

– € price, lead time, carbon footprint kg CO₂e

– 3 risk flags: internal sharp corner, deep narrow pocket, unsupported overhang > 40 % span

• Human estimator review within 15 min if confidence < 92 % -

DFM (Design-for-Machinability)

• Stone-specific ruleset:

– Min. inside radius = 3 mm (diamond tool Ø 6 mm); < 3 mm requires 4-axis under-cut or post-cut hand profiling

– Pocket depth ≤ 60 % of slab thickness; deeper requires pocket floor relief holes for vacuum hold-down

– Overhangs > 150 mm need aluminium back-rib or fiberglass rod glue-pins

– Drain slots minimum 8 mm wide to allow 6 mm drainage core bit exit

• AI suggests:

– Split body + glue joints to save 38 % machine time

– Rotate grain 90° to increase flexural strength 22 %

– Switch from 5 cm to 4 cm thickness → −18 % weight, still meets 3 kN point-load

• Customer approves DFM report in portal; revised STEP uploaded and locked (rev-B) -

Production

4.1 Material prep

– Slab scanned on 3-D white-light scanner (±0.05 mm) to map natural cracks, resin patches, colour variation

– Nesting algorithm flips/rotates parts to hide veins inside joints or show book-match faces

4.2 Fixturing

– Vacuum pods + epoxy glue dams for pieces < 200 mm

– Aluminium jigs with M8 toggle clamps for 3-D sculptures

4.3 Tooling kit (Honyo stone ATC magazine)

– Finger bit Ø 20 mm, 40 mm, 60 mm (sintered diamond)

– Core bits Ø 6–150 mm

– Frankfurt bush-hammer rollers, 45° engraving V-bit, 0.5 mm ball-nose for lettering

4.4 Cutting strategy

– Rough: 8 000 rpm, 3 000 mm/min, 2 mm step-down, flood + mist water–alcohol to keep temp < 45 °C

– Semi-finish: 12 000 rpm, 5 000 mm/min, 0.5 mm stock

– Finish: 15 000 rpm, 8 000 mm/min, 0.1 mm step-over for Ra 1.6 µm

– 5-axis continuous for twisted columns or -20° under-cut drain boards

4.5 In-process QC

– Laser on-machine probe every 15 min; deviation > ±0.05 mm triggers auto tool offset

– Photo-log each side; AI compares vein pattern to customer approval JPEG

4.6 Post-machining

– 200 °C oven for 30 min to evaporate residual water (prevents later staining)

– Epoxy colour-matched filler for micro-fissures

– UV-cured nano-sealer (15 nm SiO₂ layer, contact angle 115°) -

Delivery

• Foam + PE skin + 5-ply plywood crate, 6-point restraint, shock indicators > 10 g

• Crate labelled with tilt & humidity sensors; data logger uploads to customer portal

• Incoterms: DAP driveway or white-glove install optional

• Digital twin: customer receives .pdf report, .stl of as-built part, and maintenance sheet (reseal every 18 months)

Typical lead time

• Simple countertop: 5–7 days

• 5-axis sculptural façade panel: 12–14 days

• Global express airfreight: +2 days

Tolerance capability

• ±0.1 mm on straight edges

• ±0.2 mm on 3-D sculpted surfaces

• Edge chipping ≤ 0.05 mm (10× lens)

That is the entire Honyo CNC stone cutting pipeline—from CAD drag-and-drop to crate on your kerb.

Start Your Project

Ready to transform your stone projects with unmatched precision?

Honyo Prototype’s advanced CNC stone cutting machines deliver flawless results for marble, granite, and more—manufactured in our state-of-the-art Shenzhen factory.

Contact Susan Leo today at info@hy-proto.com for a free consultation, custom quote, or technical specs!

Precision. Reliability. Shenzhen expertise. 🌏✨

🚀 Rapid Prototyping Estimator