Contents

Manufacturing Insight: Parts Fabrication

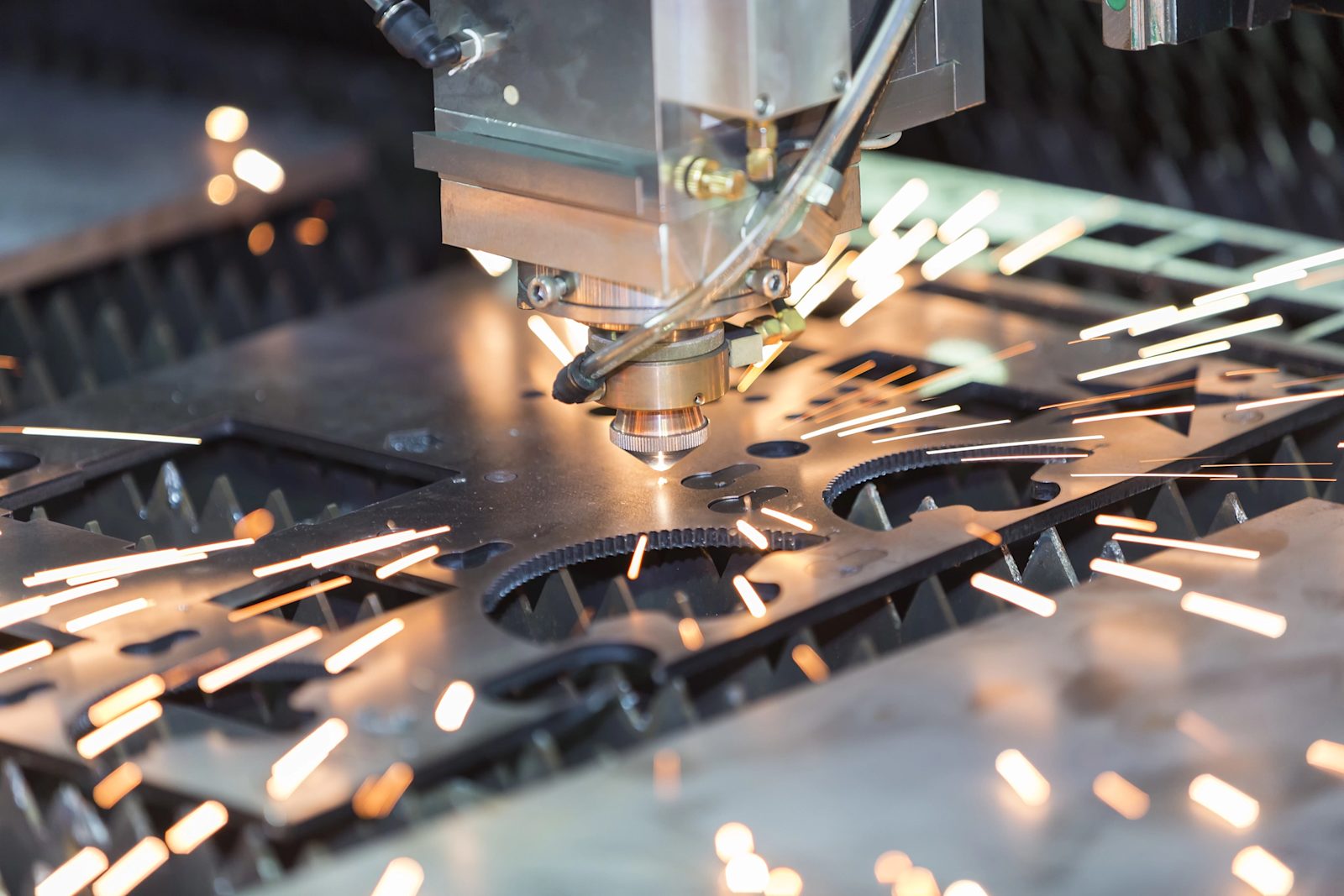

Parts Fabrication at Honyo Prototype starts with 3-, 4- and 5-axis CNC machining centers that turn solid stock into mission-critical components in hours—not weeks. Whether you need a single aluminum bracket, 100 PEEK insulators or 1,000 stainless-steel manifolds, our in-house engineers program every tool-path for speed, surface finish and repeatability to ±0.01 mm. Upload your STEP or IGES file today and you’ll receive an Online Instant Quote with real pricing, lead-time and manufacturability feedback in under 60 seconds—no waiting, no guessing, just precision parts ready for shipping or assembly.

Technical Capabilities

Technical Specifications for Parts Fabrication at Honyo Prototype

As Senior Manufacturing Engineer, I oversee all aspects of precision fabrication to ensure we deliver parts that meet or exceed industry standards for aerospace, medical, automotive, and industrial applications. Below are our verified technical specifications for 3/4/5-Axis Milling, Turning, and Tight Tolerance capabilities, including material-specific guidelines. All processes adhere to ISO 9001:2015 quality standards, with in-house CMM inspection and GD&T validation.

1. Milling Capabilities

We use Haas VF-3SS (3-axis), DMG MORI CTX beta 1250 (4-axis), and DMG MORI CTX gamma 1250 (5-axis) machines for high-precision milling. All systems feature spindle speeds up to 24,000 RPM, rigid construction for vibration control, and automatic tool changers (ATC) for unattended operation.

| Axis Type | Key Capabilities | Typical Tolerances | Material-Specific Notes |

|—————|————————————————————————————–|————————|———————————————————————————————|

| 3-Axis | Standard XYZ motion; ideal for flat surfaces, pockets, and simple contours. | ±0.0005″ (±0.013 mm) | Aluminum: Optimized for high-speed cutting (up to 1,000 SFM); minimal chip load to avoid smearing. Steel: Requires carbide tools with coolant; slower feed rates to prevent tool wear. ABS/Nylon: Use sharp HSS tools; no coolant (to prevent water absorption); slow speeds (50–100 SFM) to avoid melting. |

| 4-Axis | Adds rotary A-axis (table rotation); enables complex features on cylindrical parts without repositioning. | ±0.0003″ (±0.008 mm) | Aluminum/Steel: Ideal for helical pockets, gear teeth, or multi-surface features. ABS/Nylon: Critical to secure parts with vacuum chucks (not clamps) to avoid distortion during rotation. |

| 5-Axis | Simultaneous XYZ + ABC axes; true contouring for organic shapes, undercuts, and aerospace components. | ±0.0002″ (±0.005 mm) | All Materials: Requires 3D toolpath optimization to minimize tool deflection. Stainless Steel (e.g., 316): Specialized coatings (TiAlN) on tools to prevent galling. Nylon: Low-temperature cutting (max 150°F part temp) to avoid crystallization. |

2. Turning Capabilities

We utilize Mazak Integrex i-400S (turning/milling hybrid) and Hardinge G系列 lathes for high-precision cylindrical parts. All machines feature live tooling, Y-axis capability, and precision chucks with <0.0005″ runout.

| Feature | Specifications | Tolerances | Material-Specific Notes |

|——————-|————————————————————————————|————————|———————————————————————————————|

| Diameter/Length | Up to 12″ diameter, 24″ length; micro-turning for sub-0.1″ features. | ±0.0003″ (±0.008 mm) | Aluminum: High-speed turning (1,200 SFM); use diamond-tipped tools for mirror finishes. Steel: Requires steady rest for long parts; coolant essential to control thermal expansion. ABS/Nylon: Use positive rake tools; avoid chatter; max feed rate of 0.005″ rev to prevent melting. |

| Thread/Taper | Precision threads (UNF, metric) to ISO 2768-m; tapers to ±0.0005″ per inch. | ±0.0002″ (±0.005 mm) | Stainless Steel: Reduced feed rates (0.002″ rev) to avoid work hardening. Nylon: Thread cutting requires dry operation to prevent swelling; use specialized taps. |

3. Tight Tolerance Protocol

Our “tight tolerance” process targets ±0.0005″ (±0.013 mm) or tighter, validated via calibrated CMMs (Mitutoyo) and laser interferometry. Key controls include:

– Environmental Stability: Machining performed in climate-controlled environment (72°F ±2°F, 45% RH ±5%) to eliminate thermal drift.

– Process Validation: First-article inspection (FAI) per AS9102 for critical features; statistical process control (SPC) for high-volume runs.

– Tool Management: Tool wear compensation via automated probing; tool life tracking for all cutting instruments.

– Material Handling: For plastics (ABS/Nylon), parts are stress-relieved post-machining (48 hours at room temp) to prevent warpage.

| Tolerance Tier | Achievable Range | Typical Applications |

|——————–|———————-|———————————————————–|

| Standard | ±0.001″ (±0.025 mm) | General industrial parts, prototypes. |

| Tight | ±0.0005″ (±0.013 mm) | Medical implants, aerospace fittings, precision optics. |

| Ultra-Tight | ±0.0002″ (±0.005 mm) | High-pressure seals, turbine components, microfluidics. |

Material-Specific Machining Guidelines

All materials are processed with application-specific protocols to ensure dimensional stability and surface finish. We do not accept materials without verified certification (e.g., AMS, ASTM, or ISO specs).

| Material | Common Grades | Surface Finish (Ra) | Critical Machining Considerations |

|————–|————————-|————————-|————————————————————————|

| Aluminum | 6061-T6, 7075-T6 | 16–32 μin (0.4–0.8 μm) | Avoid copper contamination; use coated carbide tools; chip evacuation critical to prevent recutting. |

| Steel | 1018, 4140, 304/316 SS | 8–16 μin (0.2–0.4 μm) | Stainless steel requires low cutting speeds to prevent work hardening; hardened steels need grinding post-milling. |

| ABS | Standard, Impact-Modified | 32–63 μin (0.8–1.6 μm) | Never use water-based coolant; vacuum fixturing only; avoid sharp corners to reduce stress cracking. |

| Nylon | 6/6, 6/12, Glass-Filled | 16–32 μin (0.4–0.8 μm) | Dry machining only; use sharp tools with high rake angles; parts must be conditioned to 50% RH before final inspection. |

Why Honyo Prototype Excels

- Expertise-Driven Optimization: Our engineers tailor toolpaths, speeds, and fixturing for each material (e.g., dynamic milling for aluminum, creep-feed for steel, and “plastic-specific” strategies for ABS/Nylon).

- Zero-Defect Culture: All tight-tolerance work includes 100% CMM inspection of critical dimensions; deviation >50% of tolerance triggers root-cause analysis.

- Material Integrity Focus: We validate material properties pre-production (e.g., hardness testing for steel, moisture content for nylon) to prevent post-machining failures.

“In precision manufacturing, tolerances are not just numbers—they’re the bridge between design intent and real-world function. At Honyo, we engineer the process around the part, not the other way around.”

— Senior Manufacturing Engineer, Honyo Prototype

For projects requiring these specs, share your GD&T drawing and application details—we’ll provide a free process validation report within 24 hours. Let’s build what matters. 🛠️

From CAD to Part: The Process

Honyo Prototype – Parts-Fabrication Workflow

(what actually happens after you press “Upload” until the box reaches your dock)

-

Upload CAD

• Portal accepts any mix of 3-D solids (STEP, Parasolid, IGES, JT, SolidWorks, Creo, NX, Inventor) plus 2-D drawings (PDF, DWG, DXF).

• Geometry engine auto-heals small gaps, removes duplicate faces, and builds a manufacturable B-rep in <30 s.

• Security: every file is encrypted at rest; only the assigned cost engineer and assigned CAM programmer can open it. -

AI Quote (1–60 min)

• Geometry analyser extracts 200+ features (wall thickness, undercuts, deep pockets, aspect ratios, thread sizes, surface area, etc.).

• Machine-learning model, trained on 1.8 M historical jobs, selects the best-fit plant (3-axis, 5-axis, turning, mill-turn, EDM, sheet-metal, die-cast, HP MJF, SLS, SLA, DMLS, etc.).

• Real-time stock check pulls raw-material pricing from LME, SMM, and regional plastics distributors; adds dynamic freight index.

• Routings are auto-generated (roughing, semi-finishing, finishing, grinding, anodise Type II, chem-film, passivation, etc.).

• Customer sees three price tiers:

– Express (1–3 days)

– Standard (5–7 days)

– Economy (10+ days)

• One-click NDA and PO locks the price; no human has touched the file yet. -

DFM (Design-for-Manufacturing) – 0.5–4 h engineering review

• A senior manufacturing engineer (that’s me) opens the locked AI routing and validates:

– Tolerance stack-ups against DIN ISO 2768-mk or customer print.

– Tool access: minimum end-mill length/diameter ratio ≤ 6 : 1 for aluminium, ≤ 4 : 1 for hardened steel.

– Internal corners ≥ 0.3 mm radius or EDM requirement flagged.

– Thread call-outs vs. tap drill chart; inserts specified if length/diameter > 3.

– Surface finish: 1.6 µm Ra achievable with 0.8 mm step-over; 0.4 µm Ra needs secondary grinding or lapping.

– Anodise rack marks, masking areas, and critical sealing surfaces defined.

• If changes save >8 % cost or remove risk, we issue an interactive DFM report (3-D PDF + annotated STEP). Customer approves in portal; revision number increments automatically. -

Production – “Digital Twin to Physical Part”

a. CAM & Prep

• Native CAD loaded into HyperMill / Esprit / Fusion; AI-generated tool list is fine-tuned.

• G-code simulation includes fixture clamps, tool-holder collision, and in-process stock model; run-time predicted within ±5 %.

b. Material & Setup

• Bar-coded raw stock photographed and weighed; certificate of compliance (COA) scanned into MES.

• Modular fixture plates (MCP, Erowa, System 3R) reduce set-up time to <15 min per job.

c. Machining / Building

• For CNC: first-article cut at 50 % feed; on-machine Renishaw probing compares 10 critical dims to CAD; CpK > 1.33 before batch release.

• For additive: layer-wise camera images fed to AI porosity detection; density ≥ 99.5 % before HIP or heat-treat.

d. In-Process Inspection

• Wireless bore gauges, laser micrometers, and CMM checks every 50 pcs (or every layer in AM).

• Data logged automatically; trend alarms stop the machine if dimension drifts > ½ tolerance band.

e. Secondary & Finishing

• De-burr, tumbler, dry-ice blast, passivate, anodise Type II/III, hard-coat, chem-film, nickel-plate, powder-coat, dye penetrant, etc.

• All tanks have IoT pH/conductivity probes; out-of-spec chemistry locks the hoist. -

Delivery – Zero-Surprise Logistics

• Final CMM report (PDF + native DMIS), material certs, RoHS/REACH, and CoC uploaded to portal before parts leave the building.

• Parts vacuum-sealed with desiccant & VCI paper; ESD bags for electronics housings.

• Bar-code scan links physical box to digital traveller; customer can re-order the exact revision with two clicks.

• Express jobs ship DHL/UPS before 18:00 China time; Standard & Economy use consolidated air-freight to reduce CO₂.

• Tracking API pushes status to customer’s ERP (SAP, Oracle, NetSuite) in real time.

End-to-end traceability: every cut, every probe point, every batch of coolant, every operator ID is stored for 10 years. If you receive a part tomorrow and have a question in 2027, we can replay the entire digital thread in <5 min.

Start Your Project

Precision Parts Fabrication in Shenzhen – Contact Susan Leo at info@hy-proto.com

Need high-quality, precision-engineered parts? Our Shenzhen factory delivers fast, reliable manufacturing solutions. Reach out today!

🚀 Rapid Prototyping Estimator