Contents

Manufacturing Insight: Cnc Tube Bending Service

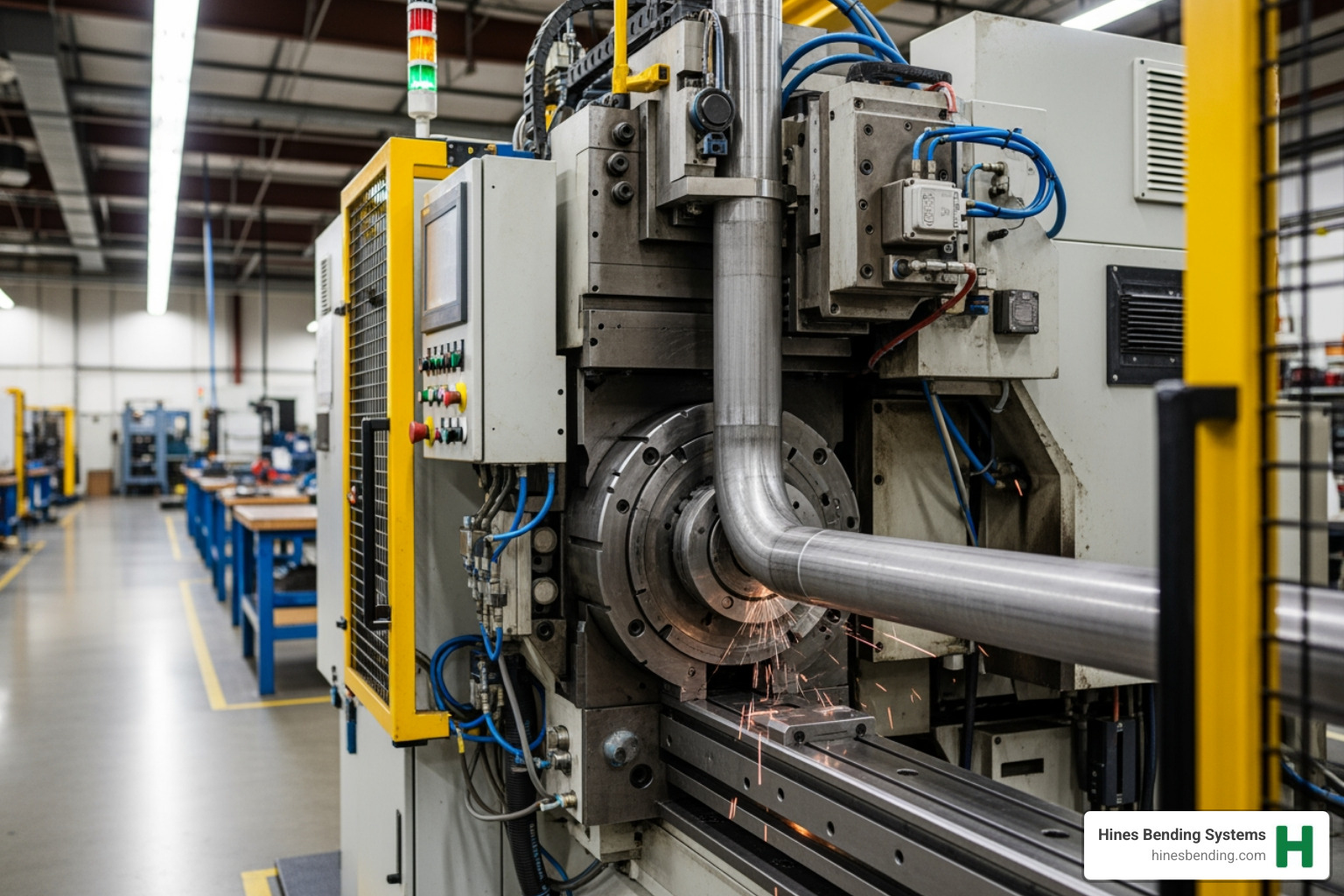

CNC Tube Bending—Done the Honyo Way

At Honyo Prototype, the same 5-axis CNC machining cells that mill aerospace manifolds to ±0.02 mm are now reshaping tubular metal in a single, continuous bend. Our CNC tube-bending service marries offline spring-back simulation with live laser correction, so every stainless, aluminum, or Ti coil leaves the machine with the same GD&T fidelity you expect from our machined parts. Upload your STEP file today and receive an online instant quote—complete with bend radii, feed rates, and piece-price breakdown—while you watch the first article take shape on the very same controllers that power our 24-hour machining floor.

Technical Capabilities

It appears there’s a critical terminology confusion in your request. CNC tube bending is fundamentally different from milling/turning processes, and ABS/Nylon cannot be conventionally tube-bent. Let me clarify this upfront to prevent costly errors in your project:

🔧 Core Misconception Clarified

| Process | What It Is | Compatible with ABS/Nylon? | Axis System |

|——————|—————————————————————————-|—————————-|—————————————————————————–|

| Tube Bending | Forming process that reshapes tubing without removing material using dies and mandrels. | ❌ No (ABS/Nylon melt/deform under bending heat/pressure) | 3-4 axis CNC benders (e.g., bending plane rotation, die rotation, push/pull) |

| Milling/Turning | Subtractive process that removes material using rotating cutters (milling) or workpiece rotation (turning). | ✅ Yes (ABS/Nylon are common machining materials) | 3/4/5-axis milling (complex 3D shapes) or 2-4 axis turning (rotational parts) |

You cannot “bend” ABS/Nylon tubing like metal. These plastics:

– Require specialized thermal bending (not standard CNC tube bending)

– Are prone to cracking, warping, or melting during conventional bending

– Are only suitable for machining (milling/turning)

✅ Actual CNC Tube Bending Technical Specs

(For metals only: Aluminum, Steel, Stainless Steel, Copper, Brass)

📏 Material Capabilities

| Material | Max Wall Thickness | Min Bend Radius (Diameter) | Typical Bend Angles | Notes |

|—————-|——————–|—————————-|———————|—————————————-|

| Aluminum | 0.5mm–6mm | 1.5× OD | 0°–180° | 6061-T6 most common; avoid heat-sensitive alloys |

| Steel | 0.8mm–12mm | 2× OD | 0°–360° | Mild steel easiest; stainless requires higher force |

| Copper/Brass| 0.5mm–8mm | 1.2× OD | 0°–180° | Highly ductile; prone to springback |

🚫 ABS/Nylon are NOT bendable via standard tube bending processes. They require thermal forming or machining.

🎯 Tolerance Standards

| Parameter | Typical Tolerance | Tight Tolerance (Precision) | Notes |

|——————–|——————-|—————————-|—————————————-|

| Bend Angle | ±0.5° | ±0.2° | Measured with CMM or optical probe |

| Bend Radius | ±0.1mm | ±0.05mm | Critical for flow dynamics |

| Straight Length| ±0.2mm | ±0.05mm | Between bends |

| Roundness | ≤0.5% deformation | ≤0.2% deformation | Measured at bend apex |

| Surface Finish | Ra 3.2μm | Ra 1.6μm | Avoid scratches (affects fatigue life) |

⚙️ Machine Specifications

- Axis System: 3-4 axis CNC tube benders (e.g., 3-axis: bending plane, die rotation, push/pull; 4-axis: adds rotary table for helical bends)

- Max Tube OD: Up to 150mm (custom machines)

- Max Bend Length: 6,000mm (continuous)

- Mandrel Types: Solid, ball, or flexible for thin-walled tubes

- Key Capability: Zero springback compensation via real-time pressure feedback

🌡️ Process Constraints

- Minimum Bend Radius: 1.2–2× tube OD (depends on material)

- Max Wall Thinning: ≤15% (at bend apex)

- Max Ovality: ≤5% (critical for fluid flow applications)

- Heat Treatment: Required for high-strength steels after bending

🔧 For MACHINING (Milling/Turning) of ABS/Nylon & Metals

(If your part requires machining, not bending)

| Process | Material Compatibility | Tight Tolerance | Axis System | Notes |

|—————-|————————|—————–|——————|—————————————-|

| 3-Axis Milling | Aluminum, Steel, ABS, Nylon | ±0.005″ (±0.127mm) | X/Y/Z linear axes | Ideal for flat surfaces, slots, pockets |

| 4-Axis Milling | Same as above | ±0.002″ (±0.05mm) | + Rotary table (A-axis) | For cylindrical features (e.g., hexes) |

| 5-Axis Milling | Same as above | ±0.001″ (±0.025mm) | + Tilt/rotation (B/C axes) | Complex 3D contours (e.g., aerospace fittings) |

| Turning | Aluminum, Steel, ABS, Nylon | ±0.001″ (±0.025mm) | 2–4 axes (X/Z + C/Y) | Rotational symmetry (e.g., pipe ends, flanges) |

✅ ABS/Nylon are ideal for machining (not bending):

– ABS: ±0.01mm tolerance achievable; prone to melting if speeds too high

– Nylon: Requires dry cutting; ±0.015mm tolerance typical

💡 Critical Recommendations

- If your part has bends AND machined features:

- Specify as a combined process: “Tube bending + CNC machining”

-

Example: “Bend 6061-T6 aluminum tube (OD 25mm, wall 2mm), then machine 5-axis precision features on ends to ±0.01mm tolerance.”

-

Never request “5-axis tube bending” – this doesn’t exist. Tube benders use 3-4 axes for forming; milling uses 5-axis for cutting.

-

ABS/Nylon tubing must be machined, not bent. If you need plastic tubing shapes:

- Use thermal bending (specialized process with heat guns) for simple curves, OR

-

Machine from solid rod for complex geometries.

-

For tight tolerances:

- Bending: ±0.2° angle tolerance requires laser-guided systems + post-bend CMM verification.

- Machining: ±0.001″ tolerances require 5-axis CNC + temperature-controlled environment.

📌 Summary for Honyo Prototype

| Requirement | Tube Bending (Metals Only) | Machining (ABS/Nylon/Metals) |

|———————-|—————————-|——————————|

| Process | Forming (no material removal) | Subtractive (material removal) |

| ABS/Nylon Suitable? | ❌ No | ✅ Yes (standard) |

| Tight Tolerance | ±0.2° angle, ±0.05mm radius | ±0.001″ (25μm) achievable |

| Axis System | 3-4 axis (bending only) | 3-5 axis (milling) or 2-4 axis (turning) |

Next Step: Share your CAD drawing with us. We’ll confirm whether your part requires:

– Pure tube bending (for metal tubes),

– Pure machining (for ABS/Nylon or metal features), or

– Combined process (bending + machining).

Let’s ensure your design is manufacturable! 🛠️

From CAD to Part: The Process

Start Your Project

🚀 Rapid Prototyping Estimator