Contents

Manufacturing Insight: Cnc Turning Center Machine

Manufacturing Insight: CNC Turning Center Capabilities at Shenzhen Honyo Prototype

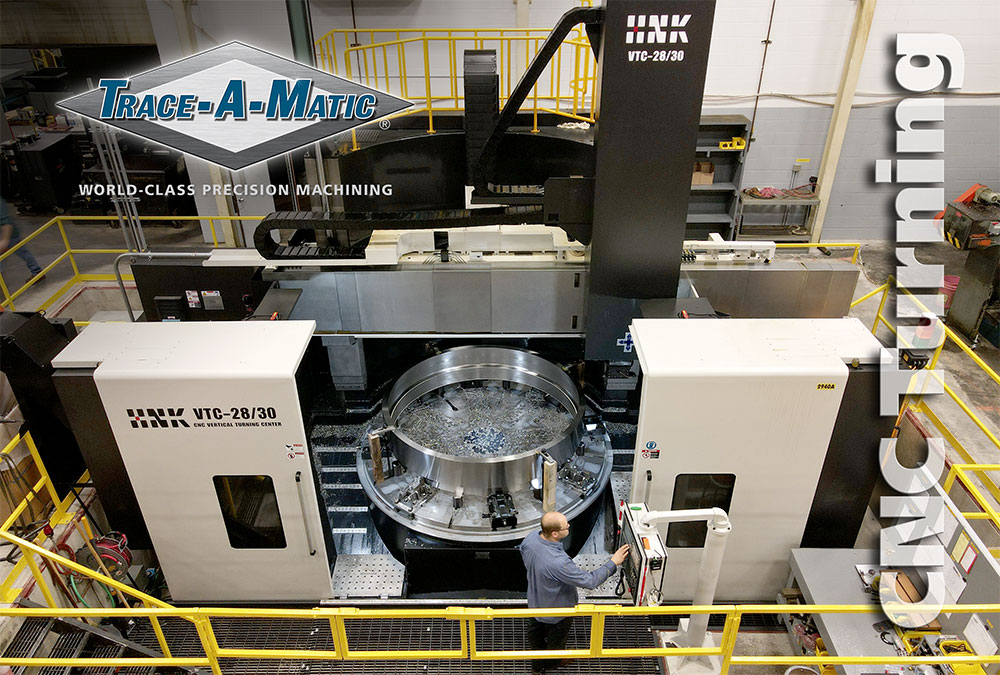

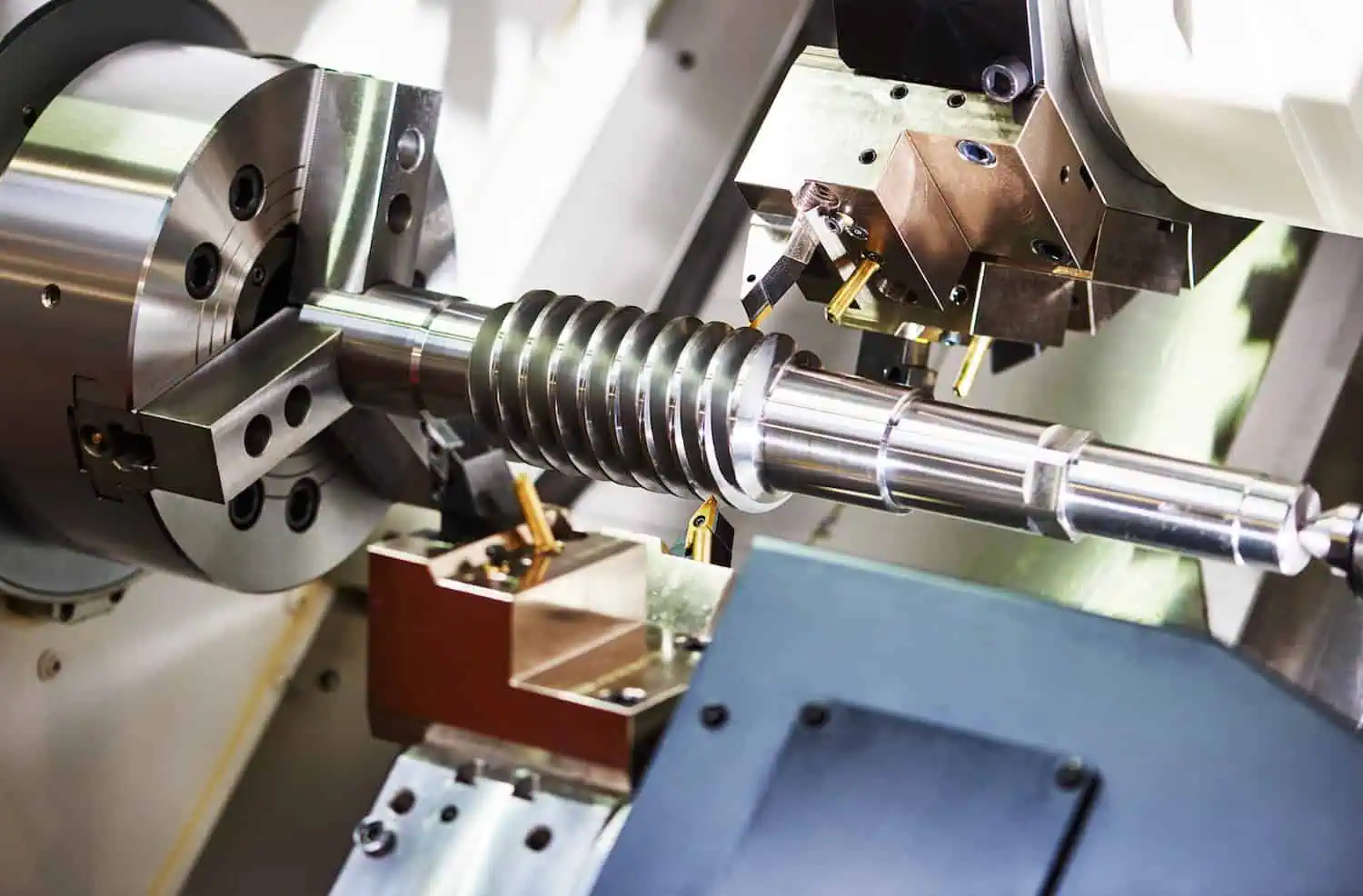

CNC turning centers represent the cornerstone of precision rotational machining, transforming raw bar stock or castings into complex cylindrical components through computer-controlled cutting processes. At Shenzhen Honyo Prototype, we leverage advanced multi-axis turning technology to deliver rapid, high-accuracy prototypes and low-volume production parts for industries demanding stringent tolerances and repeatable quality. Our turning centers integrate live tooling, Y-axis milling, and sub-spindles to perform turning, drilling, threading, and milling operations in a single setup—eliminating handling errors and significantly reducing lead times for intricate geometries. This capability is critical for clients developing medical devices, aerospace components, and automotive subsystems where form, fit, and function must be validated early in the design cycle.

Honyo’s manufacturing strategy prioritizes agility without compromising precision. Our facility houses modern CNC turning centers capable of machining a broad spectrum of materials, including aluminum alloys, stainless steels, titanium, brass, and engineering plastics. Each machine undergoes daily calibration and thermal compensation routines to maintain micron-level accuracy under varying production conditions. Crucially, our process integrates Design for Manufacturability (DFM) feedback at the quoting stage, enabling clients to optimize part geometry for cost efficiency and faster turnaround—often achieving first-article delivery within 3–5 business days for qualified projects.

The technical specifications of our primary turning platform underscore this commitment to performance. Key parameters are summarized below:

| Parameter | Specification | Relevance to Prototyping |

|——————–|———————|—————————————-|

| Maximum Spindle Speed | 8,000 RPM | Enables high-speed finishing of hard materials |

| Bar Capacity | Ø 20–42 mm | Accommodates common prototype stock sizes |

| Y-Axis Travel | ± 50 mm | Permits off-center milling and complex contouring |

| Positioning Accuracy | ± 0.003 mm | Ensures critical feature tolerances for assembly |

| Standard Tolerance | ± 0.01 mm | Meets typical aerospace/medical requirements |

Beyond machine capability, Honyo’s value lies in our closed-loop quality ecosystem. Every turning operation is monitored via in-process probes and post-machining CMM verification, with full inspection reports provided. Our engineers collaborate directly with client design teams to resolve manufacturability challenges—such as minimizing runout in thin-walled features or optimizing chip control for burr-sensitive applications. This proactive approach reduces iteration cycles and accelerates time-to-test for your prototypes.

For projects requiring rapid validation of rotational components, Honyo Prototype delivers the blend of technical precision, material expertise, and responsive engineering support essential for de-risking product development. Contact our manufacturing team to discuss how our CNC turning capabilities align with your next prototyping initiative.

Technical Capabilities

CNC Turning Center Machine – Technical Capabilities

Shenzhen Honyo Prototype utilizes advanced CNC turning center machines to deliver high-precision machined components for demanding industrial applications. Our multi-axis CNC turning centers integrate turning and milling operations in a single setup, enabling complex geometries with excellent surface finishes and tight dimensional control. These machines support 3-axis, 4-axis, and 5-axis configurations, allowing for increased flexibility in part design and manufacturing efficiency.

Our CNC turning centers are equipped with live tooling, Y-axis capability, and sub-spindles, enabling simultaneous turning and milling operations. This integration reduces cycle times and enhances accuracy by minimizing part handling and secondary setups. The 4-axis and 5-axis systems allow off-center milling, drilling, and contouring at multiple angles, making them ideal for complex, high-precision components used in aerospace, medical, automation, and automotive industries.

Tight tolerance machining is a core strength of our CNC turning process. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, with geometric tolerances maintained through in-process probing and high-resolution tool measurement systems. Our machines feature rigid construction, high-speed spindles (up to 12,000 RPM), and closed-loop feedback systems that ensure repeatability and long-term stability across production runs.

Material versatility is another key advantage. Our CNC turning centers process a wide range of engineering-grade metals and plastics, including aluminum, stainless steel, titanium, brass, copper alloys, and high-performance polymers such as PEEK and PTFE. Each material is machined using optimized cutting strategies, tooling, and coolant delivery to maintain surface integrity and dimensional accuracy.

Below is a summary of our standard machining capabilities and achievable tolerances across common materials:

| Feature | Specification |

|——–|—————|

| Machine Types | CNC Turning Centers with Live Tooling (3/4/5-Axis) |

| Spindle Speed | Up to 12,000 RPM |

| Bar Capacity | Up to Ø51 mm (2″) |

| Axis Configuration | 3-Axis (X, Z, C), 4-Axis (X, Z, C, Y), 5-Axis (X, Z, C, Y, B) |

| Minimum Feature Size | Ø1.0 mm internal/external features |

| Surface Finish | As low as Ra 0.4 µm (16 µin), achievable down to Ra 0.2 µm with polishing |

| Positional Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.003 mm (±0.0001″) |

| Material Category | Common Materials | Typical Tolerance (±) | Notes |

|——————|——————|————————|——-|

| Aluminum Alloys | 6061, 7075, 2024 | 0.010 mm | Excellent machinability, high strength-to-weight ratio |

| Stainless Steel | 303, 304, 316, 17-4 PH | 0.012 mm | Corrosion-resistant, suitable for medical and food-grade applications |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | 0.015 mm | High strength, low density; requires specialized tooling |

| Brass & Copper | C36000, C11000 | 0.010 mm | Good electrical conductivity, low friction |

| Engineering Plastics | PEEK, PTFE, Delrin, Nylon | 0.025 mm | Low moisture absorption, chemical resistance |

All components are inspected using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to ensure compliance with engineering drawings and quality standards. Shenzhen Honyo Prototype combines advanced CNC turning technology with rigorous process control to deliver precision-machined parts that meet the most stringent technical requirements.

From CAD to Part: The Process

CNC Turning Center Production Process: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC turning center workflow transforms your digital design into a high-precision physical component through a rigorously optimized sequence. This integrated process ensures manufacturability, quality, and rapid turnaround, critical for prototype and low-volume production demands. The journey begins immediately upon receipt of your CAD model.

AI-Powered Quoting Engine

Our proprietary AI system performs an instantaneous technical and cost analysis directly from your submitted 3D CAD file (STEP, IGES, or native formats). This engine evaluates geometric complexity, material requirements, tolerances, and surface finishes against our machine capabilities and material databases. It factors in toolpath complexity, estimated cycle time, material waste, and necessary secondary operations. This eliminates manual quoting delays, providing accurate cost and lead time projections within minutes, enabling faster project initiation and budgeting decisions for your team.

Engineering-Driven Design for Manufacturability (DFM)

Following the initial quote, Honyo’s senior manufacturing engineers conduct a comprehensive DFM review. This is not an automated check but a value-added engineering assessment. We scrutinize the design for optimal machinability on turning centers, identifying potential issues like thin walls prone to chatter, unnecessarily tight tolerances increasing cost, inefficient feature sequencing, or suboptimal material choices. Our engineers proactively suggest constructive modifications—such as adjusting radii, recommending standard drill sizes, or proposing feature consolidation—to enhance part integrity, reduce cycle time, minimize scrap, and lower overall cost, all while maintaining your functional requirements. Clear feedback and collaborative revision support are provided.

Precision CNC Turning Production

Approved designs move seamlessly into production on our state-of-the-art CNC turning centers. The process initiates with meticulous setup: qualified technicians verify the digital model against the program, select and calibrate optimal tooling from our extensive library, and establish precise workholding (chucks, collets, or bar feeders). The machine executes the rigorously validated CNC program, performing sequential operations—facing, turning, boring, grooving, threading, and drilling—often in a single setup using live tooling for milling or cross-drilling features. In-process gaging ensures critical dimensions remain within tolerance during machining. Upon completion, every part undergoes stringent first-article and batch inspection using calibrated CMMs, optical comparators, and surface roughness testers against the original CAD model and specifications. Final documentation, including dimensional reports, is provided before shipment.

Honyo’s integrated workflow, combining AI efficiency with deep engineering expertise and precision manufacturing, guarantees that your prototype parts meet exacting standards while accelerating your development cycle. Our machine capabilities are engineered to support this seamless transition:

| Parameter | Specification | Honyo Advantage |

| :—————– | :————————- | :———————————- |

| Max Turning Diameter | 200 mm (8″) | Accommodates most prototype sizes |

| Max Bar Capacity | 51 mm (2″) round | Efficient bar-fed production |

| Spindle Speed | 6,000 RPM | Optimized for speed & precision |

| Live Tooling | Standard (Y-axis optional) | Complex geometries in one setup |

| Positioning Accuracy | ±0.005 mm (0.0002″) | Critical for tight-tolerance parts |

| Control System | Fanuc 32i/31i | Industry-standard reliability |

This structured approach, from intelligent quoting through expert DFM to precise execution, ensures Honyo delivers functional, high-quality turned components on time, reducing your time-to-market for critical prototypes.

Start Your Project

Start Your CNC Turning Project with Honyo Prototype

When it comes to precision CNC turning, Shenzhen Honyo Prototype delivers engineering excellence and manufacturing reliability for prototyping and low-volume production. Our CNC turning center machines are engineered to handle complex geometries with tight tolerances, ensuring your parts meet exact design specifications. Whether you’re developing a functional prototype, validating a design, or preparing for scaled production, our advanced turning capabilities support a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics.

At Honyo Prototype, we understand that speed, accuracy, and repeatability are critical in today’s fast-moving product development cycles. Our CNC turning centers are equipped with live tooling, multi-axis functionality, and automated bar feeding systems, enabling us to produce intricate turned components in a single setup. This reduces lead times, minimizes human error, and improves consistency across batches.

Our team of experienced manufacturing engineers works closely with clients from the initial design review through final inspection. We provide Design for Manufacturability (DFM) feedback to optimize part geometry, material selection, and tolerancing—ensuring cost-effective production without compromising performance. From simple shafts to complex, multi-feature components, our CNC turning services support industries such as medical devices, aerospace, automotive, and industrial automation.

To ensure quality, every turned part undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. We maintain strict adherence to ISO 9001 standards, guaranteeing that each component meets international quality benchmarks.

| Feature | Specification |

|——–|—————|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 500 mm |

| Spindle Speed | Up to 6,000 RPM |

| Tolerance | ±0.005 mm typical |

| Axis Configuration | 2-axis to 7-axis |

| Bar Feed Compatibility | Yes, up to 65 mm diameter |

| Materials Supported | Aluminum, Steel, Stainless Steel, Brass, Titanium, Plastics (e.g., PEEK, Delrin) |

| Surface Finish | As low as Ra 0.4 µm |

We specialize in rapid turnaround without sacrificing precision. Most CNC turning projects are completed within 5 to 7 business days, with expedited options available for urgent requirements.

Ready to bring your design to life? Contact Susan Leo, our dedicated Project Manager, to discuss your CNC turning needs. Whether you have a 3D model, 2D drawing, or a concept sketch, we’ll provide a detailed quote and expert guidance to move your project forward efficiently.

Email Susan Leo at info@hy-proto.com to start your project today. Let Honyo Prototype be your trusted partner in high-precision CNC turning.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.