Contents

Manufacturing Insight: Aluminum Chromate Conversion

Aluminum Chromate Conversion: Essential Protection for Precision Prototypes

Aluminum chromate conversion coating, commonly specified as ASTM D1730 or MIL-DTL-5541, is a critical surface treatment for CNC-machined aluminum components requiring enhanced corrosion resistance and paint adhesion. This chemical conversion process forms a non-electrolytic, amorphous layer of chromium compounds on the aluminum substrate, effectively passivating the surface against oxidation. For prototyping applications—where parts may undergo rapid environmental testing or functional validation—this treatment mitigates premature failure due to galvanic corrosion, salt spray exposure, or humidity. Unlike anodizing, chromate conversion maintains tight dimensional tolerances (±0.0001″ typical for CNC prototypes) while providing a conductive base for grounding-sensitive electronics enclosures. At Honyo Prototype, we prioritize trivalent chromium (CrIII) processes exclusively, eliminating hazardous hexavalent chromium (CrVI) to ensure full REACH and RoHS compliance without sacrificing performance.

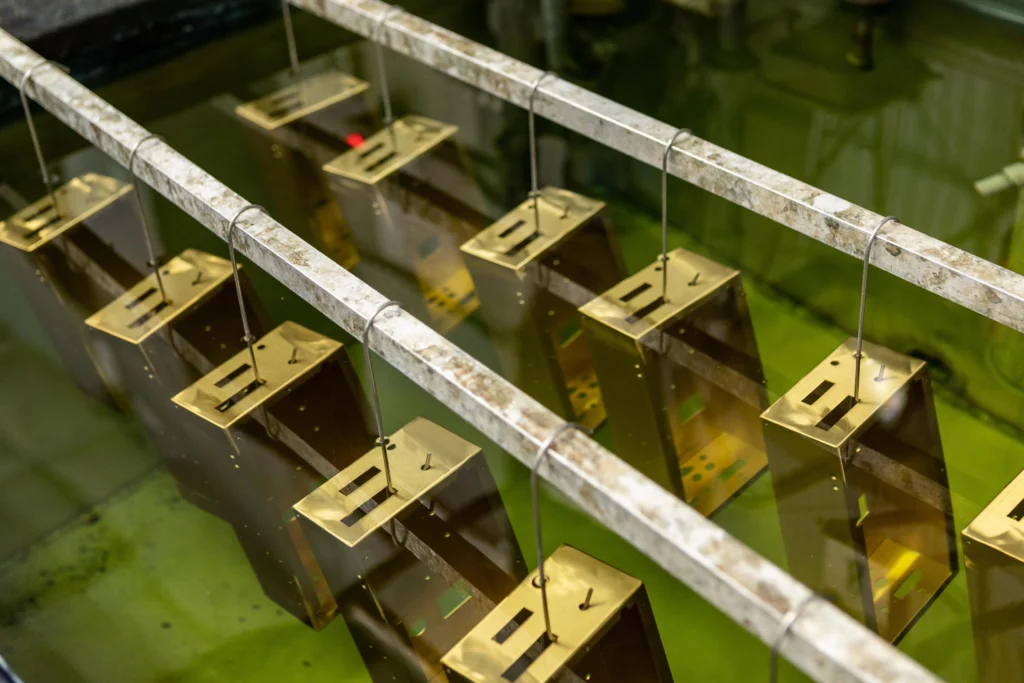

Our in-house chromate conversion line is engineered for prototype agility, supporting rapid turnaround from raw billet to finished part within 72 hours. The process begins with precision alkaline cleaning and deoxidizing to remove machining residues, followed by immersion in a temperature-controlled CrIII bath. This generates a thin, uniform film that self-heals minor scratches—a key advantage for prototypes subjected to iterative handling. The resulting coating is electrically conductive (surface resistivity <100 mΩ/sq), making it ideal for RF shields, drone frames, and medical device housings where EMI shielding or biocompatibility is critical. Honyo’s quality control includes continuous bath monitoring via ICP-MS spectroscopy to maintain optimal pH (3.8–4.2) and chromate concentration, ensuring batch-to-batch repeatability essential for engineering validation.

Honyo Prototype Chromate Conversion Specifications

| Parameter | Specification Range | Test Standard |

|——————–|—————————|——————-|

| Coating Type | Trivalent Chromium (CrIII)| ASTM D1730 Type IB|

| Film Thickness | 0.1–0.4 μm | ASTM B137 |

| Appearance | Clear to iridescent blue | Visual inspection |

| Salt Spray Resistance | 96–168 hours (no red rust)| ASTM B117 |

| Adhesion | 5B (cross-hatch) | ASTM D3359 |

| Electrical Conductivity | <100 mΩ/sq (surface) | ASTM D257 |

Honyo’s capability extends beyond standard specifications through adaptive process tuning for diverse aluminum alloys, including 2024, 6061, and 7075. We routinely validate coating integrity via cyclic corrosion testing (CCT) per GMW14872, simulating real-world conditions that accelerate failure in untreated prototypes. Crucially, our system accommodates complex geometries from CNC machining—such as deep pockets or thin walls—without hydrogen embrittlement risks associated with electroplating. This is particularly valuable for aerospace and automotive clients validating load-bearing prototypes under stress. By integrating chromate conversion directly into our CNC workflow, we eliminate third-party delays while guaranteeing that every treated part meets IPC-7525 stencil alignment requirements for subsequent conformal coating or painting. For engineers requiring accelerated development cycles, Honyo delivers not just compliance, but confidence in prototype longevity.

Technical Capabilities

Aluminum Chromate Conversion Coating at Shenzhen Honyo Prototype

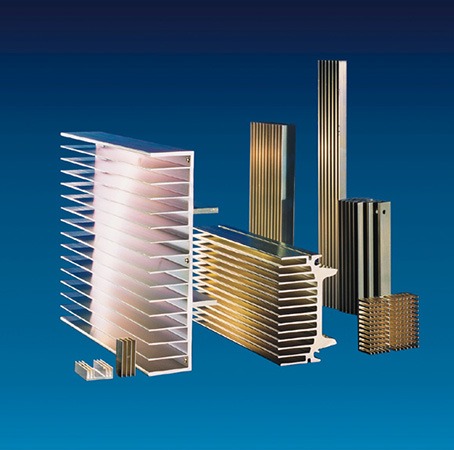

At Shenzhen Honyo Prototype, aluminum chromate conversion coating is a critical surface treatment process integrated into our precision CNC machining workflow. This chemical conversion process enhances the corrosion resistance, paint adhesion, and electrical conductivity of aluminum components, making it ideal for aerospace, defense, medical, and industrial applications where reliability under harsh environments is essential. Our chromate conversion process is compatible with a wide range of aluminum alloys commonly used in 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations.

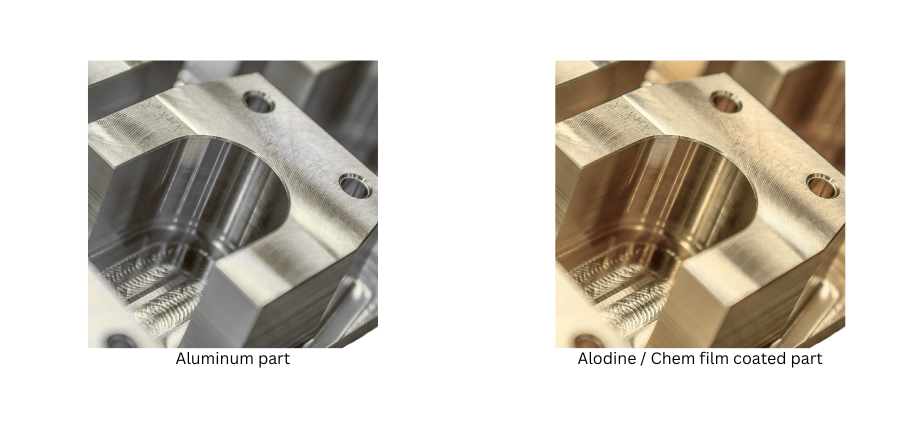

The chromate conversion process involves immersing machined aluminum parts in a chromic acid-based solution, forming a protective amorphous layer of chromium oxide and chromium hydroxide on the surface. This coating is self-healing in nature, meaning minor surface scratches can re-passivate, maintaining protective integrity. The resulting finish is typically iridescent yellow to gold in appearance, though variations exist depending on alloy composition and process parameters. The coating is thin—typically between 0.00001” to 0.00004” (0.25 to 1.0 µm)—ensuring no dimensional changes that could affect tight tolerance features.

Our in-house chromate conversion line is optimized for post-machining treatment of complex geometries produced via multi-axis CNC milling and turning. Components with intricate contours, deep pockets, or thin walls are processed with strict control over immersion time, temperature, and solution concentration to ensure uniform coverage and adherence to MIL-DTL-5541 and AMS-C-5541 standards. We routinely process parts machined to ±0.0002” (±0.005 mm) tolerances, with the coating process designed not to compromise these tight specifications.

All chromate-treated parts undergo rigorous quality inspection, including adhesion testing, corrosion resistance evaluation via salt spray testing (per ASTM B117), and visual inspection for coating uniformity. We maintain batch traceability and process documentation for full compliance with industry and customer requirements.

Below is a summary of compatible materials and achievable tolerances for machined aluminum components treated with chromate conversion at Honyo Prototype:

| Material Alloy | Temper | Typical Applications | Compatible with Chromate Conversion | Typical Machining Tolerance (±) |

|—————-|——–|———————-|————————————-|———————————|

| 6061 | T6 | Aerospace, Structural | Yes | 0.0002” (0.005 mm) |

| 7075 | T6 | High-Strength Parts | Yes | 0.0002” (0.005 mm) |

| 2024 | T3/T4 | Aircraft Components | Yes | 0.0003” (0.008 mm) |

| 5052 | H32 | Marine, Chemical | Yes | 0.0003” (0.008 mm) |

| 6063 | T5/T6 | Architectural, Light Duty | Yes | 0.0002” (0.005 mm) |

Shenzhen Honyo Prototype combines precision CNC machining with controlled surface treatment processes to deliver fully functional, durable aluminum components. Our chromate conversion capability supports high-mix, low-volume prototyping and production runs with rapid turnaround, ensuring that every part meets exacting engineering and environmental standards.

From CAD to Part: The Process

Aluminum Chromate Conversion: Integrated Production Workflow for CNC Prototypes

At Shenzhen Honyo Prototype, our CNC machining services for aluminum prototypes integrate chromate conversion coating as a critical surface finishing step within a streamlined, technology-driven workflow. This ensures optimal corrosion resistance, paint adhesion, and electrical conductivity for demanding OEM applications, directly supporting your design validation and functional testing objectives. The process begins upon receipt of your native CAD file, which is immediately processed by our proprietary AI-powered quoting system. This system performs rapid, multi-faceted analysis of geometric complexity, material selection (focusing on common aerospace and industrial alloys like 6061-T6 and 7075-T6), feature tolerances, and surface finish requirements. Crucially, it identifies early indicators where chromate conversion will be necessary or beneficial based on the part’s intended environment and function, providing an accurate, detailed cost and lead time estimate within minutes, not hours.

Following quote acceptance, the Design for Manufacturability (DFM) phase commences as a collaborative engineering dialogue. Our senior manufacturing engineers rigorously review the CAD model, specifically evaluating factors impacting the chromate conversion success. This includes assessing wall thickness for uniform coating deposition, identifying potential trap points for solution retention, verifying hole sizes and aspect ratios for adequate rinsing, and confirming material suitability. We proactively suggest design refinements, such as adding drainage holes or adjusting radii, to eliminate defects like smut or uneven coating, ensuring the final part meets both your dimensional and performance specifications without costly rework. This stage is vital for preventing adhesion failures or corrosion hotspots post-coating.

Production initiates with precision CNC machining using optimized toolpaths and strict environmental controls to minimize surface contamination. Immediately post-machining, parts undergo a meticulously controlled pre-treatment sequence: alkaline cleaning to remove oils, acid etching for uniform surface activation, and deoxidizing to eliminate smut. The chromate conversion bath application follows, governed by stringent parameters to achieve the required coating weight and performance characteristics. Key process specifications are maintained as follows:

| Parameter | Standard Specification (Type I) | Standard Specification (Type II) | Control Tolerance |

| :—————– | :—————————— | :——————————- | :—————- |

| Bath Composition | Hexavalent Chromium Based | Trivalent Chromium Based | N/A |

| Operating Temp | 20-25°C (68-77°F) | 30-40°C (86-104°F) | ±1°C |

| Dwell Time | 30-60 seconds | 60-120 seconds | ±2 seconds |

| Coating Weight | 150-300 mg/ft² | 200-400 mg/ft² | ±25 mg/ft² |

| Final Rinse Conductivity | < 50 µS/cm | < 50 µS/cm | Continuous Monitored |

Following the chromate dip, thorough multi-stage counter-current rinsing removes residual chemicals, and parts are dried in low-humidity ovens. Final inspection employs ASTM B117 salt spray testing (minimum 96 hours for Type I, 120+ hours for Type II), coating weight verification per ASTM D1654, and visual checks against AMS-C-5541 or MIL-DTL-5541 standards. This integrated workflow—from AI-driven quoting through DFM collaboration to precisely controlled production and finishing—guarantees your aluminum CNC prototype delivers the required surface performance, accelerating your path from digital model to certified physical part.

Start Your Project

Aluminum Chromate Conversion: A Critical Step in High-Performance CNC Machining

At Shenzhen Honyo Prototype, we specialize in precision CNC machining solutions tailored for industries that demand reliability, corrosion resistance, and long-term performance. One of the most effective surface treatments we offer for aluminum components is chromate conversion coating—a process that enhances durability while maintaining electrical conductivity and dimensional stability.

Chromate conversion coating, also known as chem film or alodine, is an essential post-machining treatment for aluminum parts exposed to harsh environments. This chemical process creates a protective layer that inhibits corrosion, improves paint adhesion, and preserves the base metal’s conductivity—making it ideal for aerospace, defense, telecommunications, and industrial applications where both performance and compliance are critical.

Unlike anodizing, which builds a thick oxide layer through electrolysis, chromate conversion forms a thin, conductive film through a room-temperature chemical reaction. This makes it especially suitable for components with tight tolerances or those requiring grounding capabilities. The resulting finish can range from clear and golden to olive drab, depending on the specific chemistry used and customer requirements.

At Honyo Prototype, we apply chromate conversion coatings in accordance with industry standards such as MIL-DTL-5541 and AMS-C-5541, ensuring consistent quality and regulatory compliance. Our facility is equipped to handle low-volume prototypes and high-volume production runs with equal precision, and every batch undergoes rigorous quality checks for coating thickness, adhesion, and corrosion resistance.

We understand that project success begins long before the first cut is made. That’s why our engineering team works closely with clients during the design and material selection phase to determine the optimal surface treatment strategy. Whether you’re machining 6061-T6, 7075-T6, or custom aluminum alloys, we provide end-to-end support—from DFM analysis to final finishing.

Below is a summary of our standard chromate conversion specifications:

| Parameter | Specification |

|————————–|—————————————————-|

| Applicable Alloys | 2024, 6061, 7075, and other wrought aluminum alloys |

| Coating Type | Type I (Hexavalent) and Type II (Trivalent) |

| Compliance Standards | MIL-DTL-5541 Class 1A & 3, AMS-C-5541 |

| Typical Colors | Clear, iridescent, golden yellow, olive drab |

| Coating Thickness | 0.00001″ – 0.00004″ (0.25 – 1.0 µm) |

| Electrical Resistance | Low; suitable for EMI/RFI grounding applications |

| Corrosion Resistance | 16–120+ hours salt spray (ASTM B117) |

| Curing Requirements | Air dry at ambient temperature; no heat required |

All treatments are performed in-house under controlled conditions, ensuring repeatability and traceability. We also offer compatibility testing for subsequent processes such as painting, bonding, or gasket installation.

Starting your next CNC machining project with the right surface finish can significantly impact performance and longevity. Let our team guide you through the selection process and ensure your components meet both functional and regulatory demands.

For technical consultation or to submit your design files, contact Susan Leo at info@hy-proto.com. We respond to all inquiries within 12 business hours and provide detailed feedback, including lead times and pricing, to help you move forward efficiently.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.