Contents

Manufacturing Insight: Cnc Workholding

Precision Workholding: The Unseen Foundation of CNC Accuracy

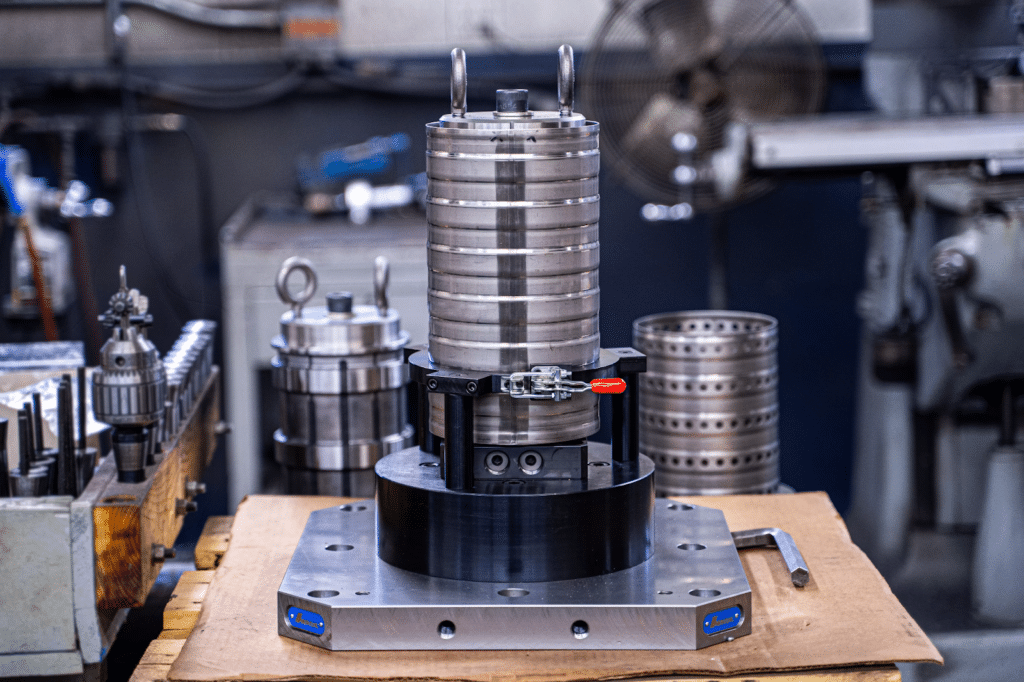

Effective CNC workholding is non-negotiable for achieving micron-level tolerances and repeatability in precision prototyping and low-volume production. At Shenzhen Honyo Prototype, we recognize that suboptimal fixturing directly compromises part quality, throughput, and cost-efficiency. Workholding systems must securely immobilize components against cutting forces while minimizing deformation, thermal drift, and machine vibration. Poorly designed fixtures introduce errors that propagate through the machining process, leading to scrap, rework, and extended lead times. Our engineering approach treats workholding as an integrated component of the CNC process—not an afterthought—ensuring optimal force distribution, accessibility for multi-axis operations, and rapid changeover to support agile manufacturing.

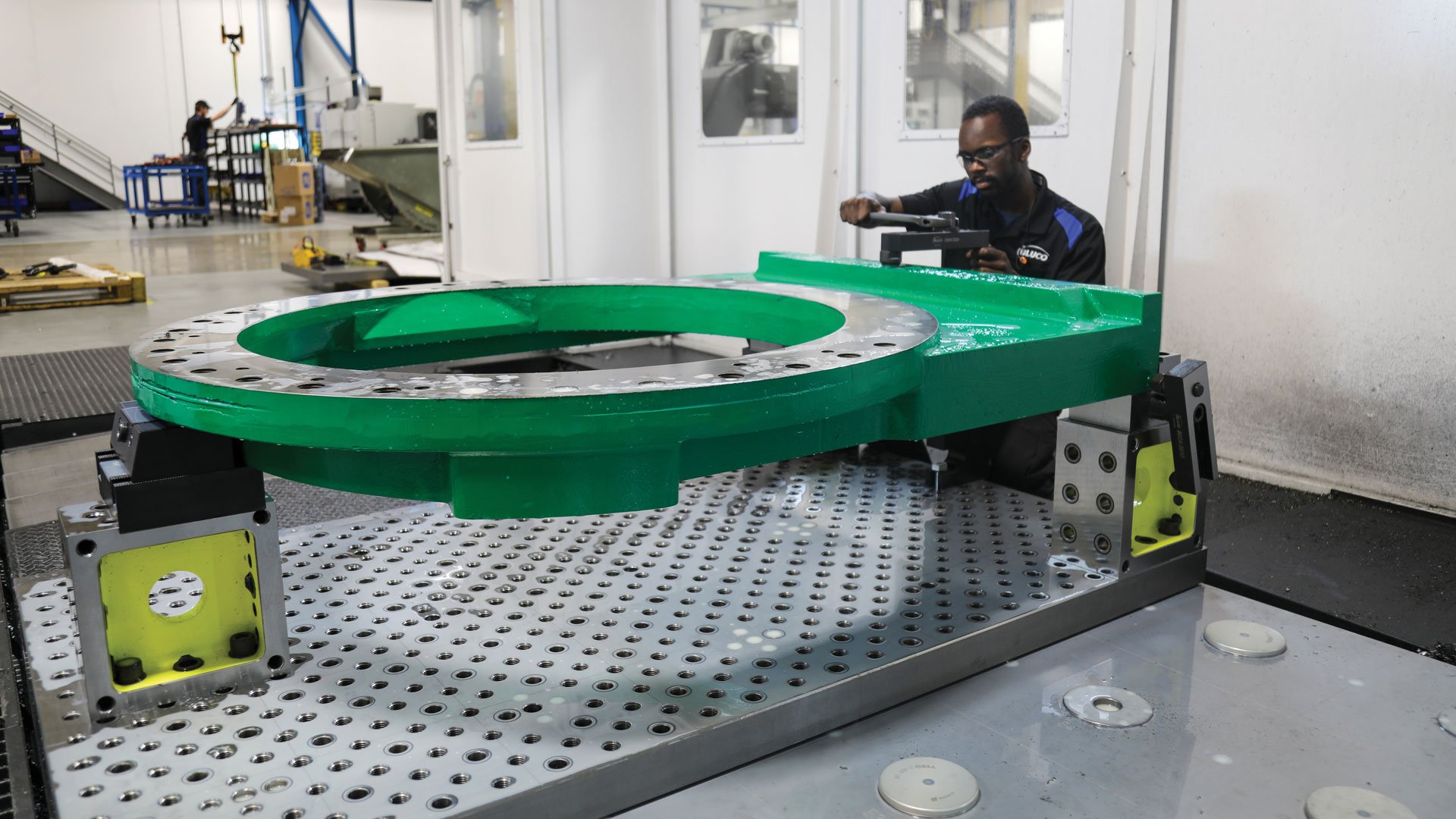

Honyo implements a rigorous methodology for workholding design, beginning with Finite Element Analysis (FEA) to simulate stress points and deflection under load. This predictive modeling allows us to select or engineer fixtures that maintain geometric integrity during high-speed milling, turning, or grinding. We prioritize modular vise systems, custom soft jaws, and vacuum chucks tailored to part geometry, material properties, and machining sequence. For complex 5-axis components, our engineers develop tombstone setups with precision-ground locators and calibrated clamping points to ensure consistent datum alignment across operations. Material selection is equally critical; we utilize hardened tool steel for durability in high-force applications and aluminum alloys for lightweight, non-marring requirements in delicate prototypes. All fixtures undergo metrology validation using CMMs to verify positional repeatability before deployment.

Our capabilities span diverse workholding solutions optimized for rapid prototyping demands. The table below outlines key specifications for our standard and custom fixture systems:

| Parameter | Standard System Range | Custom System Capability | Verification Method |

|—————————|————————|—————————|—————————|

| Clamping Force Range | 5–50 kN | Up to 120 kN | Load Cell Calibration |

| Positional Repeatability | ≤ 0.010 mm | ≤ 0.005 mm | CMM (ISO 10360-2) |

| Material Options | Tool Steel, Aluminum | Carbide, Composite | Material Certificates |

| Max Work Envelope | 600 x 400 x 300 mm | 1200 x 800 x 500 mm | Laser Tracker Scan |

| Compatible Machines | 3/4/5-Axis Mills, Lathes| Multi-Spindle Systems | Machine Interface Testing |

This technical rigor translates to tangible client benefits: reduced setup times by 30–50%, near-zero fixture-induced scrap, and the ability to hold tolerances as tight as ±0.005 mm on first-article prototypes. We collaborate with clients during DFM reviews to co-engineer workholding strategies that align with part critical-to-quality (CTQ) features, ensuring manufacturability without compromising design intent. For aerospace, medical, and automotive sectors—where regulatory compliance is paramount—our documentation includes full traceability of fixture calibration and maintenance logs.

At Honyo, workholding excellence is embedded in our manufacturing DNA. By treating fixture design as a core engineering discipline, we deliver not just parts, but guaranteed process stability from the first cut to final inspection. This commitment underpins our reputation for solving the most demanding precision machining challenges in Shenzhen’s advanced manufacturing ecosystem.

Technical Capabilities

CNC Workholding: Precision Fixturing for High-Performance Machining

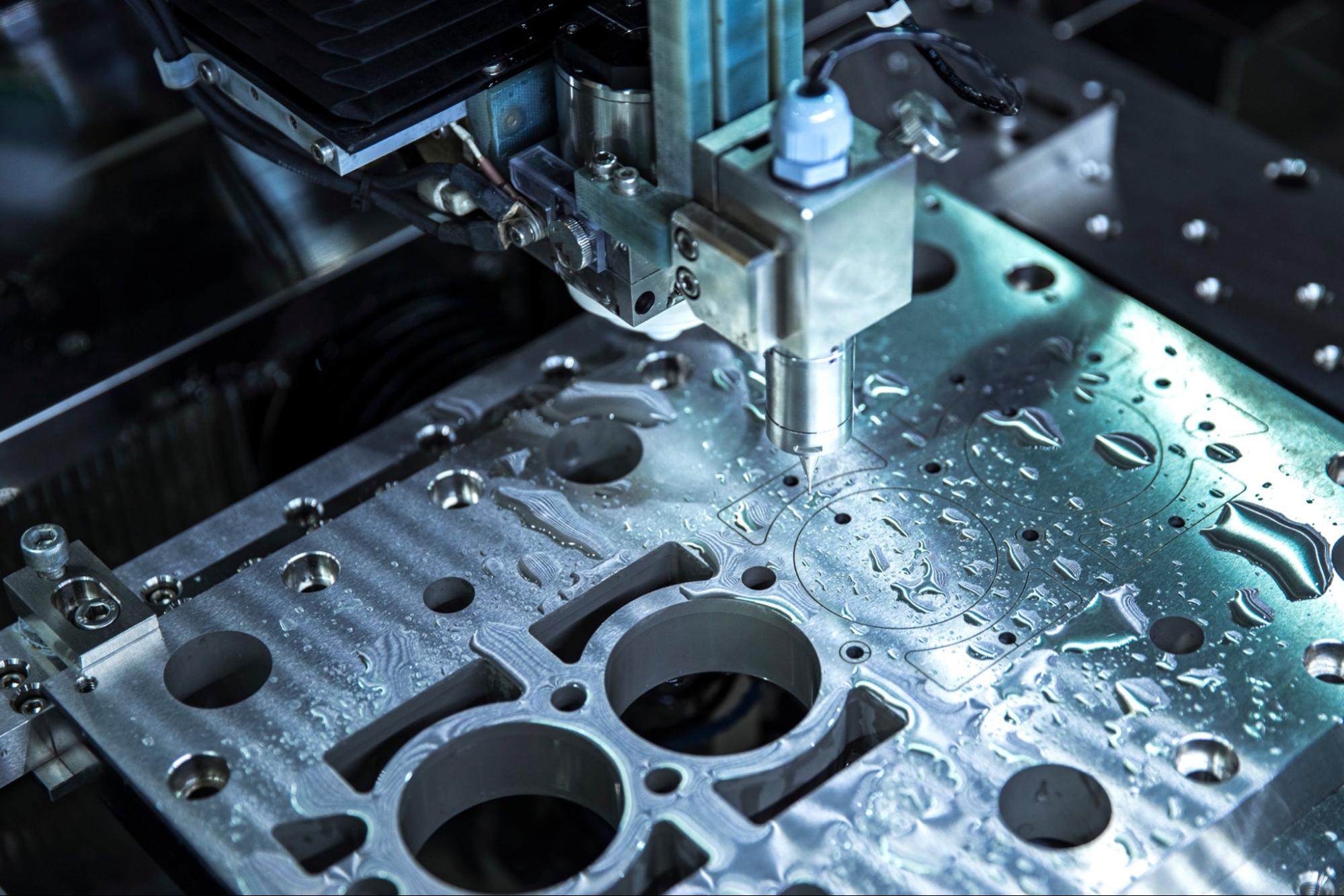

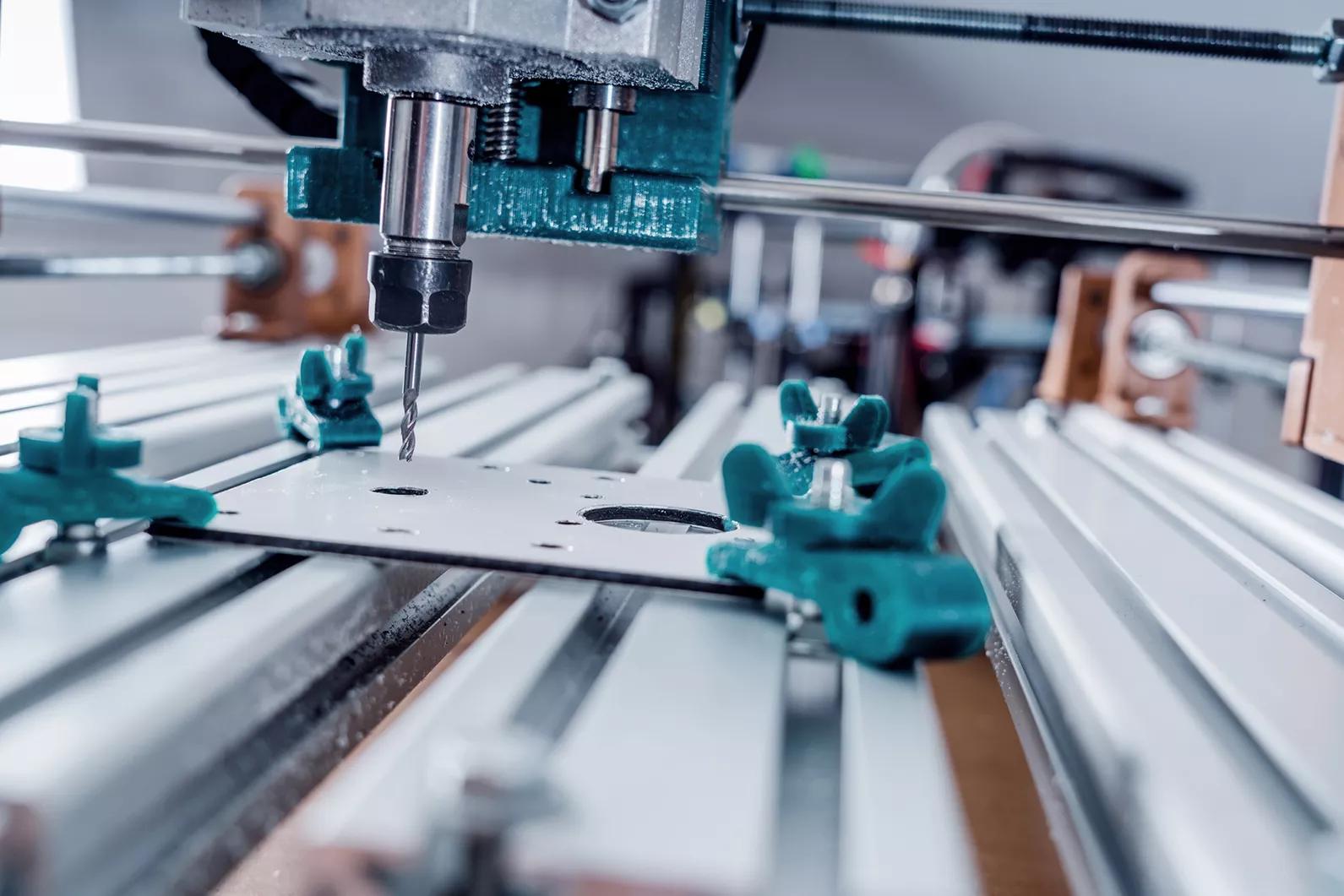

At Shenzhen Honyo Prototype, our CNC workholding solutions are engineered to support the exacting demands of 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations. Our advanced fixturing systems ensure component stability, minimize deflection, and maintain geometric accuracy throughout the machining cycle—critical for achieving tight tolerances and superior surface finishes. We utilize modular vices, custom fixtures, rotary tables, and collet chucks, all designed for rapid setup, repeatability, and compatibility across diverse material families.

For 3-axis milling, we deploy high-precision mechanical vices with parallel jaws and T-slot bases, ensuring consistent clamping force and alignment. These are ideal for prismatic components and high-volume prototypes. In 4-axis and 5-axis applications, we integrate indexing and continuous rotary tables with zero-backlash gear drives, allowing for complex contouring and multi-sided machining with minimal repositioning. Our turning setups use pneumatic and hydraulic chucks with live centers to secure cylindrical and asymmetrical parts, reducing runout and vibration.

All workholding systems are calibrated to maintain positional repeatability within ±0.002 mm, supporting our capability to hold tight tolerances down to ±0.005 mm for critical dimensions. Vacuum chucks and soft jaws are employed for delicate or thin-walled components, preventing deformation while maintaining accuracy. Custom fixture plates with grid hole patterns allow for quick changeover and are CNC trammed to within 0.003 mm TIR for alignment integrity.

Our in-house design team develops application-specific fixtures using CAD/CAM integration, ensuring optimal accessibility for tool paths and maximum rigidity. These fixtures are manufactured from hardened tool steel or aerospace-grade aluminum, depending on duty cycle and part geometry, and are surface-treated for wear resistance.

The following table outlines our standard workholding capabilities and achievable tolerances across common material types:

| Material Type | Max Tolerance (± mm) | Surface Finish (Ra µm) | Recommended Workholding Method |

|———————|———————–|————————-|—————————————-|

| Aluminum Alloys | 0.005 | 0.8–1.6 | Soft-jaw vices, vacuum plates |

| Stainless Steel | 0.008 | 1.6–3.2 | Hydraulic chucks, modular vices |

| Titanium Alloys | 0.010 | 1.6–3.2 | Custom fixtures, low-vibration chucks |

| Engineering Plastics | 0.020 | 3.2–6.3 | Vacuum tables, low-pressure clamps |

| Brass & Copper | 0.010 | 1.6–3.2 | Collet chucks, soft jaws |

We maintain strict calibration schedules for all workholding equipment, verified monthly using laser alignment systems and coordinate measuring machines (CMM). This disciplined approach ensures long-term reliability and consistency across production runs. Our capabilities support industries requiring high repeatability, including aerospace, medical devices, and precision optics.

Shenzhen Honyo Prototype’s investment in advanced CNC workholding technology enables us to deliver high-accuracy prototypes and low-volume production parts with confidence, speed, and dimensional integrity.

From CAD to Part: The Process

CNC Workholding Workflow: From CAD to Finished Part at Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining workflow integrates workholding strategy from the earliest quoting phase through production to ensure precision, efficiency, and cost control. Workholding is never an afterthought; it directly impacts lead time, part integrity, and overall manufacturability. Our structured process begins with AI-powered quoting, advances through rigorous Design for Manufacturability (DFM) analysis, and culminates in optimized production setup.

The workflow initiates with the AI Quote Phase, where our proprietary system analyzes submitted CAD geometry to generate an instant preliminary quote. Crucially, the AI assesses basic workholding requirements—such as part size, feature accessibility, and material type—to estimate fixture complexity and machine time. For instance, a part requiring multi-sided machining triggers an initial assessment of vise usage versus custom fixture needs. This early evaluation prevents unrealistic quoting by accounting for workholding constraints before engineering resources are allocated. Clients receive transparent cost drivers, including potential workholding surcharges for complex setups.

Next, the DFM Analysis Phase rigorously evaluates workholding feasibility. Our engineers collaborate with clients to refine designs, focusing on features that simplify fixturing. Key considerations include datum selection, clamping surface availability, and minimizing secondary operations. We provide actionable feedback, such as recommending strategic stock additions for vacuum chuck compatibility or adjusting tolerances to accommodate modular fixture components. Below is a summary of critical DFM workholding parameters we assess:

| Parameter | Critical Factor | Honyo Standard Practice |

|——————–|——————————————-|———————————————|

| Datum Reference | Alignment with machine axes | Standardized 3-2-1 principle implementation |

| Clamping Force | Part deformation risk | FEA-simulated force mapping for soft materials |

| Feature Access | Tool path interference | Virtual fixture simulation in Mastercam |

| Secondary Ops | Fixture repositioning needs | Modular pallet system compatibility check |

This phase reduces non-recurring engineering costs by 30–50% through early identification of workholding conflicts. Clients receive a detailed DFM report with annotated CAD suggestions, ensuring designs align with our production ecosystem.

Finally, the Production Phase executes the validated workholding plan. Based on DFM outcomes, our technicians deploy standardized solutions—such as Kurt vises, hydraulic chucks, or custom soft jaws—prioritizing repeatability and minimal setup time. For high-mix prototyping, we leverage modular fixturing systems to achieve <15-minute changeovers. Real-time in-process verification, including probe-based work offset calibration, ensures dimensional accuracy despite thermal drift or clamping variables. Every workholding configuration undergoes pre-production dry runs to validate accessibility and cycle time estimates.

By embedding workholding intelligence across the AI Quote, DFM, and Production stages, Honyo Prototype eliminates costly mid-process revisions and accelerates time-to-part. This integrated approach guarantees that your design transitions seamlessly from digital model to precision-machined component, with workholding optimized for both technical rigor and economic efficiency. Clients benefit from predictable lead times, reduced scrap rates, and parts that consistently meet tight tolerances—proving that strategic fixturing is foundational to successful CNC prototyping.

Start Your Project

Start Your CNC Machining Project with Precision Workholding from Shenzhen Honyo Prototype

When launching a CNC machining project, the foundation of accuracy, repeatability, and efficiency lies in effective workholding. At Shenzhen Honyo Prototype, we understand that secure and precise part fixation isn’t just a step in the process—it’s a critical determinant of final part quality. Whether you’re producing complex aerospace components, medical devices, or high-tolerance industrial prototypes, selecting the right workholding solution ensures optimal tool engagement, minimizes vibration, and reduces cycle times.

Our engineering team specializes in custom and standard CNC workholding systems tailored to your specific geometry, material, and production volume. From vises and clamps to modular fixturing and vacuum chucks, we evaluate your project requirements to recommend the most efficient and cost-effective method. We integrate advanced simulation tools to validate clamping forces and prevent part deformation, especially for thin-walled or delicate components.

At Honyo Prototype, we combine decades of machining expertise with state-of-the-art CNC equipment to deliver workholding solutions that enhance both productivity and precision. Our facility supports 3-axis, 4-axis, and 5-axis machining processes, and our fixturing strategies are designed to maximize machine uptime and part accessibility while minimizing setup changes.

We also offer complete project lifecycle support—from initial design consultation and DFM analysis to final inspection and delivery. Our quality management system adheres to ISO 9001 standards, ensuring every fixture and machined component meets stringent tolerance and reliability requirements.

To ensure your project starts on the right footing, we encourage direct collaboration with our lead manufacturing engineer, Susan Leo. With extensive experience in high-precision CNC operations and custom fixture development, Susan oversees client technical onboarding and ensures seamless integration of workholding strategies into your production workflow.

Contact Susan Leo today to discuss your CNC workholding needs. Whether you’re preparing for low-volume prototyping or transitioning to full-scale production, our team is ready to provide expert guidance and customized solutions. Reach out via email at info@hy-proto.com to schedule a consultation, share your CAD files, or request a project quote.

Partner with Shenzhen Honyo Prototype to transform your CNC machining performance through intelligent workholding design and precision engineering.

| Feature | Specification |

|——–|—————|

| Workholding Types | Mechanical clamps, vises, custom fixtures, modular systems, vacuum chucks |

| Compatible Machining Centers | 3-axis, 4-axis, 5-axis CNC mills and routers |

| Materials Supported | Aluminum, steel, titanium, plastics, composites |

| Tolerance Capability | As tight as ±0.005 mm |

| Design Tools | CAD/CAM integration, FEA simulation for clamping analysis |

| Quality Standards | ISO 9001 certified processes, first-article inspection, GD&T compliance |

| Lead Time (Typical) | 3–7 days for standard setups; 7–14 days for custom fixtures |

Start your project with confidence—connect with Susan Leo at info@hy-proto.com and experience the Honyo difference in CNC workholding excellence.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.