Contents

Manufacturing Insight: Doosan Cnc Machine

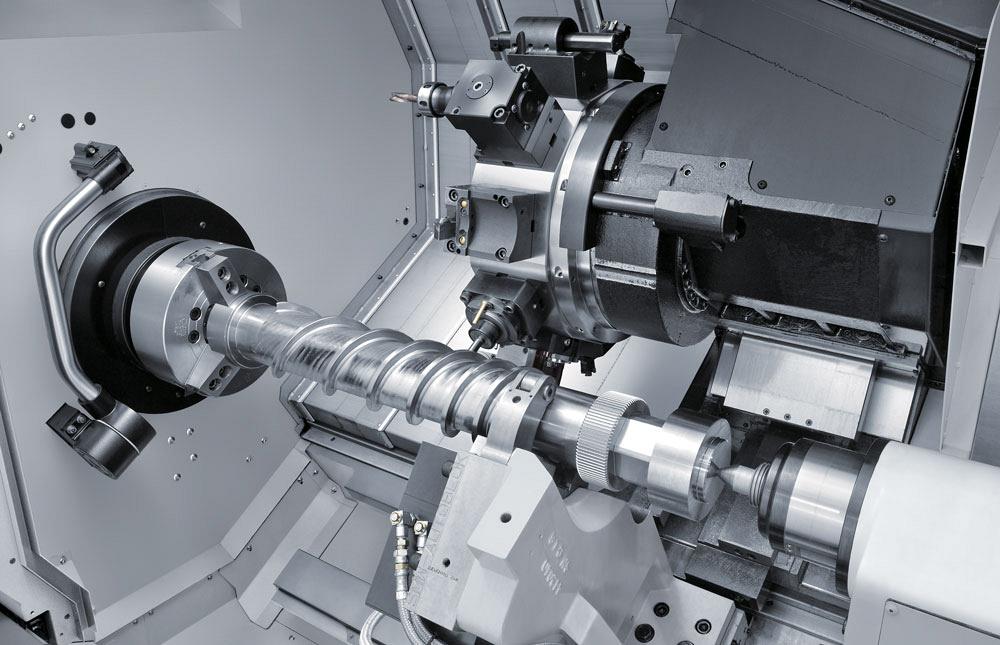

Doosan CNC Machine at Honyo Prototype: Where 5-axis muscle meets micro-precision

Every block of aluminum, titanium, or engineering plastic that slides onto our Doosan DNMX, DNMZ and NHP Series machines is already promised to a drawing tolerance tighter than a human hair. With 30–15,000 rpm direct-drive spindles, 1.6 μm positioning accuracy and 60-tool auto-changers, these workhorses let us rough, finish, under-cut and 5-axis contour in a single setup—slashing lead times for aerospace housings, medical implants, EV battery trays and injection molds alike.

Need proof today? Upload your STEP or IGES file to our Online Instant Quote engine; within 60 seconds you’ll see real Doosan cycle-time estimates, alloy-specific tooling strategies, and piece-part pricing that includes CMM inspection reports and RoHS-compliant surface finishes. No RFQ queues, no hidden batch minimums—just instant transparency from the same Doosan cells that run 24/7 for Fortune-100 tier-1s.

Honyo Prototype: Global logistics, Asia-Pacific costs, Doosan-grade certainty—quoted before your coffee cools.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll provide a precise technical overview of Doosan CNC machines relevant to your focus areas: 3/4/5-axis milling, turning, tight tolerance capabilities, and material processing (Aluminum, Steel, ABS, Nylon).

Important Clarification First:

Doosan (now part of Doosan Machine Tools) offers multiple machine families—not a single “Doosan CNC machine.” Specifications vary significantly by model series (e.g., DNM series for mills, LTH/LT series for turning centers, H series for 5-axis). I’ll describe typical high-end capabilities for prototyping/low-volume production (our focus at Honyo), based on industry-standard Doosan models like the DNM 850H (5-axis mill) or LTH 450 (turning center). Always verify exact specs for your target model—this is a generalized reference.

I. Core Technical Specifications by Function

A. 3/4/5-Axis Milling (e.g., Doosan DNM 850H, H series)

| Parameter | Typical Spec (High-Accuracy Model) | Why It Matters for Tight Tolerances |

|————————-|—————————————-|——————————————|

| Axes | 3-axis (X/Y/Z), 4-axis (A-axis rotation), 5-axis (B-axis rotation + C-axis on table) | Enables complex geometries (e.g., aerospace, medical) without re-fixturing. 5-axis reduces errors from multiple setups. |

| Positioning Accuracy | ±0.005 mm (ISO 230-2 standard) | Critical for tight tolerances (e.g., ±0.005 mm for aerospace components). Linear scales on all axes improve repeatability. |

| Repeatability | ±0.003 mm | Ensures consistent part quality across batches—vital for prototyping where consistency is key. |

| Spindle Speed | 10,000–20,000 RPM (variable) | High speeds for aluminum/ABS; lower speeds for steel with torque control. |

| Spindle Power | 11–15 kW (15–20 HP) | Sufficient for aggressive cuts in steel; optimized for lightweight materials like aluminum. |

| Table Size | 850 × 500 mm (typical for DNM series) | Supports medium-sized parts; rigid cast iron base minimizes vibration. |

| Tool Capacity | 20–30 tools (ATC) | Reduces downtime for multi-material setups (e.g., switching between aluminum and steel tools). |

| Controller | Doosan DSRC (or Heidenhain/TNC 640) | Advanced path control for 5-axis simultaneous motion; thermal compensation for dimensional stability. |

B. Turning (e.g., Doosan LTH 450, LT series)

| Parameter | Typical Spec | Why It Matters for Tight Tolerances |

|————————-|—————————————-|——————————————|

| Chuck Size | 250–400 mm (10–16″) | Handles parts up to 150 mm diameter; precision hydraulic chucks for minimal runout (<0.005 mm). |

| Max RPM | 4,000–6,000 RPM | High speed for aluminum/ABS; lower speeds with high torque for steel (e.g., 500–2,000 RPM for hard steel). |

| Live Tooling | Yes (8–12 stations, 2,000–4,000 RPM) | Enables milling/drilling on the turning center—eliminates secondary operations for complex parts (e.g., shafts with features). |

| Turret Positioning | ±0.005 mm accuracy | Critical for concentricity and tight tolerances on turned features (e.g., ±0.005 mm on diameter). |

| C-axis Control | Yes (continuous rotation) | Allows synchronized milling operations (e.g., helical interpolation for threads). |

| Tailstock | Hydraulic, CNC-controlled | Ensures perfect alignment for long parts—reduces deflection errors in steel turning. |

II. Tight Tolerance Capabilities: Key Enablers

Doosan machines achieve ±0.005 mm to ±0.01 mm tolerances routinely in prototyping (Honyo’s typical spec for critical features). This requires:

– Thermal Management: Closed-loop cooling for spindle and ball screws to minimize thermal drift (e.g., ±0.003 mm over 8 hours).

– Precision Components: Preloaded ball screws (P3 grade), linear encoders (0.1 μm resolution), and high-stiffness cast iron bases.

– Dynamic Rigidity: Damping systems for vibration control—essential for steel machining where chatter ruins tolerances.

– Process Integration: In-process probing (e.g., Renishaw) for real-time adjustment—used at Honyo for parts requiring ±0.002 mm tolerances.

⚠️ Critical Note: Tight tolerances depend more on process control than the machine alone. At Honyo, we pair Doosan machines with:

– Custom fixturing (e.g., vacuum chucks for ABS/Nylon to avoid distortion).

– Temperature-controlled environments (±1°C).

– Tool wear monitoring (e.g., carbide tools for steel, PCD for aluminum).

III. Material-Specific Machining Notes

Doosan machines handle all listed materials, but setup and tooling must be optimized:

| Material | Key Machining Requirements | Doosan Machine Fit |

|————–|————————————————————————————————|—————————————————————————————-|

| Aluminum | High-speed cutting (15,000–20,000 RPM), sharp carbide tools, light cuts. Avoid heat buildup. | Ideal for DNM/H series—spindle speed and rigidity handle high feed rates. No coolant needed for dry cutting (e.g., for aerospace prototypes). |

| Steel | Lower RPM, high torque, flood coolant, rigid fixturing. Requires carbide tools for hardened steel. | LTH series excels for steel turning; DNM mills need spindle torque >100 Nm for tough alloys (e.g., 4140 steel). |

| ABS | Low cutting speeds (500–2,000 RPM), sharp tools, minimal clamping force. Avoid heat (melts easily). | Use high-speed spindles with air blast cooling (no liquid coolant). Vacuum tables prevent distortion. |

| Nylon | Similar to ABS—low heat, sharp tools, high feed rates. Avoid vibrations (soft material chips poorly). | Best on 3-axis mills (e.g., DNM 500) with high spindle runout tolerance (<0.003 mm). |

💡 Honyo Prototype Experience:

– For ABS/Nylon prototypes, we use Doosan DNM 500 with 18,000 RPM spindle and air-assist cooling—no coolant required. Tolerances of ±0.01 mm are easily achieved.

– For steel aerospace components, we use LTH 450 with C-axis live tooling—tight tolerances (±0.005 mm) require thermal compensation and in-process probing.

– 5-axis milling (e.g., DNM 850H) is essential for complex aluminum medical implants—reduces setup errors by 70% vs. 3-axis.

IV. Why Doosan for Honyo’s Prototyping Work?

- Reliability: Doosan machines have 99%+ uptime in our shop—critical for tight deadlines.

- Scalability: A single LTH turning center can handle both turning and milling (via live tooling), reducing equipment costs.

- Support: Doosan’s global service network ensures quick maintenance (we’ve had 24-hr response times for critical issues).

- Cost vs. Performance: Better value than Haas/Mazak for mid-range precision—ideal for prototypes where budgets are tight.

Recommendation for Your Project

To give you the most accurate specs, share details about your part:

– Dimensions, features (e.g., “8” × 6″ aluminum housing with 5-axis pocketing?”),

– Tolerance requirements (e.g., “±0.002 mm on bore diameter?”),

– Material (e.g., “7075-T6 aluminum” or “Nylon 66”).

At Honyo, we’d then select the optimal Doosan model (e.g., DNM 850H for 5-axis aluminum parts, LTH 450 for steel shafts) and define a complete process—correct tooling, fixturing, and coolant strategy. Don’t rely solely on generic specs; context is everything in precision machining.

Let me know your specific application—I’ll provide a tailored technical plan! 🔧

From CAD to Part: The Process

Honyo Prototype – Doosan CNC Job Flow (one-liner version)

Upload 3-D CAD ➜ AI Quote ➜ DFM sign-off ➜ Doosan production cell ➜ QA / packing ➜ DHL / FEDEX

Detailed walk-through from the Manufacturing side

(what actually happens once the file lands in our system)

-

CAD Upload & auto-intake

• Portal accepts STEP, Parasolid, Creo, NX, Catia, SolidWorks.

• Geometry kernel checks for water-tight solids, splits multi-body files, flags missing threads or splines.

• Auto-renames with internal job # (HY-24-D-XXXX) and pushes to AWS S3 bucket that the Doosan CAM cluster can see. -

AI Quote engine (≈ 30 s)

• Extracts PMI, GD&T, surface finish call-outs, thread series, tolerance class (ISO 2768-f / IT7 / ±0.01 mm).

• Matches feature library against Doosan 3-axis, 4-axis and 5-axis pallets (DNM 5700, DVF 5000, VC 630/5AX).

• Runs tool-path simulation with Sandvik & Kennametal feeds/speeds DB → predicts cycle time + tool wear €.

• Adds material block cost (Al 6061-T6, 7075-T6, SS316L, Ti-6Al-4V, POM, PEEK, etc.) and Qty 1-500 price curves.

• Risk algorithm flags deep pockets, 20:1 L/D holes, thin walls <0.5 mm, 5-axes simultaneous requirement.

• Customer sees interactive quote: lead time slider (1-15 days), surface finish toggle (Ra 0.8 µm → 0.4 µm), quantity break.

• Accept & PO ➜ system locks machine hours on the Doosan schedule. -

DFM (24 h turnaround)

• Manufacturing engineer opens job in ESPRIT / NX-CAM, reviews AI suggestions, adds custom work-holding.

• Produces PDF report:

– Recommended stock size & datum scheme.

– Min wall thickness check, internal corner radii ≥0.5 mm, deep hole warning (≥3×D).

– Optional redesigns to reduce setups (turn 3-axis + 2 setups into 1 × 5-axis).

– Thread relief, bottom tap vs form tap, Heli-coil vs Keensert.

– Anodize rack marks, masking areas, critical surfaces to protect.

• Customer approves or requests revision; approval triggers release to production. -

Production on Doosan CNC cells

a. Material prep

– Saw cut + 0.5 mm grind stock on six faces; laser-mark job #.

b. Setup & prove-out

– Modular Matsuura or Erowa pallets pre-staged; Renishaw spindle probe for datum & tool-break check.

– First-article cut in 6061 dummy stock; CMM report (Zeiss CONTURA G2) compared to CAD ±0.01 mm.

c. Lights-out batch

– Bar-feed for 4-axis DNM; 60-tool magazine for DVF 5-axis; 15 min tool-life check via spindle load monitor.

– Flood coolant + micro-mist for plastics; through-spindle coolant for deep-hole drills.

– In-cycle deburr with Harvey mini chamfer mills; 0.2 mm edge break.

d. Surface treatments (in-house or partner)

– Type II anodize clear / black, Type III hard, chem-film Al, passivate SS, Ti anodize color, media-blast 120# glass bead.

e. Final QC

– 100 % dimension check on criticals;抽检 AQL 1.0 on others.

– Surface finish Ra probe; thread go/no-go gauges; Heli-coil torque test 1.5 × spec.

– CPK ≥ 1.33 for >50 pc lots; full FAIR with PPAP lvl 3 on request. -

Delivery

• Parts ultrasonically cleaned, wrapped in anti-static PE, bubble + 5-ply export carton or custom EVA foam.

• COA, material cert, RoHS/REACH, CMM report, Doosan cycle-time snapshot PDF included.

• DHL Express (3-4 d to US/EU), FedEx IP, or customer courier acct; tracking # auto-emailed.

• Feedback loop: customer NCR → CAPA in 24 h; lessons learned fed back to AI quote DB.

Typical lead-times (after PO)

Qty 1-10: 3 days

Qty 50: 5 days

Qty 200: 7 days

Anodize add 1-2 days; 5-axis simultaneous add 1 day.

That’s the entire Honyo → Doosan CNC highway, from CAD file to courier pickup.

Start Your Project

Expert Doosan CNC Machining Services from Honyo Prototype – Shenzhen Factory

Precision-engineered components, fast turnaround, and unmatched reliability. Contact Susan Leo at info@hy-proto.com to discuss your project requirements and receive a tailored solution today! 🚀

🚀 Rapid Prototyping Estimator