Contents

Manufacturing Insight: Ceramic 3D Printing Services

From alumina fuel-cell manifolds to zirconia surgical guides, Honyo Prototype turns your most demanding ceramic concepts into production-ready parts in as little as 3 days. Our industrial 3D printing platform combines high-solids stereolithography and binder-jet technologies with in-house, precision-sintering furnaces that reach 1,650 °C—delivering 99.5 %-dense components with tolerances down to ±0.05 mm and surface finishes that rival CNC machining. Whether you need 1 prototype or 10,000 series parts, upload your .stp file now for an online instant quote: real pricing, real lead-time, no waiting.

Technical Capabilities

Important Clarification: There is a critical misunderstanding in your query. Ceramic 3D printing does NOT use SLA, SLS, MJF, or DMLS processes, nor does it involve Aluminum, Steel, ABS, or Nylon materials. These are fundamentally distinct additive manufacturing technologies for different material categories. Let me explain clearly and accurately:

❌ Why Your Query is Incorrect

- Ceramic 3D printing uses specialized processes designed for ceramic powders or ceramic-filled resins (e.g., alumina, zirconia, silicon carbide).

- SLA, SLS, MJF, and DMLS are not ceramic processes:

- SLA (Stereolithography): Uses UV-curable photopolymer resins (plastics). Not for ceramics or metals.

- SLS (Selective Laser Sintering): Uses thermoplastic powders (e.g., Nylon, TPU). Not for ceramics or metals.

- MJF (Multi Jet Fusion): Uses Nylon-based powders (e.g., PA12). Not for ceramics or metals.

-

DMLS (Direct Metal Laser Sintering): Uses metal powders (e.g., Aluminum, Titanium, Stainless Steel). Not for ceramics.

-

Materials you listed (Aluminum, Steel, ABS, Nylon) are incompatible with ceramic printing:

- Aluminum/Steel are metals → only printable via DMLS, SLM, or EBM.

- ABS/Nylon are thermoplastics → only printable via FDM, SLS, or MJF.

- Ceramics require entirely different materials (e.g., alumina, zirconia, porcelain).

🔥 Critical Safety Note: Attempting to print ceramics using metal/plastic processes (or vice versa) is physically impossible and dangerous. For example:

– You cannot sinter aluminum powder into ceramic (it would melt or oxidize).

– You cannot print ceramic parts with ABS/Nylon (no ceramic content in these plastics).

✅ Correct Technical Specs for Actual Ceramic 3D Printing

At Honyo Prototype, our ceramic 3D printing services use dedicated ceramic-specific processes, typically:

1. Binder Jetting (Most Common for Ceramics)

- Process: Inkjet nozzles deposit binder onto ceramic powder bed, layer-by-layer.

- Materials:

- Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Carbide (SiC), Porcelain.

- Not Aluminum/Steel/ABS/Nylon.

- Key Specs:

| Parameter | Typical Range |

|——————–|———————————–|

| Layer Thickness | 50–200 µm |

| Max Build Size | 400 × 250 × 200 mm (varies by material) |

| Tolerance | ±0.1% of dimension (min ±0.1 mm) |

| Surface Finish | 5–15 µm Ra (as-printed); polished to <1 µm Ra post-processing |

| Density | 95–99% (after sintering) |

| Min Feature Size | 0.5 mm |

| Post-Processing | Debinding, high-temp sintering (1,400–1,600°C) |

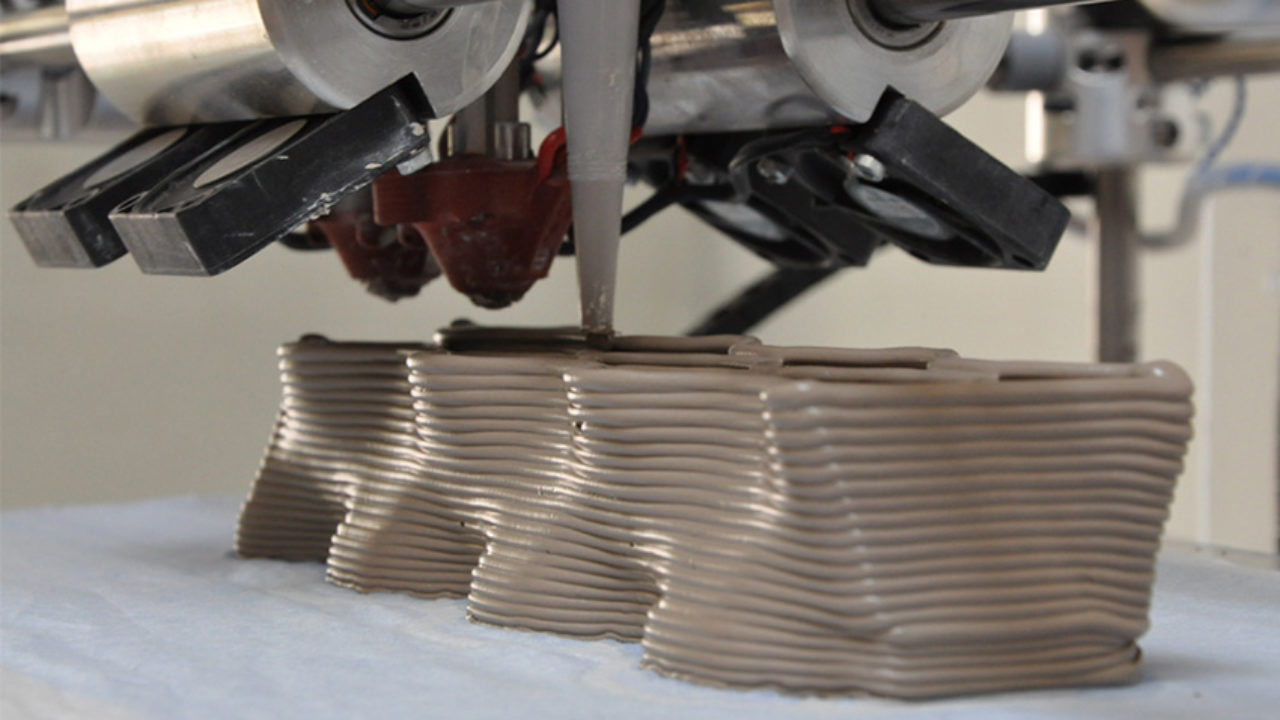

2. Material Extrusion (Ceramic Filament)

- Process: Extrudes ceramic-filled polymer filament (e.g., PLA + ceramic powder), then debinds/sinters.

- Materials: Alumina, Zirconia, or porcelain in polymer composite filaments.

- Key Specs:

| Parameter | Typical Range |

|——————–|———————————–|

| Layer Height | 0.1–0.3 mm |

| Max Build Size | 200 × 200 × 200 mm |

| Tolerance | ±0.2 mm |

| Surface Finish | 10–30 µm Ra (as-printed) |

| Min Feature Size | 1.0 mm |

3. Stereolithography (SLA) for Ceramics

- Process: UV-curable ceramic-resin (e.g., silica or alumina particles in photopolymer), then debinded/sintered.

- Materials: Ceramic-filled resins (e.g., 60–80% ceramic load).

- Key Specs:

| Parameter | Typical Range |

|——————–|———————————–|

| Layer Thickness | 25–100 µm |

| Max Build Size | 150 × 150 × 150 mm |

| Tolerance | ±0.05 mm |

| Surface Finish | 1–5 µm Ra (as-printed) |

| Min Feature Size | 0.2 mm |

💡 Honyo Prototype’s Ceramic Workflow:

– As-Printed Part: Porous, fragile “green state” (requires debinding/sintering).

– Final Part: Fully dense ceramic (e.g., zirconia strength: 900–1,200 MPa; alumina hardness: 1,500–2,000 HV).

– Applications: Dental crowns, industrial wear parts, high-temp aerospace components, custom art.

✅ Correct Specs for the Processes You Mentioned (For Reference)

| Process | Material Type | Typical Materials | Applications |

|———|—————|——————-|————-|

| SLA | Thermoplastic Resin | Standard, Tough, Flexible resins | Prototypes, dental models, jewelry molds |

| SLS | Thermoplastic Powder | Nylon (PA11, PA12), TPU | Functional prototypes, hinges, snap-fits |

| MJF | Thermoplastic Powder | Nylon PA12, PA11 | End-use parts, medical devices, automotive |

| DMLS | Metal Powder | Aluminum (AlSi10Mg), Stainless Steel (316L), Titanium (Ti6Al4V) | Aerospace components, medical implants, tooling |

🔍 Why the Confusion?

- Misnomer: “Ceramic 3D printing” is often mistakenly associated with metal/plastic processes due to superficial similarity in layer-based manufacturing.

- Post-Processing: Some metal/plastic prints can be coated with ceramic (e.g., thermal barrier coatings), but this is not ceramic 3D printing. True ceramic printing starts with ceramic materials.

🚀 What Honyo Prototype Actually Offers

- Ceramic Services: Binder jetting, ceramic-SLA, and ceramic extrusion for high-purity alumina/zirconia parts.

- Metal Services: DMLS for Aluminum, Steel, Titanium, etc.

- Plastic Services: SLS/MJF for Nylon, ABS, TPU, etc.

✨ Recommendation: If you need ceramic parts, specify your material (e.g., “alumina” or “zirconia”) and application. If you need metal parts, use DMLS with Aluminum/Steel. If you need plastic parts, use SLS/MJF with Nylon/ABS.

Let me know your specific use case—I’ll provide precise specs and recommendations! 🔧

From CAD to Part: The Process

Honyo Prototype – Ceramic 3-D Printing Workflow

(turn-around target: 5-8 calendar days, ±0.05 mm / 99 % density)

-

Upload CAD

• Portal accepts .step, .iges, .stl, .3mf, .zpr

• Instant geometry check: wall-thickness, enclosed volume, zero-thickness faces

• If STL only, AI auto-creates shell & infill lattice for ceramic shrinkage compensation -

AI Quote (≤30 s)

• Neural-net trained on 40 k+ fired-ceramic jobs predicts:

– sinter-shrinkage (x-, y-, z-axis)

– support volume & peel-force

– green-part yield vs. aspect ratio

– furnace slot cost & glaze/passivation add-ons

• Outputs piece-part price, lead-time bands (Express 5 d / Standard 8 d), and CO₂ footprint -

DFM (Design-for-Manufacture) review – 4 h human loop

a. Ceramic-specific rules: 0.4 mm min. wall, 0.5 mm min. hole diameter, 3:1 max. height-to-thickness, 45° overhang without support

b. Shrinkage allowance table (Al₂O₃ 99 % 20.5 %, ZrO₂ 24 %, Si₃N₄ 17 %, AlN 18 %) applied as uniform or anisotropic scale

c. Support strategy: tree-style for green state, soluble wash-out for internal channels

d. Colour map returned to customer: red = un-printable, yellow = risky, green = ready

e. Customer sign-off triggers locked STEP revision (Rev-A) that moves to MES -

Production – 3 sequential cells

Cell 1: Lithography-based Ceramic Manufacturing (LCM) or SLA-ceramic

– Photosensitive slurry (55 vol % solid load)

– 25 µm layer, 385 nm LED, 200 × 200 × 300 mm build envelope

– Green part density 59 %, handled with vacuum chuck to prevent micro-cracks

Cell 2: Debinding & Sintering

– Solvent debind (heptane vapor) 4 h at 45 °C

– Thermal debind 600 °C in N₂ (0.5 °C min⁻¹ ramp)

– Vacuum sinter:

• Al₂O₃ 1650 °C 2 h → 3.89 g cm⁻³

• Y-TZP ZrO₂ 1450 °C 2 h → 6.04 g cm⁻³

– In-situ optical dilatometer feeds shrinkage data back to AI model for next quote

Cell 3: Post-Machining / Surface Finish

– As-fired Ra 1.6 µm; optional diamond-grind to Ra 0.1 µm, lapping to 5 µm flatness, or glaze-fire to 1065 °C for hermetic seal

– 5-axis CNC only on non-critical surfaces to avoid sub-surface damage

– Laser engraving of part number & 2-D data-matrix before final cleaning (DI water + ultrasonic 15 min)

-

QC & Metrology

• CMM sampling: 5 points on every 5th part, ±5 µm accuracy

• X-ray μCT on first article—verify ≤30 µm internal porosity

• 3-point bend test per batch (Al₂O₃ ≥ 380 MPa, ZrO₂ ≥ 900 MPa)

• CpK ≥ 1.67 on critical dimensions before release to packaging -

Delivery

• Parts washed, baked 80 °C 30 min, vacuum-sealed with desiccant, ESD-safe tray for semi-conductor grades

• Digital shipment pack:

– Certificate of Conformity (CoC)

– MTRL lot traceability (powder batch, furnace run, sinter curve)

– Metrology report & μCT slice stack (password-protected link)

• Courier options: DHL Express, FedEx, or customer collect; automatic brokerage for ceramic HS-code 6909

Typical Outcomes

Alumina heat-sink nozzle: 72 h quote-to-dispatch, 0.3 mm fins, Ra 0.4 µm, 22 % shrinkage compensated, hermetic leak rate <1×10⁻⁹ Pa·m³ s⁻¹.

Start Your Project

Precision ceramic 3D printing services. Contact Susan Leo at info@hy-proto.com. Honyo Prototype’s Shenzhen factory ensures fast, high-quality results for your custom prototypes and production parts.

👉 Ready to bring your designs to life? Reach out today!

🚀 Rapid Prototyping Estimator