Contents

Manufacturing Insight: Granite Cnc Machines

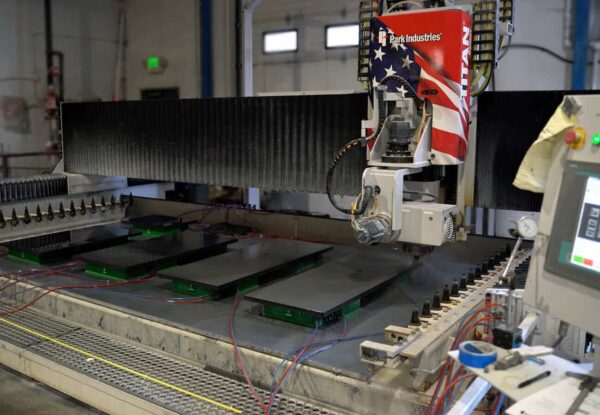

Manufacturing Insight: Granite CNC Machines at Shenzhen Honyo Prototype

Granite CNC machines represent a significant advancement in precision manufacturing infrastructure, particularly for applications demanding exceptional stability and micron-level accuracy. Unlike traditional cast iron bases, high-grade granite exhibits superior inherent damping properties, absorbing vibration up to 3-4 times more effectively. This characteristic is critical in environments susceptible to external disturbances—such as urban factories or multi-machine cells—and is fundamental for achieving consistent surface finishes and tight tolerances on complex geometries, especially during fine finishing operations or when machining thin-walled components. Furthermore, granite possesses a coefficient of thermal expansion approximately half that of steel or cast iron, significantly reducing thermally induced errors during prolonged machining cycles or in facilities with variable ambient temperatures. This thermal stability translates directly to improved part repeatability and reduced need for thermal compensation routines.

At Shenzhen Honyo Prototype, we leverage these material advantages through our dedicated fleet of high-precision granite CNC machining centers. We utilize only premium optical-grade granite (typically grade zero or better), rigorously selected for homogeneity and minimal internal stress. Our machines are engineered with optimized structural designs that maximize the material’s inherent benefits while addressing granite’s challenges, such as weight management and precise fabrication. Critical to our implementation is a proprietary kinematic mounting system that isolates the granite base from foundation vibrations without inducing stress points, ensuring long-term geometric integrity. This meticulous integration process is as vital as the material choice itself.

The performance outcomes of our granite-based CNC platforms are quantifiable and directly impact client deliverables. Below are key specifications representative of our core high-precision machining centers:

| Performance Parameter | Granite Base CNC Specification | Typical Cast Iron Base Equivalent |

| :————————– | :—————————– | :——————————– |

| Vibration Damping Ratio | 0.04 – 0.06 | 0.01 – 0.015 |

| Coefficient of Thermal Expansion (10⁻⁶/°C) | 7.5 – 8.5 | 10.5 – 12.5 |

| Positioning Accuracy (ISO 230-2) | ≤ ±1.5 µm over 300mm | ≤ ±3.0 µm over 300mm |

| Repeatability (ISO 230-2) | ≤ ±0.8 µm | ≤ ±1.5 µm |

| Surface Finish Capability (Ra) | < 0.4 µm (on suitable materials) | Typically > 0.8 µm |

Shenzhen Honyo Prototype’s commitment to granite CNC technology stems from our core mission: delivering uncompromised precision for demanding sectors including aerospace prototyping, medical device components, and high-end optical fixtures. The inherent stability of our granite platforms minimizes process variation, reduces scrap rates on critical features, and enables us to consistently hold tolerances down to ±3µm. This capability is not merely theoretical; it is validated daily through rigorous in-process measurement using calibrated CMMs and laser interferometers, ensuring the dimensional integrity our clients require for first-article submissions and low-volume production. When your project demands the ultimate in geometric fidelity and surface perfection, Honyo’s granite CNC infrastructure provides the foundational stability necessary for success.

Technical Capabilities

Technical Capabilities of Granite CNC Machines at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our granite-based CNC machining systems represent the pinnacle of precision engineering for advanced manufacturing applications. Built on a foundation of high-grade granite composite bases, these machines deliver superior thermal stability, vibration damping, and geometric accuracy, making them ideal for high-tolerance 3-axis, 4-axis, and 5-axis milling operations as well as precision turning. The inherent rigidity of the granite structure minimizes deflection during high-speed cutting, ensuring consistent part quality across complex geometries and demanding production cycles.

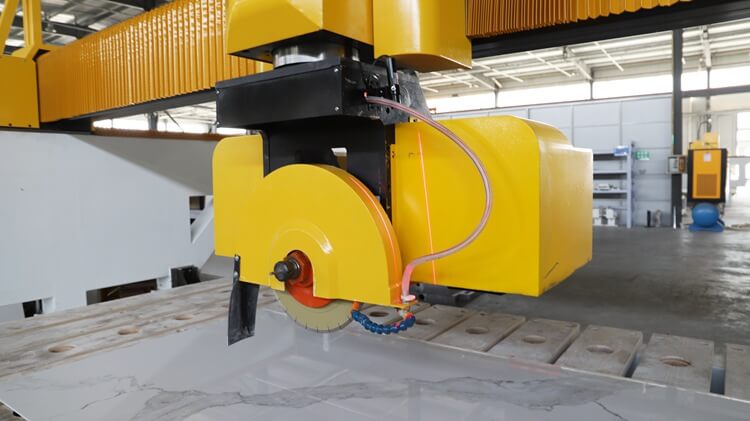

Our 3-axis CNC granite machines are optimized for high-speed milling of intricate 2D and 3D components, with rapid traverse rates up to 40 m/min and spindle speeds reaching 24,000 RPM. These systems are particularly effective for mold making, aerospace components, and medical device prototyping where surface finish and dimensional accuracy are critical. For more complex parts requiring multi-sided machining, our 4-axis and 5-axis configurations enable simultaneous multi-directional tool access, reducing setup times and improving feature alignment. The rotary axis positioning accuracy of ±2 arc seconds ensures precise angular control, essential for turbine blades, impellers, and structural aerospace fittings.

In addition to milling, our integrated turning capabilities on select granite-platform machines allow for mill-turn operations, combining the precision of CNC lathes with multi-axis milling in a single setup. This hybrid approach is especially beneficial for high-precision shafts, connectors, and housings requiring both rotational symmetry and complex secondary features.

Tight tolerance machining is a core strength of our granite CNC platform. We consistently achieve tolerances down to ±0.002 mm for linear dimensions and ±0.005 mm for geometric features such as flatness, concentricity, and positional accuracy. Surface finishes as fine as Ra 0.2 µm are routinely attainable, supporting requirements for optical, semiconductor, and fluid dynamics applications.

The following table outlines our standard capability ranges for tolerances and compatible materials:

| Parameter | Specification |

|—————————-|—————————————————-|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Linear Dimensional Tolerance | ±0.002 mm |

| Geometric Tolerance | ±0.005 mm (flatness, runout, position) |

| Angular Tolerance (4/5-axis)| ±2 arc seconds |

| Surface Finish (milled) | Ra 0.2 – 1.6 µm |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Rapid Traverse | Up to 40 m/min |

| Material Category | Examples |

|—————————-|—————————————————-|

| Metals | Aluminum 7075, 6061; Stainless Steel 303, 316; Titanium Grade 5; Inconel 718; Brass C360 |

| Plastics | PEEK, PTFE, PPS, Ultem, Acetal, Polycarbonate |

| Composites | Carbon Fiber Reinforced Polymers, G10, FR4 |

These capabilities are supported by state-of-the-art CNC controls, in-process probing, and environmental monitoring systems to ensure long-term stability and repeatability. At Honyo Prototype, our granite CNC machines enable the production of mission-critical components where precision, reliability, and material versatility are non-negotiable.

From CAD to Part: The Process

From CAD to Precision Part: Granite CNC Machining Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our granite CNC machining process transforms client CAD models into high-precision functional prototypes and low-volume production parts through a rigorously defined workflow. This structured approach ensures optimal quality, efficiency, and cost-effectiveness, leveraging the inherent stability of granite machine bases for superior dimensional accuracy. The journey begins with the AI-Powered Quotation phase, where our proprietary system rapidly analyzes uploaded CAD files. This AI engine assesses geometric complexity, material requirements, feature tolerances, and surface finish specifications against our production capabilities and real-time shop floor data. It generates a highly accurate, data-driven cost estimate and lead time within minutes, providing immediate transparency and enabling faster project initiation compared to manual quoting methods. This initial step significantly reduces administrative overhead for both Honyo and our clients.

Following quote acceptance, the Design for Manufacturability (DFM) review is conducted by our senior engineering team. This critical collaborative stage involves a detailed technical assessment of the CAD model. We proactively identify potential manufacturability challenges such as excessive thin walls, problematic undercuts, non-optimal tolerances, or features requiring complex fixturing. Our engineers provide specific, actionable recommendations for design modifications that enhance producibility without compromising functional intent, often suggesting material or tolerance adjustments that reduce cost and lead time while maintaining performance. Client feedback on DFM suggestions is integrated before finalizing the production-ready blueprint, ensuring alignment and mitigating downstream risks.

The Production phase commences only after DFM sign-off. Utilizing our high-precision CNC machining centers mounted on massive, vibration-dampening granite bases, the process executes with exceptional stability. These granite structures provide unmatched thermal stability and rigidity compared to traditional cast iron, minimizing deflection and thermal drift during extended machining cycles. This is paramount for achieving micron-level tolerances consistently across complex geometries and demanding materials like aerospace alloys or medical-grade stainless steel. Key production specifications enabled by our granite platform include:

| Parameter | Specification | Significance for Precision |

| :—————– | :—————— | :————————- |

| Machine Base Material | Black Granite (G603) | Superior vibration damping, thermal stability ≤0.5μm/°C |

| Positioning Accuracy | ≤ ±1.5 μm | Critical for tight-tolerance features and complex assemblies |

| Repeatability | ≤ ±0.8 μm | Ensures consistency across multiple parts and setups |

| Surface Finish (Typical) | Ra 0.4 – 1.6 μm | Achievable on critical mating surfaces without secondary ops |

| Max Working Volume | 1000 x 600 x 500 mm | Supports substantial prototype and bridge production parts |

Throughout production, in-process inspections verify critical dimensions at predefined stages, while final First Article Inspection (FAI) reports, including CMM data, provide full traceability. This integrated workflow—from AI-optimized quoting through collaborative DFM to granite-enabled precision machining—ensures Shenzhen Honyo Prototype delivers parts that meet the most stringent quality and performance requirements, reliably and efficiently.

Start Your Project

Start Your Project with Precision: Partner with Shenzhen Honyo Prototype for Advanced Granite CNC Machining

When precision, stability, and repeatability define the success of your manufacturing operations, the foundation of your CNC system matters. At Shenzhen Honyo Prototype, we specialize in high-performance granite CNC machines engineered for industries where micron-level accuracy is non-negotiable. Whether you’re developing aerospace components, medical devices, or high-tolerance industrial molds, our granite-based CNC solutions deliver unmatched thermal stability and vibration damping—critical attributes for achieving superior surface finishes and long-term machine reliability.

Granite, as a structural base material, outperforms traditional cast iron and steel in key performance areas. Its natural damping capacity reduces resonance by up to 95%, ensuring minimal deflection during high-speed cutting operations. Additionally, granite’s low coefficient of thermal expansion maintains dimensional stability across fluctuating shop floor environments, reducing calibration downtime and improving part consistency. These advantages make granite CNC machines ideal for applications demanding extended tool life, tighter tolerances, and reduced maintenance cycles.

At Honyo Prototype, we integrate premium-grade black granite beds sourced from controlled quarries, precision-ground to ±2 microns flatness. Our machines are built with modular configurations to support 3-axis, 5-axis, and custom multi-tasking platforms, all optimized for integration with leading CNC controls including Fanuc, Siemens, and Heidenhain. From initial concept to final commissioning, our engineering team works closely with clients to tailor machine specifications to their production requirements.

Below is a summary of standard technical specifications for our most widely deployed granite CNC platform:

| Specification | Detail |

|————–|——–|

| Base Material | Black Granite (Grade G603), precision-ground |

| Surface Flatness | ±2 μm over full surface |

| Damping Ratio | 0.08–0.12 (vs. 0.001–0.005 for cast iron) |

| Thermal Expansion Coefficient | 7.5 × 10⁻⁶ /°C |

| Maximum Table Load Capacity | Up to 3,000 kg |

| Positioning Accuracy (X/Y/Z) | ±2.5 μm |

| Repeatability | ±1.0 μm |

| Compatible Control Systems | Fanuc 31i, Siemens 840D, Heidenhain TNC7 |

| Optional Add-ons | Automatic Tool Changer (ATC), Coolant Through Spindle (CTS), In-process Probing |

Our commitment extends beyond hardware. We provide full technical documentation, on-site installation support, operator training, and preventive maintenance programs to ensure optimal machine uptime and performance longevity.

Now is the time to elevate your manufacturing precision. If you are ready to start your next high-accuracy project or need expert consultation on integrating a granite CNC solution into your workflow, contact Susan Leo at Shenzhen Honyo Prototype. With years of experience in advanced CNC system design and client-specific engineering, Susan will guide you through the process—from specification review to delivery and beyond.

Reach out today at info@hy-proto.com to discuss your project requirements. Let Honyo Prototype be your trusted partner in achieving uncompromising accuracy and reliability in CNC machining.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.