Contents

Manufacturing Insight: Laser Cnc Machine For Wood

Manufacturing Insight Laser CNC Technology for Wood Prototyping

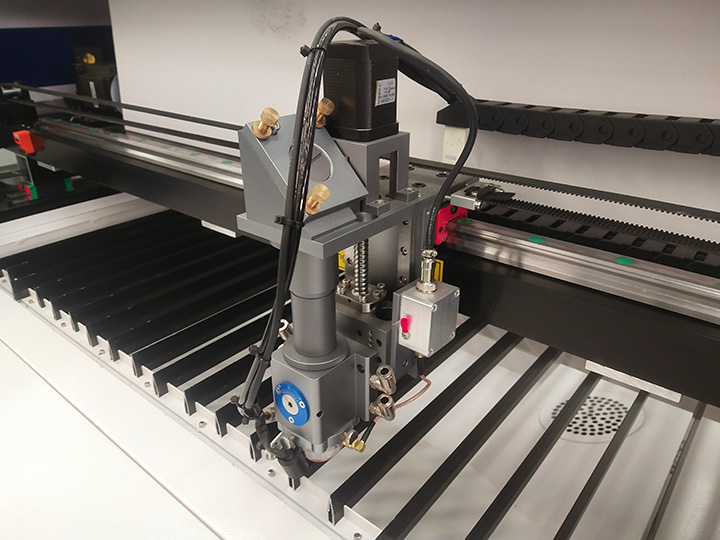

Laser CNC machining represents a precision subtractive manufacturing process uniquely suited for wood and organic materials, leveraging focused CO2 laser beams to cut, engrave, or mark substrates without mechanical contact. Unlike traditional rotary tool CNC, this non-contact method eliminates tool deflection and mechanical stress, enabling intricate geometries, fine details, and clean edges essential for high-fidelity prototypes in furniture, architectural models, signage, and consumer products. The process operates by directing a high-energy laser through galvanometer scanners or moving gantries, vaporizing material along programmed vector paths or raster patterns. Critical parameters include laser power density, pulse frequency, assist gas selection (typically compressed air for wood), and feed rate, all requiring precise calibration to prevent charring, excessive kerf width, or incomplete cuts – especially critical when validating aesthetic and functional prototypes.

At Shenzhen Honyo Prototype, we integrate industrial-grade CO2 laser CNC systems specifically optimized for rapid wood prototyping demands. Our engineering focus centers on material science compatibility and process repeatability, ensuring prototypes accurately reflect final production intent. We prioritize minimizing thermal impact zones to preserve wood grain integrity while achieving tight tolerances down to ±0.1mm. Our systems support a broad spectrum of wood types – including balsa, basswood, plywood, MDF, and hardwood veneers – alongside complementary materials like acrylics and fabrics, facilitating multi-material prototype assemblies. Advanced motion control and real-time power modulation allow us to handle complex nested geometries and variable-depth engraving in a single setup, significantly accelerating design iteration cycles. This capability is fundamental for clients validating ergonomics, assembly fit, and visual finishes before committing to expensive tooling.

Key technical specifications of our production laser CNC platforms are detailed below, reflecting our commitment to precision and scalability for prototype development.

| Parameter | Typical Range | Honyo Standard Configuration |

|——————–|———————|——————————|

| Laser Type | RF-excited CO2 | 100W Sealed RF CO2 |

| Work Area | 300x200mm to 1300x900mm | 600x400mm Active Cutting Zone |

| Positioning Accuracy | ±0.05mm | ±0.03mm |

| Max Cutting Thickness (Wood) | 15mm (Basswood) to 8mm (Hardwood) | Validated up to 12mm Birch Ply |

| Engraving Resolution | 1000dpi | 1200dpi Vector / 500dpi Raster |

| Control System | DSP-based | Integrated CAD/CAM Workflow |

These systems directly support critical prototyping workflows. For instance, architectural firms receive dimensionally accurate scale models with engraved textures within 24 hours, while furniture designers validate joinery tolerances and surface finishes on actual production-intent materials. The ability to rapidly iterate laser parameters for different wood densities ensures prototypes meet both functional and aesthetic criteria, reducing downstream design revisions. Honyo’s process documentation includes material-specific parameter libraries and kerf compensation guides, empowering clients to understand manufacturability constraints early in development. By combining rigorous process validation with agile machine capability, we transform conceptual designs into tangible, testable wood prototypes that bridge the gap between digital models and physical reality, accelerating time-to-market for our engineering partners.

Technical Capabilities

Technical Capabilities: Laser CNC Machining for Wood at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in precision laser CNC machining for wood, delivering high-accuracy components for prototyping, architectural models, furniture design, and custom fabrication. Our advanced 3-axis, 4-axis, and 5-axis CNC laser systems are engineered to handle complex geometries with superior repeatability and surface finish. These systems integrate high-powered CO₂ lasers with precision motion control, enabling clean cuts, detailed engravings, and intricate 3D profiling in a variety of wood types and composites.

Our 3-axis laser CNC machines provide efficient 2D and 2.5D machining capabilities, ideal for flat panel cutting, joinery, and engraved designs. The 4-axis configuration adds rotational control, allowing for cylindrical machining and seamless wrap-around cutting on curved wooden surfaces. For the most complex organic shapes and sculptural forms, our 5-axis laser CNC systems offer full spatial control, enabling undercuts, compound angles, and multi-faceted designs without manual repositioning. This multi-axis flexibility ensures minimal setup time and consistent dimensional accuracy across high-mix, low-volume production runs.

Dimensional precision is a core strength of our laser CNC process. We maintain tight tolerances across all axis configurations, with typical machining accuracy reaching ±0.05 mm on critical features. Laser kerf width is tightly controlled at approximately 0.1–0.2 mm, depending on material density and thickness, ensuring minimal material loss and precise edge definition. Our systems support wood materials up to 100 mm in thickness, with work envelope capacities of up to 1300 mm × 2500 mm for large-format applications.

We utilize advanced CAD/CAM software to optimize toolpaths, minimize thermal impact, and prevent charring—particularly important in fine hardwoods and laminated panels. In-process monitoring and adaptive focusing ensure consistent beam quality across the entire work surface, even on non-flat substrates.

The following table outlines the typical tolerances and compatible materials for our laser CNC machining services:

| Material Type | Maximum Thickness | Typical Tolerance (± mm) | Surface Finish (Ra, µm) | Recommended Applications |

|————————-|——————-|—————————|————————–|—————————————-|

| Baltic Birch Plywood | 18 mm | 0.05 | 6.3 | Prototypes, jigs, enclosures |

| Solid Oak | 50 mm | 0.08 | 8.0 | Furniture components, decorative parts |

| MDF (Medium-Density Fiberboard) | 30 mm | 0.05 | 6.3 | Architectural models, signage |

| Walnut | 40 mm | 0.07 | 7.0 | High-end design, luxury interiors |

| Bamboo Composite | 25 mm | 0.06 | 6.8 | Sustainable products, consumer goods |

| Acrylic-Laminated Wood | 20 mm | 0.05 | 5.5 | Display fixtures, retail installations |

All machined parts undergo rigorous in-house inspection using digital calipers, CMM-supported measurement systems, and visual quality checks to ensure compliance with design specifications. Shenzhen Honyo Prototype combines technical precision with material expertise to deliver laser CNC wood machining solutions that meet the demanding requirements of design, engineering, and architectural professionals.

From CAD to Part: The Process

Production Process: From CAD to Finished Wood Component

At Shenzhen Honyo Prototype, our laser CNC machining workflow for wood components is engineered for precision, efficiency, and seamless integration from digital design to physical part. This standardized process ensures consistent quality while minimizing lead times and material waste for our clients. The journey begins when a client submits a CAD file, typically in DXF, DWG, or vector-based formats suitable for 2D/2.5D laser processing. This file immediately enters our proprietary AI-Powered Quoting system. This system rapidly analyzes geometric complexity, material requirements (specifying plywood, MDF, solid wood species, or acrylic), estimated machine runtime, and nesting efficiency to generate an accurate, detailed cost and timeline estimate within minutes, providing immediate project visibility.

Following client approval, the CAD data undergoes rigorous Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This critical phase focuses specifically on wood characteristics. Engineers verify kerf compensation for the target laser power and material thickness, assess potential charring risks at intricate internal corners or narrow features, evaluate the impact of wood grain orientation on cut edge quality and structural integrity, and optimize part nesting to maximize sheet utilization. We proactively identify and resolve potential issues like insufficient bridge tabs for delicate internal features or inadequate clearance for venting smoke during cutting, providing actionable feedback to the client if design adjustments would enhance manufacturability or reduce cost. Client sign-off on the DFM report is mandatory before production release.

Approved jobs move to the production floor, where our fleet of high-precision CO2 laser CNC systems executes the programmed toolpaths. Material selection strictly adheres to the DFM specifications, with careful attention to moisture content and surface quality to prevent warping or inconsistent cutting. Machine operators perform final material loading, laser head calibration, and focus verification. The CNC controller then executes the optimized G-code, managing laser power, pulse frequency, and cutting speed dynamically based on material type and thickness. Critical process parameters are monitored in real-time to ensure edge quality meets specifications and minimize heat-affected zones. Post-processing, typically involving light sanding to remove minimal residual char or applying edge sealant per client requirements, is performed as specified. Every component undergoes final dimensional inspection against the original CAD model and visual quality control for surface finish before shipment.

Our integrated workflow, underpinned by AI-driven quoting and expert wood-specific DFM, guarantees that complex designs translate into high-fidelity, ready-to-use wood parts with exceptional repeatability. This structured approach is fundamental to Honyo Prototype’s reputation for reliable, high-quality CNC laser manufacturing services.

Key Laser CNC System Specifications for Wood Machining

| Parameter | Value | Wood-Specific Notes |

| :—————– | :———————— | :————————————————— |

| Laser Type | RF-excited CO2 | Optimized wavelength (10.6µm) for efficient wood absorption |

| Power Range | 80W – 130W | 80W suitable for thin veneers/paper; 130W handles 18mm plywood/MDF |

| Max Working Area | 1500mm x 3000mm | Accommodates standard 4x8ft sheet stock efficiently |

| Positioning Accuracy | ±0.05mm | Critical for tight-fitting joinery in furniture/components |

| Max Cutting Speed | 1000mm/min (thin materials) | Speed reduced significantly for thicker/denser woods |

| Material Thickness | Up to 25mm (Plywood/MDF) | Optimal quality typically achieved under 18mm; solid wood requires lower speeds |

Start Your Project

Start Your Woodworking Project with Precision CNC Laser Technology

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining solutions tailored for wood-based manufacturing. Our advanced laser CNC machines combine cutting-edge automation with industry-leading accuracy to deliver consistent, repeatable results for prototyping and low-to-mid volume production. Whether you’re developing intricate wooden components for furniture, architectural models, or decorative elements, our technology ensures every cut, engraving, and contour meets exact specifications.

Our laser CNC systems are engineered for versatility and ease of integration into your existing workflow. With non-contact laser processing, we minimize material deformation and achieve clean, polished edges without the need for secondary finishing in most applications. The integration of computer numerical control allows for complex geometries and fine detailing that traditional routing methods cannot match—ideal for custom designs requiring tight tolerances and high repeatability.

We understand that every project begins with a vision. That’s why our team works closely with clients from the initial design phase through to final production. By leveraging CAD/CAM software and real-time simulation tools, we ensure design feasibility, optimize toolpaths, and reduce lead times significantly. Our in-house engineering support helps identify potential design improvements, material selection, and cost-saving opportunities before any machining begins.

To get started, simply share your design files in DWG, DXF, STEP, or IGES format, and our engineers will provide a detailed manufacturability analysis and quote within 24 hours. We support a wide range of wood types, including plywood, MDF, solid hardwoods, and engineered composites, with thicknesses ranging from 1 mm to 25 mm.

Below are the key technical specifications of our laser CNC machining platform for wood processing:

| Parameter | Specification |

|——————————-|——————————————|

| Laser Power | Up to 150W CO₂ Laser |

| Maximum Work Area | 1300 mm × 900 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.02 mm |

| Minimum Feature Size | 0.1 mm (engraving), 1.0 mm (cutting) |

| Supported File Formats | DXF, DWG, AI, SVG, STEP, IGES |

| Material Thickness Range | 1 – 25 mm |

| Cutting Speed (varies by type)| Up to 600 mm/s |

| Engraving Resolution | Up to 1000 DPI |

| Control System | DSP-based CNC Controller with Offline Operation |

All projects are manufactured in our ISO-certified facility in Shenzhen, ensuring compliance with international quality standards. We prioritize fast turnaround times without compromising precision—typical lead times range from 3 to 7 business days, depending on complexity and volume.

Ready to bring your design to life? Contact Susan Leo, our dedicated project coordinator, to discuss your requirements, request a quote, or schedule a technical consultation. We are committed to providing responsive, expert support to help you move from concept to prototype efficiently.

Email Susan Leo at info@hy-proto.com to start your project today. Include your design files and any specific requirements, and we’ll respond promptly with next steps. At Shenzhen Honyo Prototype, we don’t just machine parts—we partner in innovation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.