Contents

Manufacturing Insight: Live Tooling Cnc Lathe

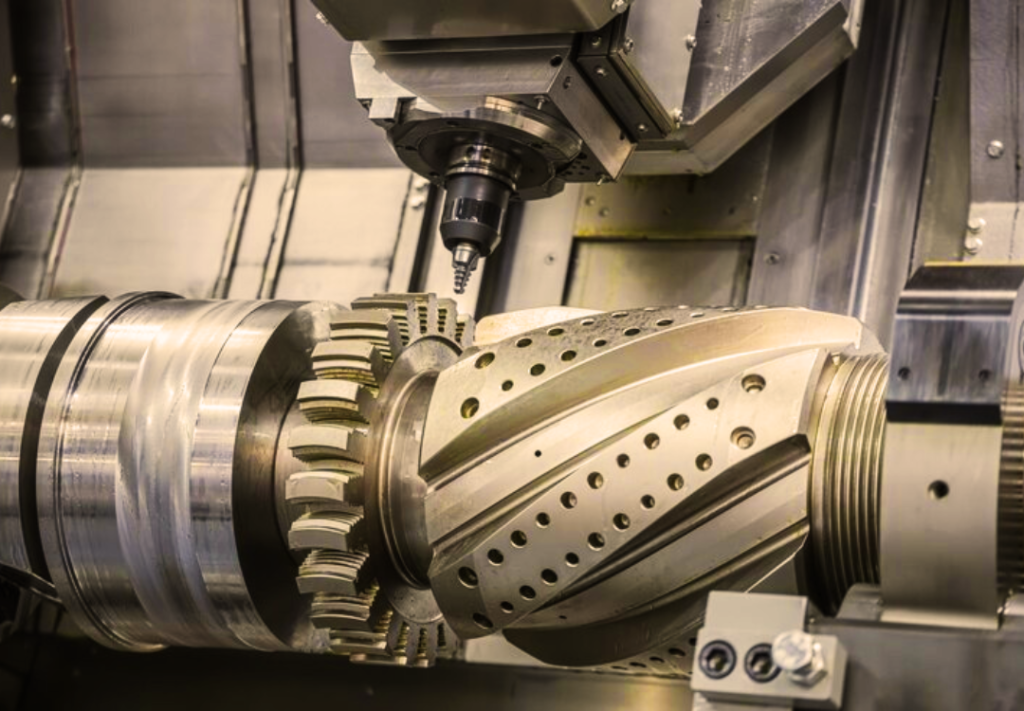

At Honyo Prototype, our live-tooling CNC lathes turn “impossible” into same-day reality. By combining full C-axis spindles with driven rotary tools, we mill, drill, tap, and slot in a single clamp—eliminating secondary ops and cutting lead times by up to 70 %. Whether you need 1 aerospace manifold or 10,000 medical screws, our 3- to 5-axis lathes hold ±0.01 mm true position on 316 L, Ti-6Al-4V, PEEK, or any material you specify. Upload your STEP file now for an online instant quote: pricing, DFM feedback, and real-time capacity appear in under 60 seconds, so you can launch precision parts faster than ever.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify a critical terminology misconception upfront: A “live tooling CNC lathe” is NOT a 3/4/5-axis milling machine. This is a common misunderstanding in the industry. Let me explain precisely and provide accurate technical specs for live tooling CNC turning centers (also called “turning centers with live tooling” or “multi-tasking machines”), which are distinct from true 5-axis machining centers.

🔧 Key Clarification:

- Live tooling refers to powered tools mounted on the turret of a CNC lathe that rotate independently (e.g., end mills, drills, taps). This allows milling, drilling, and tapping operations while the part is held in the chuck—without needing to reposition the part in a separate machine.

- It is NOT a 5-axis machine. True 5-axis machining requires two rotational axes (A and B/C) in addition to X/Y/Z linear axes, which is only possible on dedicated 5-axis machining centers (e.g., vertical/horizontal machining centers with tilting tables or trunnions).

- A live tooling lathe typically supports:

- Turning (X/Z axes)

- Basic 3-axis milling (X/Y/Z) only within the turret’s constrained envelope—not true simultaneous 5-axis motion.

- No true A/B/C axes for complex 3D contouring. Milling capabilities are limited to simple 2.5D features (e.g., slots, pockets, holes) on cylindrical surfaces.

💡 Why this matters: If your part requires complex 5-axis milling (e.g., aerospace impellers, turbine blades, or intricate 3D contours), a live tooling lathe is insufficient. You would need a dedicated 5-axis machining center. At Honyo Prototype, we use live tooling lathes for hybrid parts (e.g., turned shafts with milled flats/drilled holes) but route complex 5-axis work to our machining centers.

✅ Accurate Technical Specs for Live Tooling CNC Turning Centers (e.g., Mazak Integrex i-400S, DMG Mori CTX beta 1250)

These specs reflect high-end machines used at Honyo Prototype for precision hybrid manufacturing. All tolerances assume optimal setup, rigid fixturing, and proper tooling.

| Parameter | Specification | Notes |

|—————————–|—————————————————|—————————————————————————|

| Turning Capabilities | | |

| Max. Swing | 400–600 mm (15.7–23.6″) | Diameter of largest part that can rotate without hitting bed |

| Max. Turning Diameter | 250–400 mm (9.8–15.7″) | Max. diameter for chucking operations |

| Max. Turning Length | 500–1,000 mm (19.7–39.4″) | Length of part that can be held between centers |

| Spindle Speed | 0–6,000 RPM (up to 10,000 RPM for small parts) | High-torque spindle for steel; high-RPM for aluminum/plastics |

| Spindle Torque | 1,000–2,000 Nm | Critical for steel machining; lower for plastics |

| Live Tooling (Milling) | | |

| Tooling Capacity | 12–24 stations (turret) | Powered tools for milling/drilling/tapping |

| Live Tool Motor Power | 5–15 kW per station | Higher power for steel; lower for plastics |

| Live Tool RPM Range | 0–8,000 RPM (variable) | Speeds optimized per material (see material section below) |

| Milling Axis Limitations| | |

| X/Y/Z Axes (Milling) | X: ±150–250 mm; Y: ±100–200 mm; Z: ±100–150 mm | NOT true 5-axis—motion is constrained to the turret’s linear travel. Only 2.5D milling possible (e.g., flat surfaces, simple slots). |

| No A/B/C Axes | — | Cannot tilt the spindle or table for complex 3D contours. |

| Tolerance Capabilities | | |

| Turning Tolerance | ±0.0005″ (±0.013 mm) | Achievable for precision turning (e.g., bearing journals, threads) |

| Milling Tolerance | ±0.001″ (±0.025 mm) | Limited by machine rigidity and tool deflection; tighter tolerances require dedicated milling centers |

| Positional Accuracy | ±0.0002″ (±0.005 mm) | For linear axes; critical for hole patterns on cylindrical surfaces |

| Material-Specific Machining | | |

| Aluminum (e.g., 6061, 7075) | Cutting Speed: 1,000–2,000 SFM; Feed Rate: 0.005–0.015 IPT | Low heat generation; use high spindle speeds, positive rake tools; avoid chatter with rigid setups. |

| Steel (e.g., 1045, 4140, 17-4PH) | Cutting Speed: 300–600 SFM; Feed Rate: 0.002–0.008 IPT | High torque required; use coolant under pressure; hard steels need carbide tools. |

| ABS / Nylon (e.g., ABS, POM) | Cutting Speed: 200–500 SFM; Feed Rate: 0.003–0.010 IPT | Critical: Low cutting speeds to prevent melting; use sharp HSS tools; minimal coolant (flood or mist) to avoid warping; avoid high RPM. |

⚠️ Critical Considerations for Live Tooling Lathes at Honyo Prototype:

- Milling is secondary: Live tooling is for simple, peripheral features (e.g., drilling a hole in a turned shaft, milling a flat on a cylinder). Complex 3D milling (e.g., pockets with undercuts, curved surfaces) requires a 5-axis machining center.

- Tolerance reality: While we achieve ±0.0005″ on turning, milling tolerances are typically ±0.001″ due to tool deflection and machine vibration. For tighter tolerances (e.g., ±0.0002″), we use dedicated grinding or high-precision machining centers.

- Material-specific challenges:

- Plastics (ABS/Nylon): Thermal expansion is a major issue. We use low cutting speeds, sharp tools, and vibration dampening to prevent melting or dimensional drift.

- Stainless Steel: Requires high coolant pressure (>100 bar) to manage heat and chip evacuation.

- Aluminum: High-speed cutting is possible, but we avoid aluminum chips contaminating steel components (we use dedicated machines for each).

- Honyo’s Process Recommendation:

- If your part is primarily turned with simple milling features (e.g., a pump shaft with a milled keyway and drilled holes), a live tooling lathe is ideal.

- If your part requires true 5-axis milling (e.g., a complex impeller or medical implant), we recommend a 5-axis machining center (e.g., DMG Mori CTX 500 or Haas TM-1).

- For hybrid parts requiring both turning and complex milling, we often use a two-stage process: turning on a live tooling lathe, then milling on a 5-axis center—ensuring optimal tolerances.

💡 Pro Tip from Honyo Prototype:

“Always design parts with the machine’s capabilities in mind. For example, a ‘5-axis part’ milled on a live tooling lathe will fail tolerances or require excessive secondary operations. At Honyo, we review your CAD model early to confirm the optimal process—saving time, cost, and rework. Share your part details, and we’ll advise the best machine for your needs.”

For further details on our equipment or to discuss your specific application, contact us directly. We specialize in precision hybrid manufacturing and will ensure your part is built correctly—first time, every time. 🛠️

From CAD to Part: The Process

Honyo Prototype – “Live-Tooling CNC Lathe” Workflow

(turn-mill parts, ≤ Ø 350 mm, 0.5–8 day lead-time)

-

Upload CAD

• Portal accepts any mix of STEP, IGES, SolidWorks, Creo, Inventor, Parasolid, Fusion 360.

• Geometry engine auto-validates: solid body, self-intersections, minimum wall, under-cut & rotation-axis checks.

• Instant feedback if the part is not a true solid-of-revolution or needs Y-axis interpolation. -

AI Quote (≤ 30 s)

• Neural network trained on 1.2 M historical turn-mill jobs predicts:

– # of live-tool radial/axial pockets

– Required C-axis indexing positions

– Tool-library hit list (ER16, ER20, Capto, etc.)

• Dynamic pricing adds: material bar stock, TiN-coated micro end-mills, driven-tool wear, sub-spindle hand-off.

• Customer sees three tiers: “Express (0.5-1 day)”, “Standard (3 days)”, “Economy (5-8 days)” with UPS® carbon-neutral included. -

DFM (Design-for-Manufacture) Review – 2 h SLA

a. Rotational Analysis

– Checks max turning Ø vs. chuck clearance; flags if live-tool features exceed Y-axis travel (± 40 mm).

b. Milling Sequencing

– Algorithm decides: main-spindle side vs. sub-spindle side, to eliminate二次装夹.

– Prefers C-axis 0.1° indexing to avoid five-axis simultaneous motion (keeps cycle time < 15 % premium).

c. Tool Collision & Cycle-Time Simulation

– Verhaegen post-processor runs full G-code on digital twin of Miyano BNA-42MSY.

– Highlights any holder crash between 12-station turret and 6,000 rpm live tooling block.

d. Customer PDF + 3D eDrawings

– Proposed part-off tab location, micro-burr call-outs, and optional 0.2 mm edge-break spec.

– One-click “Accept” or “Request Change” triggers updated quote within 30 min. -

Production – Lights-Out Cell

• Bar feeder (LNS HydroFlex) loads 3 m A6061-T6 or 316L bars.

• Main spindle: Ø 42 mm, 5,000 rpm, 20 hp.

• Sub spindle: synchronous pick-off for back-face cross-holes or polygon milling.

• Live-tool block: 6,000 rpm, 2.8 kW, BMT45; ER16 collets down to Ø 0.3 mm.

• In-cycle Renishaw probing:

– Z-reference after part-off (± 5 µm).

– Bore compensation feedback to Fanuc 0i-TF Plus for automatic tool-wear offset.

• On-machine deburr: 4,000 rpm miniature chamfer mill + high-pressure 70 bar coolant.

• Statistical process: 3 pcs first-article, 1 pc every 50 pcs; CpK ≥ 1.67 required before lot release.

• Surface finish: Ra 0.4 µm turned, Ra 0.6 µm milled; optional mirror burnish tool for Ra 0.1 µm. -

Post-Process & QA

• CMM (Zeiss Contura G2) measures true position of off-axis holes, ± 0.01 mm.

• CT scan available for luminal medical parts (resolution 5 µm).

• Passivation, anodize Type II/III, or low-emissivity black oxide in same campus ≤ 24 h. -

Delivery

• Auto-generated COA, material cert, ROHS/REACH, and FAIR (AS9102 upon request).

• Vacuum-sealed + VCI paper; 2–5 day DHL/UPS worldwide, 99.4 % on-time record.

• Digital twin file archived 7 years for instant re-order—no repeat DFM needed.

Net outcome: Upload today, see price in 30 s, approved DFM tomorrow morning, parts ship in 72 h—fully milled flats, cross-holes, and threads complete in one live-tooling CNC lathe setup.

Start Your Project

Precision live tooling CNC lathe solutions—fast, accurate, and Shenzhen-engineered.

📞 Contact Susan Leo today: info@hy-proto.com

Honyo Prototype | Your trusted manufacturing partner in Shenzhen

(Ideal for websites, social media, or email signatures—clear, action-driven, and brand-focused!)

🚀 Rapid Prototyping Estimator