Contents

Manufacturing Insight: Live Tooling Cnc Lathe

Manufacturing Insight: Live Tooling CNC Lathe Technology at Honyo Prototype

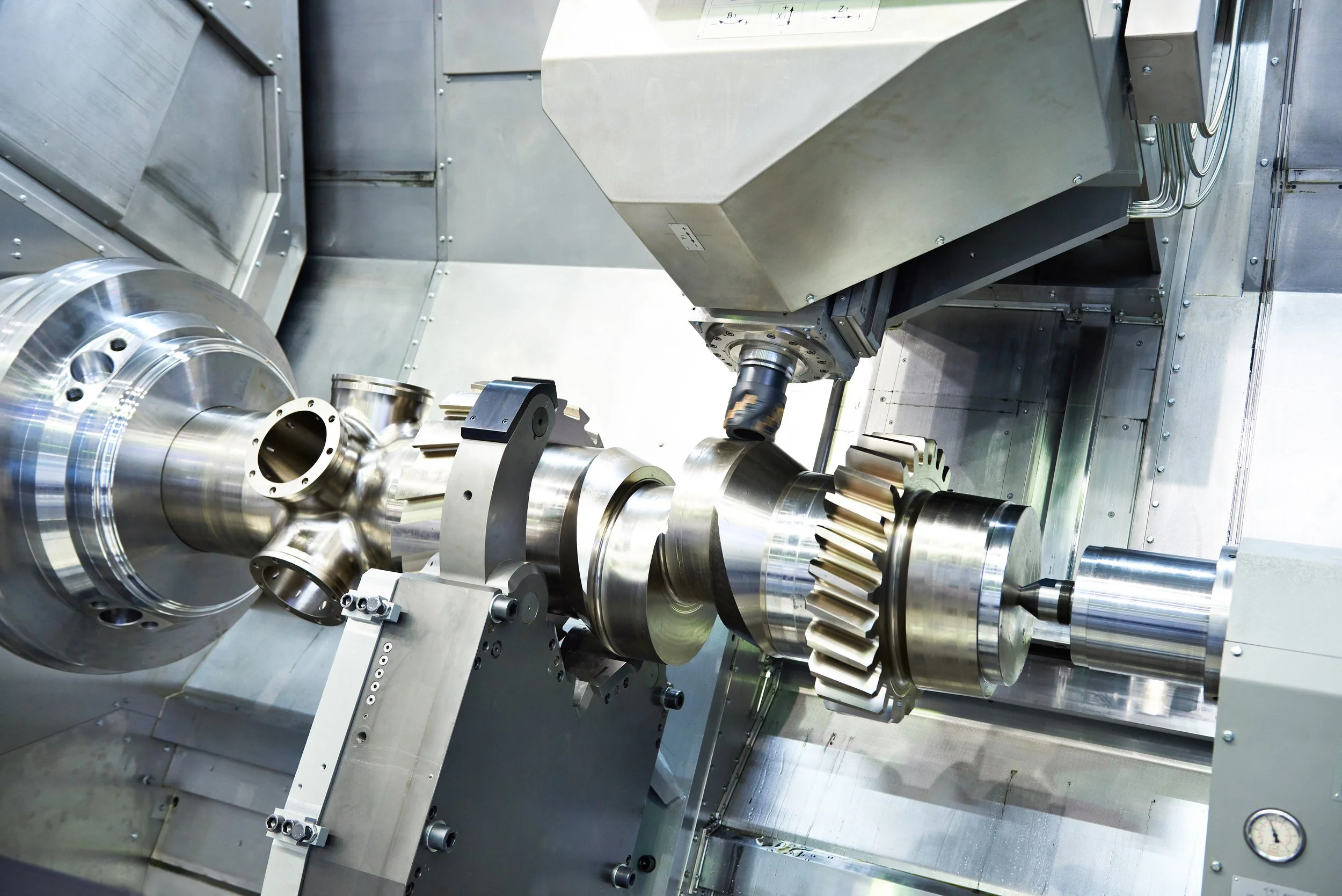

Live tooling CNC lathes represent a significant advancement over conventional turning centers, fundamentally transforming the production capabilities for complex rotational components. Unlike standard lathes that rely solely on rotating the workpiece against fixed cutting tools, live tooling lathes integrate motorized, driven toolholders within the turret. These live tools—typically milling cutters, drills, or taps—can operate independently of the main spindle rotation. This enables simultaneous turning, milling, drilling, tapping, and contouring operations on a single workpiece without requiring secondary setups or machine transfers. The core technological enabler is the C-axis, which precisely positions and indexes the workpiece spindle to act as a fourth axis of motion, allowing the live tools to engage the part at exact angular locations. This capability is essential for manufacturing parts with off-axis features such as radial holes, flats, keyways, hex heads, and complex profiles directly within the primary machining cycle.

The operational advantages of live tooling are substantial for precision prototyping and low-to-mid volume production. By consolidating multiple operations into one setup, manufacturers achieve significantly reduced lead times, minimized handling errors, and enhanced overall part accuracy. Critical geometric relationships between turned and milled features are maintained inherently, eliminating cumulative tolerances from multiple fixtures. This is particularly vital for high-integrity components in aerospace, medical devices, and fluid power systems where positional accuracy between features is non-negotiable. Furthermore, live tooling optimizes material utilization and lowers overall production costs by streamlining the manufacturing flow, reducing work-in-progress inventory, and maximizing machine uptime.

Shenzhen Honyo Prototype leverages a modern fleet of multi-axis live tooling CNC lathes to deliver these advanced capabilities to our clients. Our machines feature robust Y-axis travel, high-torque live tool spindles, and integrated C-axis control, enabling the production of highly intricate geometries in a single chucking. We routinely achieve tight tolerances down to ±0.005mm and surface finishes under Ra 0.8µm on challenging materials including stainless steels, titanium alloys, aluminum, brass, and engineering plastics. Our engineering team possesses deep expertise in programming complex live tooling sequences using advanced CAM software, ensuring optimal toolpaths, cycle times, and part integrity. This technical proficiency, combined with rigorous in-process inspection, allows us to transform complex designs into high-precision, fully functional prototypes and production parts efficiently.

The table below outlines the key performance specifications of Honyo Prototype’s standard live tooling lathe platform compared to conventional alternatives:

| Feature | Standard CNC Lathe | Honyo Prototype Live Tooling Lathe |

| :——————— | :—————– | :——————————— |

| Primary Operations | Turning only | Turning, Milling, Drilling, Tapping |

| Secondary Setups | Typically Required | Eliminated |

| Max Tool Stations | 8-12 | 12-20+ (incl. live tools) |

| Off-Axis Feature Capability | None | Full (Y-axis + C-axis) |

| Typical Positional Accuracy | ±0.01mm | ±0.005mm |

| Complex Geometry Suitability | Low | High |

At Honyo Prototype, our commitment to advanced live tooling technology ensures clients receive geometrically complex, high-precision components faster and with superior dimensional integrity. We transform intricate design requirements into manufacturable realities, providing a critical competitive edge in demanding engineering applications. Partner with us to leverage true single-setup machining excellence for your most challenging turning and milling projects.

Technical Capabilities

Live Tooling CNC Lathe – Technical Capabilities

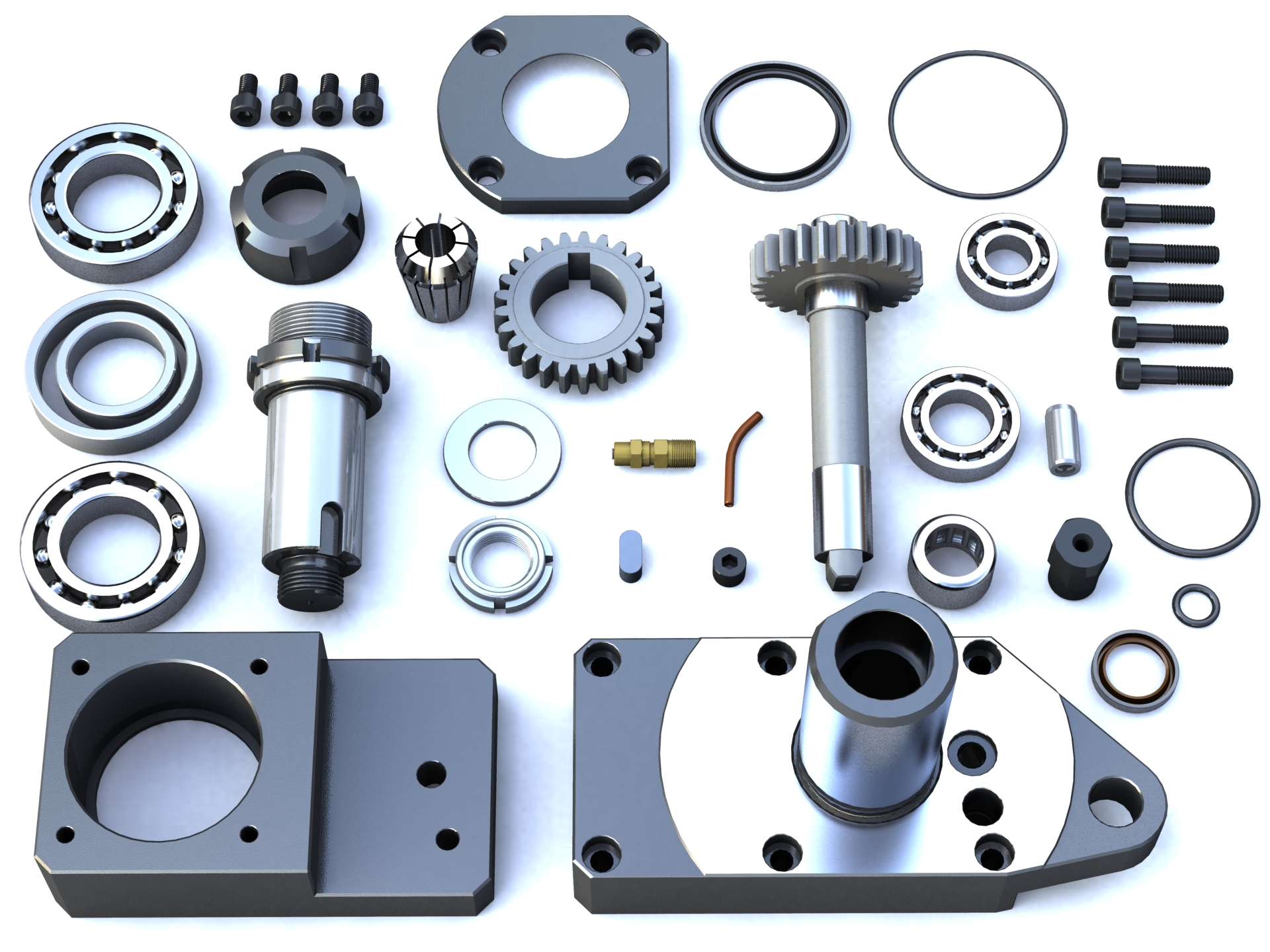

Shenzhen Honyo Prototype leverages advanced live tooling CNC lathe technology to deliver high-precision, complex components that combine turning and milling operations in a single setup. Our multi-axis live tooling lathes support 3-axis, 4-axis, and full 5-axis simultaneous milling capabilities, enabling intricate geometries, off-center features, and precision cross-drilling or contouring that standard CNC lathes cannot achieve. This integration significantly reduces cycle times, minimizes part handling, and enhances dimensional consistency across production runs.

Our machines are equipped with high-speed, servo-driven live tooling spindles capable of radial and axial machining operations such as drilling, tapping, end milling, and slotting—all while the main spindle is rotating or indexed. The Y-axis offset in 4-axis and 5-axis configurations allows for off-center milling and asymmetric feature creation, expanding design flexibility for complex turned-milled parts. Tool changers with high-capacity magazines support automated processing of multi-operation parts, ensuring repeatability and throughput.

Tight tolerances are a core strength of our live tooling CNC lathe platform. We consistently maintain tolerances down to ±0.005 mm for critical dimensions, with surface finishes reaching Ra 0.8 µm or better, depending on material and geometry. This precision is sustained through rigid machine construction, real-time tool compensation, in-process probing, and temperature-controlled machining environments.

The table below outlines our standard tolerance capabilities and compatible materials:

| Feature | Tolerance Range |

|——–|—————–|

| Linear Dimensions | ±0.005 mm to ±0.025 mm |

| Diameter Control | ±0.005 mm (tight-bore), ±0.01 mm (general) |

| Positional Accuracy | ±0.01 mm |

| Concentricity | 0.01 mm TIR |

| Surface Finish (Typical) | Ra 0.8 µm – 3.2 µm |

| Material Category | Common Materials |

|——————|——————|

| Metals | Aluminum 6061, 7075; Stainless Steel 303, 304, 316; Steel 1018, 4140; Titanium Grade 5 (Ti-6Al-4V); Brass C3604 |

| Plastics | PEEK, Delrin (POM), Nylon, PTFE, Polycarbonate, Acrylic |

| Specialty Alloys | Inconel 625, Hastelloy C276, Monel 400 |

Parts produced on our live tooling lathes are ideal for industries requiring high repeatability and complex feature integration, including medical devices, aerospace components, automotive sensors, and precision connectors. Our technical team works closely with design engineers to optimize part geometry for manufacturability, ensuring that tight tolerances and multi-axis requirements are met without compromising cost-efficiency.

With full 5-axis live tooling, Honyo Prototype delivers complete machining solutions—eliminating secondary operations and reducing time-to-market for prototype and low-to-mid volume production runs.

From CAD to Part: The Process

Live Tooling CNC Lathe Production Process: From CAD to Precision Component

At Shenzhen Honyo Prototype, our live tooling CNC lathe workflow transforms customer CAD models into high-integrity rotational components through a rigorously defined sequence: AI-Powered Quoting, Engineering-Driven DFM, and Optimized Production. This integrated approach ensures manufacturability, cost efficiency, and on-time delivery for complex turned parts requiring milling, drilling, or tapping operations completed in a single setup.

The process initiates with the AI-Powered Quoting System. Upon secure upload of the native CAD file (STEP, IGES, or native formats preferred), our proprietary AI engine performs an instant geometric and feature analysis. It identifies rotational elements, evaluates the necessity and complexity of live tooling operations (such as off-axis milling pockets, radial holes, or polygonal features), and cross-references material specifications against machine capabilities and historical production data. This system generates a technically validated preliminary quote within minutes, highlighting potential cost drivers like extreme aspect ratios or tight tolerances inherent to multi-axis live tooling work. This immediate feedback allows for rapid project scoping and early collaboration.

Critical refinement occurs during the Engineering Design for Manufacturability (DFM) Review. Our senior manufacturing engineers conduct a detailed manual assessment, focusing specifically on live tooling feasibility. We scrutinize tool access paths to prevent collisions, verify that feature locations align with the live tooling turret’s angular and radial reach, and assess the stability of thin-walled sections during secondary operations. Material selection is validated against tooling recommendations for optimal chip evacuation and surface finish during milling. Crucially, we identify opportunities to consolidate operations onto the live tooling lathe, eliminating secondary setups and potential datum shifts. Customer collaboration at this stage is essential; we provide actionable recommendations, such as minor feature relocation or tolerance relaxation, to enhance producibility without compromising function, significantly reducing lead time and unit cost.

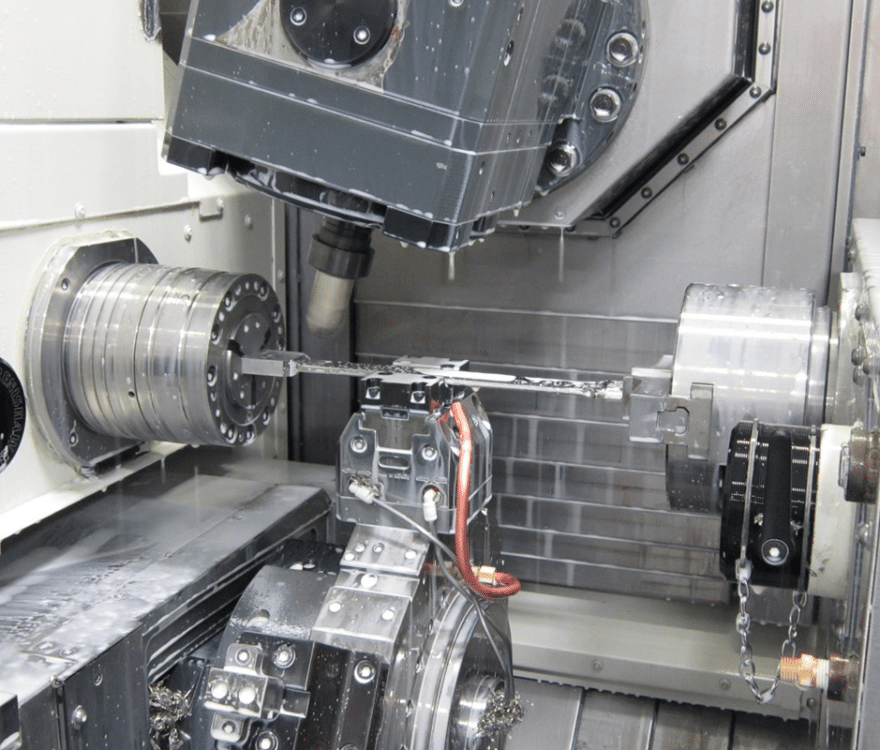

Final execution occurs in Precision Live Tooling Production. Approved programs, rigorously verified via simulation software, drive our advanced Y-axis equipped lathes (e.g., Okuma, DMG MORI). The workpiece is machined from raw bar stock or pre-turned blanks in a single chucking. The main spindle handles traditional turning and threading, while the synchronized live tool turret performs milling, drilling, tapping, and contouring perpendicular or at angles to the main axis. This concurrent processing is fundamental to achieving tight positional tolerances between turned and milled features. In-process probing ensures dimensional accuracy, and final inspection utilizes CMMs and optical comparators against the original CAD model. Key production parameters for our standard live tooling operations are summarized below.

| Parameter | Typical Capability | High-Precision Capability |

| :—————– | :———————– | :———————— |

| Max Spindle RPM | 6,000 RPM | 4,000 RPM (for fine finish) |

| Live Tool RPM | 12,000 RPM | 8,000 RPM |

| Tool Capacity | 12-24 Stations | 8-12 Stations (Y-axis) |

| Positional Tolerance | ±0.025 mm | ±0.005 mm |

| Surface Finish (Ra)| 1.6 µm | 0.4 µm |

This seamless CAD-to-part workflow, underpinned by AI efficiency, engineering expertise, and advanced multi-tasking machinery, guarantees that Honyo Prototype delivers complex live tooling components with exceptional accuracy, reduced lead times, and optimal value for demanding B2B applications.

Start Your Project

Start Your Project with Precision Live Tooling CNC Lathe Services at Honyo Prototype

When it comes to high-precision, complex component manufacturing, Shenzhen Honyo Prototype delivers unmatched expertise in live tooling CNC lathe machining. Our advanced capabilities allow us to produce intricate turned parts with milling, drilling, tapping, and cross-axis operations—all in a single setup. This integrated approach reduces cycle times, improves accuracy, and ensures consistent part quality, making us the preferred partner for industries ranging from medical and aerospace to automation and electronics.

At Honyo Prototype, we understand that every project begins with a vision. Whether you’re developing a prototype or scaling to low-volume production, our team of experienced manufacturing engineers works closely with you from design review to final delivery. We specialize in machining a wide range of materials, including aluminum alloys, stainless steel, brass, titanium, and engineering plastics, ensuring your components meet exact functional and dimensional requirements.

Our state-of-the-art live tooling lathes combine turning with synchronized milling operations, enabling features such as off-center holes, keyways, flats, and radial drilling—features that traditional CNC lathes cannot achieve without secondary operations. This capability not only streamlines your supply chain but also reduces handling, lowers costs, and accelerates time to market.

To ensure the highest level of precision and repeatability, we utilize advanced CNC controls, in-process inspection, and real-time tool monitoring systems. Every part is manufactured to strict quality standards, with full traceability and inspection reports available upon request. Our ISO 9001-compliant processes guarantee consistency and reliability across all production volumes.

We invite you to start your next manufacturing project with confidence. Share your design files—whether in STEP, IGES, or PDF format—and our engineering team will provide a detailed manufacturability analysis, material recommendation, and competitive quote within 24 hours.

Key Live Tooling CNC Lathe Specifications

| Parameter | Specification |

|——————————|——————————————-|

| Maximum Turning Diameter | 42 mm |

| Maximum Turning Length | 150 mm |

| Spindle Speed | Up to 12,000 RPM |

| Live Tool Drive | Servo-motor powered, C-axis control |

| Tapered Tooling Support | Yes (ER25 collet system) |

| Axes Configuration | Y-axis, C-axis, and sub-spindle available |

| Positioning Accuracy | ±0.005 mm |

| Supported Materials | Steel, Stainless Steel, Aluminum, Brass, Titanium, Plastics |

| Maximum Drilling Depth | 30 mm (with peck drilling) |

| Tapping Capabilities | Rigid and spiral tapping up to M12 |

Partnering with Honyo Prototype means gaining access to advanced technology, deep technical expertise, and responsive customer service. We are committed to supporting your success at every stage of production.

For immediate assistance, contact Susan Leo at info@hy-proto.com. Include your project specifications, preferred materials, and desired quantities, and we’ll respond promptly with a comprehensive solution tailored to your needs. Let us help you turn your designs into precision-engineered reality—efficiently, accurately, and on time.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.