Contents

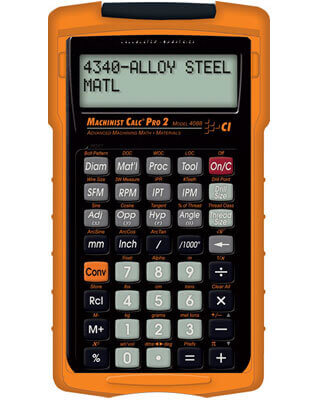

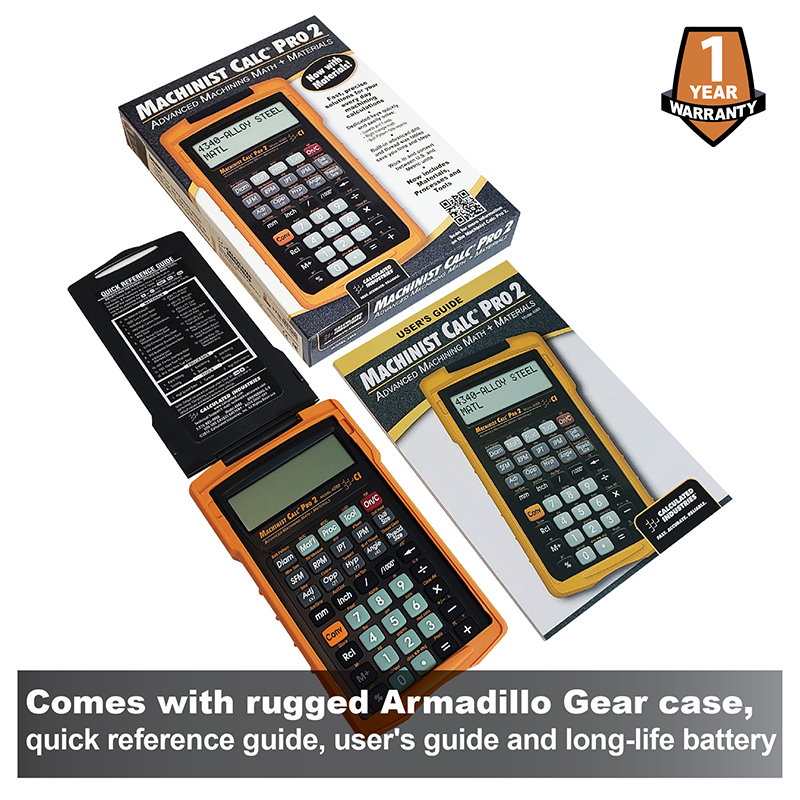

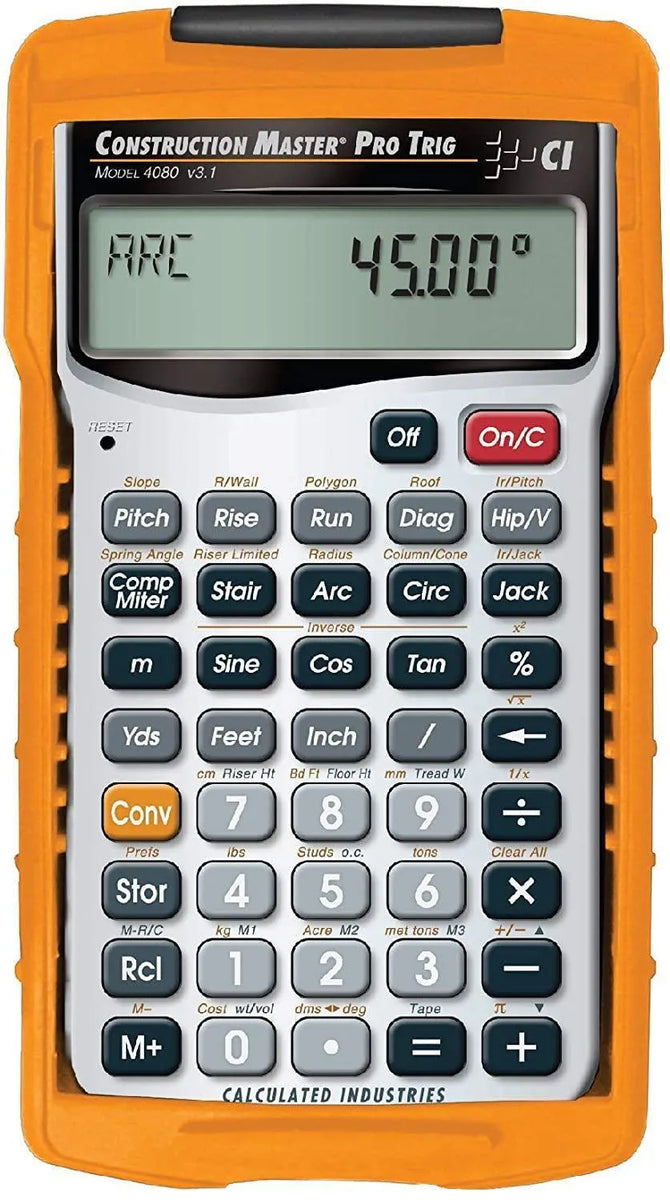

Manufacturing Insight: Machining Calculator

Manufacturing Insight: Precision Machining Calculator

In the high-stakes realm of rapid CNC prototyping and low-volume production, inaccurate cost or lead time estimates create significant project risk and operational inefficiency. Traditional manual quoting methods are prone to human error, lack real-time data integration, and often fail to account for complex interactions between design geometry, material selection, and machine capabilities. This uncertainty directly impacts a client’s ability to make informed sourcing decisions and manage project timelines effectively. Shenzhen Honyo Prototype addresses this critical industry challenge through our proprietary, web-based Machining Calculator – a sophisticated engineering tool integrated directly into our manufacturing workflow.

Our Machining Calculator transcends basic cost estimation. It leverages a comprehensive database of machine parameters, real-time shop floor utilization data, material costs, and our extensive historical process knowledge to deliver instant, highly accurate projections. Unlike generic online tools, it performs deep geometric analysis of uploaded 3D CAD models (STEP, IGES, Parasolid) to automatically identify features requiring multi-axis milling, complex turning operations, or tight tolerances. This granular analysis feeds into dynamic algorithms that calculate precise machine time, tooling requirements, and labor costs specific to Honyo’s certified equipment fleet, including 3-axis, 4-axis, and 5-axis machining centers alongside precision lathes. Crucially, the system is continuously updated with current material pricing and our actual production throughput metrics, ensuring estimates reflect genuine market and operational conditions.

The core technical capabilities are engineered for actionable insight:

| Calculation Type | Parameters Analyzed | Output Impact |

| :——————— | :———————————————– | :——————————————— |

| Real-Time Cost | Material density/waste, machine hourly rate, toolpath complexity, fixturing, secondary ops | Accurate per-part quotation within ±5% variance |

| Lead Time Projection | Machine availability, queue status, setup complexity, batch size | Reliable delivery date reflecting true capacity |

| DFM Feedback | Wall thickness, hole depth/diameter ratios, undercuts, tolerance stack-up | Early identification of manufacturability risks |

Beyond speed, the calculator provides immediate Design for Manufacturability (DFM) feedback during the quoting phase. It flags potential issues like excessive thin walls, non-standard hole depths, or tolerance conflicts that could cause machining delays or part failure. This proactive insight allows engineers to refine designs before committing to production, significantly reducing the iteration cycle and accelerating time-to-prototype. For Honyo clients, this translates to confident budget planning, minimized project risk, and the assurance that quoted timelines are grounded in our actual production capability. We invite design and manufacturing engineers to utilize this tool during the conceptual phase – it’s not merely a quoting mechanism, but a strategic asset for optimizing the entire prototyping journey through Honyo’s precision CNC machining services. Leverage this engineering rigor to de-risk your next project from the initial sketch.

Technical Capabilities

Technical Capabilities: Precision CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our advanced CNC machining capabilities are engineered to deliver high-precision components for industries demanding reliability, repeatability, and tight tolerances. Our in-house fleet of 3-axis, 4-axis, and 5-axis milling centers, combined with multi-axis turning systems, enables us to produce complex geometries with exceptional surface finish and dimensional accuracy. These capabilities support rapid prototyping, bridge production, and low-volume manufacturing for aerospace, medical, automation, and industrial equipment sectors.

Our 3-axis milling platforms are optimized for prismatic parts with straightforward geometries, delivering excellent accuracy and fast turnaround times. For components requiring access to multiple faces or complex contours, our 4-axis CNC machines provide rotational indexing around the A-axis, enabling efficient machining of cylindrical features and angled pockets without manual repositioning. For the most intricate designs—such as impellers, organic housings, or lightweight structural components—our 5-axis simultaneous milling systems offer unparalleled flexibility. With full simultaneous motion along X, Y, Z, A, and B axes, we minimize setup次数 and achieve superior surface integrity on highly contoured parts.

In addition to multi-axis milling, our CNC turning centers support bar feeding, live tooling, and sub-spindle operations, allowing us to produce precise rotational components with milled features in a single setup. This integrated approach reduces cycle times and ensures tighter concentricity and geometric control.

Tight tolerance machining is a core competency at Honyo Prototype. We consistently hold standard tolerances of ±0.005 mm (±0.0002″) and can achieve tighter specifications down to ±0.002 mm (±0.00008″) for critical features, depending on part geometry and material. Our quality assurance process includes first-article inspection (FAI), in-process checks using precision CMMs and optical comparators, and final validation per customer requirements.

We support a wide range of engineering materials, including aluminum alloys, stainless steels, tool steels, titanium, brass, copper, and high-performance plastics such as PEEK, PTFE, and PPS. Each material is machined using optimized toolpaths, cutting parameters, and tooling strategies to ensure dimensional stability and surface quality.

The following table outlines our standard and tight tolerance capabilities across common material categories:

| Material Category | Standard Tolerance (±) | Tight Tolerance (±) | Max Part Size (mm) | Max Part Size (in) |

|——————-|————————|———————-|——————–|——————–|

| Aluminum Alloys | 0.005 mm | 0.002 mm | 1000 x 600 x 500 | 39.4 x 23.6 x 19.7 |

| Stainless Steel | 0.005 mm | 0.002 mm | 800 x 500 x 400 | 31.5 x 19.7 x 15.7 |

| Titanium Alloys | 0.005 mm | 0.003 mm | 600 x 400 x 300 | 23.6 x 15.7 x 11.8 |

| Engineering Plastics | 0.01 mm | 0.005 mm | 1200 x 800 x 600 | 47.2 x 31.5 x 23.6 |

| Brass & Copper | 0.005 mm | 0.003 mm | 700 x 500 x 400 | 27.6 x 19.7 x 15.7 |

All machining operations are supported by robust process planning, CAD/CAM integration, and real-time tool wear monitoring to ensure consistency across batches. At Shenzhen Honyo Prototype, we combine technical expertise with advanced equipment to deliver machined parts that meet the most demanding specifications.

From CAD to Part: The Process

From CAD to Precision Part: Integrated Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining process transforms digital designs into high-precision physical components through a rigorously optimized workflow. This seamless integration of AI-driven quoting, expert Design for Manufacturability (DFM) analysis, and advanced production ensures minimal lead times and maximum part integrity. The journey begins when a client uploads their CAD file to our machining calculator platform. Our AI engine instantly analyzes geometric complexity, material requirements, and dimensional tolerances against live machine capacity and material stock databases. This generates a preliminary quote within minutes, including estimated cost, lead time, and initial feasibility flags—eliminating manual quoting delays while providing transparent upfront insights.

Following client confirmation, the project enters the critical DFM phase. Our senior manufacturing engineers conduct a comprehensive review to identify potential manufacturability risks that automated systems might overlook. This includes evaluating thin wall stability, internal corner radii, tool access for deep cavities, and optimal workholding strategies. Crucially, we collaborate directly with the client to suggest geometric refinements that maintain functional intent while enhancing producibility—such as modifying non-critical features to avoid secondary operations. This proactive step prevents costly revisions during production and typically reduces total project time by 15–25%. Below are key DFM parameters our engineers prioritize:

| Parameter | Critical Threshold | Impact of Non-Compliance |

|——————–|——————–|——————————–|

| Minimum Wall Thickness | < 0.5mm (Aluminum) | Vibration-induced chatter, part deformation |

| Hole Depth-to-Diameter | > 10:1 | Tool deflection, poor surface finish |

| Internal Corner Radius | < 0.2x feature depth | Unmachinable geometry, stress concentrations |

| Tolerance Stack-up | > ±0.025mm cumulative | Assembly failures, fit issues |

Once DFM sign-off is achieved, the part transitions to production. Honyo Prototype leverages a hybrid CNC fleet—including 3-axis vertical mills, 5-axis indexed machines, and precision lathes—to execute the optimized toolpaths. All programs undergo virtual simulation to verify collision avoidance and cycle time accuracy. During machining, our technicians implement real-time process monitoring: in-process probing validates critical dimensions after roughing, while thermal compensation algorithms counteract material expansion in tight-tolerance features. Final quality assurance involves CMM inspection against the original CAD model, with full traceability of material certifications and process parameters documented in the client’s digital project dossier.

This end-to-end workflow—from AI-informed quoting through collaborative DFM to metrology-verified production—embodies Honyo Prototype’s commitment to engineering excellence. By embedding manufacturability intelligence at every stage, we consistently deliver complex CNC-machined prototypes and low-volume production parts with industry-leading speed and reliability, directly translating your CAD vision into certified physical reality.

Start Your Project

Start Your CNC Machining Project with Confidence at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we understand that precision, speed, and reliability are non-negotiable in CNC machining. Whether you’re developing a single prototype or scaling up to low-volume production, our advanced manufacturing capabilities ensure your components meet the highest standards of quality and accuracy. Our machining calculator is designed to give you fast, real-time insights into lead times, material options, and cost estimates—helping you make informed decisions before your project even begins.

However, every engineering challenge is unique. While our online tools streamline the initial planning phase, direct collaboration with our manufacturing experts ensures your design is optimized for manufacturability, cost-efficiency, and performance. This is where personalized support becomes critical. Our team specializes in turning complex designs into high-precision parts using state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling, as well as turning and mill-turn operations.

We work with a wide range of engineering-grade materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance plastics such as PEEK and Delrin. Surface treatments like anodizing, powder coating, passivation, and plating are also available to meet your functional or aesthetic requirements. Our quality control processes are backed by ISO 9001:2015 certification, with CMM inspection, optical measurement, and first-article reporting available upon request.

To ensure your project starts on the right foot, we recommend consulting with an experienced manufacturing engineer who can review your CAD files, suggest design improvements, and guide material selection based on your application. This proactive approach reduces iterations, minimizes waste, and accelerates time to market.

Key CNC Machining Specifications at Honyo Prototype

| Parameter | Capability |

|—————————-|———————————————|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 × 600 × 500 mm (XYZ) |

| Minimum Feature Size | 0.5 mm (internal radii, thin walls) |

| Standard Tolerances | ±0.05 mm (standard), down to ±0.005 mm (tight) |

| Lead Times | As fast as 3–5 days for prototypes |

| Supported File Formats | STEP, IGES, X_T, SolidWorks, PDF (for 2D) |

When you’re ready to move forward, contact Susan Leo, our dedicated project coordinator, to receive a personalized quote and technical consultation. Susan ensures seamless communication between you and our engineering team, providing updates at every stage of production.

Contact Susan Leo

Email: info@hy-proto.com

Let us help you transform your concept into a precision-engineered reality. At Shenzhen Honyo Prototype, your success starts with a single email.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.