Contents

Manufacturing Insight: Injection Mould Tooling

Manufacturing Insight: Injection Mould Tooling at Shenzhen Honyo Prototype

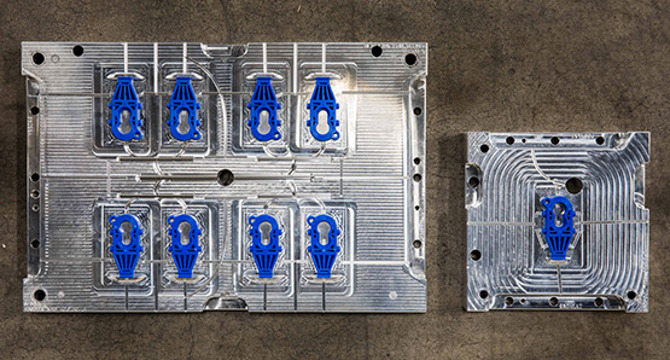

Precision injection mould tooling forms the backbone of efficient plastic part production, directly influencing component quality, consistency, and manufacturability. At Shenzhen Honyo Prototype, we specialize in rapid injection mould tooling solutions designed to bridge the critical gap between product concept validation and low-to-mid volume production. Our expertise lies in transforming detailed CAD models into fully functional, production-ready moulds with exceptional speed and technical fidelity, enabling clients to accelerate development cycles without compromising on critical dimensional or surface quality requirements. We understand that time-to-market is paramount; therefore, our processes prioritize rapid iteration and manufacturability feedback from the earliest design stages.

Honyo leverages advanced CNC machining, precision EDM, and skilled craftsmanship to deliver robust tooling capable of producing high-integrity parts for functional testing, pre-production runs, and end-use applications requiring quantities typically ranging from 100 to 50,000+ parts. We strategically select tool steel grades based on project-specific requirements for durability, surface finish, and part complexity. Our standard capabilities encompass single and multi-cavity configurations, incorporating essential features such as hot runner systems, lifters, and complex core pulls where necessary. Rigorous in-process quality checks and final mould validation ensure dimensional accuracy and process stability before part production commences. This integrated approach guarantees that the tool performs optimally within the injection moulding press, minimizing trial-and-error during initial production runs.

The following table outlines key specifications for Honyo’s rapid injection mould tooling services:

| Parameter | Standard Capability | Notes |

| :——————— | :————————————– | :—————————————– |

| Tool Steel Options | NAK80, P20, 718H, H13, Aluminum (7075) | Selection based on part volume, material, and finish requirements |

| Lead Time | 2 – 4 Weeks (from approved design) | Varies with complexity, cavities, and features |

| Cavity Configurations | 1 to 8 cavities | Multi-cavity for higher volume efficiency |

| Part Size Range | Max. 300 x 300 x 200 mm | Larger projects evaluated case-by-case |

| Surface Finish | As-Machined to SPI-A2 (VDI 14-18) | Polishing, texturing, and metallization available |

| Typical Volume Range | 100 – 50,000+ parts per mould | Optimized for rapid production tooling |

Our rapid tooling solutions are particularly valuable for startups, established OEMs, and R&D departments requiring functional prototypes indistinguishable from end-production parts, conducting design for manufacturability (DFM) analysis early, or fulfilling initial market demand before committing to high-cost production tooling. By utilizing our rapid injection moulds, clients gain critical insights into part performance, assembly fit, and material behavior under real production conditions. Honyo Prototype’s commitment to engineering excellence and accelerated timelines ensures your plastic components meet stringent specifications while significantly reducing the path from prototype to market-ready product. Partner with us to transform your design vision into tangible, high-quality plastic parts efficiently.

Technical Capabilities

Injection Mould Tooling Technical Capabilities

Shenzhen Honyo Prototype delivers high-precision injection mould tooling solutions tailored for rapid prototyping and low-to-medium volume production. Our expertise in both steel and aluminum tooling enables fast turnaround without compromising on quality, ensuring customers receive functional prototypes and production-ready parts within tight timelines. We specialize in T1 sample delivery within 7 days for qualified projects, leveraging advanced CNC machining, EDM, and mold assembly techniques to meet demanding engineering requirements.

Our rapid tooling services support a wide range of applications, from concept validation to pre-production runs. Aluminum molds (typically 7075-T6 or Al6061) are ideal for quick-turn projects requiring up to 10,000 shots, offering excellent thermal conductivity and machinability. For higher volume needs or enhanced wear resistance, we utilize hardened and pre-hardened steels such as P20, 718H, H13, S136, and 420 stainless steel, supporting mold life cycles from 50,000 to over 500,000 cycles depending on material and part geometry.

All molds are designed and manufactured in-house using 3D CAD/CAM workflows, ensuring tight integration between design intent and manufacturability. We apply mold flow analysis to optimize gate locations, cooling channels, and ejection systems, minimizing warpage and cycle time. Mold bases are sourced from standard systems (DME, LKM, or Hasco-compatible) unless custom configurations are required.

Tooling accuracy is maintained through stringent quality control processes, including CMM inspection and first-article reporting. We support both 2-plate and 3-plate molds, side-actions, lifters, and hot runner systems based on part complexity and production goals. All molds undergo rigorous testing prior to shipment, including dry cycle checks, filling trials, and T1 sample validation.

The following table outlines key specifications and capabilities for our injection mould tooling services:

| Parameter | Aluminum Molds | Steel Molds |

|——————————-|——————————|———————————-|

| Typical Materials | 7075-T6, Al6061 | P20, 718H, H13, S136, 420SS |

| Mold Life | 1,000 – 10,000 shots | 50,000 – 500,000+ shots |

| Lead Time (T1 Sample) | As fast as 7 days | 10–25 days (depending on complexity) |

| Surface Finishes | As-machined, polished, textured, SPI standards | Full range including mirror polish and VDI texturing |

| Tolerances (per inch) | ±0.005 in (±0.13 mm) | ±0.003 in (±0.076 mm) |

| Maximum Mold Size | 600 x 500 x 400 mm | 800 x 600 x 500 mm |

| Supported Processes | Cold runner, hot runner | Cold runner, hot runner, family molds |

| Common Applications | Rapid prototyping, bridge tooling | Low-to-medium volume production |

We maintain full traceability of materials and process parameters, ensuring consistency across mold builds. Our team collaborates directly with clients during DFM review to resolve potential issues early, reducing iterations and accelerating time-to-market. With T1 samples delivered in as little as 7 days, Honyo Prototype is engineered for speed, precision, and reliability in rapid injection mould tooling.

From CAD to Part: The Process

Production Process: From CAD to Certified Part

At Shenzhen Honyo Prototype, our rapid injection mould tooling workflow is engineered for speed, precision, and seamless integration, transforming your CAD model into functional parts within days. This streamlined process eliminates traditional bottlenecks while ensuring manufacturability and quality. The journey begins immediately upon receipt of your 3D CAD file.

AI-Powered Quoting & Feasibility Assessment

Our proprietary AI engine rapidly analyzes the submitted CAD geometry, automatically extracting critical features like part volume, projected area, and complexity factors. This enables generation of an initial tooling and part cost estimate within hours, significantly faster than manual methods. Crucially, the AI also performs a preliminary feasibility scan, flagging potential high-risk areas such as extreme undercuts or non-manufacturable thin walls before human review. This initial digital triage provides clients with rapid budgetary insight and sets the stage for efficient engineering collaboration.

Engineer-Led Design for Manufacturability (DFM)

Following the AI assessment, Honyo’s senior tooling engineers conduct an in-depth DFM review. This is not a checklist but a collaborative value-engineering phase. We evaluate wall thickness uniformity, gate location optimization, draft angles, ejection strategy, and material flow dynamics specific to your geometry and target resin. Our goal is to identify and resolve potential defects (sinks, warpage, weld lines) virtually, minimizing costly physical iterations. We provide actionable, annotated feedback and revised recommendations directly within the CAD environment or via detailed reports, ensuring alignment before tool fabrication commences. This proactive DFM integration is fundamental to our rapid success rate and cost control.

Precision Tool Fabrication & Molding Execution

Approved designs move directly to our in-house CNC machining, wire EDM, and surface finishing cells. Utilizing high-grade P20 or 718H steel for rapid tool longevity, we fabricate single-cavity or multi-cavity molds with tight tolerances (±0.02mm typical). Concurrently, material procurement is initiated based on the final DFM-approved specification. Once the mold is assembled and pre-qualified, initial molding trials commence on our high-precision, monitored presses. Process parameters (temperature, pressure, cooling time) are optimized using scientific molding principles. Every production run undergoes rigorous first-article inspection against your CAD nominal, including critical dimensions via CMM and visual surface quality checks. Full traceability, from raw material lot to final inspection report, is maintained.

The outcome is certified, production-intent plastic parts meeting your specifications, ready for functional testing or low-volume production, delivered with the speed demanded by modern product development cycles. Our integrated digital and engineering workflow ensures minimal time-to-part without compromising on quality or manufacturability insights.

| Common Material Properties for Rapid Tooling Runs | Typical Melt Temp (°C) | Mold Temp (°C) | Max Injection Pressure (MPa) | Key Application Notes |

| :———————————————— | :——————— | :————- | :————————— | :—————————– |

| ABS (General Purpose) | 210 – 250 | 40 – 80 | 80 – 120 | Good impact, ease of processing |

| Polycarbonate (PC) | 260 – 310 | 80 – 110 | 100 – 150 | High impact, optical clarity |

| Polypropylene (PP) | 200 – 280 | 20 – 60 | 70 – 100 | Chemical resistance, flexibility |

| Acetal (POM) | 190 – 230 | 60 – 100 | 80 – 120 | Low friction, high stiffness |

Start Your Project

Start Your Injection Mould Tooling Project with Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in rapid tooling and injection molding solutions designed to accelerate your product development cycle without compromising on quality or precision. Whether you’re in the prototype phase or preparing for low-volume production, our injection mould tooling services offer a fast, cost-effective pathway from concept to physical part.

Our expertise lies in delivering high-performance aluminium and steel tooling within tight timelines, enabling you to validate designs, conduct functional testing, and even enter limited market launch—all before committing to expensive production tooling. With in-house CNC machining, EDM, and finishing capabilities, we maintain full control over quality, lead time, and communication throughout the process.

We understand that every project is unique. That’s why we work closely with engineers and product designers to assess part geometry, material requirements, surface finish, and production volume—ensuring the optimal tooling strategy is implemented from the start. Our team supports gate location analysis, draft evaluation, and wall thickness optimization to prevent defects and improve mouldability.

Below are the key specifications we offer for rapid injection mould tooling:

| Feature | Specification |

|——–|—————|

| Tooling Material | 7075 Aluminium, NAK80, P20, H13, S136 |

| Mould Base | Standard LKM or DME bases; customizable upon request |

| Cavities | 1–8 cavities (multi-cavity for higher volumes) |

| Lead Time | 7–25 days depending on complexity and material |

| Part Life Expectancy | 1,000–100,000 shots (varies by tool steel and part design) |

| Supported Plastics | ABS, PC, PP, PA (nylon), POM, PMMA, PE, and more |

| Surface Finishes | As-machined, polished (SPI standards), texture, metallization |

| Secondary Operations | Insert molding, overmolding, post-machining, assembly |

All tools are rigorously tested on our in-house injection machines to ensure proper function, ejection, and part quality before shipment. We also provide initial sample parts for your approval, along with process documentation for traceability and future scaling.

If you’re ready to move forward with your injection mould tooling project, now is the time to connect with our engineering team. We are committed to responsive, transparent collaboration that keeps your development on track.

Contact Susan Leo today at info@hy-proto.com to discuss your part design, receive a detailed quotation, and begin the tooling process. Please include your 3D model (STEP or IGES), quantity requirements, material preference, and any special technical notes to expedite your quote.

At Shenzhen Honyo Prototype, we don’t just build tools—we build partnerships that turn ideas into reality. Let us help you reduce time-to-market and de-risk your next product launch with precision rapid tooling engineered for success.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.