Contents

Manufacturing Insight: Lost Wax Casting Molds

Manufacturing Insight: Lost Wax Casting Molds at Honyo Prototype

Lost wax casting, also known as investment casting, remains a cornerstone process for producing complex, high-fidelity metal components with exceptional surface finish and dimensional accuracy. At Shenzhen Honyo Prototype, we leverage this ancient yet highly refined technique within our rapid tooling and injection molding ecosystem to deliver near-net-shape prototypes and low-to-mid volume production parts efficiently. Our specialized approach integrates modern rapid prototyping methods with traditional casting expertise, significantly accelerating the path from digital model to functional metal component while maintaining rigorous quality standards essential for aerospace, medical, and precision engineering applications.

The core process begins with creating a precise wax pattern, typically injection molded using tooling fabricated rapidly via CNC machining or 3D printing based on the client’s CAD data. This pattern is meticulously assembled onto a ceramic investment “tree,” dipped into a slurry of refractory materials, and stuccoed with fine ceramic particles. Multiple layers build a robust, heat-resistant shell. After dewaxing, where the wax is melted out, the shell is fired to high temperature and filled with molten metal. Once solidified, the ceramic shell is removed, revealing the casting, which undergoes precision finishing. Honyo Prototype excels in optimizing each stage for speed and repeatability. Our proprietary ceramic slurry formulations and controlled dipping cycles ensure shell integrity and surface quality, minimizing post-cast machining. Advanced thermal modeling guides optimal firing and pour parameters for diverse alloys, from aluminum and stainless steel to superalloys like Inconel.

Honyo’s rapid tooling capabilities are pivotal in the initial wax pattern production phase. We utilize high-precision injection molding tooling, often fabricated in-house within days using hardened steel or advanced composites, enabling rapid iteration of pattern geometry based on initial casting feedback. This tight integration between rapid tooling and casting allows for swift design validation and process refinement, reducing traditional development timelines by up to 50% compared to conventional foundry approaches. Rigorous in-process inspection, including CMM verification of critical dimensions on sacrificial first articles and real-time shell thickness monitoring, guarantees consistency and adherence to demanding specifications.

Our technical capabilities for investment casting are defined by precision parameters achievable across common production scenarios:

| Parameter | Honyo Prototype Standard | Typical Industry Range |

| :———————- | :———————– | :——————— |

| Dimensional Tolerance | ±0.005 in (0.13 mm) per inch | ±0.010 – 0.020 in per inch |

| Surface Finish (Ra) | 125 – 250 μin (3.2 – 6.3 μm) | 250 – 500 μin (6.3 – 12.7 μm) |

| Minimum Wall Thickness | 0.040 in (1.0 mm) | 0.060 – 0.120 in (1.5 – 3.0 mm) |

| Part Weight Range | 0.1 oz – 100 lbs (2.8g – 45kg) | Varies significantly by foundry |

| Lead Time (Pattern Tooling) | 5-10 days | 2-6 weeks |

This combination of rapid pattern tooling, optimized ceramic shell processing, stringent quality control, and metallurgical expertise allows Honyo Prototype to deliver investment castings that meet exacting functional requirements while accelerating time-to-market. We transform complex geometries into high-integrity metal components, providing clients a critical advantage in competitive development cycles. Partner with Honyo to leverage lost wax casting not just as a manufacturing method, but as a strategic rapid prototyping and low-volume production asset.

Technical Capabilities

Lost Wax Casting Molds – Technical Capabilities

Shenzhen Honyo Prototype delivers precision-engineered lost wax casting molds tailored for rapid tooling and injection molding applications. Our expertise lies in producing high-integrity steel and aluminum molds that support both prototyping and low-to-mid volume production runs. These molds are designed to meet stringent dimensional accuracy and surface finish requirements, ensuring compatibility with investment casting processes used in aerospace, medical, and industrial manufacturing sectors.

We specialize in fabricating molds from premium-grade materials, including H13 tool steel, P20 steel, and 7075 aluminum, selected based on customer requirements for durability, thermal conductivity, and cycle life. Each mold undergoes CNC machining with multi-axis milling centers, followed by precision EDM (Electrical Discharge Machining) where tight internal features are required. This hybrid manufacturing approach ensures geometric complexity is achieved without compromising structural integrity.

A key strength of our service is the ability to deliver T1 samples within 7 business days from design approval. This rapid turnaround is enabled by our in-house toolroom, automated workflow management, and parallel processing of design validation, material preparation, and mold assembly. Our engineering team conducts a full Design for Manufacturing (DFM) review prior to production, identifying potential undercuts, draft angles, and ejection challenges to minimize rework and ensure first-time-right outcomes.

Mold surfaces are finished to customer-specified standards, ranging from as-machined (Ra 3.2 µm) to high-polish (Ra 0.2 µm), with optional textures or coatings applied upon request. All molds are pressure-tested and evaluated for part consistency before shipment. We also offer mold storage and revision tracking for repeat orders, ensuring long-term part repeatability.

The following table outlines standard material options and achievable tolerances for lost wax casting molds:

| Parameter | H13 Tool Steel | P20 Steel | 7075 Aluminum |

|——————————-|———————-|———————-|————————|

| Hardness | 48–52 HRC | 28–32 HRC | 150 HB |

| Typical Mold Life | 100,000+ cycles | 50,000–80,000 cycles | 5,000–10,000 cycles |

| Surface Finish (Standard) | Ra 0.8 µm | Ra 1.6 µm | Ra 3.2 µm |

| Machining Tolerance (± mm) | 0.02 | 0.02 | 0.03 |

| Feature Detail Resolution | 0.1 mm | 0.1 mm | 0.2 mm |

| Lead Time (T1 Sample) | 7 days | 7 days | 7 days |

Tolerances may vary slightly depending on part geometry and complexity. All molds are compatible with standard silicone and ceramic shell investment systems. Shenzhen Honyo Prototype combines advanced manufacturing technology with rigorous quality control to deliver reliable, repeatable tooling solutions that accelerate product development timelines.

From CAD to Part: The Process

Production Process Workflow: Lost Wax Casting (Investment Casting)

At Shenzhen Honyo Prototype, our lost wax casting process—more accurately termed precision investment casting—delivers complex, high-integrity metal components directly from CAD data. This rapid tooling method eliminates traditional hard tooling, significantly accelerating time-to-part while maintaining exceptional dimensional accuracy and surface finish. The workflow is rigorously structured into three integrated phases: AI Quote, DFM Analysis, and Production Execution, ensuring seamless transition from digital design to certified physical part.

The process initiates with our proprietary AI Quote System. Upon receiving a client’s 3D CAD model (STEP, IGES, or native formats), the AI engine rapidly analyzes geometric complexity, wall thickness distribution, material requirements, and surface finish specifications. It cross-references this data against our extensive historical production database and real-time material/feedstock costs. This generates an instant, highly accurate quotation with estimated lead time—typically within 2 hours—providing immediate project feasibility insight without manual engineering hours. Critical parameters like draft angles or undercuts are flagged here for preliminary assessment.

Phase two involves collaborative Engineering DFM (Design for Manufacturability) Review. Honyo’s senior manufacturing engineers conduct a deep-dive analysis, working directly with the client’s design team. We focus on optimizing the pattern design for wax injection stability, identifying optimal gating and runner systems to minimize turbulence during metal pour, and verifying thermal solidification paths to prevent shrinkage defects. Material selection is validated against performance requirements, considering factors like corrosion resistance, mechanical properties, and post-cast heat treatability. This phase often includes rapid iteration on the CAD model to enhance castability while preserving functional intent, reducing downstream rework risk.

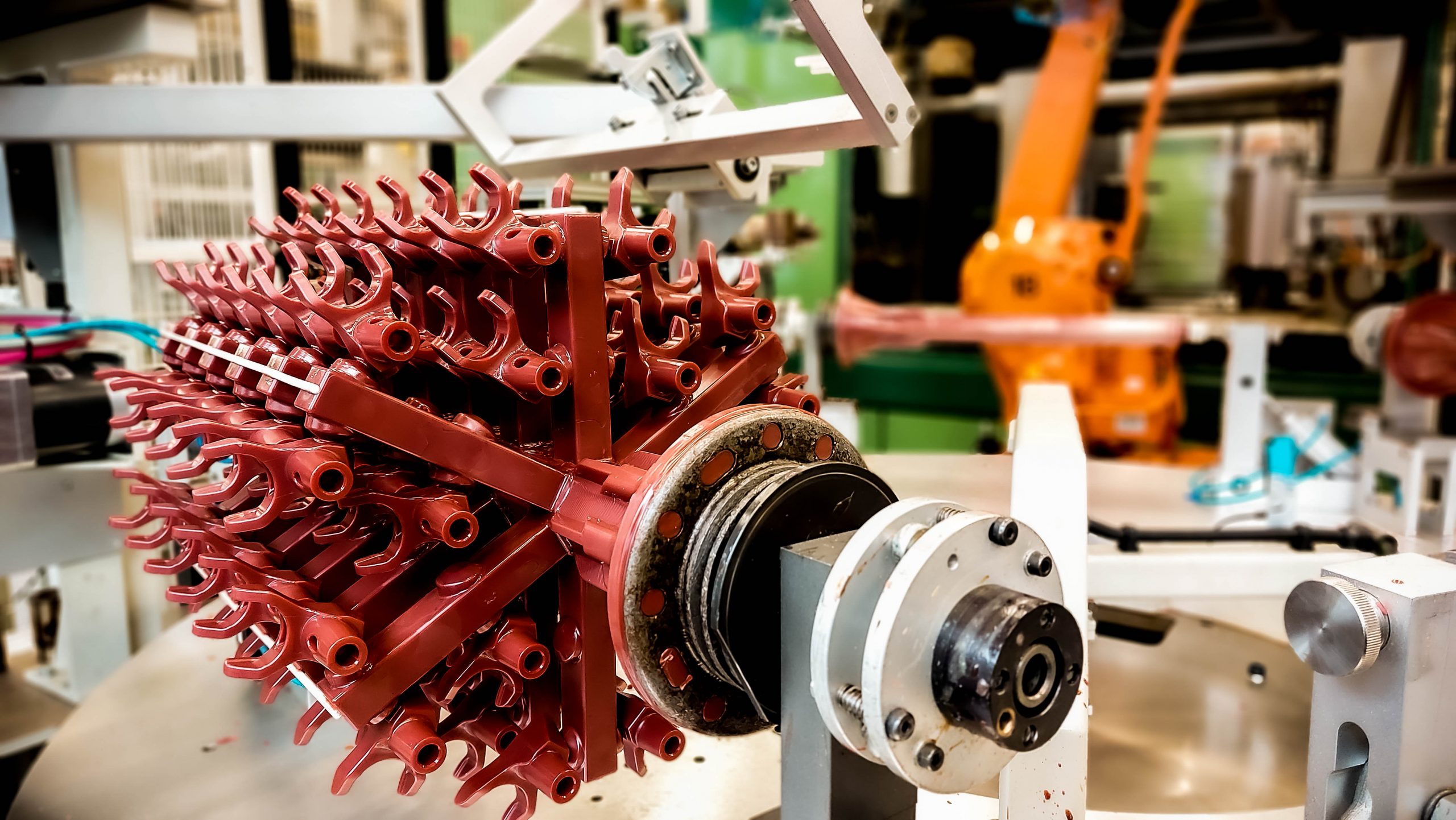

Production Execution commences upon DFM sign-off. First, a high-precision silicone pattern mold is fabricated via rapid tooling, enabling swift wax pattern production. These patterns are assembled into tree-like gates, repeatedly dipped in ceramic slurry, and stuccoed to build a robust refractory shell. After dewaxing and shell firing, molten metal is precision-poured into the preheated ceramic mold. Post-solidification, the shell is removed, gates are cut, and parts undergo meticulous finishing—including vibratory deburring, shot peening, and precision grinding—to achieve specified tolerances and surface quality. Final inspection employs CMM, optical comparators, and metallurgical testing per client drawings.

Key material and tolerance capabilities are summarized below for reference:

| Parameter | Standard Capability | Precision Capability |

|——————–|—————————|————————-|

| Materials | 304/316 Stainless Steel, Aluminum Alloys (356, A380), Carbon Steel | Inconel 718, Titanium Grade 5, Tool Steels |

| Linear Tolerance | ±0.1% of dimension | ±0.05 mm (on features < 50 mm) |

| Surface Finish | 125-250 μin Ra | 32-63 μin Ra (as-cast) |

| Min. Wall Thickness | 0.8 mm | 0.5 mm (optimized geometry) |

Throughout production, Honyo implements real-time process monitoring and statistical process control (SPC). Each lot undergoes comprehensive dimensional verification and material certification, ensuring full traceability from raw alloy to finished component. This integrated digital-to-physical workflow—powered by AI-driven quoting, rigorous DFM collaboration, and controlled production execution—delivers investment cast parts with rapid turnaround (typically 10-15 days for first article) without compromising on quality or complexity.

Start Your Project

Start Your Project with Precision-Engineered Lost Wax Casting Molds at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in rapid tooling and injection molding solutions that bridge the gap between prototype development and full-scale production. Our expertise in lost wax casting molds ensures your complex metal components are manufactured with exceptional accuracy, surface finish, and repeatability. Whether you’re developing aerospace components, medical devices, or high-performance industrial parts, our engineering team is equipped to support your project from concept to completion.

Lost wax casting, also known as investment casting, is a time-tested manufacturing process ideal for producing intricate geometries with tight tolerances. At Honyo Prototype, we integrate modern rapid tooling techniques with traditional casting precision to reduce lead times and improve cost efficiency—without compromising quality. Our in-house capabilities include CNC-machined wax pattern tooling, ceramic shell molding, automated dewaxing, and precision metal pouring, all controlled under strict quality standards.

We understand that every project has unique requirements. That’s why we offer fully customizable mold development tailored to your material specifications, part complexity, and production volume. Our engineering team works closely with clients to optimize gate design, runner systems, and shrinkage compensation, ensuring consistent casting integrity across batches. With rapid turnaround times and scalable production capacity, Honyo Prototype is your trusted partner for low-volume prototyping and medium-volume manufacturing.

To get started, simply provide your 3D CAD file or technical drawings. Our team will conduct a comprehensive design for manufacturability (DFM) review, offering feedback on parting lines, draft angles, wall thickness, and potential defect mitigation. We support a wide range of casting alloys, including stainless steel, carbon steel, aluminum, and superalloys, and can accommodate both small and large part sizes.

Below are key technical specifications for our lost wax casting mold services:

| Parameter | Specification |

|——————————|———————————————-|

| Minimum Wall Thickness | 0.6 mm (stainless steel), 1.0 mm (aluminum) |

| Dimensional Accuracy | ±0.05 mm/mm (up to 100 mm) |

| Surface Finish (as-cast) | Ra 1.6 – 3.2 µm |

| Maximum Part Weight | 25 kg (steel), 15 kg (aluminum) |

| Lead Time (Mold + First Run) | 12–20 days (depending on complexity) |

| Supported Alloys | 304/316 Stainless Steel, 4140 Steel, A356 Aluminum, Inconel 718 |

| Tooling Life (Wax Patterns) | 1,000–5,000 cycles (steel molds) |

Our mission is to empower innovators with agile, high-precision manufacturing solutions. If you’re ready to move forward with your lost wax casting project, contact Susan Leo, our dedicated project coordinator. She will guide you through the onboarding process, provide a detailed quotation, and ensure your technical requirements are fully addressed.

Contact Susan Leo today at info@hy-proto.com to start your project. Let Honyo Prototype be the foundation of your next breakthrough in metal component manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.