Contents

Manufacturing Insight: Cnc Machining Projects

Manufacturing Insight: CNC Machining Projects at Honyo Prototype

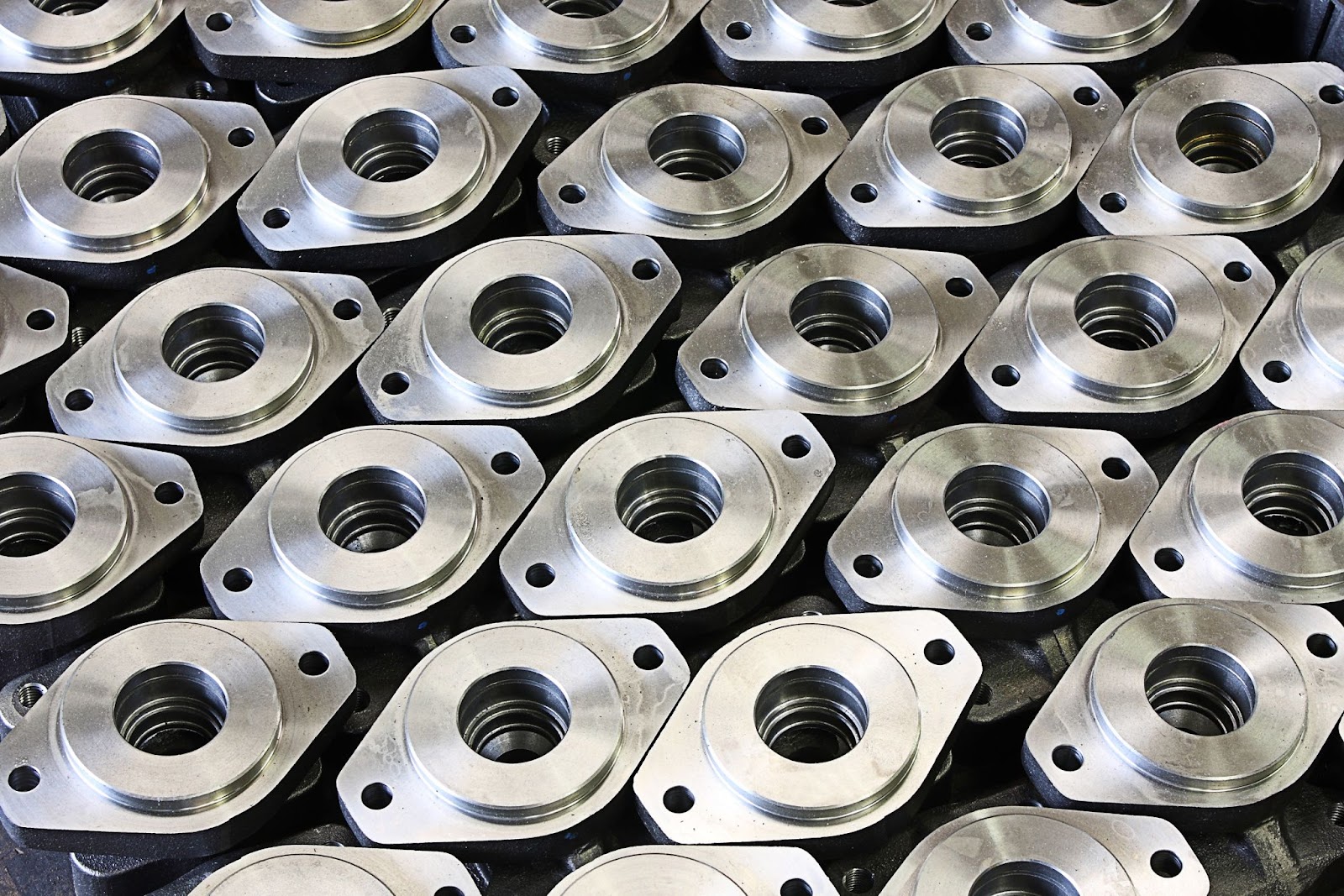

CNC machining remains the cornerstone of precision manufacturing for functional prototypes and low-to-medium volume production, delivering unmatched accuracy, material versatility, and repeatability. At Shenzhen Honyo Prototype, we leverage state-of-the-art CNC technology to transform complex 3D CAD models into high-fidelity physical components, critical for validation, testing, and bridging the gap between design and full-scale production. Our integrated approach ensures that every machined part meets stringent engineering requirements while optimizing for manufacturability and cost-effectiveness from the earliest project stages.

Honyo Prototype operates a comprehensive CNC machining facility equipped with advanced multi-axis systems, enabling us to handle geometrically intricate parts that challenge conventional manufacturing. Our capabilities span 3-axis, 4-axis, and full 5-axis simultaneous machining, allowing for complex contouring, deep cavity work, and minimized setup requirements – significantly reducing lead times and potential error sources. We maintain rigorous process control through continuous in-process inspection and final verification using calibrated CMMs and optical comparators, ensuring dimensional integrity down to sub-0.005mm tolerances. This precision is fundamental for industries like medical device development, aerospace components, and high-performance automotive systems where failure is not an option.

Our material expertise is a key differentiator. We routinely machine an extensive range of engineering-grade metals and plastics, including but not limited to aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), brass, copper, and high-performance polymers like PEEK, PPSU, and Ultem. This breadth allows us to match material properties precisely to your application’s thermal, chemical, and mechanical demands. Combined with our rapid prototyping focus, we deliver functional parts in as little as 3-5 business days for simple geometries, accelerating your development cycle without compromising quality. All processes adhere to ISO 9001:2015 quality management standards, providing documented traceability and consistent output.

Honyo’s value extends beyond machine operation. Our engineering team proactively engages in Design for Manufacturing (DFM) analysis during quoting, identifying potential machining challenges, material savings opportunities, and tolerance optimizations before cutting begins. This collaborative insight prevents costly revisions and delays, ensuring your design intent is realized efficiently. We understand that CNC projects demand more than just equipment; they require deep process knowledge, material science understanding, and a partner committed to your project’s success from concept to functional reality.

The following table summarizes our core CNC machining specifications and their impact on your project:

| Capability Category | Specification Range | Application Impact |

| :—————— | :—————— | :—————– |

| Machining Types | 3-Axis, 4-Axis, 5-Axis Simultaneous | Handles complex geometries, reduces setups, improves surface finish on contours |

| Tolerance Range | Standard: ±0.05mm; Precision: ±0.005mm | Ensures fit, function, and interchangeability for critical assemblies |

| Material Range | Metals: Aluminum, Steel, Titanium, Brass; Plastics: ABS, Nylon, PEEK, PC | Supports diverse functional requirements from structural to biocompatible |

| Part Size Range | Max Work Envelope: 1000 x 600 x 500mm | Accommodates both small precision components and larger assemblies |

| Surface Finish | As-Machined Ra 3.2µm; Polished to Ra 0.4µm | Meets aesthetic and functional requirements for sealing or wear |

Partnering with Honyo Prototype for your CNC machining projects means accessing a blend of advanced technology, rigorous quality systems, and engineering expertise focused squarely on accelerating your product development while guaranteeing the performance of every component. Let us apply our precision manufacturing capabilities to turn your design into a tangible, reliable solution.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining services tailored for rapid prototyping, low-volume production, and high-complexity components across aerospace, medical, automotive, and industrial sectors. Our advanced manufacturing facility supports 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to produce intricate geometries with exceptional accuracy and surface finish. With a focus on tight-tolerance machining, we consistently meet demanding engineering specifications while maintaining fast turnaround times.

Our 3-axis milling capabilities are ideal for prismatic parts with straightforward geometries, offering high-speed machining with excellent dimensional stability. For complex contours and angled features, our 4-axis and 5-axis CNC machining centers provide enhanced flexibility by allowing rotation around the A-axis and B-axis, respectively. This enables single-setup machining of multi-faceted components, reducing cumulative error and improving part consistency. 5-axis simultaneous machining is particularly effective for organic shapes, impellers, turbine blades, and structural aerospace components.

CNC turning is employed for cylindrical or near-cylindrical parts, including shafts, bushings, and threaded components. We support both standard and live-tooling turning centers, allowing for mill-turn operations that combine rotational machining with off-center features such as keyways, flats, and cross-holes—minimizing secondary operations.

Tight-tolerance machining is a core strength at Honyo Prototype. Our machines operate within controlled environments, and we utilize in-process probing and post-process inspection via coordinate measuring machines (CMM) to ensure compliance with stringent requirements. Typical tolerances are maintained within ±0.005 mm for critical dimensions, with surface finishes as fine as Ra 0.4 µm achievable upon request.

We process a wide range of engineering-grade materials, including aluminum alloys, stainless steels, tool steels, titanium, brass, copper, and high-performance plastics such as PEEK and PTFE. Material selection is supported by our engineering team to balance machinability, mechanical performance, and cost-efficiency.

The following table outlines our standard technical capabilities and tolerance ranges by process:

| Process | Typical Tolerance | Positional Tolerance | Max Work Envelope (mm) | Common Materials |

|——————-|——————-|————————|————————-|——————|

| 3-Axis Milling | ±0.01 mm | ±0.01 mm | 1000 × 600 × 500 | Aluminum 6061, 7075; Steel 1018; Stainless 303, 304, 316; POM, ABS |

| 4-Axis Milling | ±0.008 mm | ±0.01 mm | 800 × 500 × 400 | Aluminum 6061, 7075; Stainless 316; Titanium Grade 5; PEEK |

| 5-Axis Milling | ±0.005 mm | ±0.008 mm | 600 × 400 × 300 | Aluminum 7075; Stainless 17-4PH; Titanium; Inconel 718 |

| CNC Turning | ±0.01 mm | ±0.01 mm | Ø300 × 600 (diameter × length) | Aluminum 6061; Brass C360; Steel 4140; PTFE, Nylon |

All machined parts undergo first-article inspection and are delivered with material certifications and inspection reports when required. At Shenzhen Honyo Prototype, we combine state-of-the-art equipment with rigorous quality control to ensure every CNC machining project meets the highest standards of precision and reliability.

From CAD to Part: The Process

From CAD to Part: CNC Machining Workflow at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining workflow ensures precision, efficiency, and cost-effectiveness from initial design to final part delivery. This structured process—AI Quote, DFM Analysis, and Production—minimizes errors and accelerates time-to-market for your prototypes and low-volume production runs. We prioritize transparency and engineering rigor at every stage to align with your technical and commercial objectives.

AI-Powered Quoting

Upon receiving your 3D CAD model (STEP, IGES, or native formats), our proprietary AI quoting engine performs an instant technical and cost analysis. The system evaluates geometric complexity, material requirements, tolerances, and surface finishes to generate a detailed quote within hours. Key parameters assessed include feature accessibility, minimum wall thickness, and cavity depth ratios. This initial scan identifies potential high-cost drivers early, allowing for informed design decisions before formal order placement. Material selection is critical at this phase; common options and their baseline capabilities are summarized below.

| Material Category | Common Grades | Standard Tolerance (mm) | Max Part Size (mm) | Lead Time Factor |

|——————-|—————|————————-|——————–|——————|

| Aluminum Alloys | 6061, 7075 | ±0.025 | 1000 x 600 x 500 | 1.0x |

| Engineering Plastics | POM, Nylon, PEEK | ±0.05 | 800 x 500 x 400 | 1.2x |

| Stainless Steel | 303, 304, 17-4PH | ±0.02 | 700 x 400 x 350 | 1.5x |

Engineering-Led DFM Analysis

Following quote acceptance, our manufacturing engineers conduct a comprehensive Design for Manufacturability (DFM) review. This is not an automated step but a hands-on evaluation where we scrutinize toolpath feasibility, fixture requirements, and secondary operation needs. We verify geometric dimensioning and tolerancing alignment with machining capabilities, flag undercuts requiring 5-axis solutions, and assess optimal stock sizes to minimize material waste. Critical considerations include avoiding thin walls below 0.5mm in aluminum, recommending fillets for internal corners to prevent tool breakage, and suggesting tolerance relaxation where possible without compromising function. Client collaboration is essential here; we provide actionable feedback within 24 hours to resolve conflicts before programming begins.

Precision Production Execution

Once DFM is approved, your project enters production on our certified Haas, DMG MORI, and Makino equipment. All programs undergo rigorous simulation using Mastercam and NCSIMUL to eliminate collisions and verify G-code accuracy. Machining occurs in climate-controlled environments with in-process inspections at critical stages using Zeiss CMMs and optical comparators. For complex geometries, we deploy 5-axis simultaneous machining to reduce setups and maintain datum integrity. Final parts undergo 100% dimensional verification against your CAD model, followed by deburring, surface finishing per your specifications, and first-article validation. Throughout production, our real-time tracking system provides milestone updates, ensuring on-time delivery without compromising quality.

This integrated workflow—leveraging AI efficiency, human engineering expertise, and precision manufacturing—ensures your CNC project transitions seamlessly from digital design to a fully validated physical component. By addressing manufacturability upfront and maintaining strict process control, Honyo Prototype delivers parts that meet exacting functional requirements while optimizing your development timeline and budget.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision, speed, and reliability in CNC machining, Shenzhen Honyo Prototype delivers engineering excellence from concept to final part. Whether you’re developing a prototype for validation or scaling into low-volume production, our advanced CNC capabilities ensure your design is manufactured to exact specifications. We specialize in multi-axis machining, tight-tolerance components, and rapid turnaround times—making us the preferred partner for engineering teams across the automotive, medical, aerospace, and consumer electronics industries.

Our state-of-the-art facility in Shenzhen is equipped with a full range of CNC milling and turning centers, including 3-axis, 4-axis, and 5-axis machines capable of handling complex geometries with micron-level accuracy. We work with a broad selection of engineering-grade materials such as aluminum alloys (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and high-performance plastics like PEEK and Delrin. Our skilled machinists and quality engineers follow strict process controls to ensure every component meets or exceeds industry standards.

To get started, simply provide your 3D CAD model (STEP, IGES, or native formats preferred) along with any technical requirements, tolerances, or surface finish specifications. Our team will review your design for manufacturability, suggest optimizations if needed, and deliver a detailed quotation within 12 hours. With a typical lead time of 5–10 business days for most prototypes, we help accelerate your development cycle without compromising on quality.

We understand that every project is unique. That’s why we offer full customization—from material selection and finishing options to secondary operations such as tapping, anodizing, plating, and laser engraving. Our quality assurance process includes first-article inspection reports (FAIR), coordinate measuring machine (CMM) verification, and in-process inspections to ensure consistency across runs.

Below is an overview of our standard CNC machining capabilities:

| Specification | Details |

|—————————-|——–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Maximum Work Envelope | 1200 x 600 x 500 mm (47 x 23.6 x 19.7 in) |

| Tolerances | ±0.005 mm (±0.0002 in) standard; tighter on request |

| Materials | Aluminum, stainless steel, brass, titanium, plastics (PEEK, ABS, Nylon, etc.) |

| Lead Time | 5–10 days average (varies by complexity and quantity) |

| Finishing Options | As-machined, bead blast, anodizing (Type II & III), powder coating, passivation |

| Quality Standards | ISO 9001:2015 compliant; inspection reports available upon request |

Ready to bring your next design to life? Contact Susan Leo today at info@hy-proto.com to submit your project files and receive a fast, detailed quote. At Shenzhen Honyo Prototype, we’re committed to supporting your innovation with precision manufacturing, responsive service, and technical expertise you can trust. Let’s build something exceptional—together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.