Contents

Manufacturing Insight: Cnc Skills

Manufacturing Insight: CNC Machining Capabilities at Shenzhen Honyo Prototype

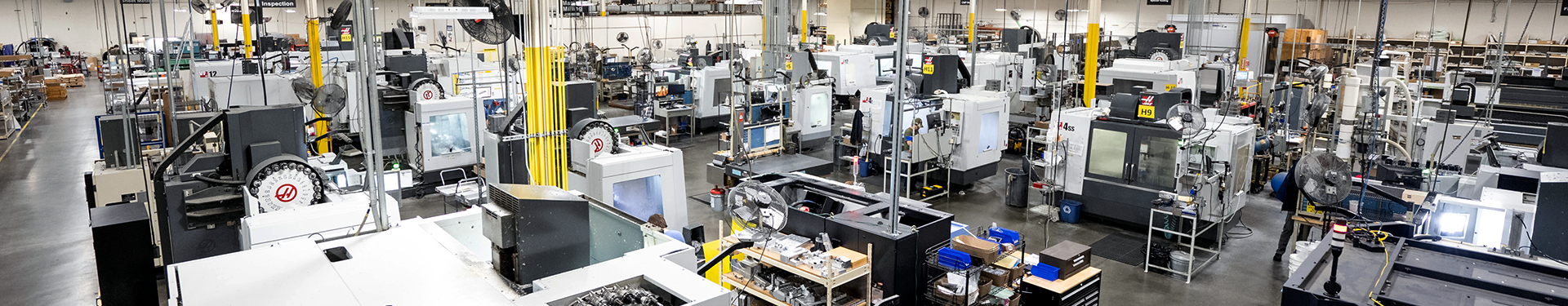

CNC machining remains the cornerstone of precision prototyping and low-volume production, transforming digital CAD models into high-fidelity physical components with exceptional accuracy and repeatability. At Shenzhen Honyo Prototype, we leverage this foundational subtractive manufacturing technology to deliver rapid, reliable parts across diverse materials including aerospace-grade aluminum, medical stainless steel, engineering plastics, and exotic alloys. Our commitment extends beyond mere operation; we integrate deep process knowledge with advanced hardware to solve complex engineering challenges inherent in modern product development, ensuring prototypes perform as intended and transition smoothly to production.

Honyo’s CNC expertise is built upon a foundation of rigorous engineering oversight and state-of-the-art equipment. Our manufacturing engineers possess extensive hands-on experience in optimizing toolpaths, selecting optimal cutting parameters, and mitigating thermal deformation – critical factors for achieving tight tolerances and superior surface finishes. We prioritize in-house control of the entire process, from CAM programming and fixture design to final inspection, eliminating external dependencies that compromise quality and speed. This vertical integration allows for rapid iteration; design modifications identified during initial machining can be implemented and re-machined within hours, significantly accelerating development cycles for our clients. Our facility operates under strict ISO 9001 quality management protocols, ensuring consistent adherence to specifications on every project.

The core strength of our CNC service lies in the precision and versatility of our machine park, meticulously maintained and calibrated for sub-micron repeatability. Below are key specifications representative of our primary machining centers:

| Parameter | Typical Capability Range | Significance for Prototyping |

|——————–|——————————-|——————————————–|

| Positioning Accuracy | ±0.002 mm | Ensures critical features align perfectly |

| Repeatability | ±0.001 mm | Guarantees consistency across multiple parts |

| Max. Spindle Speed | 24,000 RPM | Enables high-speed machining of hardened materials |

| Axis Configuration | 3, 4, and 5-Axis Simultaneous | Handles complex geometries in single setups |

| Work Envelope | Up to 1000 x 600 x 500 mm | Accommodates mid-sized structural prototypes |

| Material Range | Metals, Plastics, Composites | Supports diverse functional testing needs |

We excel in producing components demanding intricate features, thin walls, tight positional tolerances (routinely holding ±0.005 mm), and challenging surface finishes (Ra 0.4 µm and below). Our engineers proactively engage with client design teams during the DFM (Design for Manufacturability) phase, identifying potential machining constraints early – such as deep cavities requiring specialized tooling or internal radii limitations – and providing actionable solutions to avoid costly delays. This collaborative approach, combined with our technical mastery of CNC processes, transforms complex designs into reality with speed, precision, and confidence. For projects where form, fit, and function validation are paramount, Honyo Prototype delivers the manufacturing insight necessary to de-risk product development and accelerate time-to-market.

Technical Capabilities

CNC Machining Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers precision CNC machining services tailored for rapid prototyping and low-to-medium volume production. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with CNC turning and tight-tolerance machining expertise, enable us to produce complex, high-accuracy components across a wide range of engineering materials. Our facility is equipped with state-of-the-art machining centers and supported by experienced engineers who ensure optimal toolpath strategies, material utilization, and quality control.

Our 3-axis milling services are ideal for prismatic parts with straightforward geometries, offering fast turnaround and high repeatability. For components requiring multi-sided machining or complex contours, our 4-axis and 5-axis CNC machining centers provide enhanced flexibility. The addition of rotational axes allows for single-setup machining of intricate features, reducing cumulative errors and improving surface finish. This capability is particularly beneficial for aerospace, medical, and automotive applications where geometric complexity and precision are critical.

CNC turning is employed for cylindrical or symmetrical parts, delivering excellent surface quality and dimensional accuracy. We support both bar-fed and chucking methods, accommodating various part lengths and geometries. When combined with live tooling, our mill-turn centers enable complete machining of turned components with milled flats, slots, or cross-drilled holes—minimizing secondary operations.

Tight-tolerance machining is a core competency at Honyo Prototype. We consistently hold tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, depending on part geometry, material, and feature size. Our quality assurance process includes first-article inspection, in-process checks, and final CMM verification to ensure compliance with technical drawings and GD&T requirements.

The following table outlines our standard machining tolerances and compatible materials:

| Process | Standard Tolerance | Tight Tolerance Capability | Typical Surface Finish (Ra) | Common Materials |

|———————-|——————–|—————————-|—————————–|——————|

| 3-Axis Milling | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 1.6 – 3.2 µm (63 – 125 µin) | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 316), Brass (C360), Plastics (ABS, POM, PEEK, Nylon) |

| 4-Axis Milling | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 1.6 – 3.2 µm (63 – 125 µin) | Same as above, plus titanium (Grade 2, 5) |

| 5-Axis Milling | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 0.8 – 1.6 µm (32 – 63 µin) | Aluminum, Titanium, Stainless Steel, PEEK, Inconel |

| CNC Turning | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 1.6 – 3.2 µm (63 – 125 µin) | Aluminum, Steel, Stainless Steel, Brass, Plastics |

| Mill-Turn (Live Tooling) | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 1.6 – 3.2 µm (63 – 125 µin) | Aluminum, Stainless Steel, Titanium, Brass |

All CNC programs are developed using industry-standard CAM software, ensuring optimized toolpaths and efficient material removal. We support customer-provided 3D models in STEP, IGES, and native CAD formats, and our DFM feedback process helps identify potential manufacturability improvements early in the design phase.

From CAD to Part: The Process

CNC Machining Production Process: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC machining workflow is engineered for precision, efficiency, and seamless client collaboration. We transform digital designs into high-fidelity physical prototypes through a rigorously defined three-stage process: AI-Powered Quotation, Comprehensive Design for Manufacturability (DFM) Analysis, and Controlled Production Execution. This structured approach minimizes iteration cycles and ensures optimal part quality from the initial concept.

The process initiates with our proprietary AI Quote system. Upon receiving client CAD files (STEP, IGES, or native formats), the AI engine performs an instant preliminary analysis. It assesses geometric complexity, material suitability based on client specifications, machine time estimation, and identifies potential high-risk features requiring immediate attention. This generates a preliminary cost and lead time quote within minutes, providing clients with rapid feasibility feedback. Crucially, the AI flags elements likely to cause manufacturability issues early, setting the stage for proactive refinement rather than reactive correction.

Following quote acceptance, the project enters the mandatory DFM analysis phase. Our senior manufacturing engineers conduct a detailed technical review, collaborating directly with the client’s design team. This is not a simple checklist but a value-engineering dialogue focused on optimizing the design for CNC production without compromising functional intent. Key parameters are scrutinized to prevent costly delays and rework:

| DFM Parameter | Critical Threshold | Impact of Non-Compliance |

| :——————— | :———————- | :———————————– |

| Minimum Wall Thickness | < 0.8mm (Aluminum) | Vibration, breakage during machining |

| Hole Depth to Diameter | > 10:1 (Standard Drill) | Breakage, poor surface finish, drift |

| Internal Corner Radius | < 0.5x Feature Depth | Tool access issues, stress points |

| Tolerance Stack-Up | Exceeds GD&T capability | Assembly failure, non-functional part |

This collaborative DFM stage typically resolves 85% of potential production issues before metal cutting begins, significantly reducing lead time variance and non-conformance costs for the client.

Only after DFM sign-off does the project advance to Production. Our CNC programmers generate optimized toolpaths using Mastercam and Siemens NX CAM, leveraging Honyo’s extensive material and tooling databases. Machining occurs on our calibrated fleet of 3-axis, 4-axis, and 5-axis milling centers and turning centers, operating under strict environmental controls. Every step adheres to ISO 9001:2015 protocols. In-process inspections using calibrated CMMs and optical comparators verify critical dimensions at predefined stages. Final inspection provides full dimensional reporting against the approved drawing, including surface finish verification. Throughout production, real-time data monitoring ensures process stability, with any deviation triggering immediate corrective action. The result is a prototype part that meets exact design specifications, delivered on schedule, ready for validation or integration. This disciplined workflow ensures Honyo consistently delivers manufacturable, high-precision prototypes that accelerate our clients’ product development cycles.

Start Your Project

Start Your CNC Machining Project with Confidence at Shenzhen Honyo Prototype

When it comes to precision CNC machining for prototypes and low-volume production, Shenzhen Honyo Prototype delivers unmatched quality, speed, and technical expertise. Whether you’re developing a new product, iterating on a design, or scaling from prototype to production, our advanced CNC capabilities ensure your components meet the highest standards of accuracy and surface finish.

Our state-of-the-art facility in Shenzhen is equipped with a full range of CNC machining technologies, including 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-tasking machines. We support a wide variety of materials—from aluminum, stainless steel, and titanium to engineering plastics like PEEK, PTFE, and nylon—ensuring your parts perform exactly as intended in real-world applications.

At Honyo Prototype, we understand that every project begins with a vision. That’s why our engineering team works closely with clients from the earliest stages to review designs for manufacturability, suggest material optimizations, and identify potential cost-saving opportunities. Our goal is not only to produce your parts but to help you refine your product for better performance, durability, and scalability.

We maintain tight tolerances down to ±0.005 mm and support complex geometries with minimal setup time, thanks to our integrated CAD/CAM systems and experienced machinists. Surface finishing options—including anodizing, powder coating, passivation, and polishing—are available to meet both functional and aesthetic requirements.

All parts are inspected using precision metrology equipment, including coordinate measuring machines (CMM) and optical comparators, ensuring full compliance with your specifications. Our quality management system is aligned with ISO standards, giving you confidence in every component we deliver.

Below is an overview of our core CNC machining capabilities:

| Feature | Specification |

|————————–|———————————————-|

| Maximum Work Envelope | 1200 x 600 x 500 mm (47 x 23.6 x 19.7 in) |

| Positioning Accuracy | ±0.005 mm |

| Spindle Speed | Up to 24,000 RPM |

| Supported Materials | Metals (Al, Steel, Ti, Brass), Plastics (PEEK, ABS, Nylon, etc.) |

| Lead Times | As fast as 3–5 days for prototypes |

| Finishing Options | Anodizing, Plating, Powder Coating, Polishing, Bead Blasting |

| Quality Standards | ISO-aligned, Full First Article Inspection (FAI) available |

Starting your project with Honyo Prototype is simple. Just send your 3D CAD file, preferred material, quantity, and any special requirements, and we’ll provide a detailed quotation within hours.

Contact Susan Leo today at info@hy-proto.com to begin your CNC machining project. With technical expertise, rapid turnaround, and a commitment to excellence, we’re ready to bring your ideas to life—precisely, efficiently, and reliably. Let Honyo Prototype be your trusted partner in innovation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.