Contents

Manufacturing Insight: Cnc Machine Automation

Manufacturing Insight: CNC Machine Automation

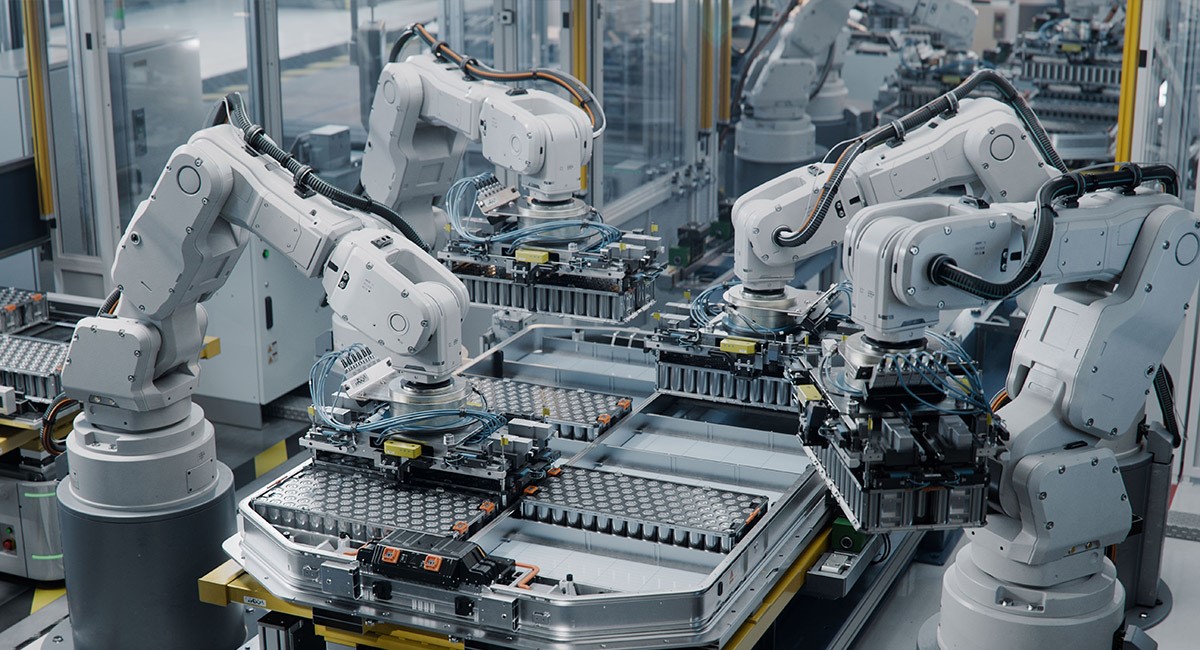

CNC machine automation represents a transformative advancement in precision manufacturing, particularly critical for rapid prototyping environments where speed, repeatability, and scalability are non-negotiable. At Shenzhen Honyo Prototype, we integrate advanced automation solutions directly into our CNC machining workflows to eliminate manual intervention during critical production phases. This technology extends beyond simple robotic loading; it encompasses coordinated systems including robotic arms, pallet changers, automated tool management, and in-process inspection, creating a seamless, lights-out manufacturing capability. For engineering teams requiring multiple design iterations or low-volume production parts, automation ensures consistent dimensional accuracy across every unit, regardless of complexity or operator fatigue, directly accelerating the path from CAD model to physical prototype.

Honyo Prototype has strategically implemented modular automation cells across our facility, specifically engineered to handle the high-mix, low-volume demands inherent in prototype and bridge production. Our systems utilize FANUC and KUKA robotics interfaced with industry-leading CNC platforms from DMG MORI and Haas, enabling 24/7 operation for extended unmanned runs. Key to our approach is the integration of automated material handling with real-time process monitoring. Sensors track tool wear, part dimensions, and machine health, feeding data back to our central Manufacturing Execution System (MES). This closed-loop control allows immediate corrective actions, minimizing scrap and ensuring first-article quality compliance even during overnight production cycles. Configurations are tailored to each project’s specific geometry and tolerance requirements, whether machining intricate aerospace components from titanium or high-speed milling of medical device housings in PEEK polymer.

The performance metrics achievable through our integrated automation platform deliver significant value for time-sensitive development projects. Below outlines core capabilities within our standard automation configurations:

| Feature Category | Specification Detail | Impact on Prototyping |

| :——————— | :—————————————————- | :—————————————- |

| Machine Types Supported | 3/4/5-Axis Milling, Turning Centers, Mill-Turn | Handles complex geometries in one setup |

| Max Unmanned Runtime | 72+ hours (with auto pallet storage) | Enables multi-day continuous operation |

| Positioning Accuracy | ±0.005 mm repeatability (robotic handling) | Maintains tight tolerances consistently |

| Typical Throughput Gain| 300-500% vs. manual operation for batch sizes >5 pcs | Dramatically reduces lead times |

| Integration Standard | FMS-ready with Honyo MES for real-time job tracking | Provides full production transparency |

Automation fundamentally shifts prototyping from a sequential, labor-dependent process to a concurrent engineering asset. By deploying these systems, Honyo Prototype consistently delivers functional prototypes with production-intent quality within 3-5 business days for most machined components, even with complex multi-operation requirements. The elimination of manual handling errors and reduced machine idle time directly translates to higher first-pass yield rates and predictable delivery schedules. For clients navigating stringent regulatory pathways or aggressive product launch timelines, our automated CNC capability provides the repeatability and speed necessary to validate designs confidently and iterate rapidly. This operational excellence forms the backbone of Honyo’s commitment to being a true extension of your engineering team, transforming design concepts into high-fidelity physical assets with unmatched efficiency.

Technical Capabilities

Technical Capabilities: CNC Machine Automation at Shenzhen Honyo Prototype

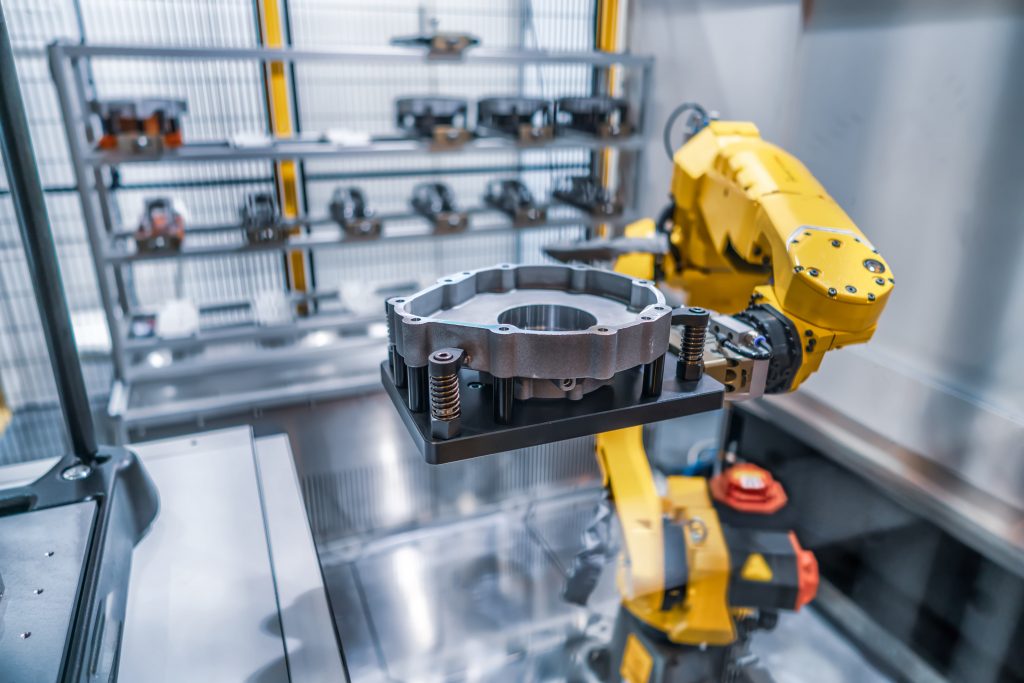

At Shenzhen Honyo Prototype, our CNC machine automation systems are engineered to deliver precision, repeatability, and efficiency across complex manufacturing workflows. Our automated 3-axis, 4-axis, and 5-axis CNC milling platforms are integrated with high-speed spindles, robotic part handling, and real-time tool monitoring systems, enabling continuous, lights-out production for both prototyping and low-to-mid volume manufacturing. These systems are complemented by automated CNC turning centers capable of handling bar feeders and part catchers, ensuring minimal human intervention and consistent part quality.

Our 5-axis simultaneous machining capability allows for the production of highly complex geometries in a single setup, reducing cumulative error and improving surface finish. The integration of automated fixturing and probing systems ensures rapid workpiece alignment and in-process inspection, critical for maintaining tight tolerances. All automated CNC operations are supported by advanced CAM programming and simulation software, minimizing cycle times and optimizing toolpaths for material efficiency.

Tight tolerance machining is a core strength of our automated systems. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, with surface finishes as fine as Ra 0.4 µm (16 µin), depending on material and geometry. This precision is maintained through temperature-controlled environments, preventive maintenance protocols, and closed-loop feedback systems that adjust for tool wear and thermal drift in real time.

We support a wide range of engineering-grade materials, including aluminum alloys (e.g., 6061, 7075), stainless steels (e.g., 303, 304, 316), titanium (Grade 5), brass, and high-performance plastics such as PEEK and PTFE. Material selection is optimized based on functional requirements, machinability, and environmental resistance, with automated bar loading and chip management systems ensuring clean, uninterrupted processing.

The table below outlines the key machining tolerances and compatible materials for our automated CNC processes:

| Process Type | Axis Configuration | Standard Tolerance (Linear) | Tight Tolerance Capability | Surface Finish (Typical) | Common Materials Supported |

|——————–|——————–|——————————|—————————–|—————————|————————————————-|

| CNC Milling | 3-Axis | ±0.010 mm | ±0.005 mm | Ra 1.6 – 3.2 µm | Aluminum, Steel, Brass, Plastics |

| CNC Milling | 4-Axis | ±0.010 mm | ±0.005 mm | Ra 1.6 – 3.2 µm | Aluminum, Stainless Steel, PEEK |

| CNC Milling | 5-Axis | ±0.008 mm | ±0.003 mm | Ra 0.8 – 1.6 µm | Aluminum, Titanium, Inconel, PTFE |

| CNC Turning | 2-Axis (Auto) | ±0.010 mm | ±0.005 mm | Ra 1.6 – 3.2 µm | Aluminum, Brass, 304/316 Stainless, PEEK |

| CNC Mill-Turn | Multi-Axis | ±0.008 mm | ±0.003 mm | Ra 0.8 – 1.6 µm | Titanium, 17-4 PH, Inconel, PTFE |

All automated CNC operations are monitored through centralized control systems that track tool life, spindle load, and dimensional accuracy. This data-driven approach ensures traceability and enables continuous process improvement. At Shenzhen Honyo Prototype, our investment in CNC automation translates into faster lead times, reduced variability, and superior part quality for demanding industrial, aerospace, medical, and automotive applications.

From CAD to Part: The Process

From CAD to Part: Streamlined CNC Automation Workflow at Honyo Prototype

Shenzhen Honyo Prototype leverages integrated CNC machine automation to transform digital designs into precision metal and plastic prototypes with exceptional speed and reliability. Our standardized workflow—AI Quote, DFM Analysis, and Automated Production—minimizes lead times while ensuring manufacturability and quality, critical for rapid prototyping cycles in demanding B2B sectors.

The process initiates with the AI-Powered Quoting System. Clients upload native CAD files (STEP, IGES, Parasolid, or native formats from SolidWorks, Fusion 360, etc.) directly to our secure portal. Our proprietary AI engine performs instantaneous geometry analysis, identifying key features, material requirements, and complexity factors. This enables generation of an accurate, detailed quote within minutes, including estimated lead time and cost breakdown, eliminating traditional manual quoting delays. This immediate feedback loop allows engineering teams to make informed decisions early in the design phase.

Following quote acceptance, every design undergoes rigorous Digital Manufacturing Feasibility (DFM) Analysis by our senior manufacturing engineering team. This step is non-negotiable for prototype success. We systematically evaluate the CAD model against CNC machining constraints, identifying potential issues that could cause delays, increased costs, or part failure. Key focus areas include geometric complexity, feature accessibility, wall thickness, tolerances, and material suitability. Proactive DFM resolution prevents costly revisions post-quoting and ensures the design is optimized for efficient, high-yield machining on our automated platforms. Common findings and our mitigation strategies are summarized below:

| DFM Issue Category | Potential Impact | Honyo Prototype Solution |

|:————————-|:——————————————|:———————————————|

| Thin Walls/Features | Chatter, deflection, breakage during cut | Adaptive toolpath strategies, specialized tooling, staged roughing |

| Deep Cavities/High Aspect Ratio Holes | Tool breakage, poor surface finish, chip evacuation issues | Custom tool selection, peck drilling cycles, high-pressure coolant |

| Tight Tolerances on Complex Geometry | Extended machining time, CMM inspection bottlenecks | Tolerance rationalization consultation, strategic datum selection |

| Inaccessible Features | Requirement for complex fixtures or 5-axis, increasing cost | Design modification suggestion, optimal workholding strategy planning |

The final phase, Automated CNC Production, executes the validated design using our integrated robotic cells. Parts are manufactured on state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers, seamlessly connected to robotic arms and pallet systems. This automation enables true lights-out manufacturing: raw material is automatically loaded, the part is precisely machined per the optimized CAM program (itself refined based on DFM insights), and finished components are unloaded to designated staging areas—all with minimal human intervention. In-process probing ensures dimensional accuracy during machining, while automated part handling maintains traceability. This continuous flow, operating 24/7 where required, delivers complex prototypes in as little as 3-5 business days without compromising on the stringent quality standards demanded by aerospace, medical, and robotics clients. The result is a seamless, predictable transition from your CAD model to a functional prototype, accelerating your product development timeline significantly.

Start Your Project

Start Your CNC Machine Automation Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering precision CNC machining solutions integrated with advanced automation technologies. Whether you’re developing high-volume production components or complex one-off prototypes, our automated CNC systems ensure unmatched accuracy, repeatability, and efficiency. As a trusted partner in the manufacturing ecosystem, we combine cutting-edge equipment with engineering expertise to streamline your production workflow from concept to delivery.

CNC machine automation is transforming modern manufacturing by reducing human intervention, minimizing error rates, and increasing throughput. At Honyo, our automation solutions include robotic loading/unloading systems, pallet changers, bar feeders, and integrated quality inspection modules—all synchronized with our CNC machining centers to deliver seamless operations. This level of integration allows for 24/7 production cycles, optimal tool utilization, and consistent part quality across batches.

Our facility in Shenzhen is equipped with a comprehensive range of CNC machines, including 3-axis, 4-axis, and 5-axis machining centers, all retrofitted or factory-built for automated operation. We support a wide variety of materials such as aluminum alloys, stainless steel, titanium, brass, and engineering plastics, ensuring versatility across industries like aerospace, medical devices, automotive, and consumer electronics.

To begin your project, simply provide your design files in STEP, IGES, or native CAD formats. Our engineering team will conduct a detailed Design for Manufacturability (DFM) review, offering feedback on geometry optimization, tolerances, material selection, and cost-saving opportunities. Once approved, your parts enter our automated production queue with real-time tracking and scheduled updates.

We understand that every project has unique requirements. That’s why our automation workflows are fully customizable—whether you need small-batch automated prototyping or large-scale production runs. Our quality management system adheres to ISO 9001 standards, and every component undergoes rigorous in-process and final inspections using CMM, optical comparators, and surface roughness testers.

Below are key specifications of our automated CNC machining capabilities:

| Parameter | Specification |

|——————————|————————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC machining centers |

| Automation Integration | Robotic loading, pallet changers, bar feeders |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Lead Times (Automated Runs) | As fast as 3–7 days for qualified projects |

| Quality Standards | ISO 9001:2015 compliant, full inspection reports |

Ready to leverage the power of CNC automation for your next project? Contact Susan Leo today at info@hy-proto.com to discuss your requirements, request a quote, or schedule a technical consultation. At Honyo Prototype, we’re committed to accelerating your product development with smart, scalable manufacturing solutions.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.