Contents

Manufacturing Insight: Machining & Fabrication

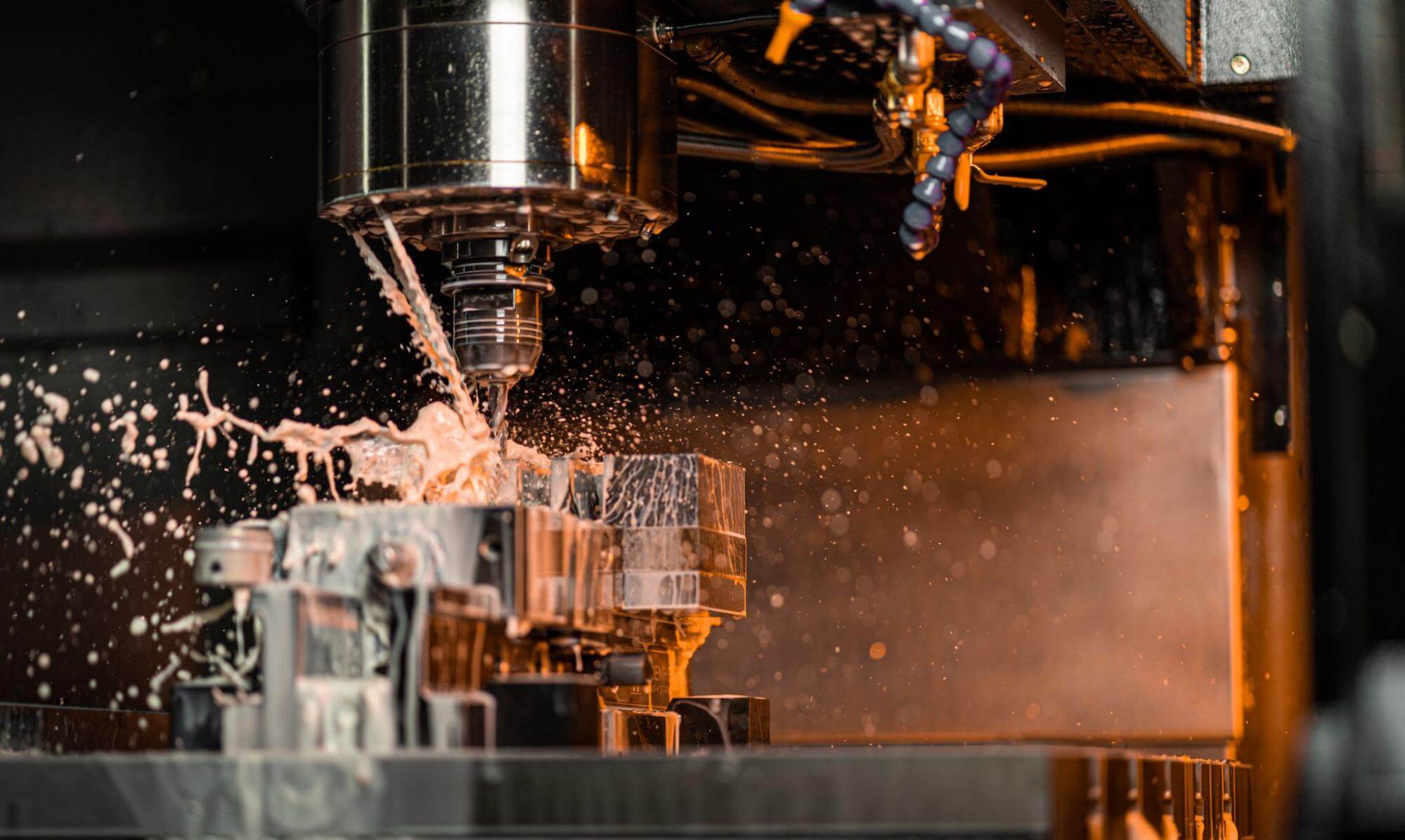

Precision Engineering Foundation: CNC Machining at Shenzhen Honyo Prototype

CNC machining represents the cornerstone of modern precision manufacturing, transforming digital CAD models into high-fidelity physical components through computer-controlled subtractive processes. At Shenzhen Honyo Prototype, we leverage advanced 3-, 4-, and 5-axis milling and turning centers to produce complex geometries with exceptional accuracy and repeatability. This technology is indispensable for rapid prototyping, low-volume production, and functional validation across aerospace, medical, automotive, and consumer electronics sectors. Our core strength lies in translating intricate design intent into tangible parts while maintaining strict adherence to dimensional tolerances and surface finish requirements, directly supporting Design for Manufacturability (DFM) optimization during the critical development phase.

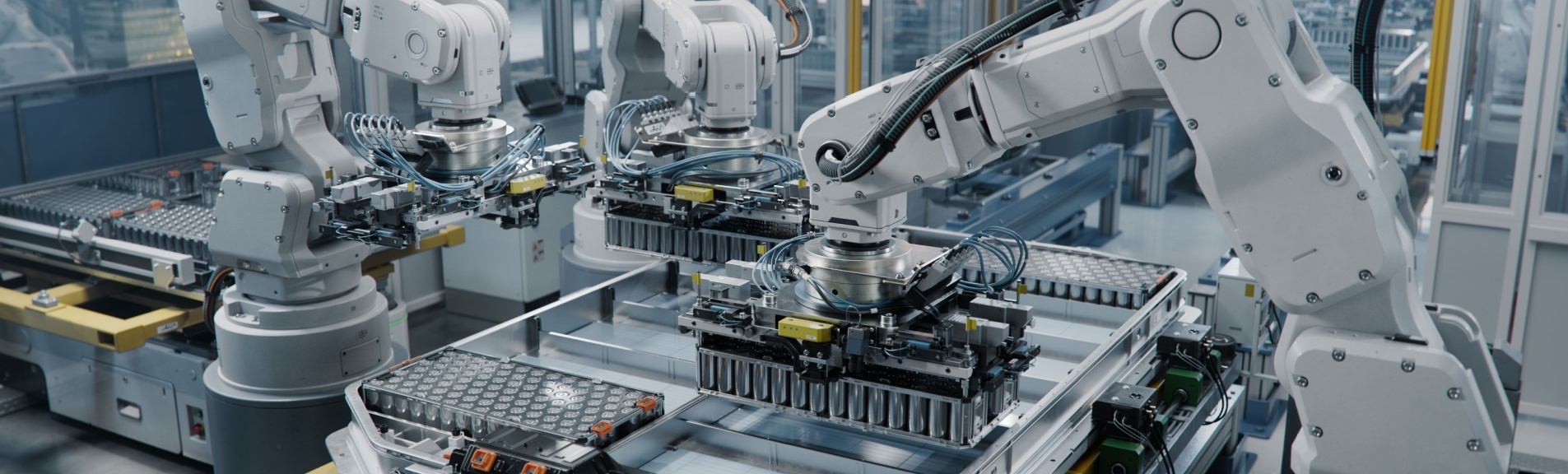

Our integrated manufacturing ecosystem extends beyond core CNC capabilities to encompass comprehensive fabrication services, including precision sheet metal forming, laser cutting, welding, and finishing. This holistic approach ensures seamless transition from prototype to pilot production, eliminating supply chain fragmentation. Honyo’s technical differentiators include rapid setup optimization using advanced CAM software, rigorous in-process inspection protocols, and material expertise spanning aluminum alloys, stainless steels, titanium, engineering plastics like PEEK and Delrin, and specialized composites. We prioritize minimizing lead times without compromising quality, enabling our clients to accelerate time-to-market while mitigating production risks.

Honyo Prototype’s machining infrastructure is calibrated for demanding applications. The table below summarizes key capabilities supporting complex project execution:

| Capability Category | Specification Range | Application Impact |

|—————————|—————————————–|———————————————|

| Positional Accuracy | ±0.005 mm | Critical for mating surfaces & assemblies |

| Surface Finish (Ra) | 0.8 μm to 3.2 μm (machined) | Functional performance & aesthetic quality |

| Max Work Envelope | 1000 x 600 x 500 mm (5-axis) | Accommodates medium-sized assemblies |

| Material Diversity | Metals (Al, SS, Ti, Brass), Plastics (PEEK, PC, ABS), Composites | Supports multi-material prototypes |

| Typical Lead Time | 3-7 days (standard prototypes) | Accelerates design iteration cycles |

Our commitment to technical excellence is reinforced by ISO 9001-certified quality management systems, featuring first-article inspection (FAI) reports, CMM verification, and real-time process monitoring. Engineers benefit from direct collaboration with our manufacturing team during design review stages, ensuring manufacturability insights are incorporated early. This proactive engagement prevents costly redesigns and facilitates smoother transitions to volume production. By combining cutting-edge equipment with deep process knowledge, Honyo Prototype delivers machined and fabricated components that meet stringent functional and regulatory demands. We serve as a strategic extension of your engineering team, providing the precision, speed, and technical partnership necessary to transform innovative concepts into validated, production-ready solutions. Partner with us to leverage CNC machining not merely as a production step, but as an integrated engineering asset driving product success.

Technical Capabilities

CNC Machining Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers high-precision CNC machining and fabrication services tailored for rapid prototyping, low-volume production, and complex component manufacturing. Our advanced machining center is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling machines, as well as multi-tasking CNC turning centers, enabling us to produce intricate geometries with exceptional accuracy and surface finish. Our in-house capabilities support a broad range of engineering materials, ensuring flexibility across industries such as aerospace, medical devices, robotics, and consumer electronics.

Our 3-axis milling systems are ideal for prismatic parts with straightforward geometries, offering fast turnaround and high repeatability. For components requiring access to multiple faces or complex contours, our 4-axis and 5-axis machining centers provide simultaneous multi-directional cutting, reducing setup times and enhancing dimensional consistency. 5-axis machining allows for the production of highly complex organic shapes, deep cavities, and angled features that are unattainable with conventional 3-axis methods.

In addition to milling, our CNC turning capabilities support both standard and Swiss-type turning operations, accommodating parts with tight diameter tolerances and high length-to-diameter ratios. We integrate live tooling and sub-spindles to perform secondary operations such as cross-drilling, milling, and threading in a single setup, improving precision and reducing lead times.

A core strength of our machining service is our ability to maintain tight tolerances across a variety of materials. Typical tolerances range from ±0.005 mm to ±0.025 mm, depending on part geometry, material, and feature type. Critical dimensions can be held to ±0.002 mm with proper design considerations and inspection protocols. All parts undergo rigorous quality control using calibrated CMMs, optical comparators, and surface roughness testers to ensure compliance with customer specifications.

We support a wide selection of metals and engineering plastics, including aluminum, stainless steel, titanium, brass, PEEK, and polycarbonate. Material selection is optimized based on mechanical requirements, environmental exposure, and functional performance.

Standard Machining Tolerances and Material Capabilities

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Supported Materials |

|———————-|——————–|—————————-|———————|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass (C360), PEEK, PC, ABS |

| Hole Diameter | ±0.012 mm | ±0.005 mm | Same as above |

| Positional Tolerance | ±0.025 mm | ±0.010 mm | Same as above |

| Surface Roughness | Ra 3.2 µm (typical)| Ra 0.8 µm (machined), Ra 0.2 µm (polished) | Same as above |

| Angular Features | ±0.1° | ±0.05° | Same as above |

All machining processes are supported by full CAD/CAM integration, with programming conducted using Mastercam, Siemens NX, and Fusion 360. We accept STEP, IGES, and native CAD formats to ensure seamless translation from design to finished part. With a focus on precision, repeatability, and technical excellence, Shenzhen Honyo Prototype ensures that every machined component meets the highest standards of quality and performance.

From CAD to Part: The Process

From CAD to Part: CNC Machining Workflow at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers precision CNC machined components through a rigorously defined workflow, ensuring manufacturability, quality, and speed from initial concept to final part. Our process integrates advanced digital tools with expert engineering oversight, specifically structured into three critical phases: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution. This integrated approach minimizes iteration, reduces lead times, and guarantees parts meet exact specifications.

AI-Powered Quoting initiates the workflow upon receipt of the client’s CAD model. Our proprietary AI quotation engine rapidly analyzes the 3D geometry, automatically identifying key manufacturing parameters including feature complexity, required operations (milling, turning), estimated machine hours, material utilization, and secondary processes. This system cross-references real-time data on material costs, machine availability, and labor rates to generate a highly accurate, detailed quote within hours, not days. The output provides transparent cost breakdowns and preliminary lead time estimates, enabling swift project initiation and informed client decision-making before engineering resources are deeply engaged.

Comprehensive DFM Analysis follows quote acceptance and is the cornerstone of our quality and efficiency. Senior manufacturing engineers conduct an in-depth review of the CAD model, focusing specifically on optimizing the design for CNC fabrication. This critical step identifies potential issues such as non-manufacturable geometries, excessive tolerances in non-critical areas, inadequate tool access, thin walls prone to chatter, or suboptimal feature placement affecting fixturing. We provide actionable, specific feedback to the client, suggesting practical modifications that maintain functional intent while significantly enhancing machinability, reducing cycle time, minimizing scrap risk, and lowering overall cost. Client collaboration during DFM ensures the final design is robust and production-ready.

Precision Production Execution commences only after DFM sign-off. Our state-of-the-art CNC machining center utilizes the approved CAD/CAM data to generate optimized toolpaths. Skilled technicians meticulously set up the selected machine, verifying tooling, workholding, and coordinate systems. Machining proceeds under strict process control, with in-process inspections at critical stages to confirm dimensional accuracy and surface finish against the print. Post-machining, parts undergo final precision inspection using calibrated CMMs and optical comparators before any required secondary operations like deburring, anodizing, plating, or laser marking. Final quality documentation accompanies every shipment.

Honyo Prototype leverages advanced multi-axis CNC capabilities to handle complex geometries efficiently. Key production assets include:

| Machine Type | Axes | Max Travel (X/Y/Z) | Typical Materials Handled | Standard Tolerance |

|——————–|——|———————|—————————|——————-|

| 3-Axis Vertical Mill | 3 | 1000 x 500 x 500 mm | Aluminum 6061/T6, 7075; Steels; Plastics | ±0.025 mm |

| 4-Axis Mill | 4 | 800 x 400 x 400 mm | Same as above + Titanium alloys | ±0.025 mm |

| 5-Axis Mill | 5 | 600 x 400 x 400 mm | Complex geometries in all above materials | ±0.0125 mm |

| CNC Turning Center | 2+Y | Ø300 x 500 mm | Bar stock metals (Al, SS, Brass, Ti) | ±0.0125 mm |

This seamless transition from AI-Driven Quoting through proactive DFM to tightly controlled Production Execution ensures Shenzhen Honyo Prototype consistently delivers high-integrity CNC machined prototypes and low-volume production parts with exceptional speed and reliability, directly translating client designs into tangible, functional components.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When precision, speed, and reliability matter in CNC machining and fabrication, Shenzhen Honyo Prototype delivers engineered excellence from concept to completion. As a trusted partner in rapid prototyping and low-volume production, we specialize in turning your design visions into high-accuracy metal and plastic components using advanced 3-, 4-, and 5-axis CNC machining technologies. Whether you’re developing a functional prototype, refining a design for manufacturability, or preparing for small-batch production, our team ensures tight tolerances, consistent quality, and fast turnaround times.

At Honyo Prototype, we understand that every project begins with a clear objective. That’s why we offer a seamless onboarding process tailored to your technical requirements. Simply provide your 3D CAD files, specify materials, tolerances, surface finishes, and quantities, and our engineering team will conduct a comprehensive Design for Manufacturability (DFM) review. This ensures optimal part geometry, minimizes machining complexity, and reduces lead times—saving you time and cost without compromising performance.

We support a broad range of materials, including aluminum (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics such as PEEK, ABS, and Delrin. With in-house capabilities in milling, turning, wire EDM, and finishing processes—including anodizing, powder coating, and bead blasting—we deliver fully finished parts ready for integration into your assemblies.

Our facility in Shenzhen is equipped with state-of-the-art CNC systems and inspection equipment, including CMM and optical comparators, ensuring every component meets ISO 9001 standards for quality assurance. We serve industries ranging from aerospace and medical devices to consumer electronics and robotics, where precision and repeatability are non-negotiable.

To ensure your project starts on the right foot, we recommend submitting your design early for a free manufacturability analysis. This proactive step identifies potential issues before machining begins, helping avoid costly revisions and delays.

CNC Machining Capabilities at a Glance

| Parameter | Specification |

|—————————-|———————————————-|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning |

| Tolerances | ±0.005 mm standard, tighter on request |

| Materials | Metals: Al, SS, Ti, brass; Plastics: PEEK, ABS, Delrin, PC |

| Max Work Envelope | 1200 × 600 × 500 mm (milling), Ø300 × 500 mm (turning) |

| Lead Time | As fast as 3–7 days for prototypes |

| Finishing Options | Anodizing (Type II & III), powder coating, sandblasting, polishing |

| Quality Standards | ISO 9001 certified, full inspection reports |

Starting your project with Honyo Prototype is simple. Contact Susan Leo directly at info@hy-proto.com to submit your design files and receive a detailed quote within 12 hours. Our engineering team is ready to support you from initial consultation through final delivery, ensuring your CNC-machined parts meet exacting specifications and arrive on schedule. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.