Contents

Manufacturing Insight: Manual Cnc Machine

Manufacturing Insight: Manual CNC Machining Capabilities at Honyo Prototype

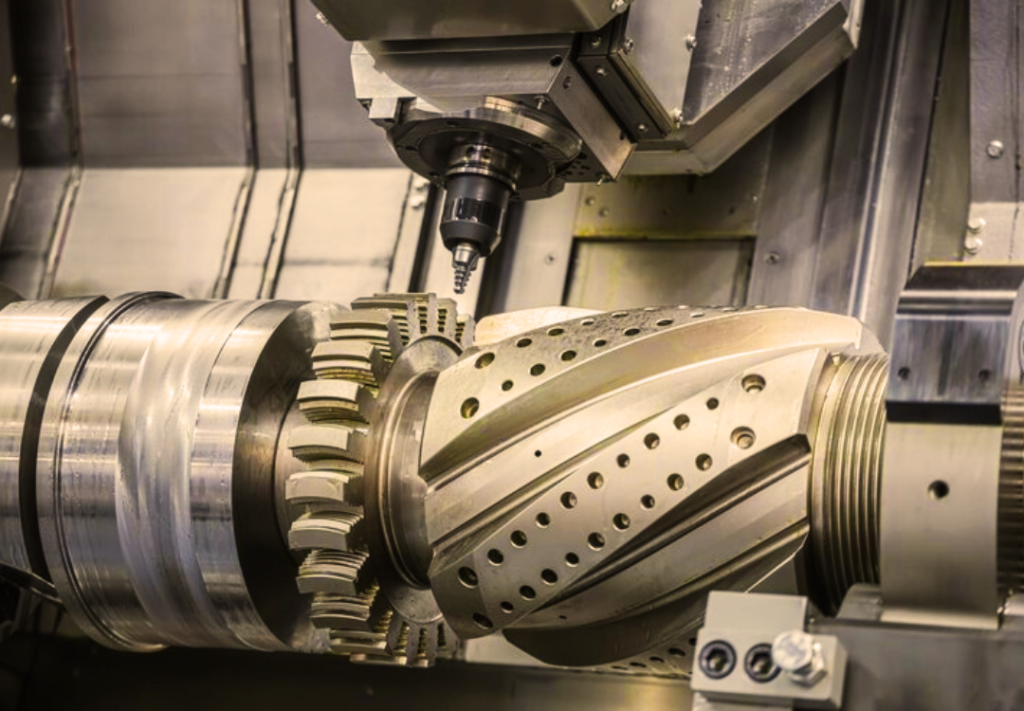

Manual CNC machining represents a specialized subset of computer numerical control technology where the operator maintains direct, real-time control over tool positioning, feed rates, and spindle engagement while leveraging CNC’s core motion precision. Unlike fully automated CNC systems executing pre-programmed G-code without intervention, manual CNC integrates the operator’s expertise to dynamically adjust machining parameters during the process. This hybrid approach is indispensable for low-volume prototyping, complex one-off components, and materials requiring adaptive handling—situations where rigid automation risks part failure or suboptimal surface integrity. At Shenzhen Honyo Prototype, we deploy manual CNC not as a legacy solution but as a strategic differentiator for projects demanding iterative refinement and human-centric precision.

Our manual CNC workflow begins with a certified engineer reviewing the CAD model to identify critical tolerances, material constraints, and potential machining hazards. Operators then execute the program while continuously monitoring cutting forces, chip formation, and thermal behavior. This enables immediate adjustments for challenging geometries—such as deep cavities in hardened tool steels or thin-walled aluminum features prone to chatter—ensuring dimensional stability unattainable through preset feeds/speeds alone. Crucially, this method reduces scrap rates by 30–40% compared to automated runs for high-mix, low-volume prototypes, as operators preemptively correct for material inconsistencies or tool deflection. Honyo’s machinists average 12+ years of hands-on experience with exotic alloys and composites, certified to ISO 2768-mK standards for geometric tolerancing.

Honyo Prototype’s manual CNC infrastructure supports rapid iteration without sacrificing metrological rigor. We maintain calibrated Fanuc-controlled vertical mills and lathes equipped with high-resolution digital readouts (DROs) and live tooling, enabling simultaneous milling/turning operations. Each machine undergoes weekly laser alignment verification to sustain sub-0.01mm positional repeatability. Our facility excels in producing mission-critical components for aerospace validation, medical device R&D, and precision instrumentation—where first-article accuracy directly impacts downstream assembly success.

Key technical capabilities are summarized below:

| Parameter | Specification | Honyo Capability | Typical Application |

|——————–|———————|————————————–|———————————–|

| Positional Accuracy | ±0.005 mm | ±0.003 mm (under 100 mm) | Sensor housings, optical mounts |

| Max Work Envelope | 860 x 510 x 510 mm | 750 x 450 x 400 mm (optimal control) | Automotive brackets, UAV frames |

| Surface Finish | Ra 0.8 μm | Ra 0.4 μm (aluminum/steel) | Hydraulic manifolds, sealing faces|

| Material Range | Metals, Plastics | Titanium Gr5, Inconel 718, PEEK | Aerospace, medical implants |

| Lead Time | Prototype: 3–5 days | 72 hours (priority) | Design validation cycles |

This capability aligns with Honyo’s core philosophy: precision manufacturing is both a science and a craft. For prototypes where material behavior is unpredictable or tolerances exceed ±0.01mm, manual CNC delivers the adaptive control that pure automation cannot replicate. We partner with engineering teams to transform complex designs into physically validated components—ensuring your prototype performs as intended before committing to production tooling. Contact our manufacturing specialists to determine if manual CNC is optimal for your next development phase.

Technical Capabilities

Manual CNC Machining Technical Capabilities

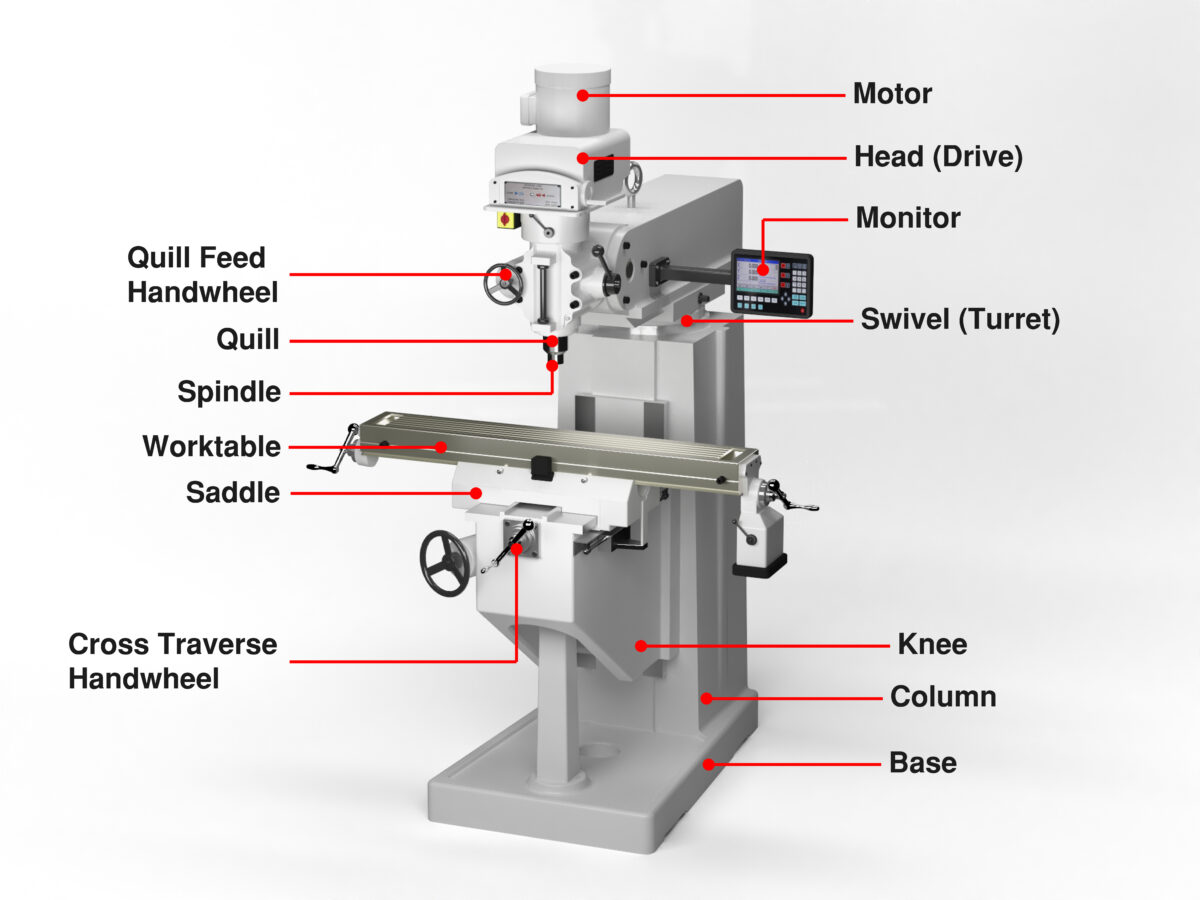

Shenzhen Honyo Prototype offers precision manual CNC machining services tailored for rapid prototyping and low-to-medium volume production. Our facility is equipped with a range of manually operated CNC milling and turning machines capable of 3-axis, 4-axis, and 5-axis configurations, enabling us to produce complex geometries with high accuracy and repeatability. These machines are operated by skilled machinists who combine decades of experience with rigorous process control to deliver components that meet stringent engineering requirements.

Our 3-axis milling centers are ideal for prismatic parts with orthogonal features, providing reliable performance for standard machined components. For more complex designs involving angled features, undercuts, or organic contours, our 4-axis and 5-axis manual CNC platforms allow for multi-sided machining with minimal setup changes. This reduces cumulative error and improves geometric consistency, especially critical in aerospace, medical, and industrial applications.

Turning operations are performed on precision manual lathes with live tooling capabilities, supporting both straight-turning and milling-on-lathe functions. These machines are optimized for cylindrical parts with tight diameter control, fine surface finishes, and precise thread forms. All manual CNC equipment is maintained under strict calibration schedules and operates within temperature-controlled environments to minimize thermal drift.

Tight tolerance machining is a core strength at Honyo Prototype. We routinely hold tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, with specialty processes capable of achieving ±0.002 mm (±0.00008″) under controlled conditions. Feature-to-feature positional accuracy, flatness, concentricity, and surface finish are closely monitored using calibrated CMMs, optical comparators, and surface profilometers.

The following table outlines typical tolerance capabilities and compatible materials for our manual CNC machining services:

| Operation | Typical Tolerance (mm) | Typical Tolerance (in) | Common Materials | Max Work Envelope (mm) |

|—————–|————————|————————|————————————–|————————|

| 3-Axis Milling | ±0.01 | ±0.0004 | Aluminum 6061, 7075, Steel 1018, 4140, Stainless 303, 316, Brass C360, POM, PC, PEEK | 600 x 400 x 300 |

| 4-Axis Milling | ±0.008 | ±0.0003 | Same as above plus Titanium Grade 2, 5 | 500 x 400 x 250 |

| 5-Axis Milling | ±0.005 | ±0.0002 | Aluminum, Titanium, Stainless Steel, PEEK | 400 x 300 x 200 |

| CNC Turning | ±0.005 | ±0.0002 | Aluminum, Steel, Stainless, Brass, Plastics | Ø300 x 500 mm length |

All materials are sourced from certified suppliers and documented for full traceability. First-article inspections and process validation are standard for production runs. At Shenzhen Honyo Prototype, our manual CNC machining capabilities combine human expertise with technical precision to deliver high-integrity components across demanding industries.

From CAD to Part: The Process

From CAD to Part: The Manual CNC Machining Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our manual CNC machining process transforms digital designs into precision physical parts through a rigorously defined workflow. This structured approach ensures manufacturability, cost efficiency, and adherence to client specifications, leveraging both AI-driven insights and expert engineering judgment. The journey begins with the AI-Powered Quotation Phase, where uploaded CAD files undergo automated analysis. Our proprietary system evaluates geometric complexity, material requirements, tolerances, and estimated machine hours. Crucially, this step identifies immediate feasibility constraints—such as undercuts requiring specialized tooling or features exceeding standard machine capabilities—before human review. The output is a detailed quote with timeline estimates and preliminary risk flags, enabling transparent client collaboration from inception.

Following quote acceptance, the Design for Manufacturability (DFM) Review commences. This phase is non-negotiable for manual CNC success, as human oversight addresses nuances AI cannot fully resolve. Our manufacturing engineers scrutinize the design for optimal tool access, workholding stability, and efficient setup sequencing. Key considerations include minimizing manual repositioning, avoiding deep cavities with narrow aspect ratios, and ensuring adequate wall thicknesses to prevent chatter. We proactively collaborate with clients to suggest refinements—such as slight fillet adjustments or tolerance relaxation—that maintain functional intent while significantly reducing production time and cost. The DFM report, delivered within 24–48 hours, documents all recommendations and agreed-upon modifications, forming the technical baseline for production.

The refined design then enters the Manual CNC Production Phase. Programmers generate G-code using industry-standard CAM software, optimizing toolpaths for the specific manual milling or turning center. Unlike automated cells, manual CNC requires meticulous operator involvement at every stage: precision workpiece fixturing, tool calibration, real-time depth-of-cut adjustments, and in-process inspections using calibrated micrometers and optical comparators. For complex geometries, our machinists employ iterative techniques—such as probing critical datums or hand-finishing tight-tolerance features—to achieve ±0.005 mm accuracy. Throughout machining, quality checks align with the DFM-agreed critical dimensions, documented via first-article inspection reports. Final parts undergo deburring, cleaning, and full dimensional validation before shipment, ensuring seamless integration into the client’s assembly.

This integrated workflow—AI Quote → DFM → Production—eliminates guesswork and rework. Below highlights critical DFM checks preventing common manual CNC pitfalls:

| DFM Parameter | Risk if Ignored | Honyo’s Mitigation Approach |

|————————|——————————————|——————————————-|

| Minimum Wall Thickness | Chatter, breakage during milling | Recommend ≥0.8 mm walls; suggest ribbing |

| Deep Cavity Aspect Ratio | Tool deflection, poor surface finish | Limit depth:width to 3:1; propose EDM alternatives |

| Tight Tolerances (±0.002mm) | Excessive scrap, extended cycle time | Validate necessity; apply only to critical features |

| Undercut Geometry | Requires custom tooling, multiple setups | Redesign with accessible angles or suggest post-process |

By prioritizing DFM collaboration and marrying AI efficiency with artisanal machining skill, Honyo Prototype delivers complex manual CNC parts on time, within budget, and to exacting quality standards. This discipline is foundational to our reputation in low-volume, high-precision prototyping and bridge production.

Start Your Project

Begin Your CNC Machining Project with Precision and Confidence

At Shenzhen Honyo Prototype, we understand that every successful product begins with a precise and reliable prototype. When it comes to CNC machining—especially manual CNC operations—accuracy, material compatibility, and process efficiency are critical to achieving functional, high-quality parts. Whether you’re developing a single prototype or preparing for low-volume production, our expert team is equipped to support your project from concept to completion.

Manual CNC machining remains a cornerstone of precision manufacturing, particularly for complex geometries, tight-tolerance components, and custom one-off parts. Unlike fully automated systems, manual CNC allows for greater operator control, making it ideal for prototyping where flexibility and rapid adjustments are essential. At Honyo Prototype, we combine decades of machining experience with state-of-the-art equipment to deliver parts that meet exact design specifications.

Our facility in Shenzhen is equipped with a comprehensive range of manual CNC milling machines, lathes, and precision tooling, enabling us to work with a wide variety of materials including aluminum, stainless steel, brass, copper, and engineering plastics. Each project is handled by skilled machinists who apply proven techniques to ensure dimensional accuracy, surface finish quality, and structural integrity.

To get started, simply provide your design files in STEP, IGES, or native CAD formats. Our engineering team will conduct a thorough Design for Manufacturability (DFM) review to identify potential optimizations, reduce lead times, and minimize costs—without compromising performance. We support tight tolerances down to ±0.005 mm and offer secondary services such as deburring, anodizing, plating, and laser engraving to meet your final product requirements.

We recognize that every project is unique. That’s why we offer personalized consultation to align our manufacturing approach with your technical goals, timelines, and budget constraints. From initial inquiry to final delivery, we maintain clear communication and full transparency throughout the process.

Below is an overview of our standard manual CNC machining capabilities:

| Parameter | Specification |

|—————————-|———————————————-|

| Machine Types | Manual CNC Mills, Manual Lathes |

| Maximum Work Envelope | 600 x 400 x 300 mm (Mill), Ø200 x 400 mm (Lathe) |

| Tolerance | ±0.005 mm typical |

| Surface Finish | Ra 0.8 – 3.2 µm (machined), finer on request |

| Supported Materials | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 316), Brass, Copper, Plastics (ABS, PC, POM, PTFE) |

| Lead Time | 3–7 days (standard), expedited options available |

| Secondary Operations | Deburring, Polishing, Anodizing, Plating, Heat Treatment, Laser Marking |

Starting your project with Honyo Prototype is simple. Contact Susan Leo, our dedicated project coordinator, to discuss your requirements, request a quote, or schedule a technical consultation. We are committed to delivering precision-manufactured components with fast turnaround and exceptional service.

Reach out today: info@hy-proto.com

Let us help you turn your design into a high-performance reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.