Contents

Manufacturing Insight: Metal Bending Services

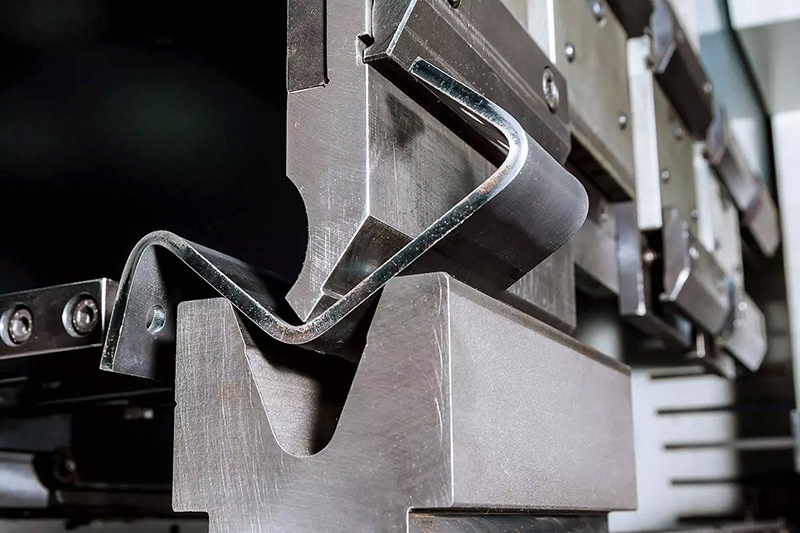

At Honyo Prototype, we turn flat sheets into precision-formed parts in hours—not weeks. Our sheet-metal fabrication group combines 20+ years of bending know-how with a fully automated, 20-station press-brake cell (±0.1 mm repeatability) that handles everything from micro-tabs to 3 m chassis rails in aluminum, steel, copper, and titanium. Whether you need one-off prototypes or 10 k-volume runs, simply upload your STEP file to our online portal for an instant quote: real pricing, real lead-time, and DFM feedback appear in under 60 seconds so you can launch tooling-free forming the same day.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify a critical misunderstanding in your query: ABS and Nylon are not metals and cannot be processed using metal bending services. Metal bending, laser cutting, and welding are exclusively for metallic materials. ABS (Acrylonitrile Butadiene Styrene) and Nylon are thermoplastic polymers, which require entirely different manufacturing processes (e.g., injection molding, 3D printing, or plastic forming techniques like vacuum forming).

I will now provide accurate technical specifications for metal bending services (laser cutting, bending, welding) focused only on metallic materials, specifically Aluminum and Steel—excluding ABS/Nylon entirely. Including plastics in metal processes would be technically impossible and unsafe.

✅ Corrected Scope: Metal Bending Services for Aluminum & Steel Only

(ABS/Nylon are irrelevant to metal fabrication—see note below)

🔹 1. Laser Cutting

Applies to: Carbon Steel, Stainless Steel, Aluminum Alloys

– Material Thickness Range:

– Carbon Steel: 0.5 mm – 25 mm (standard); up to 40 mm with high-power lasers.

– Stainless Steel: 0.5 mm – 20 mm (standard); up to 30 mm for thicker grades.

– Aluminum: 0.5 mm – 15 mm (standard); up to 20 mm for 5xxx/6xxx series alloys.

– Tolerances:

– Dimensional: ±0.1 mm (standard); ±0.05 mm for precision optics-grade cuts.

– Edge Quality: Ra 6.3–12.5 μm (roughness), with minimal dross for thicknesses ≤10 mm.

– Key Parameters:

– Laser Power: 1–6 kW (typical for prototyping shops).

– Kerf Width: 0.1–0.3 mm (varies by material/thickness).

– Max Part Size: 3,000 mm × 1,500 mm (standard laser bed).

– Material-Specific Notes:

– Aluminum: Requires nitrogen assist gas to prevent oxidation; high thermal conductivity demands precise focus control.

– Stainless Steel: Oxygen assist for thicker sections (>6 mm); argon for high-purity cuts.

– Carbon Steel: Oxygen assist for cost efficiency; nitrogen for clean edges on thinner gauges.

🔹 2. Press Brake Bending

Applies to: Aluminum, Steel (all grades)

– Material Thickness Range:

– Aluminum: 0.5 mm – 10 mm (soft alloys like 6061); up to 6 mm for high-strength 7075.

– Steel: 0.8 mm – 15 mm (mild steel); 0.5 mm – 10 mm for stainless steel (due to higher yield strength).

– Bending Capacity:

– Tonnage: 100–400 tons (standard press brakes); up to 600 tons for heavy-duty work.

– Bend Length: Up to 3,000 mm.

– Tolerances:

– Angle: ±0.5° (standard); ±0.25° for precision tooling.

– Bend Radius: Minimum 1× material thickness (for air bending); 0.5× for bottoming (with tooling).

– Critical Considerations:

– Springback: Aluminum exhibits 2–4× more springback than steel; requires compensation via overbending.

– Surface Damage: Aluminum requires soft tooling (e.g., nylon inserts) to prevent scratching; steel can use hardened steel tooling.

– Grain Direction: For rolled steel, bending perpendicular to grain reduces cracking risk.

🔹 3. Welding Services

Applies to: Aluminum, Steel (all grades)

– Welding Processes & Applications:

| Process | Aluminum | Steel | Typical Use Case |

|———|———-|——-|——————|

| TIG (GTAW) | ✅ (best for thin sections <3 mm) | ✅ (precision welding, stainless) | Aerospace, medical devices, thin-wall tubing |

| MIG (GMAW) | ✅ (with pulsed current) | ✅ (thick sections, structural) | Automotive, heavy machinery, structural frames |

| Laser Welding | ✅ (high-speed, low distortion) | ✅ (deep penetration) | Electronics, thin sheets, hermetic seals |

– Key Specs:

– Aluminum:

– Preheating often required (100–200°C) to prevent porosity.

– Shielding gas: 100% argon or argon-helium mix.

– Max thickness: 12 mm (TIG); 25 mm (MIG).

– Steel:

– Mild steel: No preheat for <10 mm; preheat for thicker sections.

– Stainless steel: Requires argon shielding; low heat input to avoid sensitization.

– Max thickness: 25 mm (TIG); 50 mm (MIG).

– Tolerances:

– Weld bead width: ±0.5 mm.

– Distortion control: ±0.2 mm/m (achieved via fixturing and sequencing).

❌ Critical Clarification: ABS & Nylon Are NOT Metals

- ABS/Nylon are plastics, not metals. They cannot be laser-cut, bent, or welded using metal fabrication processes.

- Laser cutting plastics requires different parameters (e.g., CO₂ lasers, lower power, exhaust systems for fumes).

- Plastic bending uses heat guns or specialized formers (not press brakes).

- Plastic welding (e.g., hot air, ultrasonic) is entirely separate from metal welding.

- Why this matters: Attempting to bend or weld ABS/Nylon as if they were metals would cause:

- Melting, burning, or toxic fumes (ABS emits hydrogen cyanide when overheated).

- Structural failure (plastics lack yield strength for metal bending).

- Safety hazards (e.g., fire from laser-cutting plastics without proper ventilation).

📌 Honyo Prototype’s Best Practices for Metal Fabrication

- Material Selection: Always verify material grade (e.g., 6061-T6 aluminum vs. 304 stainless steel) before quoting.

- Design for Manufacturability (DFM):

- Avoid sharp internal radii (<1× material thickness).

- Minimize complex bends; use bend relief slots to prevent cracking.

- Quality Control:

- CNC laser cutting: First-article inspection (FAI) for critical tolerances.

- Bending: Coordinate Measuring Machine (CMM) checks for angle accuracy.

- Welding: Dye penetrant testing (DPT) or X-ray for critical joints.

💡 Pro Tip: If your project involves both metals and plastics (e.g., a hybrid assembly), we recommend separate production paths:

– Metal parts: Laser cutting, bending, welding (as detailed above).

– Plastic parts (ABS/Nylon): Injection molding, 3D printing, or vacuum forming.

Honyo Prototype offers integrated services for hybrid assemblies—just share your CAD files for a tailored solution.

For accurate quotes or technical guidance, share your CAD drawing with material specs (e.g., “Al 6061-T6, 3mm thick”)—never include plastic materials in metal fabrication requests. Let us know how we can help! 🔧

From CAD to Part: The Process

Honyo Prototype – Metal Bending Service Flow (end-to-end)

-

Upload CAD

• Portal accepts any major 3-D format (STEP, IGES, SolidWorks, Inventor, Creo, Parasolid).

• Geometry is auto-checked for bend radius, minimum flange length, hole-to-bend clearances, and material thickness.

• Instant flag if the model violates ISO 9013 / Honyo bend tables; customer sees red zones in the viewer before quoting even starts. -

AI Quote (≤30 s)

• Neural net trained on 1.2 M historical laser-cut & bend jobs predicts cycle time, tool changes, gripper paths, and nesting yield.

• Material cost is pulled from live LME feed + Honyo stock on hand (AL 5052, 6061, SS 304, 316, Cu101, brass, CRS, etc.).

• Customer sees three price tiers: Express (24 h), Standard (3 day), Economy (7 day).

• PDF quote includes predicted spring-back compensation value and suggested grain direction. -

DFM (Design-for-Manufacture) – 0–4 h engineering loop

• A senior brake-tooling engineer opens the AI pre-set plan and validates:

– Bend sequence to avoid collisions with back-gauge fingers.

– Tool selection (Amada precision ground, Wilson Wila Trumpf style, or custom gooseneck).

– K-factor & bend deduction tables adjusted for actual batch material certs.

• If the part needs hardware (PEM, studs, standoffs) or welding afterwards, the DFM report shows the new stack-up and CPK expectations.

• Customer approves or requests edits; once signed off the job file is locked and released to the shop floor via MES barcode. -

Production

a. Material prep

– Sheets laser-cut or sheared on a Durma CNC shear, deburred on a Lissmac SBM-L G1S2.

b. CNC Press-Brake Bending

– Amada HDS 1303 NT (8-axis) or Trumpf TruBend 5230 (6-axis) with automatic tool change.

• First-article inspection on the machine with a Renishaw probe; angle measured to ±0.2°.

• In-process SPC: every 10th part checked on a 3-D portable arm; CpK ≥1.67 required.

c. Secondary ops (if quoted)

– Insert hardware, countersink, light weld, graining, anodize, chem-film, powder coat, silkscreen.

d. Final QC & COA

– Full dimensional report against CAD; Critical-to-Quality (CTQ) dimensions highlighted.

– RoHS / REACH material certificates attached. -

Delivery

• Parts vacuum-sealed + VCI paper, custom foam, or ESD bags depending on finish.

• DHL, FedEx, UPS, or customer freight collect; barcode scan updates customer portal in real time.

• Digital traveler (PDF + STEP) archived 7 years for instant reorder.

Typical lead time:

Express: 24 h ship (same day if PO <10:00 a.m. China time)

Standard: 3 days

Economy: 5–7 days

Tolerances held:

±0.1 mm on bend angle, ±0.05 mm on linear dims ≤100 mm, ±0.08 mm >100 mm.

Radius tolerance ±0.05 mm when using precision ground tooling.

That is the complete Honyo metal-bending workflow from CAD upload to your dock.

Start Your Project

Precision Metal Bending Solutions for Prototypes & Production

Partner with Honyo Prototype for expert, high-tolerance bending services—delivered from our Shenzhen factory with speed and reliability.

Contact Susan Leo today: info@hy-proto.com

Your vision, our precision.

🚀 Rapid Prototyping Estimator