Contents

Manufacturing Insight: Metal Laser Cutting Services

Precision Through Photonic Energy: Laser Cutting Fundamentals

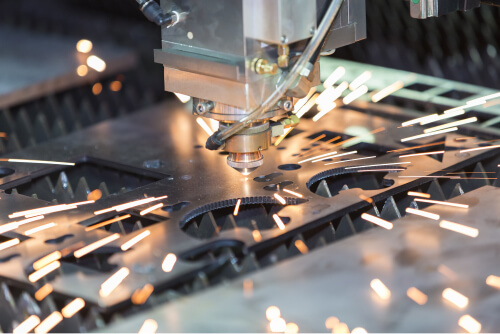

Metal laser cutting remains a cornerstone of modern sheet metal fabrication, leveraging focused photonic energy to achieve unparalleled accuracy and versatility. This non-contact thermal process utilizes high-power laser beams—typically from fiber or CO₂ sources—to melt, vaporize, or eject material along programmed paths. The technology excels in producing complex geometries, intricate contours, and clean edges with minimal heat-affected zones, significantly reducing post-processing requirements. Its compatibility with diverse metals—including stainless steel, aluminum, brass, and carbon steel—makes it indispensable for prototyping and low-to-mid volume production where dimensional fidelity and repeatability are critical. Unlike mechanical cutting methods, laser systems eliminate tool wear concerns and enable rapid design iterations, directly supporting agile product development cycles.

Honyo Prototype’s Industrial-Grade Laser Cutting Capabilities

Shenzhen Honyo Prototype operates a dedicated fleet of high-precision fiber laser cutting systems engineered for demanding B2B applications. Our infrastructure supports rapid turnaround without compromising on tight tolerances or material integrity, specifically addressing the challenges of prototype and bridge production environments. We prioritize optimizing material yield and edge quality through advanced beam control and intelligent nesting algorithms, ensuring cost efficiency for clients. Below are key technical specifications defining our production envelope:

| Parameter | Specification | Application Benefit |

|————————-|————————|———————————————-|

| Laser Source | Fiber (IPG/Precitec) | Superior absorption for reflective metals; lower operating costs |

| Max. Cutting Thickness | 25mm (Mild Steel) | Accommodates heavy-gauge structural parts |

| Positioning Accuracy | ±0.05mm | Ensures repeatable feature alignment |

| Edge Quality (Ra) | ≤1.6μm (up to 6mm) | Minimizes deburring needs for assemblies |

| Kerf Width | 0.1–0.2mm | Enables micro-features and tight tolerances |

| Tolerance Control | ±0.1mm (standard) | Meets critical fit-for-function requirements |

Integrated Value for Engineering Partnerships

Beyond core cutting performance, Honyo Prototype integrates laser cutting within a comprehensive sheet metal ecosystem. Our proprietary nesting software dynamically optimizes part placement to reduce scrap rates by 15–20% compared to industry averages, directly lowering material costs for clients. All processes adhere to ISO 9001 quality management protocols, with in-line metrology verifying critical dimensions via CMM and optical comparators before part release. For engineering teams, this translates to accelerated time-to-prototype with guaranteed dimensional compliance—eliminating rework loops during validation. We further support design for manufacturability (DFM) feedback, advising on kerf compensation, bridge tabbing, and feature spacing to maximize cut quality from the earliest design stages. This holistic approach ensures that every laser-cut component delivered meets the rigorous functional and aesthetic standards demanded by aerospace, medical, and industrial automation sectors. By combining cutting-edge hardware with deep process expertise, Honyo Prototype transforms digital designs into precision metal components with unmatched speed and reliability.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision metal laser cutting services as part of our comprehensive sheet metal fabrication capabilities. Our advanced fiber laser cutting systems ensure high accuracy, clean edges, and fast turnaround for prototypes and low-to-mid volume production runs. Designed for engineering and manufacturing clients across electronics, automotive, and industrial equipment sectors, our processes support complex geometries and tight tolerances on a wide range of metal materials.

Our laser cutting technology utilizes high-powered fiber lasers capable of cutting materials up to 25 mm in thickness with consistent edge quality and minimal heat distortion. The non-contact cutting method allows for intricate shapes, narrow kerf widths, and excellent repeatability, making it ideal for components requiring fine details and high precision. All cutting operations are CNC-controlled, ensuring dimensional accuracy and compatibility with CAD/CAM workflows for seamless integration into your design-to-manufacturing pipeline.

In addition to laser cutting, we offer precision bending and welding services to support full in-house fabrication. Our press brakes are equipped with CNC controls and automatic tool changers, enabling accurate bends on complex parts with tight angular tolerances. We support multiple bend radii and can accommodate both simple and multi-stage forming operations. For assembly and structural integrity, our welding services include TIG, MIG, and spot welding, performed by certified technicians to ensure strong, clean, and consistent joints.

Below is a detailed overview of our technical specifications for materials, tolerances, and capabilities.

| Parameter | Specification |

|————————-|————-|

| Laser Cutting | |

| Max Cutting Thickness | Carbon Steel: 25 mm, Stainless Steel: 20 mm, Aluminum: 15 mm |

| Min Feature Size | 1.2 x 1.2 mm (varies by material and thickness) |

| Kerf Width | 0.15 – 0.3 mm (depending on material and power settings) |

| Cutting Tolerance | ±0.1 mm for parts < 300 mm; ±0.2 mm for parts 300–1000 mm |

| Supported Materials | Carbon Steel (Q235, 45#), Stainless Steel (304, 316), Aluminum (5052, 6061), Galvanized Steel, Brass |

| Max Cutting Area | 1500 mm × 3000 mm |

| Bending | |

| Max Bend Length | 2000 mm |

| Min Bend Radius | 0.8 mm (material-dependent) |

| Bending Tolerance | ±0.2° angular tolerance; ±0.1 mm linear |

| Tooling Options | V-dies, gooseneck punches, specialty tooling for tight spaces |

| Welding | |

| Techniques | TIG, MIG, Spot Welding |

| Weld Quality | Smooth finish, minimal spatter, full penetration on critical joints |

| Post-Weld Options | Grinding, polishing, deburring, dimensional inspection |

| Certification | ISO 9001-compliant welding procedures; operator certifications available upon request |

All fabricated components undergo rigorous in-process and final inspections using precision measuring tools, including CMMs and optical comparators, to ensure compliance with client specifications. Shenzhen Honyo Prototype is committed to delivering reliable, high-quality sheet metal parts with fast lead times and expert technical support throughout the manufacturing cycle.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s Laser Cutting Workflow

Shenzhen Honyo Prototype delivers precision sheet metal components through a streamlined, technology-driven laser cutting process. Our workflow, designed for efficiency and quality, begins the moment a client submits a CAD file and concludes with certified, ready-to-ship parts. This integrated system ensures manufacturability, minimizes lead times, and guarantees adherence to stringent specifications throughout production.

AI-Powered Quoting System

The process initiates with our proprietary AI-driven quoting platform. Clients upload industry-standard CAD formats (DXF, DWG, STEP). The AI engine performs an immediate, multi-faceted analysis: automatically identifying material type and thickness requirements, calculating part geometry complexity, estimating machine time based on contour length and pierce points, and factoring in standard finishing needs. This sophisticated analysis generates an accurate, transparent quote within hours, not days, including detailed cost breakdowns and preliminary lead time estimates, significantly accelerating the project kickoff phase compared to manual quoting methods.

Engineer-Validated DFM Analysis

Following quote acceptance, every design undergoes mandatory Design for Manufacturability (DFM) review by our senior sheet metal engineering team. This critical step moves beyond automated checks. Engineers meticulously assess the CAD model for laser cutting feasibility, scrutinizing minimum feature sizes, internal corner radii, hole-to-edge distances, and material-specific constraints like heat-affected zones. We proactively identify potential issues such as excessive kerf loss on thin materials, nesting inefficiencies, or distortion risks on large, intricate parts. Clients receive a comprehensive DFM report with actionable recommendations, fostering collaborative refinement to optimize cost, speed, and quality before cutting commences, preventing costly rework.

Precision Laser Cutting Production

Approved designs enter high-volume production on our state-of-the-art fiber and CO2 laser cutting systems. Advanced CAM software automatically nests parts with maximum material utilization efficiency, directly translating CAD geometry into precise machine code. Cutting occurs under strictly controlled parameters optimized for each specific material and thickness. Our process maintains tight tolerances, typically ±0.1 mm for critical features, with kerf widths ranging from 0.1 mm to 0.3 mm depending on material and laser type. Rigorous in-process quality control, including first-article inspection and random sampling against the original CAD model using calibrated metrology equipment, ensures dimensional accuracy and edge quality. All parts undergo deburring and visual inspection for surface integrity prior to final packaging and shipment, with full traceability documentation provided.

Material capabilities are standardized across our production floor as shown below:

| Material | Thickness Range | Max Sheet Size (mm) |

| :—————- | :————– | :—————— |

| Stainless Steel | 0.5 – 25.0 mm | 3000 x 1500 |

| Mild Steel | 0.8 – 25.0 mm | 3000 x 1500 |

| Aluminum | 0.5 – 15.0 mm | 3000 x 1500 |

| Brass / Copper | 0.5 – 10.0 mm | 2000 x 1000 |

This seamless integration of AI intelligence, expert engineering validation, and precision manufacturing execution allows Honyo Prototype to transform client CAD data into high-quality, functional metal components reliably and efficiently, meeting the demanding requirements of modern sheet metal fabrication.

Start Your Project

Start Your Metal Laser Cutting Project with Precision and Confidence

When it comes to rapid, accurate, and cost-effective metal fabrication, Shenzhen Honyo Prototype delivers unmatched expertise in laser cutting services. Whether you’re developing a prototype or scaling up for low to mid-volume production, our advanced CNC laser cutting technology ensures tight tolerances, clean edges, and consistent quality across a wide range of sheet metal materials. Our facility in Shenzhen is equipped with high-powered fiber laser cutting systems capable of processing materials with precision up to ±0.1 mm, making us a trusted partner for engineers, product designers, and manufacturing teams worldwide.

At Honyo Prototype, we understand that every project begins with a vision. That’s why we prioritize seamless collaboration from the very first step. Our engineering team works closely with clients to review designs, optimize for manufacturability, and recommend material and thickness options that align with functional and budgetary requirements. We support a comprehensive range of metals, including stainless steel, carbon steel, aluminum, brass, and copper, with sheet thicknesses from 0.5 mm to 25 mm depending on material type.

To ensure fast turnaround without compromising quality, we’ve streamlined our workflow from file submission to finished part. Simply provide your 2D vector file in DXF, DWG, or STEP format, and our team will generate a detailed quote within hours. We support both metric and imperial units and can accommodate complex geometries, intricate contours, and tight nesting requirements. With automated nesting software and high-speed cutting capabilities, we minimize material waste and reduce lead times—typically delivering projects in 3–7 business days, depending on complexity and volume.

Our certifications and in-process quality checks guarantee that every cut meets rigorous industry standards. All parts undergo dimensional inspection and surface finish evaluation before shipment, and first-article inspection reports are available upon request. Whether you’re iterating on a prototype or preparing for production, you can count on Honyo Prototype for reliability, transparency, and technical excellence.

| Material | Thickness Range (mm) | Tolerance (± mm) | Max Sheet Size (mm) |

|——————|————————|——————|———————-|

| Stainless Steel | 0.5 – 20 | 0.1 | 1500 x 3000 |

| Carbon Steel | 0.5 – 25 | 0.1 | 1500 x 3000 |

| Aluminum | 0.5 – 15 | 0.1 | 1500 x 3000 |

| Brass | 0.5 – 10 | 0.1 | 1000 x 2000 |

| Copper | 0.5 – 8 | 0.1 | 1000 x 2000 |

Ready to bring your design to life? Contact Susan Leo, our dedicated Project Coordinator, to discuss your requirements, request a quote, or submit your design files for review. We’re here to support your project with technical insight, responsive communication, and on-time delivery.

Email Susan Leo at info@hy-proto.com and take the first step toward precision metal fabrication done right.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.