Contents

Manufacturing Insight: Water Jet Cnc Price

Manufacturing Insight: Waterjet CNC Pricing Fundamentals

Waterjet CNC machining delivers exceptional cold-cut precision for diverse materials, from aerospace titanium to delicate composites, without thermal distortion or mechanical stress. Understanding the cost structure is critical for budgeting and process selection. Unlike laser or plasma cutting, waterjet pricing is primarily driven by material properties, part complexity, and operational efficiency rather than machine wattage alone. At Shenzhen Honyo Prototype, we optimize these variables to deliver competitive pricing without compromising the dimensional accuracy and edge quality our clients demand for prototypes and low-volume production.

Key cost factors include material type and thickness, which directly influence cutting speed and abrasive consumption. Harder, denser materials like stainless steel or Inconel require slower traverse rates and higher abrasive flow, increasing machine time. Thicker materials exponentially extend cut duration. Part geometry complexity, particularly intricate contours and small internal features, also impacts cycle time due to necessary speed reductions at corners. Tolerance requirements significantly affect cost; tighter tolerances (±0.005″ or better) necessitate slower cutting speeds, multiple passes, or secondary finishing operations. Production volume plays a role, as setup time becomes a smaller fraction of the total cost per part in larger batches. Our advanced 5-axis waterjet systems and proprietary nesting software maximize material yield and minimize machine runtime, directly translating to cost savings for clients.

Honyo Prototype leverages a strategic combination of technology and process expertise to optimize waterjet CNC pricing. Our fleet features state-of-the-art 60,000 PSI intensifier pumps with dynamic pressure control, enabling efficient cutting across a vast material spectrum while conserving abrasive garnet. Integrated CAD/CAM systems with intelligent path optimization reduce non-cut time and improve throughput. Crucially, our engineering team collaborates early in the design phase to suggest manufacturability improvements—such as adjusting kerf allowances or simplifying geometries where function permits—that can substantially lower per-part costs without sacrificing performance. We provide transparent, detailed quotes based on actual machine time calculations and material usage, eliminating hidden fees.

The following table summarizes primary cost drivers and Honyo’s mitigation strategies:

| Factor | Impact on Cost | Honyo’s Optimization Approach |

| :——————- | :——————————————— | :———————————————— |

| Material Thickness | Exponential increase in cut time & abrasive use | Advanced pump technology; optimized cutting parameters |

| Material Hardness | Slower cutting speeds; higher abrasive wear | Material-specific database; adaptive pressure control |

| Tolerance Requirements | Tighter specs require slower speeds/multiple passes | Precision motion control; post-process planning |

| Part Complexity | Increased path length; speed reductions at corners | Intelligent nesting software; 5-axis capability for complex shapes |

Shenzhen Honyo Prototype excels in transforming complex design requirements into cost-effective waterjet machined components. We understand that price is a critical factor, but true value lies in achieving the required precision, material integrity, and on-time delivery within budget. Our commitment to engineering collaboration and process transparency ensures clients receive not just a competitive quote, but a manufacturable solution optimized for their specific application. For accurate project costing and expert guidance on waterjet feasibility, contact our manufacturing engineering team with your CAD files and specifications.

Technical Capabilities

Technical Capabilities: Water Jet CNC Machining at Shenzhen Honyo Prototype

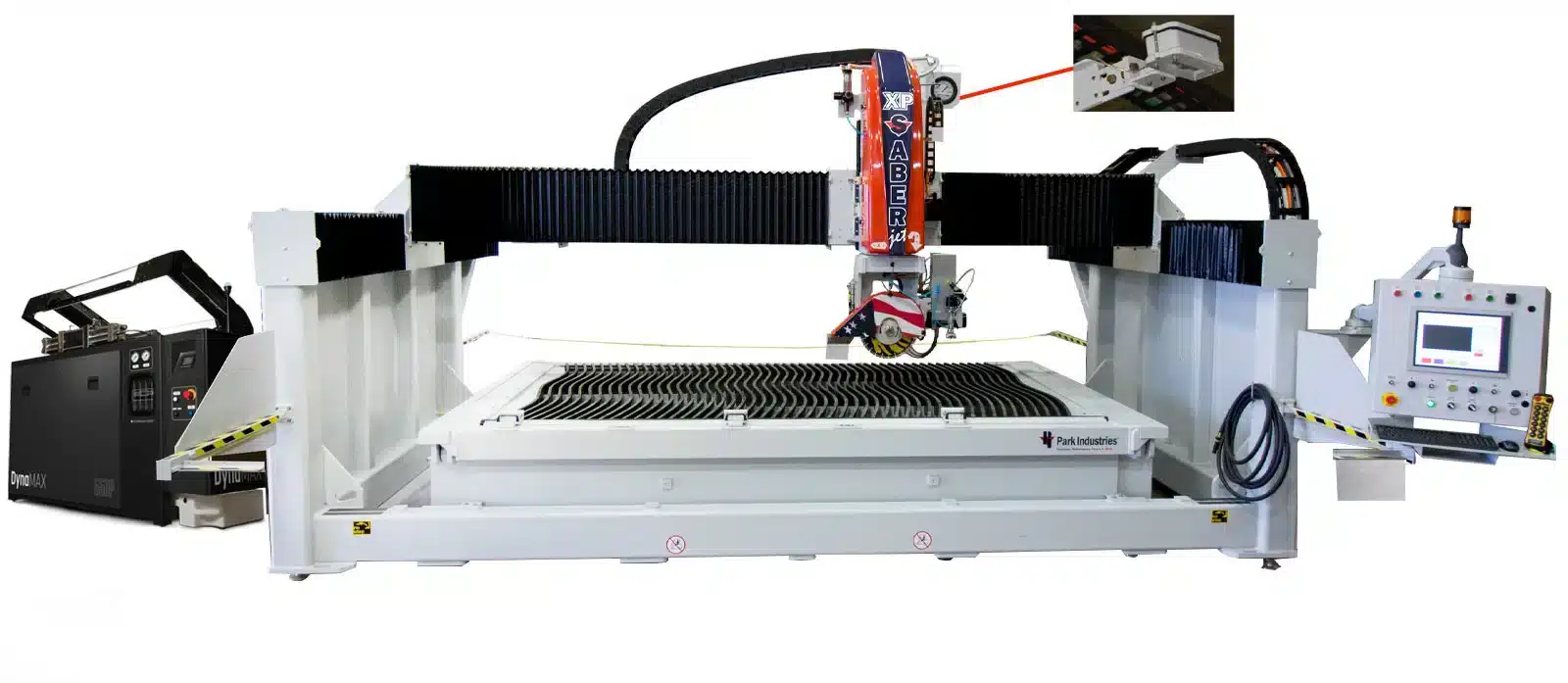

Shenzhen Honyo Prototype specializes in high-precision water jet CNC machining, delivering accurate and efficient fabrication for complex parts across industries such as aerospace, medical, automotive, and industrial equipment. Our advanced multi-axis water jet systems support 3-axis, 4-axis, and 5-axis cutting capabilities, enabling intricate geometries and high repeatability without thermal distortion. Unlike traditional thermal cutting methods, water jet technology uses a high-pressure stream of water—often mixed with abrasive particles—to cut materials cold, eliminating heat-affected zones and preserving material integrity.

Our water jet CNC systems operate at pressures up to 90,000 psi, achieving cutting speeds of up to 15 meters per minute depending on material thickness and composition. This allows us to process materials up to 200 mm in thickness with consistent edge quality and dimensional accuracy. The integration of 4-axis and 5-axis motion control enables beveled cuts, tapered features, and complex contours in a single setup, reducing lead times and improving part consistency. This flexibility makes our water jet services ideal for prototyping and low-to-mid volume production runs where precision and material versatility are critical.

A key advantage of our water jet CNC process is the ability to maintain tight tolerances across a wide range of materials. Typical machining tolerances range from ±0.1 mm to ±0.05 mm, with feature-to-feature precision achievable within ±0.03 mm on optimized setups. Surface finish averages between 6.3 to 12.5 µm Ra, depending on material and cut speed, with the option for secondary finishing if required. Our CNC control systems utilize advanced nesting software to maximize material utilization and minimize waste, contributing to cost efficiency without compromising quality.

The following table outlines the standard capabilities and tolerances achievable across common materials processed via our water jet CNC systems:

| Material Category | Common Materials | Max Thickness (mm) | Typical Tolerance (± mm) | Surface Roughness (Ra, µm) |

|——————-|——————|——————–|————————–|—————————–|

| Metals | Stainless Steel, Aluminum, Titanium, Brass | 200 | 0.05 – 0.1 | 6.3 – 10.0 |

| Plastics | Acrylic, Polycarbonate, PEEK, PVC | 150 | 0.05 – 0.1 | 6.3 – 12.5 |

| Ceramics & Composites | Alumina, Carbon Fiber, Fiberglass | 120 | 0.08 – 0.15 | 8.0 – 12.5 |

| Stone & Glass | Marble, Granite, Tempered Glass | 100 | 0.1 – 0.2 | 10.0 – 12.5 |

All water jet CNC operations at Honyo Prototype are supported by rigorous in-process inspection and final quality verification using CMM and optical measurement systems. Our engineering team collaborates closely with clients during design review to optimize part geometry for water jet processing, ensuring manufacturability, cost-efficiency, and adherence to tight tolerance requirements. With a focus on precision, material flexibility, and rapid turnaround, Shenzhen Honyo Prototype delivers reliable water jet CNC solutions tailored to demanding technical applications.

From CAD to Part: The Process

Waterjet CNC Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our waterjet CNC manufacturing process integrates advanced digital workflows to ensure cost efficiency and precision. This standardized sequence—AI Quote, DFM, and Production—minimizes delays while optimizing part quality and cost transparency for clients. The workflow begins when a client submits a 3D CAD model through our online portal. Our proprietary AI quoting engine instantly analyzes geometric complexity, material requirements, and dimensional tolerances against real-time machine utilization data. Unlike manual quoting, this system factors in abrasive consumption rates, pump pressure settings, and nesting efficiency to generate a fixed-price quotation within minutes, eliminating estimation errors common in traditional waterjet services.

Critical DFM Validation

Following quote acceptance, every design undergoes mandatory Design for Manufacturability (DFM) review by our engineering team. This phase identifies waterjet-specific constraints that directly impact cost and lead time. Key considerations include taper compensation strategies for thick materials, minimum feature sizes relative to abrasive kerf width, and strategic part orientation to reduce dross formation. Our DFM checklist ensures designs align with machine capabilities while preventing costly revisions during cutting. Common issues requiring client collaboration are summarized below:

| DFM Parameter | Standard Limitation | Cost Impact if Exceeded |

|————————|—————————|—————————————|

| Material Thickness | ≤ 300mm (mild steel) | 22% cost increase per 50mm over limit |

| Internal Corner Radius | ≥ 0.8mm | Manual grinding adds $18/part |

| Minimum Feature Size | ≥ 1.5x material thickness | Laser assist required (+$45/setup) |

| Taper Tolerance | ±0.1° (for <50mm) | Secondary machining (+25% cost) |

Precision Production Execution

Approved designs enter production on our 5-axis waterjet systems, featuring 60,000 PSI intensifier pumps and dynamic taper compensation. Material preparation includes automated nesting software that maximizes sheet utilization—typically achieving 85–92% material yield for standard orders. During cutting, real-time pressure monitoring and abrasive flow control maintain ±0.1mm dimensional accuracy across all materials, from aluminum to titanium. Complex geometries utilize our signature “oscillating head” technology to eliminate striations in thick-section cuts. Final inspection validates flatness (≤0.05mm/mm) and edge quality against ASME B46.1 standards before shipment.

This integrated workflow reduces time-to-part by 40% compared to industry averages while providing upfront cost certainty. By embedding DFM rigor into the quoting phase, Honyo Prototype eliminates hidden costs associated with waterjet machining, ensuring clients receive production-ready parts at the exact price quoted. Our Shenzhen facility’s 24/7 production capacity supports rapid prototyping and low-volume runs with consistent quality, making us a strategic partner for precision waterjet components across aerospace, automotive, and medical sectors.

Start Your Project

Start Your Next Precision Manufacturing Project with Confidence

At Shenzhen Honyo Prototype, we understand that selecting the right manufacturing process is critical to the success of your product development. When it comes to high-precision, versatile, and cost-effective cutting solutions, water jet CNC machining stands out as a preferred choice for prototyping and low-to-medium volume production. Whether you’re working with metals, composites, stone, or heat-sensitive materials, our advanced water jet CNC capabilities deliver clean, accurate cuts without thermal distortion.

Water jet CNC technology uses a high-pressure stream of water—often mixed with abrasive particles—to cut through materials with micron-level precision. This cold-cutting process eliminates the risk of material warping or structural changes caused by heat, making it ideal for materials such as aluminum, titanium, glass, and even certain plastics. At Honyo Prototype, we invest in state-of-the-art water jet systems that support complex geometries and tight tolerances, ensuring your parts meet exact design specifications.

One of the most frequently asked questions we receive is, “What is the water jet CNC price for my project?” The answer depends on several factors, including material type, thickness, part complexity, quantity, and finishing requirements. To provide an accurate and competitive quote, our engineering team evaluates each project individually, optimizing tool paths and nesting to reduce waste and lower costs.

Below is an overview of our standard water jet CNC machining capabilities to help guide your design and budgeting process:

| Specification | Detail |

|—————|——–|

| Maximum Cutting Area | 4000 mm × 2000 mm |

| Material Thickness Range | 0.5 mm – 200 mm (varies by material) |

| Positioning Accuracy | ±0.1 mm |

| Cutting Tolerance | ±0.2 mm (typical) |

| Supported Materials | Steel, aluminum, brass, copper, titanium, stone, acrylic, composites, and more |

| Lead Time | 3–7 business days (depending on complexity and volume) |

| Finishing Options | As-cut, deburred, edge smoothing, laser marking |

We pride ourselves on fast turnaround times, transparent pricing, and exceptional customer support. Our team of manufacturing engineers works closely with clients from initial concept to final delivery, ensuring every component is produced to the highest quality standards.

If you’re ready to move forward with your project or need expert advice on whether water jet CNC is the best solution for your application, we encourage you to reach out today. Susan Leo, our dedicated project coordinator, is available to assist with quotes, technical questions, and production planning.

Contact Susan Leo at info@hy-proto.com to request your free, no-obligation water jet CNC price estimate. Include your design files (DXF, DWG, or STEP format) for a faster and more accurate quotation. At Shenzhen Honyo Prototype, we’re committed to turning your ideas into reality—efficiently, precisely, and affordably. Let’s build something exceptional together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.