Contents

Manufacturing Insight: Mini Cnc Router

Manufacturing Insight: Mini CNC Router Technology

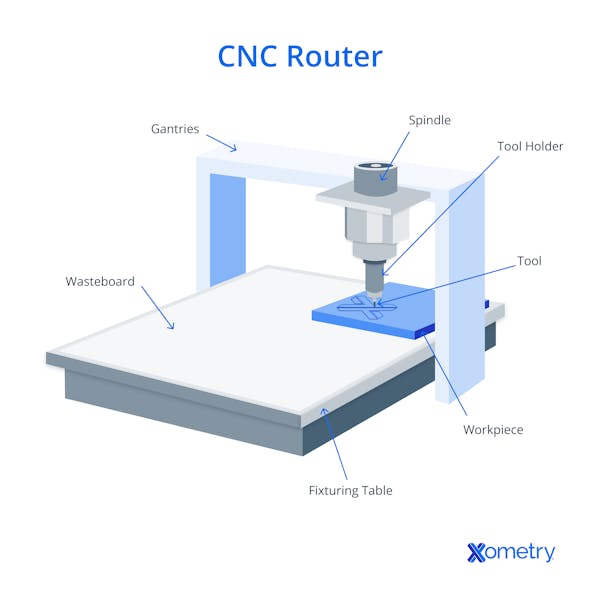

Mini CNC routers represent a critical advancement in precision prototyping and low-volume production for intricate components. These compact systems deliver exceptional accuracy for small workpieces, typically within a 300x300x100mm envelope, making them indispensable for industries requiring rapid iteration on electronics enclosures, detailed signage, medical device components, and educational models. Unlike larger industrial CNC machinery, mini routers offer reduced footprint, lower operational costs, and faster setup times without compromising on the essential rigidity and repeatability demanded by modern engineering standards. Their significance lies in bridging the gap between conceptual design and functional validation, enabling engineers to physically test form, fit, and function early in the development cycle.

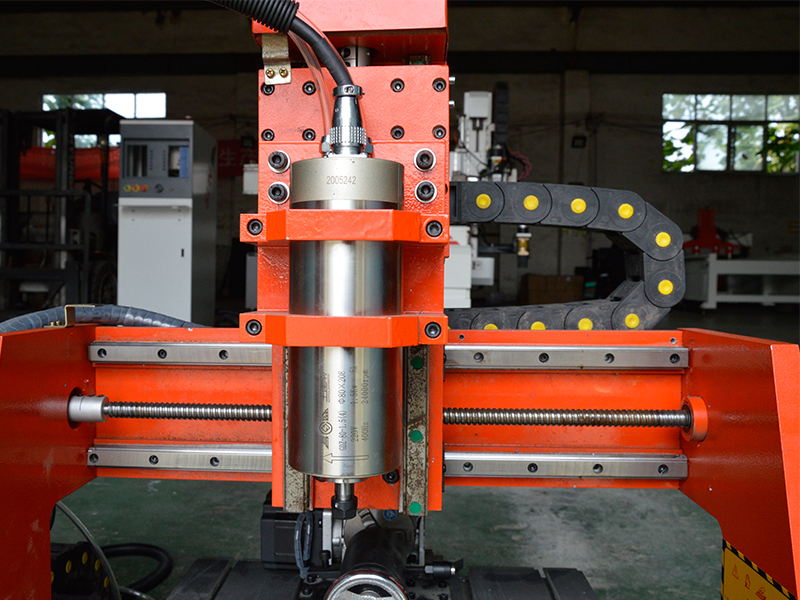

At Shenzhen Honyo Prototype, we leverage state-of-the-art mini CNC routing systems specifically optimized for high-fidelity prototyping. Our manufacturing process begins with rigorous CAD/CAM programming, utilizing industry-standard software to generate precise toolpaths that minimize material waste and machine cycle time. We prioritize spindle stability and thermal management, employing high-frequency spindles (24,000 RPM) with micron-level runout control to ensure clean edges and superior surface finishes on diverse non-ferrous materials. Our dedicated mini router cells are maintained to stringent calibration protocols, verified daily using laser interferometers and master gauge blocks, guaranteeing consistent dimensional accuracy across all production runs. This focus on process control allows us to routinely achieve tolerances of ±0.02mm on complex 3D contours and tight internal features.

Key operational capabilities of our mini CNC router fleet are detailed below:

| Parameter | Specification | Honyo Prototype Standard |

|——————–|———————|————————–|

| Max Work Envelope | 300 x 300 x 100 mm | 295 x 295 x 95 mm |

| Positioning Accuracy | ±0.01 mm | ±0.008 mm |

| Repeatability | ±0.005 mm | ±0.003 mm |

| Max Spindle Speed | 24,000 RPM | 24,000 RPM (HSK-E25) |

| Supported Materials| Aluminum, Plastics, Wood, Composites | 6061-T6, 7075, ABS, POM, HDPE, MDF |

Our expertise extends beyond machine operation to comprehensive material science understanding. We select optimal tooling geometries and cutting parameters based on substrate properties, preventing material tear-out in delicate plastics like acrylic or ensuring burr-free edges in aluminum alloys. This technical proficiency, combined with our integrated quality assurance workflow featuring in-process CMM verification, ensures that every part meets exacting client specifications. For engineering teams facing accelerated development timelines, Honyo Prototype provides a reliable pathway from digital model to precision-engineered physical prototype within 72 hours, significantly de-risking product validation and accelerating time-to-market. This capability is fundamental to our commitment to enabling innovation through advanced, accessible manufacturing solutions.

Technical Capabilities

Technical Capabilities: Mini CNC Router at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype leverages advanced mini CNC router technology to deliver high-precision machining solutions for prototyping and low-volume production. Our compact yet powerful mini CNC routers are engineered to support versatile multi-axis operations, including 3-axis, 4-axis, and selective 5-axis milling capabilities. These systems are ideal for intricate part geometries, detailed surface engraving, and complex 3D contouring, particularly in applications requiring high repeatability and tight dimensional control.

Our mini CNC routers are optimized for non-metallic and soft-metal materials, making them suitable for rapid prototyping in industries such as electronics, consumer products, medical devices, and architectural modeling. The integration of high-speed spindles, rigid frame structures, and precision linear guides ensures minimal vibration and superior surface finish. Advanced CNC controls enable seamless execution of G-code generated from CAD/CAM software, supporting complex toolpaths with smooth interpolation across multiple axes.

For turning operations, our hybrid mini CNC systems combine milling and rotary axis functionality, allowing for 360° part access and cylindrical feature machining. This capability is particularly effective for small-diameter components such as connectors, shafts, and custom knobs, where both flat and curved surfaces require precision detailing.

A hallmark of our mini CNC router service is our commitment to tight tolerance machining. We maintain consistent tolerances down to ±0.005 mm for critical dimensions, with typical machining accuracy ranging between ±0.01 mm and ±0.02 mm, depending on material and geometry. These tolerances are achieved through in-process probing, tool length compensation, and rigorous environmental control within our machining cells.

Below is a detailed summary of achievable tolerances and compatible materials on our mini CNC router platforms:

| Material Type | Examples | Typical Tolerance (± mm) | Max Precision (± mm) | Notes |

|———————|——————————|————————–|————————|——-|

| Engineering Plastics | ABS, POM (Delrin), Nylon, PC | 0.02 | 0.005 | Low thermal expansion; excellent for snap-fits and housings |

| Soft Metals | Aluminum 6061, Brass, Copper | 0.02 | 0.01 | Limited to shallow cuts and low spindle loads |

| Wood & Composites | Plywood, MDF, Bamboo | 0.03 | 0.02 | Ideal for models and jigs; surface finish dependent on grain |

| Foam & Modeling | EPS, Polyurethane | 0.05 | 0.03 | High-speed contouring; minimal tool wear |

| Acrylic & PMMA | Clear/Colored Acrylic | 0.02 | 0.01 | Polished edges achievable; anti-static tooling recommended |

All machined parts undergo first-article inspection using calibrated metrology tools, including digital micrometers, bore gauges, and coordinate measuring machines (CMM) for critical features. Shenzhen Honyo Prototype ensures full traceability and process documentation, supporting clients in industries where compliance and repeatability are paramount.

With our mini CNC router capabilities, we bridge the gap between design intent and physical realization—delivering precision, speed, and technical excellence for demanding prototyping applications.

From CAD to Part: The Process

Mini CNC Router Manufacturing Workflow: From CAD to Finished Part

Shenzhen Honyo Prototype utilizes a streamlined, technology-driven workflow to transform client CAD models into high-precision mini CNC router components. This integrated process ensures manufacturability, optimizes lead times, and guarantees part quality while minimizing cost inefficiencies. The core sequence comprises three critical phases: AI-Powered Quoting, Engineering-Driven DFM, and Precision Production.

The workflow initiates upon receipt of the client’s native 3D CAD file (STEP, IGES, or native formats preferred). Our proprietary AI quoting engine performs an immediate, multi-faceted analysis. It assesses geometric complexity, identifies potential undercuts or non-manufacturable features, calculates raw material requirements, estimates machine time based on toolpath simulation, and evaluates fixturing needs. Crucially, the AI cross-references this data against real-time machine availability, material stock levels, and current production capacity. This generates an accurate, data-backed quotation within hours, not days, providing clients with transparency on cost and feasibility before project commitment.

Following quote acceptance, the design enters the mandatory Design for Manufacturing (DFM) review stage. Our senior manufacturing engineers conduct a detailed technical assessment, moving beyond the AI’s initial scan. This human expertise focuses on optimizing the design specifically for our precision mini CNC router platforms and prototyping standards. Key considerations include verifying minimum feature sizes against tooling capabilities, confirming achievable tolerances relative to material properties, assessing optimal stock size to minimize waste, identifying opportunities for feature consolidation to reduce setups, and recommending material-specific strategies to prevent chatter or deflection. The DFM report, delivered within 24 business hours, provides actionable feedback and collaborative suggestions to enhance manufacturability without compromising functional intent.

Upon DFM sign-off, the project transitions to production. Our CAM programming team generates optimized, collision-avoidant toolpaths using industry-standard software, meticulously selecting appropriate end mills, stepovers, and spindle speeds for the specified material (typically aluminum 6061-T6, 7075-T6, or engineering plastics). Rigorous in-house verification via simulation software precedes any machine engagement. Parts are then machined on our multi-axis mini CNC routers under strict environmental controls. Each operation undergoes in-process inspection at critical stages using calibrated CMMs and optical comparators. Final parts receive comprehensive first-article inspection against the original CAD model and client specifications, documented in a full quality report before shipment. This closed-loop workflow, integrating AI efficiency with deep engineering expertise, consistently delivers mini CNC router components with ±0.025 mm accuracy and exceptional surface finish.

Critical DFM Parameters for Mini CNC Router Components

| Parameter | Typical Capability (Aluminum) | Critical Consideration |

| :———————- | :—————————- | :———————————————- |

| Minimum Feature Size | 0.5 mm | Dictated by smallest available end mill diameter |

| Standard Tolerance | ±0.05 mm | Tighter tolerances (±0.025 mm) achievable with process control |

| Maximum Part Dimension | 300 x 200 x 100 mm | Must align with specific machine envelope |

| Minimum Wall Thickness | 1.0 mm | Thinner walls require specialized strategies to prevent deflection |

| Surface Finish (As-Machined) | Ra 1.6 – 3.2 µm | Fine finishes require additional tooling/pass planning |

Start Your Project

Start Your Project with a High-Precision Mini CNC Router from Shenzhen Honyo Prototype

When it comes to prototyping, small-scale manufacturing, or intricate design work, the mini CNC router has become an indispensable tool across industries ranging from electronics and education to jewelry and architectural modeling. At Shenzhen Honyo Prototype, we specialize in delivering compact, high-accuracy CNC machining solutions tailored for precision-driven applications. Our mini CNC routers combine robust engineering with user-friendly operation, making them ideal for startups, R&D labs, and small production facilities that demand reliability without the footprint of industrial-sized machines.

Whether you’re machining lightweight aluminum, plastics, wood, or composite materials, our mini CNC routers offer exceptional repeatability and surface finish. Designed with a rigid aluminum frame, precision linear guides, and a high-speed spindle, these systems ensure consistent performance even under continuous operation. All units are pre-calibrated and tested in our Shenzhen facility to meet strict quality control standards before shipment.

To help you get started quickly, we offer full technical documentation, software integration support, and optional training sessions. Our systems are compatible with popular CAD/CAM platforms such as Fusion 360, AutoCAD, and Mastercam, enabling seamless workflow integration. We also provide customization options including work envelope adjustments, spindle upgrades, and vacuum table integration—ensuring the machine fits your specific production needs.

Below are the standard technical specifications of our most widely deployed mini CNC router model:

| Specification | Detail |

|—————————-|———————————————|

| Working Area (X-Y-Z) | 300 mm × 300 mm × 100 mm |

| Spindle Speed | 24,000 RPM (Air-Cooled, ER11 Collet) |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Control System | DSP or Offline Controller (Optional) |

| Supported Materials | Aluminum, Brass, Plastics, Wood, Acrylic |

| Software Compatibility | G-code, Mach3, UGS, Fusion 360 |

| Power Supply | AC 110/220 V, 50/60 Hz |

| Machine Weight | 45 kg |

| Communication Interface | USB, SD Card |

Every project begins with a conversation. At Shenzhen Honyo Prototype, we understand that your requirements are unique—whether you need a turnkey solution for rapid prototyping or a customized machining system for specialized components. That’s why we offer personalized consultations to match your application with the right configuration.

Ready to take the next step? Contact Susan Leo, our dedicated Project Coordinator, to discuss your machining needs, request a quote, or schedule a live demonstration. With fast response times and global shipping capabilities, we make it easy to integrate high-performance CNC technology into your workflow.

Email Susan Leo at info@hy-proto.com to start your project today. Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.