Contents

Manufacturing Insight: Cnc Machine Products

Manufacturing Insight: Precision CNC Machining for Rapid Prototyping and Production

Computer Numerical Control (CNC) machining remains the cornerstone of precision manufacturing for functional prototypes, bridge tooling, and low-to-medium volume production. At Shenzhen Honyo Prototype, we leverage this subtractive technology to transform digital CAD models into high-integrity components with exceptional repeatability and material versatility. Unlike additive methods, CNC machining removes material from solid billets using computer-guided cutting tools, ensuring superior mechanical properties, tight tolerances, and industry-standard surface finishes critical for validation testing and end-use applications. Our strategic investment in advanced CNC infrastructure directly addresses the urgent need for speed and accuracy in product development cycles, enabling clients to de-risk designs and accelerate time-to-market without compromising on quality.

Honyo Prototype operates a dedicated facility featuring 3-axis, 4-axis, and 5-axis CNC machining centers from industry-leading OEMs. This multi-axis capability allows us to machine complex geometries—including intricate contours, undercuts, and deep cavities—in a single setup, minimizing handling errors and reducing lead times. Our engineering team specializes in optimizing toolpaths for material efficiency and surface integrity, while our stringent process controls ensure dimensional stability across diverse material families. We prioritize rapid iteration, supporting design modifications with swift reprogramming and fixture adjustments to keep development momentum uninterrupted.

The following table outlines our core CNC machining capabilities for client reference

| Parameter | Specification |

|————————-|———————————————–|

| Machine Types | 3-Axis Vertical Milling, 4-Axis Indexing, 5-Axis Simultaneous |

| Max Work Envelope | 1000 x 600 x 500 mm |

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Typical Tolerances | ±0.025 mm (standard), ±0.005 mm (precision) |

| Surface Finish (Ra) | 0.8 μm to 3.2 μm (as-machined) |

| Common Materials | Aluminum 6061-T6, 7075; Stainless Steel 304/316; Titanium Gr5; POM, Nylon, PEEK; Brass C360 |

| Lead Time (Prototype) | 3-7 business days (depending on complexity) |

Quality is non-negotiable in our process. Every component undergoes rigorous in-process and final inspection using calibrated CMMs, optical comparators, and surface roughness testers against AS9100-aligned protocols. Our engineers provide detailed first-article inspection reports (FAIRs) with geometric dimensioning and tolerancing (GD&T) verification, ensuring full traceability and compliance with client specifications. By integrating CNC machining with complementary services like finishing, assembly, and rapid tooling, Honyo Prototype delivers end-to-end manufacturing solutions that bridge the gap between concept validation and scalable production. Partner with us to achieve precision that performs—where every micron matters and every deadline is engineered.

Technical Capabilities

Technical Capabilities: Precision CNC Machining at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers advanced CNC machining solutions tailored for rapid prototyping and low-to-medium volume production. Our in-house fleet of high-performance 3-axis, 4-axis, and 5-axis CNC milling machines, combined with precision turning centers, enables us to produce complex, high-integrity components across a wide range of engineering materials. With a focus on accuracy, repeatability, and fast turnaround, we support industries including aerospace, medical devices, automation, and consumer electronics.

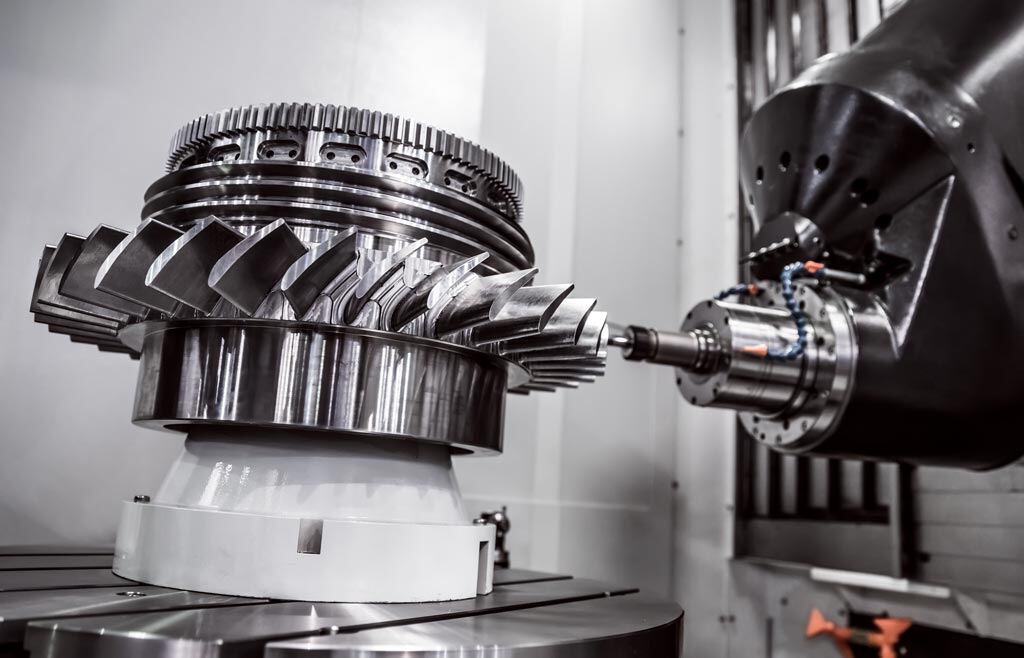

Our 3-axis milling capabilities are ideal for prismatic parts with straightforward geometries, offering efficient material removal and excellent surface finishes. For components requiring access to multiple faces or angled features, our 4-axis CNC machines provide rotational indexing around the A-axis, enabling deeper cavities and improved setup efficiency. For the most complex organic shapes—such as impellers, housings, and ergonomic enclosures—our 5-axis simultaneous machining centers deliver superior precision with minimal fixturing, reducing lead times and enhancing geometric accuracy.

In addition to multi-axis milling, we offer precision CNC turning for cylindrical and symmetrical parts. Our turning centers support live tooling, allowing for milling, drilling, and tapping operations in a single setup—ideal for turned-milled components such as shafts, bushings, and connectors. All machines are equipped with high-resolution probing systems and run under strict process controls to ensure dimensional consistency.

A cornerstone of our service is the ability to hold tight tolerances consistently. Standard tolerances are maintained at ±0.05 mm, with critical features achievable down to ±0.005 mm under controlled conditions. Our quality assurance process includes first-article inspection, in-process checks, and final CMM verification to meet ISO 9001 standards.

We support a broad spectrum of engineering-grade materials, including aluminum, stainless steel, titanium, brass, PEEK, ABS, and polycarbonate. Material selection is supported by our engineering team to match performance requirements such as strength, corrosion resistance, thermal stability, and machinability.

The following table outlines key technical specifications for our CNC machining services:

| Parameter | Specification |

|—————————-|——————————————————————————-|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning with live tooling |

| Maximum Work Envelope | 1000 × 600 × 500 mm (3-axis/4-axis); 500 × 400 × 350 mm (5-axis simultaneous) |

| Standard Tolerance | ±0.05 mm |

| Tight Tolerance Capability | ±0.005 mm (with process validation and inspection) |

| Surface Finish | As-machined: 3.2 μm; Optional: 1.6 μm, 0.8 μm (via polishing or grinding) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass (C36000), PEEK, ABS, PC, Nylon, and more |

| Lead Time | As fast as 3–5 days for prototypes; scalable for batch production |

All CNC programs are generated using industry-leading CAM software, with toolpath simulation and collision detection to ensure safe, efficient machining. At Shenzhen Honyo Prototype, we combine advanced technology with engineering expertise to deliver CNC-machined parts that meet the highest standards of quality and precision.

From CAD to Part: The Process

Precision Manufacturing Workflow: From CAD to Finished CNC Part at Shenzhen Honyo Prototype

Achieving exceptional prototype and low-volume production parts via CNC machining demands a rigorously defined workflow. At Shenzhen Honyo Prototype, we transform client CAD data into high-precision physical components through an integrated three-stage process: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Optimized Production Execution. This structured approach minimizes risk, accelerates time-to-part, and ensures manufacturability from the outset.

The workflow initiates with our proprietary AI-Powered Quoting Engine. Upon receipt of validated 3D CAD models (STEP, IGES, or native formats), the system performs rapid geometric analysis. It automatically identifies critical features, assesses part complexity, estimates material requirements and machine time, and evaluates necessary operations (milling, turning, drilling). Crucially, the AI cross-references this data against our extensive database of historical production parameters, material costs, and machine capabilities. This enables generation of highly accurate, data-driven cost and lead time estimates within hours, not days, providing clients with immediate project feasibility insight before formal commitment.

Following quote acceptance, the project enters the mandatory Design for Manufacturability (DFM) Analysis phase. Our senior manufacturing engineers conduct a thorough technical review, moving beyond the AI’s geometric assessment to evaluate practical manufacturability and identify potential pitfalls. This deep dive focuses on optimizing the design for CNC processes, ensuring the final part meets functional requirements while maximizing efficiency and yield. Key DFM checks are systematically applied:

| Check Category | Key Parameters | Honyo Standard Verification |

| :——————- | :—————————————— | :—————————————— |

| Geometric Feasibility | Internal radii, thin walls, deep cavities | Validates tool access, prevents deflection |

| Tolerance Analysis | GD&T application, critical feature callouts | Assesses capability vs. machine precision |

| Material Selection | Grade suitability, stock availability | Confirms machinability & lead time impact |

| Setup Optimization | Feature orientation, datum strategy | Minimizes secondary operations & cost |

Based on this analysis, we provide actionable feedback and collaborate with the client to resolve any manufacturability concerns, often suggesting subtle design modifications that significantly reduce cost and lead time without compromising function.

Only after DFM sign-off does the project advance to Production Execution. Our CAM programming team generates optimized toolpaths using industry-leading software (Mastercam, Fusion 360), meticulously selecting cutting tools, speeds, feeds, and machining sequences tailored to the specific material and geometry. Programs undergo rigorous virtual simulation to eliminate collisions and verify path accuracy. Parts are then manufactured on our precision CNC equipment, including advanced 3-axis and 5-axis machining centers and multi-axis lathes with live tooling. Throughout production, our quality technicians perform in-process inspections using calibrated CMMs, optical comparators, and surface roughness testers against the original engineering specifications. Final first-article inspection reports are provided, confirming all critical dimensions and surface finishes meet requirements before shipment.

This seamless integration of AI efficiency, expert engineering judgment, and precision manufacturing ensures Shenzhen Honyo Prototype delivers CNC machined parts that are not only dimensionally accurate but also produced with optimal speed and reliability, directly translating your CAD vision into a high-quality physical reality. Rigorous validation at each stage guarantees project success from digital concept to certified component.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision CNC machining for prototypes and low-volume production, Shenzhen Honyo Prototype delivers unmatched quality, speed, and technical expertise. Whether you are developing a new product, refining a design, or scaling from prototype to production, our advanced CNC machining capabilities ensure your components meet exact specifications with tight tolerances, superior surface finishes, and rapid turnaround times.

At Honyo Prototype, we specialize in turning complex designs into high-precision parts using state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling and turning centers. Our facility is equipped to handle a wide range of materials, including aluminum, stainless steel, brass, titanium, PEEK, and engineering plastics, ensuring compatibility with diverse application requirements across industries such as aerospace, medical devices, robotics, and consumer electronics.

To begin your project, all we need is a detailed 3D CAD model in STEP, IGES, or SolidWorks format, along with your material preferences, required quantities, and any critical tolerances or finishing specifications. Our engineering team will conduct a comprehensive Design for Manufacturability (DFM) review to optimize your part for performance, cost-efficiency, and rapid production. We provide expert feedback within 12 hours of submission, helping you resolve potential issues before machining begins—saving time and reducing development costs.

Our commitment to transparency and client collaboration ensures you stay informed at every stage. From initial quotation to final inspection, we maintain open communication and provide real-time updates. All parts undergo rigorous quality control, including first-article inspection and final dimensional verification using precision CMM and optical measurement systems.

We understand that speed is critical in product development. That’s why Honyo Prototype offers turnaround times as fast as 3–5 business days for standard CNC machined parts, with expedited options available for urgent projects. Our streamlined workflow, combined with in-house tooling and finishing capabilities—including anodizing, powder coating, plating, and laser engraving—ensures consistency and faster delivery without compromising quality.

Below are the key technical specifications for our CNC machining services:

| Specification | Capability |

|————–|————|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning |

| Tolerances | ±0.005 mm (standard), down to ±0.001 mm (tight tolerance) |

| Materials | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Brass, Titanium, PEEK, ABS, PC, Nylon |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Surface Finishes | As-machined, bead blasting, anodizing (Type II & III), powder coating, passivation, plating |

| Quality Standards | ISO 9001:2015 compliant, full inspection reports available |

Ready to move from concept to physical prototype? Contact Susan Leo today to start your CNC machining project. Email us at info@hy-proto.com with your design files, and we’ll provide a competitive quote and DFM feedback within hours. At Shenzhen Honyo Prototype, we’re not just manufacturers—we’re your engineering partners in innovation. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.