Contents

Manufacturing Insight: Grade 5 Titanium Price

Manufacturing Insight: Understanding Grade 5 Titanium Pricing in Precision CNC Machining

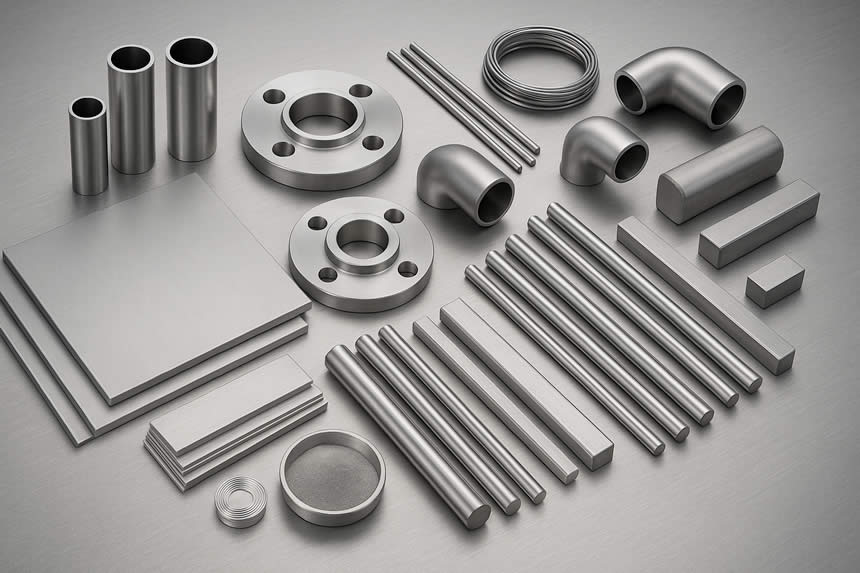

Grade 5 titanium (Ti-6Al-4V) remains the aerospace and medical industry’s premier alloy for demanding applications, prized for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, its premium performance directly influences machining costs, making price a critical factor in prototyping and low-volume production planning. At Shenzhen Honyo Prototype, we recognize that material cost is only one component of the total expense; the inherent challenges of machining Ti-6Al-4V significantly impact final part pricing. This alloy exhibits significant work hardening, generates high cutting temperatures, and demands precise toolpath strategies to avoid galling or premature tool failure. These factors necessitate slower feed rates, specialized tooling, and extended machine time compared to common steels or aluminum, directly affecting unit cost.

Our CNC machining process for Grade 5 titanium leverages decades of metallurgical expertise and process optimization to mitigate these cost drivers. We utilize rigid 5-axis machining centers with high-torque spindles, ensuring stability during deep cavity work or thin-wall features common in aerospace brackets or medical implants. Proprietary coolant delivery systems maintain optimal cutting temperatures, reducing thermal deformation and extending carbide tool life by up to 30% versus standard approaches. Crucially, our engineers develop custom machining sequences that minimize work hardening through controlled depth-of-cut strategies and optimized chip evacuation, directly lowering scrap rates and rework costs for clients. This technical proficiency translates to predictable lead times and reduced total cost of ownership, even for complex geometries.

Understanding the variables influencing Grade 5 titanium pricing is essential for accurate budgeting. The table below outlines key cost factors beyond raw material rates:

| Factor | Impact on Cost | Honyo Mitigation Strategy |

|———————–|————————————————|———————————————–|

| Material Cost | 3-4x base titanium price; subject to market volatility | Long-term supplier partnerships for stable pricing |

| Machining Complexity | High feature density or thin walls increase cycle time 25-50% | Feature-based process planning & adaptive toolpaths |

| Tooling Expense | Carbide inserts cost 40-60% more than steel machining; 50% faster wear | Precision tool monitoring & optimized tool geometry selection |

| Volume Requirements | Low volumes (<50 pcs) lack economies of scale; setup dominates cost | Modular fixturing & digital twin validation to reduce setup time |

Honyo Prototype excels in transforming Grade 5 titanium’s challenges into competitive advantages for clients. Our integrated approach—from material sourcing to final inspection—ensures that every machined component meets stringent AS9100 and ISO 13485 standards while optimizing cost efficiency. We provide detailed cost breakdowns during quoting, highlighting opportunities for design-for-manufacturability adjustments that can reduce part cost by 15-25% without compromising performance. For prototyping or bridge production runs, our rapid iteration capabilities allow clients to validate designs in actual Grade 5 titanium faster than traditional suppliers, accelerating time-to-market. Partner with Honyo to navigate the complexities of titanium machining with engineering precision and transparent pricing discipline.

Technical Capabilities

Technical Capabilities: Precision CNC Machining of Grade 5 Titanium at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in high-precision CNC machining of aerospace-grade materials, with extensive expertise in processing Grade 5 titanium (Ti-6Al-4V). As one of the most widely used titanium alloys in critical industries such as aerospace, medical, and defense, Grade 5 titanium offers an exceptional strength-to-density ratio, excellent corrosion resistance, and superior performance at elevated temperatures. Our advanced 3-, 4-, and 5-axis milling capabilities, combined with precision turning operations, enable us to deliver complex, mission-critical components with consistent accuracy and reliability.

Grade 5 titanium presents unique machining challenges due to its low thermal conductivity and high chemical reactivity with cutting tools. At Honyo Prototype, we address these challenges through optimized toolpath strategies, specialized carbide tooling, and controlled cutting parameters that minimize work hardening and tool wear. Our CNC machining centers are equipped with high-speed spindles and rigid construction to maintain stability during deep cutting and thin-wall machining, which are common in titanium components.

Our 5-axis simultaneous machining capability allows for the production of highly complex geometries in a single setup, reducing part handling and improving dimensional consistency. This is particularly beneficial for Grade 5 titanium parts that require intricate contours, undercuts, or organic shapes commonly found in aerospace structural components and medical implants. Similarly, our 4-axis indexing and 3-axis milling platforms support a broad range of part configurations with tight positional accuracy.

For applications demanding micron-level precision, our tight-tolerance machining processes consistently achieve tolerances down to ±0.005 mm (±0.0002″) on critical features. We utilize in-process probing, temperature-compensated CMM inspection, and statistical process control (SPC) to ensure every component meets stringent quality requirements. Secondary operations such as deburring, passivation, and non-destructive testing can be integrated upon request.

The following table outlines our standard machining capabilities and achievable tolerances for Grade 5 titanium:

| Parameter | Specification |

|—————————-|————————————————|

| Material | Grade 5 Titanium (Ti-6Al-4V), ASTM B265/B348 |

| Machining Processes | 3-Axis, 4-Axis, 5-Axis Milling, CNC Turning |

| Standard Tolerance | ±0.025 mm (±0.001″) |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) |

| Surface Finish (Milling) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm |

| Feature Resolution | Minimum wall: 0.5 mm; Hole depth-to-dia: 10:1 |

| Max Work Envelope (5-axis) | 1,200 x 800 x 600 mm |

| Max Work Envelope (Turning)| Ø500 mm x 1,000 mm length |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace compliance) |

At Shenzhen Honyo Prototype, we combine technical expertise with rigorous process control to deliver high-integrity Grade 5 titanium components tailored to the performance demands of advanced engineering applications. Our focus on precision, repeatability, and material understanding ensures competitive lead times and consistent part quality.

From CAD to Part: The Process

From CAD to Precision Grade 5 Titanium Part: Honyo Prototype’s Streamlined Workflow

At Shenzhen Honyo Prototype, we transform Grade 5 titanium (Ti-6Al-4V) designs into high-integrity CNC machined components through a rigorously defined workflow. This process prioritizes accuracy, cost efficiency, and manufacturability from the initial inquiry to final inspection, specifically addressing the unique challenges and cost drivers of titanium machining. Our integrated system ensures clients receive realistic pricing and feasible production timelines upfront, minimizing downstream revisions.

The workflow initiates with our AI-Powered Quotation System. Clients upload native CAD files (STEP, IGES, Parasolid) directly to our portal. Our proprietary AI engine instantaneously analyzes geometric complexity, feature density, material volume, and critical tolerances inherent to Grade 5 titanium. It cross-references this data against our extensive database of historical machining times, tool wear rates specific to Ti-6Al-4V, and real-time material cost fluctuations. This generates a highly accurate preliminary quote within minutes, explicitly detailing how titanium’s properties—such as low thermal conductivity and high chemical reactivity—impact cost factors like machine hours and tooling consumption. This transparency sets clear expectations before engineering commitment.

Following client approval of the AI-generated quote, the project enters the critical Engineering DFM Review phase. Our senior manufacturing engineers conduct a comprehensive Design for Manufacturability analysis. We scrutinize the CAD model for titanium-specific pitfalls: excessive thin walls prone to chatter, deep cavities requiring specialized tooling, inadequate draft for potential secondary operations, and geometric features demanding slow, precise cutting to prevent work hardening or thermal distortion. We collaborate directly with the client to suggest pragmatic optimizations—such as minor radius increases, strategic stock allowances, or tolerance rationalization—that significantly reduce machining time and cost without compromising function. This stage is vital for Grade 5 titanium, where inefficient toolpaths or poor fixturing directly escalate part cost due to extended cycle times and accelerated tool wear.

Upon DFM sign-off, the project advances to CNC Production. We utilize state-of-the-art 3-, 4-, and 5-axis machining centers equipped with high-torque spindles, rigid toolholding, and high-pressure through-spindle coolant systems essential for titanium. Machining Grade 5 titanium demands strict adherence to optimized parameters to manage heat generation and ensure chip evacuation. Our proven parameters for Ti-6Al-4V are summarized below:

| Parameter | Typical Range for Ti-6Al-4V | Critical Reason |

| :—————– | :————————– | :———————————- |

| Spindle Speed | 80 – 150 SFM | Prevents excessive heat buildup |

| Feed Rate | 0.002 – 0.008 IPT | Manages chip load, avoids rubbing |

| Depth of Cut | 0.020 – 0.060 inch | Balances material removal & rigidity |

| Coolant Pressure | 1000+ PSI High Pressure | Ensures chip evacuation, cooling |

| Tool Material | Carbide (TiAlN coating) | Resists heat, abrasion, adhesion |

Machining occurs under stringent environmental controls. Each operation undergoes in-process inspection using calibrated CMMs to verify critical dimensions against the approved DFM-modified model. Final parts receive comprehensive FAI (First Article Inspection) reporting, including material certification traceability to mill test reports, surface finish verification, and dimensional conformance to AS9102 standards. This end-to-end workflow, from AI-driven quoting through titanium-optimized DFM and precision production, ensures Shenzhen Honyo Prototype delivers Grade 5 titanium prototypes and low-volume production parts with exceptional quality, predictable cost, and accelerated time-to-market.

Start Your Project

Start Your Next Precision Project with Grade 5 Titanium – Contact Susan Leo Today

When it comes to high-performance CNC machining, Grade 5 titanium—also known as Ti-6Al-4V—is one of the most sought-after materials in aerospace, medical, and industrial applications. At Shenzhen Honyo Prototype, we specialize in delivering precision-machined components from Grade 5 titanium with tight tolerances, exceptional surface finishes, and fast turnaround times. If you’re evaluating the cost and feasibility of your next project, understanding the current grade 5 titanium price is just the beginning. What truly matters is the value delivered through expert manufacturing, material sourcing, and engineering support.

Grade 5 titanium offers an outstanding strength-to-density ratio, excellent corrosion resistance, and the ability to perform under extreme temperatures. These properties make it ideal for mission-critical components. However, machining this alloy requires advanced CNC capabilities, specialized tooling, and deep technical expertise—especially due to its low thermal conductivity and tendency to work-harden. At Honyo Prototype, our CNC machining centers are optimized for titanium alloys, ensuring dimensional accuracy and repeatability across both prototypes and low-volume production runs.

We understand that material cost is a key factor in project planning. While the base price of Grade 5 titanium fluctuates based on global market conditions, our procurement network allows us to source high-quality domestic and imported stock at competitive rates. More importantly, we minimize waste through efficient nesting, toolpath optimization, and in-house quality control—helping you reduce overall project cost without compromising performance.

Below is a general reference for Grade 5 titanium material specifications commonly used in CNC machining:

| Property | Value |

|—————————–|————————————–|

| Alloy Designation | Ti-6Al-4V (Grade 5) |

| Density | 4.43 g/cm³ |

| Tensile Strength (min) | 900 MPa |

| Yield Strength (min) | 830 MPa |

| Elongation at Break | 10% |

| Common Forms Available | Bar, rod, block, plate |

| Typical Tolerance (CNC) | ±0.025 mm |

| Surface Finish (as machined)| Ra 1.6–3.2 µm (adjustable) |

Whether you’re developing a prototype for flight testing or scaling up for small-batch production, Honyo Prototype ensures your Grade 5 titanium components meet the highest standards of quality and performance. Our team supports DFM feedback, material certification, and rapid quoting to keep your project moving forward efficiently.

For a detailed quote and current grade 5 titanium pricing based on your specific geometry, volume, and finish requirements, contact Susan Leo directly at info@hy-proto.com. We respond to all inquiries within 12 business hours and offer multilingual support for global clients. Start your project with confidence—partner with a manufacturer who combines precision engineering with responsive service.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.