Contents

Manufacturing Insight: Hardness Of Titanium Vs Stainless Steel

Manufacturing Insight: Hardness of Titanium vs Stainless Steel in Precision CNC Machining

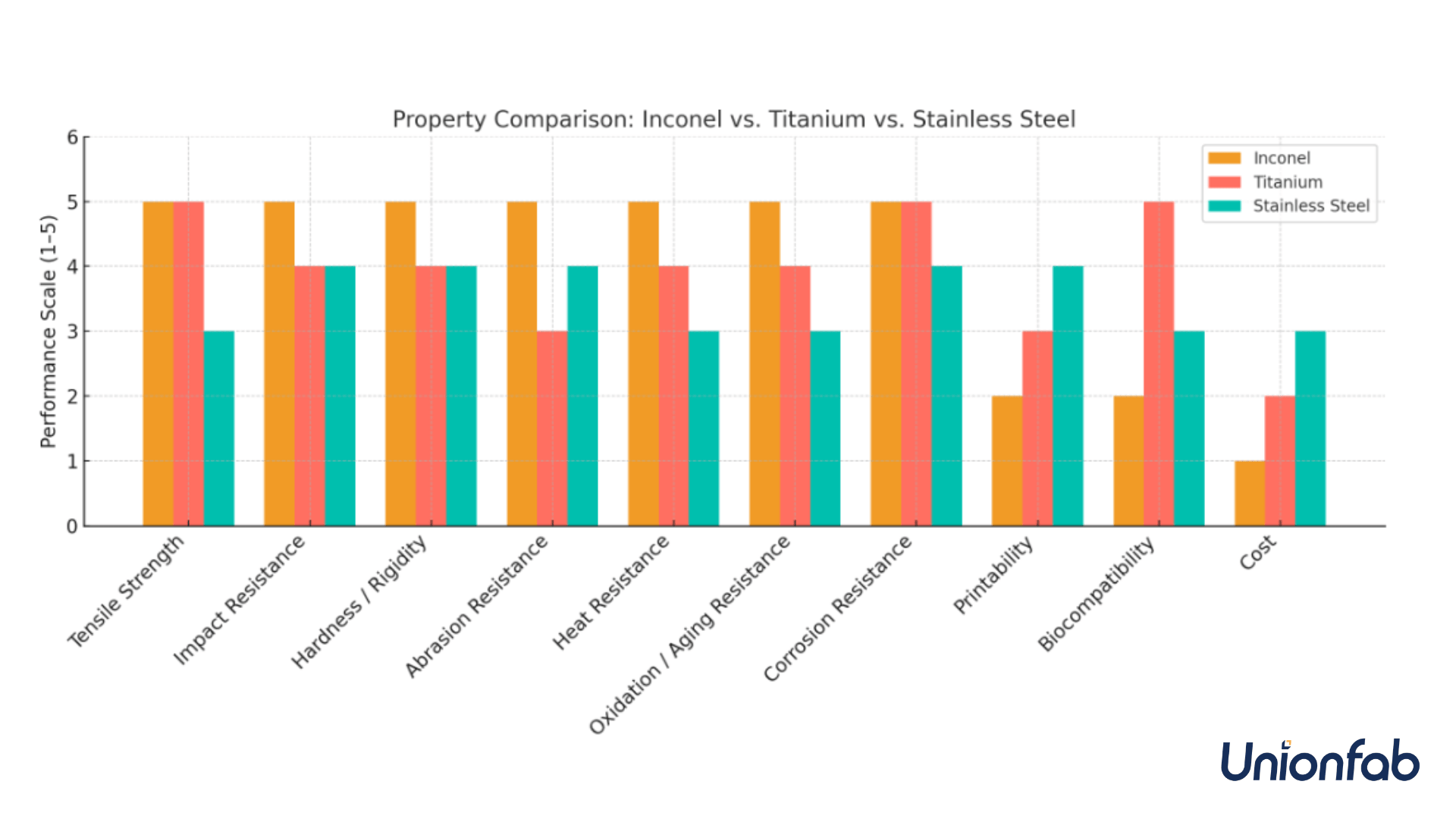

Understanding material hardness is critical when selecting alloys for demanding CNC machining applications. At Shenzhen Honyo Prototype, we frequently encounter titanium and stainless steel in aerospace, medical, and industrial components. While both are high-performance materials, their hardness profiles—and implications for machinability—differ significantly. Hardness directly influences tool selection, cutting parameters, and surface integrity, making this comparison essential for efficient production. Titanium alloys, particularly Ti-6Al-4V (Grade 5), typically exhibit a Brinell hardness of 330 HB (equivalent to 33–36 HRC). In contrast, stainless steel hardness varies widely by grade and condition. Austenitic grades like 304 and 316 are relatively soft in annealed states (70–90 HRB), while martensitic and precipitation-hardening grades such as 17-4PH can reach 40–45 HRC after heat treatment. This disparity necessitates tailored machining strategies to avoid tool failure or part distortion.

The following table summarizes key hardness characteristics and machining considerations:

| Material | Typical Hardness Range | Condition | Key Machining Challenge |

|——————-|————————|—————–|—————————————|

| Ti-6Al-4V (Titanium) | 330 HB / 33–36 HRC | Annealed | Low thermal conductivity causing heat buildup; moderate work hardening |

| Stainless 304 | 70–90 HRB | Annealed | Severe work hardening during cutting; galling tendency |

| Stainless 316 | 75–95 HRB | Annealed | Similar to 304; higher corrosion resistance increases abrasiveness |

| Stainless 17-4PH | 35–45 HRC | H900/H1025 Temp | Extreme abrasiveness; requires rigid setups and sharp tools |

Critically, hardness alone does not dictate machinability. Titanium’s lower thermal conductivity (17 W/m·K vs. stainless steel’s 16.2 W/m·K for 304) causes heat concentration at the tool edge, accelerating wear despite its moderate hardness. Conversely, austenitic stainless steels (304/316) work-harden rapidly during cutting—sometimes doubling surface hardness—leading to built-up edge and premature tool chipping. Precipitation-hardening grades like 17-4PH combine high baseline hardness with abrasive carbide structures, demanding specialized tool geometries and aggressive coolant delivery.

At Honyo Prototype, we leverage this metallurgical insight to optimize CNC processes. For titanium, we employ sharp, polished carbide tools with high positive rake angles, reduced cutting speeds (40–60 m/min), and high-pressure coolant to manage heat. Stainless steel machining requires distinct approaches: austenitic grades benefit from high-speed steel (HSS) tools or micro-grain carbide with interrupted cut strategies to mitigate work hardening, while hardened 17-4PH demands PVD-coated carbide inserts at lower feeds (0.05–0.15 mm/rev) to withstand abrasion. Our facility utilizes real-time tool monitoring and adaptive CNC programming to maintain tolerances within ±0.005 mm, even in challenging sections.

By aligning material science with precision machining expertise, Honyo Prototype ensures optimal throughput and part longevity. We collaborate with engineers to select the right alloy and process parameters early in design—turning material constraints into manufacturing advantages. Contact our team for tailored solutions that balance hardness, cost, and performance in your next prototype or low-volume production run.

Technical Capabilities

Hardness of Titanium vs Stainless Steel in CNC Machining

When evaluating materials for precision CNC machining, understanding the mechanical properties of titanium and stainless steel is critical, particularly in high-performance applications across aerospace, medical, and industrial sectors. At Shenzhen Honyo Prototype, our 3, 4, and 5-axis milling and turning capabilities are optimized to handle both materials with tight-tolerance consistency, despite their differing hardness characteristics and machining behaviors.

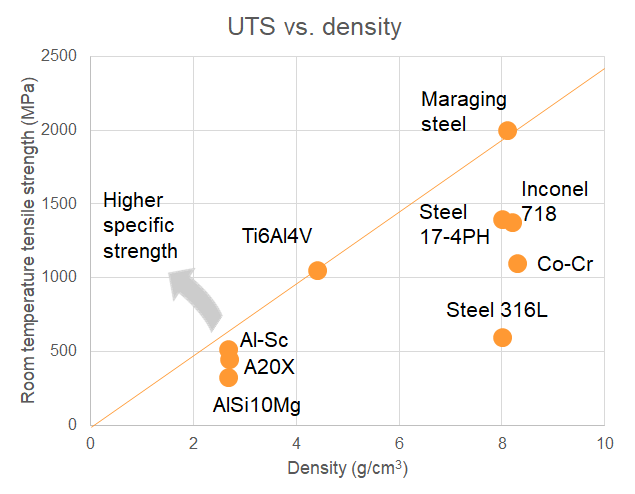

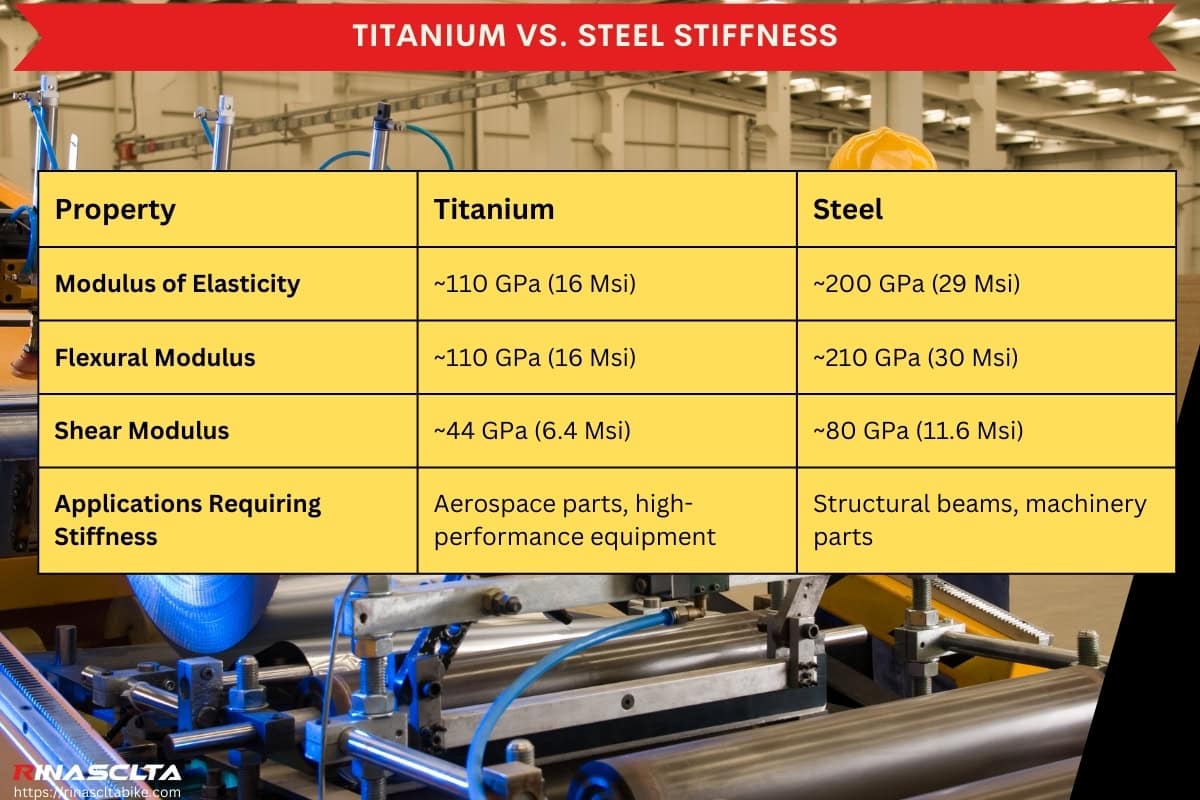

Titanium, particularly Grade 5 (Ti-6Al-4V), exhibits a Brinell hardness of approximately 330–360 HB, while common stainless steel alloys such as 304 and 17-4 PH range from 150 HB (annealed 304) to over 380 HB (precipitation-hardened 17-4 PH). This variation means that while some stainless steel grades are softer than titanium in the annealed state, hardened variants can exceed titanium’s surface hardness. However, titanium’s strength-to-density ratio and resistance to fatigue and corrosion make it uniquely challenging during machining due to work hardening and low thermal conductivity.

Stainless steel, especially in its austenitic forms like 304 and 316, is generally easier to machine than titanium due to better thermal conductivity and chip evacuation. However, martensitic and precipitation-hardened grades such as 17-4 PH require specialized tooling and slower cutting parameters when in hardened conditions. In contrast, titanium’s tendency to generate high localized heat and react with cutting tools necessitates rigid setups, sharp carbide tools, and conservative feed rates to maintain dimensional accuracy and surface finish.

Our CNC machining centers are equipped with high-torque spindles, advanced cooling systems, and real-time tool monitoring to manage these challenges. For both materials, maintaining tight tolerances demands precise control over thermal expansion and tool deflection. We achieve consistent results down to ±0.005 mm on critical dimensions, leveraging in-process inspection and high-resolution probing systems.

Below is a comparative overview of achievable tolerances and material properties relevant to our 3/4/5-axis milling and turning processes:

| Material | Hardness (HB) | Typical Condition | Max Achievable Tolerance (CNC Milling) | Max Achievable Tolerance (CNC Turning) | Recommended Tooling |

|——————|—————|——————-|—————————————-|—————————————-|—————————–|

| Titanium (Ti-6Al-4V) | 330–360 | Annealed | ±0.005 mm | ±0.008 mm | Carbide, PCD, or CBN coated |

| Stainless 304 | 150–200 | Annealed | ±0.005 mm | ±0.005 mm | Carbide with sharp edge |

| Stainless 316 | 160–220 | Annealed | ±0.005 mm | ±0.005 mm | Carbide, high-feed milling |

| Stainless 17-4 PH| 270–380 | H900 (Hardened) | ±0.008 mm | ±0.010 mm | Carbide, micro-grain coated |

Shenzhen Honyo Prototype applies material-specific cutting strategies, including optimized RPM, step-down depth, and toolpath algorithms, to ensure repeatability and surface integrity. Whether machining complex titanium aerospace components or corrosion-resistant stainless steel medical housings, our technical capabilities support tight-tolerance production with full traceability and quality assurance.

From CAD to Part: The Process

Titanium vs Stainless Steel Hardness: CNC Production Workflow Implications

Understanding the hardness differential between titanium alloys and stainless steel is critical when transitioning from CAD design to finished part in CNC machining. At Honyo Prototype, this knowledge directly shapes our AI quoting accuracy, DFM validation, and production execution. Titanium Grade 5 (Ti-6Al-4V) typically exhibits a Brinell hardness of 334 HB, while common stainless steels like 304/316 range from 140–200 HB in annealed states. However, precipitation-hardening grades such as 17-4PH can reach 330–450 HB post-heat treatment, overlapping with titanium’s range. This variance necessitates material-specific process adjustments throughout our workflow.

During the AI quoting phase, our system cross-references hardness data with historical machining metrics to predict tooling costs and cycle times. Titanium’s high strength-to-weight ratio and low thermal conductivity increase tool wear rates by 30–50% compared to annealed stainless steel, directly elevating cost estimates. For 17-4PH in H900 condition, the system flags extended setup times due to required specialized cutters. This data-driven approach ensures quotes reflect realistic production constraints before engineering engagement.

DFM analysis becomes pivotal for hardness management. Our engineers validate whether designs accommodate material behavior: titanium’s tendency for work hardening demands conservative depth-of-cut parameters (<0.5mm) and rigid setups to prevent chatter, while thin-walled stainless features risk distortion if hardness exceeds 300 HB without stress-relief steps. Key considerations include avoiding sharp internal corners in titanium to reduce stress concentration and verifying that stainless steel parts specify hardness tolerances compatible with machinability—e.g., 316L annealed (160 HB max) versus hardened 17-4PH (380 HB min).

Material hardness properties significantly influence production parameters as shown below:

| Material | Typical Hardness (HB) | Max Recommended Cutting Speed (m/min) | Primary Machining Challenge |

|——————-|————————|————————————–|———————————–|

| Ti-6Al-4V | 330–340 | 30–50 | Heat accumulation, chip welding |

| 304/316 Stainless | 140–200 | 80–120 | Work hardening in deep cuts |

| 17-4PH (H900) | 380–450 | 40–60 | Abrasive tool wear, burr formation|

In production, our CNC protocols adapt to these hardness profiles. Titanium machining employs rigid toolholders, positive-rake carbide inserts with TiAlN coating, and high-pressure coolant to dissipate heat. Stainless steel workflows vary: annealed grades use aggressive feeds but controlled speeds to avoid galling, while hardened 17-4PH requires intermittent cutting and frequent tool inspections. Post-machining, titanium undergoes vibratory deburring to mitigate work-hardened edges, whereas stainless parts may need passivation only if hardness-induced micro-cracks are detected.

Honyo Prototype’s integrated workflow ensures hardness characteristics are never an afterthought. By embedding material science into AI quoting, DFM rigor, and adaptive CNC strategies, we deliver precision parts that meet aerospace and medical specifications without costly iterations. This systematic approach minimizes scrap rates and guarantees first-article success for both titanium and high-hardness stainless steel applications.

Start Your Project

Understanding Hardness: Titanium vs Stainless Steel in CNC Machining

When selecting materials for precision CNC machining projects, understanding the mechanical properties of your chosen alloy is critical—especially hardness. At Shenzhen Honyo Prototype, we frequently guide clients through the decision between titanium and stainless steel, two of the most widely used metals in aerospace, medical, and high-performance industrial applications. While both materials offer excellent strength and corrosion resistance, their hardness characteristics significantly influence machinability, tool life, and final part performance.

Hardness, typically measured on the Rockwell or Vickers scale, reflects a material’s resistance to deformation. Stainless steel, particularly grades like 304 and 17-4 PH, exhibits moderate hardness levels that make it relatively easier to machine compared to titanium. For example, annealed 304 stainless steel has a Rockwell B hardness of approximately 70–80 HRB, while precipitation-hardened 17-4 PH can reach up to 40 HRC. This range allows for efficient cutting with standard tooling and predictable chip formation.

Titanium, especially in its most common grade—Ti-6Al-4V—presents a different challenge. While its base hardness may appear lower—around 36 HRC when solution treated and aged—the material’s low thermal conductivity and high strength-to-density ratio create significant heat buildup during machining. This results in accelerated tool wear and increased cutting forces, making it behave as if it were much harder than its measured value suggests. Additionally, titanium’s tendency to gall and react chemically with cutting tools demands specialized tooling, reduced feed rates, and precise coolant application.

Below is a comparative overview of key hardness and mechanical properties:

| Material | Grade | Hardness (Typical) | Tensile Strength (MPa) | Common Applications |

|——————-|————-|——————–|————————|—————————–|

| Stainless Steel | 304 (Annealed) | 70–80 HRB | 515 | Food processing, hardware |

| Stainless Steel | 17-4 PH (H900)| ~40 HRC | 1310 | Aerospace, valves, shafts |

| Titanium | Ti-6Al-4V | 36 HRC | 950 | Medical implants, aircraft |

The choice between titanium and stainless steel is not solely about hardness—it involves trade-offs in cost, weight, corrosion resistance, and manufacturability. At Honyo Prototype, we leverage years of CNC machining expertise to optimize tool paths, select appropriate inserts, and ensure tight tolerances—whether you’re working with galling-prone titanium or work-hardening stainless alloys.

Every successful project begins with the right material selection and a clear understanding of machining requirements. If you’re evaluating titanium versus stainless steel for your next prototype or production run, our engineering team is ready to assist.

Contact Susan Leo at info@hy-proto.com to discuss your project specifications, material options, and precision machining solutions. Let Honyo Prototype be your trusted partner in turning high-performance designs into reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.