Contents

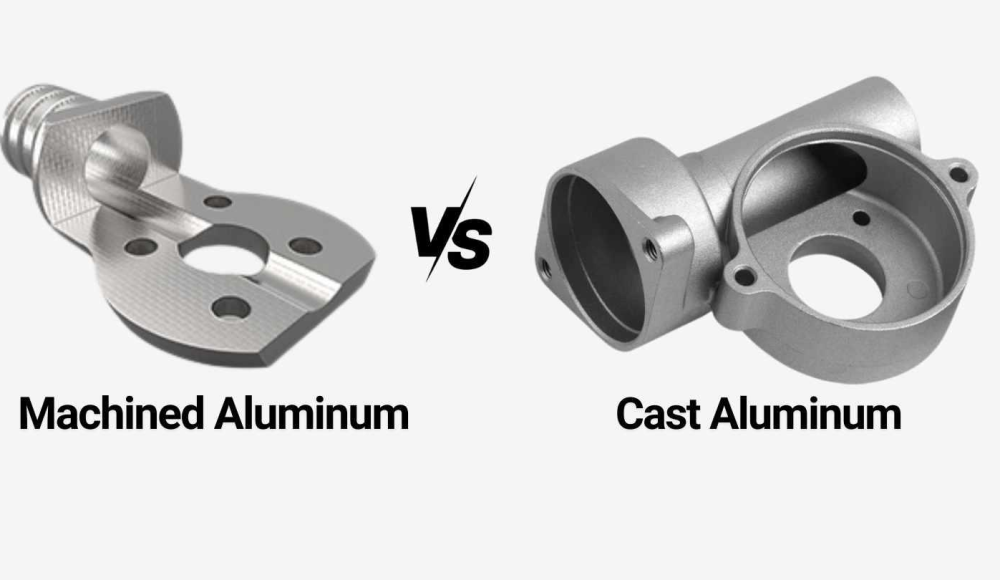

Manufacturing Insight: Cast Aluminum Vs Aluminum

Manufacturing Insight: Cast Aluminum versus Wrought Aluminum for Precision CNC Machining

Understanding the distinction between cast aluminum and wrought aluminum is critical for optimizing part design, manufacturability, and performance in CNC machining applications. A common misconception conflates “aluminum” as a single material category; in reality, aluminum alloys are processed into fundamentally different forms—cast or wrought—each with inherent structural characteristics that significantly impact machining strategy and final part integrity. At Shenzhen Honyo Prototype, we specialize in precision CNC machining for both material types, leveraging our deep material science expertise to guide clients toward the optimal solution for their prototype or low-volume production needs.

Cast aluminum alloys, such as A380 or A356, are formed by pouring molten metal into molds. This process yields near-net shapes ideal for complex geometries but introduces inherent porosity and microstructural inconsistencies. Wrought aluminum alloys, like 6061-T6 or 7075-T6, are mechanically deformed via rolling, forging, or extrusion after solidification, resulting in a homogeneous, denser grain structure with superior mechanical properties. Material integrity differs significantly: cast variants offer excellent fluidity for intricate designs but lower fatigue strength, while wrought forms provide higher tensile strength and ductility essential for structural components. Machinability also varies; cast aluminum’s silicon content can cause abrasive tool wear, whereas wrought alloys produce cleaner chips but require precise parameter control to avoid work hardening.

Key mechanical and machining properties contrast as follows:

| Property | Cast Aluminum (A380) | Wrought Aluminum (6061-T6) |

|————————-|———————-|—————————-|

| Tensile Strength (MPa) | 310 | 310 |

| Yield Strength (MPa) | 165 | 276 |

| Elongation at Break (%) | 3 | 12 |

| Typical Machinability | Good (moderate tool wear) | Excellent (with optimized parameters) |

| Primary Applications | Housings, brackets, complex enclosures | Structural frames, shafts, high-stress components |

Honyo Prototype bridges this material divide through integrated process mastery. Our CNC machining center utilizes ISO-compliant equipment with rigid tooling setups specifically calibrated for each alloy’s thermal and mechanical behavior. For cast aluminum, we implement pre-machining vacuum impregnation to seal porosity and apply specialized cutting strategies to manage abrasive silicon particles, ensuring dimensional stability. When machining wrought aluminum, we leverage high-speed spindles and coolant-through tooling to maintain surface integrity and prevent built-up edge. Crucially, our engineering team conducts upfront Design for Manufacturability (DFM) reviews to identify whether a part’s functional requirements align better with cast or wrought stock—preventing costly iterations. This material-agnostic capability allows us to machine cast billets directly or refine near-net castings, reducing lead times by up to 40% compared to traditional multi-vendor workflows.

Selecting the appropriate aluminum form is not merely a material choice but a strategic manufacturing decision. Honyo Prototype delivers unmatched agility in transforming both cast and wrought aluminum into mission-critical components, combining material-specific machining expertise with rapid prototyping efficiency. Partner with us to ensure your design leverages the inherent advantages of each aluminum variant while maximizing CNC precision, structural reliability, and time-to-market.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining services tailored to meet the demanding requirements of modern industrial applications. Our expertise in 3-axis, 4-axis, and 5-axis milling, as well as precision turning, enables us to process both cast aluminum and wrought aluminum with exceptional accuracy and surface finish. Understanding the material differences between cast aluminum and wrought (commonly referred to as “aluminum”) is critical in selecting the appropriate stock for high-tolerance components used in aerospace, automotive, and consumer electronics.

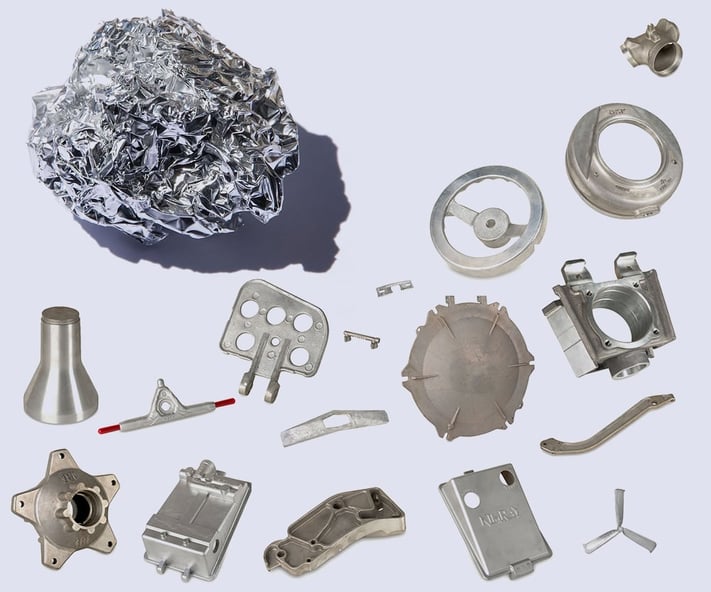

Cast aluminum, typically alloys such as A380 or ADC12, is produced through die-casting or sand-casting methods. It offers excellent flow characteristics during casting, good dimensional stability, and high thermal conductivity. However, cast aluminum generally exhibits lower mechanical strength and ductility compared to wrought aluminum due to its heterogeneous microstructure and porosity. Despite these limitations, it is ideal for complex geometries that benefit from near-net-shape casting followed by precision CNC machining to achieve final critical features.

Wrought aluminum, including grades like 6061-T6 and 7075-T6, is formed through extrusion, rolling, or forging processes. These materials provide superior strength-to-weight ratios, consistent grain structure, and enhanced machinability. Wrought aluminum is the preferred choice for structural and load-bearing components requiring tight tolerances and high fatigue resistance. At Honyo Prototype, we leverage our multi-axis CNC platforms to fully exploit the machinability of wrought aluminum, enabling intricate features, fine surface finishes, and repeatable accuracy.

Our advanced CNC systems support tight tolerance machining down to ±0.005 mm for critical dimensions, with surface finishes as fine as Ra 0.8 μm achievable through optimized toolpaths and in-process inspection. We apply material-specific cutting strategies, including high-speed machining for wrought aluminum and controlled-depth passes for cast variants to avoid subsurface defects.

The following table outlines the typical material and tolerance capabilities across our CNC machining services:

| Material Type | Common Alloys | Max Part Size (mm) | Typical Tolerance (mm) | Surface Finish (Ra, μm) | Best Suited For |

|——————-|——————-|——————–|————————|————————-|————————————-|

| Cast Aluminum | A380, ADC12 | 600 × 500 × 400 | ±0.01 to ±0.02 | 3.2 – 6.3 | Enclosures, housings, low-stress parts |

| Wrought Aluminum | 6061-T6, 7075-T6 | 800 × 600 × 500 | ±0.005 to ±0.01 | 0.8 – 1.6 | Structural components, high-precision parts |

All machined components undergo rigorous quality control using CMM and optical measurement systems to ensure compliance with engineering drawings and GD&T specifications. By combining material science insight with advanced CNC technology, Shenzhen Honyo Prototype ensures optimal performance, reliability, and repeatability across both cast and wrought aluminum applications.

From CAD to Part: The Process

From CAD to Part: Streamlined Production Workflow for Aluminum Components

Shenzhen Honyo Prototype clarifies a critical distinction upfront: the comparison is not “cast aluminum vs aluminum” but rather cast aluminum parts versus machined aluminum parts, both utilizing aluminum alloys. Aluminum is the base material; casting and CNC machining are distinct manufacturing processes. Our integrated workflow ensures optimal path selection from initial inquiry to finished prototype or low-volume part.

The process initiates with the AI-Powered Quotation System. Upon receiving a client’s CAD file (STEP, IGES, or native formats preferred), our proprietary AI engine performs rapid geometric analysis. It evaluates key factors including part volume, complexity, feature density, and critical tolerances. Crucially, the system simultaneously assesses feasibility and cost implications for both primary aluminum manufacturing routes: investment casting (typically using A356 alloy) and direct CNC machining (using alloys like 6061-T6 or 7075-T6). This dual-path analysis provides an immediate, data-driven cost and lead time estimate, highlighting the most efficient method for the specific geometry and requirements, presented within minutes.

This transitions directly into the Engineering DFM Review phase. Our senior manufacturing engineers conduct a meticulous Design for Manufacturability analysis, building on the AI assessment. For potential cast parts, we scrutinize draft angles, minimum wall thickness (critical to avoid casting defects), fillet radii, and parting line feasibility. For machined parts, we focus on tool access, undercuts, thin wall stability, and optimal stock allowance. We proactively identify potential issues like excessive machining time due to deep pockets or non-castable features requiring costly post-machining. Clients receive specific, actionable recommendations to enhance manufacturability, reduce cost, and ensure part functionality – whether the final path is casting, machining, or a hybrid approach.

The approved design then moves to Precision Production. For cast aluminum components, we proceed with precision investment casting: creating master patterns, building ceramic shells, melting and pouring A356 alloy, followed by fettling and heat treatment. CNC machined aluminum parts are produced directly from solid billet on our multi-axis milling centers, utilizing optimized toolpaths for accuracy and surface finish. Both paths converge on stringent quality control, including CMM verification against the original CAD model. The table below summarizes key process characteristics:

| Parameter | Cast Aluminum (A356) | CNC Machined Aluminum (e.g., 6061-T6) |

| :—————– | :————————- | :———————————— |

| Typical Lead Time | 10-15 days (incl. tooling) | 3-7 days |

| Best For | Complex geometries, large parts, near-net shape | High precision, tight tolerances, simpler geometries, lower volumes |

| Standard Tolerance | ±0.5% of dimension | ±0.05 mm (±0.002″) |

| Surface Finish (As-Processed) | ~3.2 µm Ra (125 µin) | ~1.6 µm Ra (63 µin) |

| Minimum Feature | ~1.5 mm wall thickness | Limited by tool diameter (e.g., Ø1mm) |

Honyo Prototype’s strength lies in leveraging this seamless AI Quote → DFM → Production workflow to guide clients toward the optimal aluminum manufacturing solution, whether casting or machining delivers the best balance of performance, cost, and speed for their specific application. We transform CAD data into high-integrity aluminum components with engineering rigor.

Start Your Project

Start Your Project with Confidence: Expert Guidance in Aluminum CNC Machining

When launching a new product development cycle, selecting the right material and manufacturing process is critical to achieving performance, cost-efficiency, and time-to-market goals. At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services, with extensive expertise in both cast aluminum and wrought aluminum alloys. Understanding the differences between these materials—and how they impact manufacturability, strength, and application suitability—is essential for making informed decisions early in the design phase.

Cast aluminum refers to alloys formed through casting processes such as die casting or sand casting, where molten metal is poured into a mold. These alloys, such as A380 or A356, are valued for their excellent fluidity, dimensional stability, and ability to form complex geometries with thin walls. However, cast aluminum typically exhibits lower mechanical strength and ductility compared to wrought forms, making it more suitable for non-structural or low-stress applications such as housings, brackets, or enclosures.

In contrast, wrought aluminum—such as 6061-T6 or 7075-T6—is processed through mechanical methods like extrusion, rolling, or forging. These alloys offer superior strength-to-weight ratios, enhanced fatigue resistance, and better machinability, making them ideal for high-performance components in aerospace, automotive, and industrial machinery. CNC machining of wrought aluminum allows for tight tolerances, excellent surface finishes, and greater consistency across production runs.

The choice between cast and wrought aluminum should be driven by application requirements, including load conditions, environmental exposure, and production volume. At Honyo Prototype, our engineering team evaluates your design intent, functional needs, and budget constraints to recommend the optimal material and process path. We support rapid prototyping, low-volume production, and full-scale manufacturing with seamless scalability.

Below is a comparative overview of common aluminum types used in CNC machining:

| Property | Cast Aluminum (A380) | Wrought Aluminum (6061-T6) | Wrought Aluminum (7075-T6) |

|————————–|————————–|—————————-|—————————-|

| Tensile Strength (MPa) | 310 | 310 | 570 |

| Yield Strength (MPa) | 160 | 275 | 505 |

| Elongation at Break (%) | 3.5 | 12 | 5.5 |

| Density (g/cm³) | 2.7 | 2.7 | 2.8 |

| Machinability Rating | Good | Excellent | Good |

| Typical Applications | Enclosures, brackets | Structural parts, fixtures | Aerospace components |

Our in-house CNC machining centers are equipped to handle both cast and wrought aluminum with precision down to ±0.005 mm, ensuring your parts meet exact design specifications. From material sourcing to final inspection, Honyo Prototype delivers integrated solutions that reduce lead times and eliminate supply chain complexity.

Ready to move forward? Let our team guide you in selecting the best aluminum solution for your project. Contact Susan Leo today at info@hy-proto.com for a personalized consultation and fast-turn quotation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.