Contents

Manufacturing Insight: Swiss Turning Machines

Manufacturing Insight: Swiss Turning Technology at Honyo Prototype

Swiss turning represents a pinnacle of precision machining for complex, high-integrity turned components, particularly excelling in the production of small-diameter, intricate parts where tight tolerances and superior surface finishes are non-negotiable. Unlike conventional CNC lathes, the Swiss-type machine’s defining feature is its sliding headstock combined with a guide bushing positioned immediately adjacent to the cutting tools. This configuration physically supports the bar stock at the exact point of cut, virtually eliminating material deflection during machining. The result is exceptional geometric accuracy and repeatability, even for long, slender parts prone to vibration on standard equipment. This inherent rigidity makes Swiss turning indispensable for industries demanding miniaturization and reliability, such as medical devices, aerospace actuators, optical assemblies, and precision instrumentation – core sectors served by Shenzhen Honyo Prototype.

The core technical capabilities enabled by this architecture include simultaneous multi-axis machining using numerous live tooling stations (often 4+ axes plus Y-axis and C-axis contouring), integrated sub-spindles for complete part-off operations without secondary handling, and high-speed bar feeding for efficient unattended production of small batches. These machines achieve micron-level tolerances consistently, typically holding ±0.005 mm or better on critical features, with surface finishes routinely reaching Ra 0.4 μm or finer. Material versatility spans demanding alloys like 316L stainless steel, titanium grades, Inconel, aluminum, brass, and engineering plastics such as PEEK and Delrin.

Honyo Prototype leverages this advanced technology specifically within the demanding context of rapid prototyping and low-to-medium volume production. Our dedicated Swiss turning cell features state-of-the-art equipment calibrated for the unique challenges of prototype development, where design validation and first-article accuracy are paramount. We focus on transforming complex CAD models into fully functional, high-precision prototypes and bridge production parts with minimal lead time, directly supporting our clients’ product development cycles.

Honyo Prototype Swiss Turning Capabilities Overview

| Parameter | Specification Range | Relevance for Prototyping |

| :—————– | :———————— | :——————————— |

| Max. Bar Diameter | 3 mm – 20 mm | Ideal for miniature components |

| Typical Tolerance | ±0.003 mm – ±0.008 mm | Meets stringent medical/aerospace |

| Surface Finish (Ra)| 0.2 μm – 0.8 μm | Critical for sealing/optics |

| Key Materials | Stainless, Ti, Al, Brass, Plastics | Broad material validation support |

| Max. Complexity | 8+ Tools, Y/C Axes, Milling | Single-setup complex geometries |

| Batch Size Focus | 1 – 500 pcs | Optimized for prototype & bridge |

Our process integrates rigorous in-process dimensional verification using high-resolution probes and post-process validation via calibrated Coordinate Measuring Machines (CMMs), ensuring every prototype meets the exacting standards required for functional testing and design sign-off. Honyo’s engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase, providing actionable feedback to optimize part geometry specifically for Swiss turning efficiency without compromising performance. This deep technical partnership, combined with our precision Swiss machining capability, ensures clients receive not just a prototype, but a manufacturable, high-integrity component that accurately reflects the intended production quality, accelerating time-to-market for the most demanding applications.

Technical Capabilities

Swiss Turning Machines – Technical Capabilities

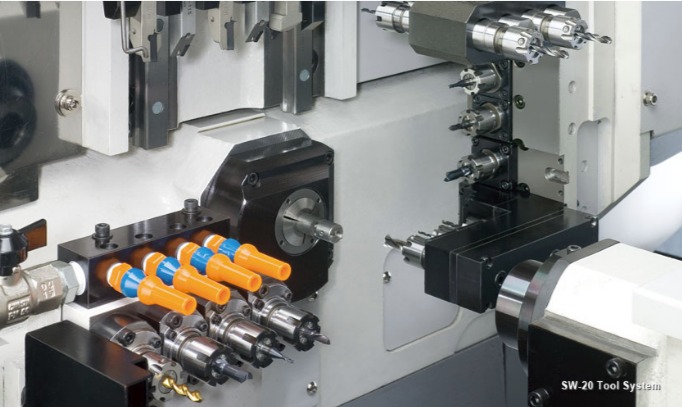

Shenzhen Honyo Prototype utilizes advanced Swiss turning machines to deliver high-precision, complex components for industries requiring tight tolerances and repeatable accuracy. These machines are engineered to perform simultaneous turning, milling, drilling, and tapping operations on small-diameter parts, making them ideal for medical devices, aerospace components, and precision instrumentation. Our Swiss turning capabilities span 3-axis, 4-axis, and 5-axis configurations, enabling multi-tasking operations that reduce cycle times and improve part consistency.

Our Swiss-type CNC lathes are equipped with live tooling, allowing for off-centerline machining operations such as cross-drilling, contour milling, and keyway cutting—all in a single setup. This integration of milling and turning functions within the Swiss platform ensures minimal part handling, reduced risk of error, and superior geometric accuracy. The sliding headstock design provides excellent support for long, slender workpieces, minimizing deflection and vibration during high-speed cutting.

We specialize in machining parts with diameters ranging from Ø0.5 mm to Ø32 mm, with maximum bar feed lengths up to 420 mm depending on material and configuration. Our machines operate with sub-micron level positioning accuracy and are maintained under strict environmental controls to ensure thermal stability. All equipment is integrated with high-resolution feedback systems and advanced CNC controls (Fanuc, Siemens, or Mitsubishi) to maintain consistent process control.

A core strength of our Swiss turning process is our ability to achieve and sustain tight tolerances. Dimensional tolerances as tight as ±0.002 mm and geometric tolerances down to ±0.005 mm are routinely maintained across production runs. Surface finishes as fine as Ra 0.4 µm are achievable with appropriate tooling and process parameters.

The table below outlines our standard achievable tolerances and compatible materials:

| Feature | Tolerance Range |

|——–|—————–|

| Linear Dimensions | ±0.002 mm to ±0.010 mm |

| Diameter Control | ±0.003 mm (typical) |

| Concentricity | ≤ 0.005 mm |

| Runout | ≤ 0.008 mm |

| Positional Accuracy (Milled Features) | ±0.010 mm |

| Surface Finish (Ra) | 0.4 µm to 3.2 µm (depending on material and geometry) |

| Material Category | Common Materials Machined |

|——————-|—————————-|

| Stainless Steel | 303, 304, 316, 17-4 PH, 440C |

| Alloy Steel | 4140, 4340, 8620 |

| Aluminum | 6061, 7075, 2024 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) |

| Brass & Copper | C36000, C11000, C10100 |

| Plastics | PEEK, Delrin (POM), Nylon, PTFE |

| Exotic Alloys | Inconel 625, Hastelloy C276, Monel 400 |

All Swiss turning operations are supported by comprehensive in-process inspection using coordinate measuring machines (CMM), optical comparators, and laser micrometers. First article inspection (FAI) and PPAP documentation are available upon request.

At Honyo Prototype, we combine state-of-the-art Swiss machining technology with rigorous quality systems to deliver precision-turned components that meet the most demanding engineering specifications.

From CAD to Part: The Process

From CAD to Precision Part: Swiss Turning Workflow at Honyo Prototype

The journey from digital design to physical component in Swiss turning begins with seamless integration of our AI-powered quoting system. Upon receiving a validated CAD model, our proprietary AI engine instantly analyzes geometric complexity, material requirements, and dimensional tolerances against live machine capabilities and current production loads. This generates an accurate, data-driven cost and lead time estimate within minutes, eliminating manual interpretation delays. Crucially, the AI flags potential manufacturability red flags early, such as undercuts violating Swiss turning principles or tolerances exceeding standard machine capability, providing immediate feedback to the client before formal order placement. This initial digital handshake ensures alignment on feasibility and expectations from the outset.

Following quote acceptance, the design undergoes rigorous Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This is not a checklist but a dynamic engineering dialogue. We scrutinize material selection against Swiss machining characteristics, assess feature placement relative to the guide bushing’s critical support zone, and evaluate secondary operation requirements. Key focus areas include optimizing parting-off sequences to minimize burr formation, verifying thread milling feasibility versus traditional tapping within the constrained Swiss environment, and ensuring adequate chip clearance paths to prevent re-cutting and surface defects. Client collaboration is essential here; we provide specific, actionable recommendations—such as minor radius adjustments or tolerance relaxation on non-critical features—to enhance process stability and reduce cost without compromising function. This phase typically resolves 95% of potential production issues before metal is cut.

Once DFM sign-off is achieved, production commences on our state-of-the-art Tsugami and Citizen Swiss-type lathes. Programmers leverage the finalized CAD/CAM data to generate optimized G-code, implementing strategies like synchronized multi-turret movements and live tooling sequences for complete part machining in a single setup. Setup technicians meticulously validate bar feed alignment, tool offsets, and coolant pressure profiles. Real-time process monitoring tracks spindle load, vibration, and dimensional drift on critical features using in-process probes, ensuring consistent conformance to tight tolerances. Every part undergoes 100% first-article inspection against the original CAD model using CMM and optical comparators before batch release.

Honyo Prototype’s Swiss turning capabilities are engineered for complex micro-components demanding micron-level precision. Key machine specifications enable this performance:

| Parameter | Standard Capability | Honyo Enhancement |

|———————–|————————–|———————————|

| Max Bar Diameter | 20 mm | 25 mm (Selective Models) |

| Primary/Secondary Axes| 7-9 Axes | Up to 12 Axes (Y2, C2, B-Axis) |

| Typical Tolerance | ±0.005 mm | ±0.002 mm (Critical Features) |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm (Optimized Processes) |

| Max Part Length | 150 mm | 300 mm (Extended Guide Bushing)|

This integrated workflow—AI-driven quoting, collaborative DFM, and precision-controlled production—ensures Honyo Prototype delivers complex Swiss-turned components with exceptional repeatability, minimized lead times, and demonstrable cost efficiency for medical, aerospace, and semiconductor applications. Our process transforms CAD data into mission-critical hardware through engineered precision at every stage.

Start Your Project

Start Your Precision Machining Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services tailored for industries that demand reliability, repeatability, and tight tolerances—especially medical, aerospace, automotive, and electronics. Our advanced Swiss turning machines are engineered to deliver exceptional accuracy for complex, high-volume components with intricate geometries and strict quality requirements.

Swiss turning, also known as Swiss-type or sliding headstock machining, is ideal for manufacturing long, slender parts with outstanding concentricity and surface finish. Unlike standard CNC lathes, Swiss machines support the workpiece close to the cutting zone using a guide bushing, minimizing deflection and vibration. This makes them perfect for turning parts with diameters typically ranging from 1 mm to 38 mm and lengths up to 200 mm, all while maintaining tolerances as tight as ±0.005 mm.

If your project involves small-diameter, high-precision shafts, pins, connectors, or medical device components, Swiss turning provides a cost-effective and scalable solution. At Honyo Prototype, our fleet of multi-axis Swiss machines integrates live tooling, Y-axis capabilities, and automated bar feeding systems to perform turning, milling, drilling, threading, and grooving in a single setup—reducing cycle times and ensuring part consistency.

To get started, simply share your design files—preferably in STEP, IGES, or DWG format—along with your material specifications, quantity requirements, and any critical tolerances or surface finish needs. Our engineering team will conduct a comprehensive Design for Manufacturability (DFM) review to optimize your part for precision, speed, and cost-efficiency. Whether you need rapid prototypes or full production runs, we offer scalable solutions with fast turnaround times and strict adherence to ISO 9001 quality standards.

We work with a wide range of materials, including stainless steel (303, 304, 316), aluminum (6061, 7075), brass (C36000), titanium, and various engineering plastics such as PEEK and Delrin. Our in-house metrology lab, equipped with CMMs, optical comparators, and surface roughness testers, ensures every component meets your exact specifications.

| Specification | Capability |

|—————|————|

| Maximum Bar Diameter | 38 mm (1.5″) |

| Typical Tolerance | ±0.005 mm (±0.0002″) |

| Minimum Feature Size | 0.1 mm (0.004″) |

| Materials | Stainless Steel, Aluminum, Brass, Titanium, Plastics |

| Secondary Operations | Deburring, Heat Treatment, Plating, Passivation |

| Lead Time (Prototype) | 5–7 Days |

| Lead Time (Production) | 10–15 Days (volume-dependent) |

Partnering with Honyo Prototype means gaining access to cutting-edge Swiss machining technology backed by expert engineering support. We are committed to delivering precision components on time and to the highest quality standards.

Contact Susan Leo today at info@hy-proto.com to start your project. Share your CAD files and requirements, and we’ll provide a detailed quote and DFM feedback within 24 hours. Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.