Contents

Manufacturing Insight: Commercial Cnc Machine

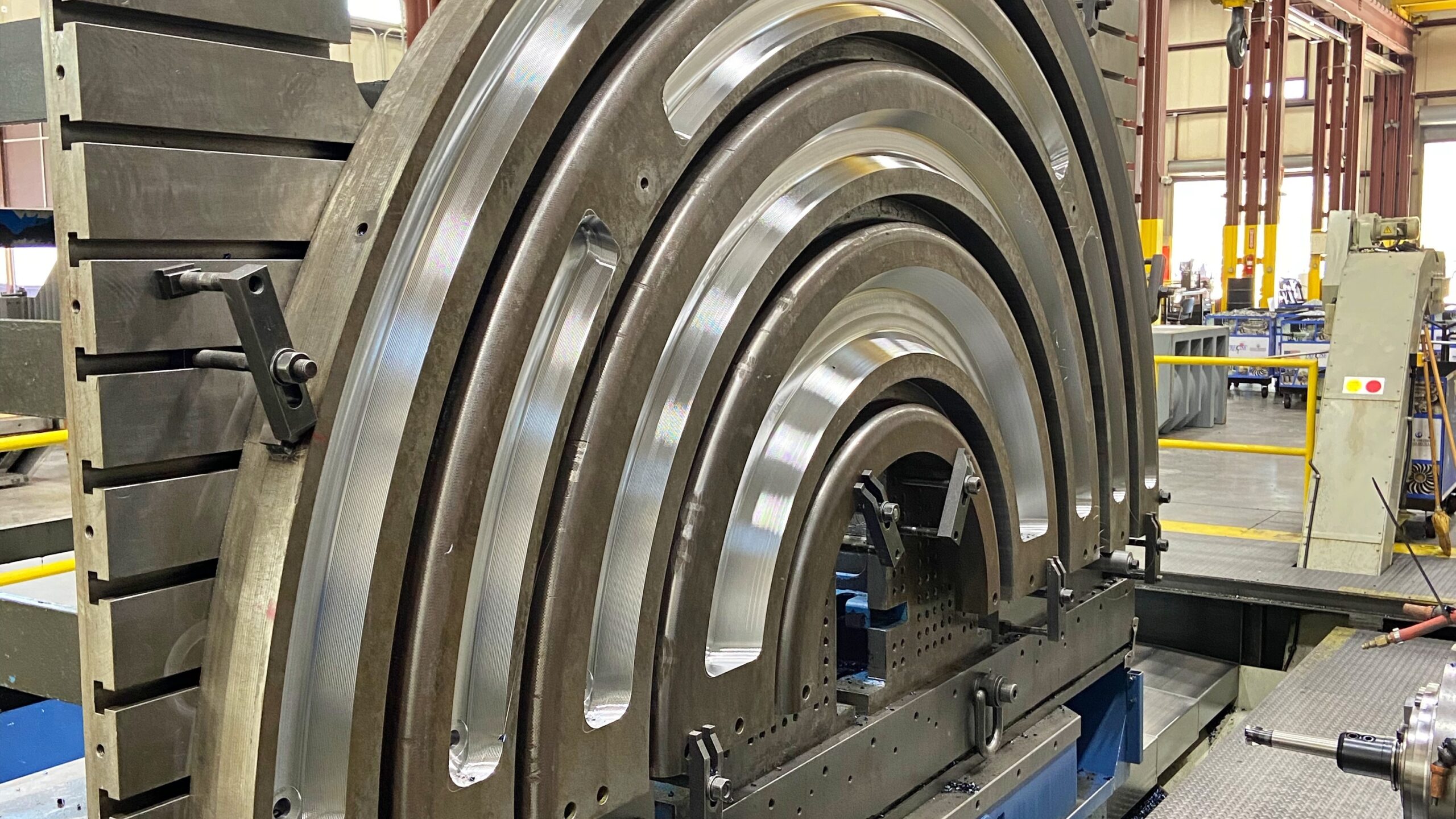

Commercial CNC Machining: Precision Engineering at Scale

Commercial CNC machining represents the cornerstone of modern precision manufacturing, enabling the production of complex, high-tolerance components across aerospace, medical, automotive, and industrial sectors. At Shenzhen Honyo Prototype, we leverage advanced Computer Numerical Control technology to transform digital CAD/CAM models into physical realities with exceptional accuracy, repeatability, and material versatility. Our focus extends beyond basic part creation; we deliver engineered solutions optimized for performance, manufacturability, and cost-efficiency within demanding commercial production environments. Understanding the capabilities and limitations of commercial CNC platforms is fundamental to successful product development and volume manufacturing.

Honyo Prototype operates a strategically configured fleet of multi-axis CNC machining centers, specifically selected to handle the diverse requirements of commercial clients. Our core strength lies in precision 3-axis, 4-axis, and 5-axis simultaneous machining capabilities. This multi-axis proficiency allows us to machine complex geometries in fewer setups, significantly improving accuracy, reducing lead times, and minimizing potential handling errors. We routinely achieve tight tolerances down to ±0.005mm while maintaining excellent surface finishes, critical for functional components and assemblies. Our machines handle a broad spectrum of engineering materials, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium grades, engineering plastics (PEEK, Delrin, Nylon), brass, and copper alloys. Material selection is rigorously matched to the application’s mechanical, thermal, and environmental demands.

The strategic selection of the appropriate CNC configuration is paramount for optimizing commercial production. The following table outlines the key characteristics and typical applications for the primary machine types utilized within our facility:

| Axis Configuration | Typical Applications | Key Advantages for Commercial Production | Material & Tolerance Range |

| :—————– | :———————————————— | :———————————————— | :—————————————– |

| 3-Axis Milling | Prismatic parts, plates, brackets, simple housings | Highest speed for 2.5D features, lowest cost/part | All standard metals/plastics; ±0.01mm |

| 4-Axis Milling | Impellers, camshafts, complex fixtures, curved surfaces | Indexing for multi-sided features, improved access | Metals, plastics; ±0.008mm |

| 5-Axis Simultaneous | Aerospace structural components, medical implants, complex molds | Single-setup complex geometry, superior surface finish, reduced cycle times | High-temp alloys, hardened steels; ±0.005mm |

All machining processes at Honyo Prototype are executed within our ISO 9001-certified quality management system. This ensures rigorous process control from raw material inspection through final part verification using calibrated CMMs, optical comparators, and surface roughness testers. Our engineering team collaborates closely with clients during the Design for Manufacturing (DFM) phase, proactively identifying opportunities to enhance part geometry for optimal CNC manufacturability, reducing waste and accelerating time-to-market without compromising functional requirements. We understand that commercial success hinges on consistent quality, on-time delivery, and scalable production capacity – capabilities deeply embedded in our CNC machining operations. Partnering with Honyo Prototype provides access to advanced technology, stringent quality assurance, and engineering expertise dedicated to bringing your commercial product visions to life with precision and reliability.

Technical Capabilities

Technical Capabilities: Precision CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our commercial CNC machining services are engineered to deliver high-precision components for demanding industrial, aerospace, medical, and automotive applications. Our advanced machining center is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling machines, as well as multi-axis CNC turning centers, enabling us to handle complex geometries and tight-tolerance requirements with consistency and repeatability. Our integrated manufacturing workflow supports rapid prototyping and low-to-mid volume production runs, ensuring fast turnaround without compromising on quality.

Our 3-axis milling systems are ideal for prismatic parts with straightforward geometries, offering high-speed material removal and excellent surface finishes. For components requiring access to multiple faces or compound angles, our 4-axis and 5-axis machining centers provide enhanced flexibility by enabling rotational movement around the A and B axes. This reduces the need for multiple setups, improves dimensional accuracy, and supports the production of highly complex parts such as impellers, turbine blades, and structural aerospace components.

CNC turning operations are performed on advanced live-tooling lathes, allowing us to produce precision cylindrical parts with secondary milling, drilling, and tapping features in a single setup. This capability supports the efficient manufacturing of shafts, bushings, connectors, and other rotational components.

A core strength of our machining services is our ability to consistently achieve tight tolerances. Standard tolerances are maintained within ±0.05 mm, while precision features can be held to ±0.005 mm when required. Critical dimensions are verified using calibrated CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers to ensure compliance with customer specifications.

The following table outlines our typical tolerance capabilities and compatible materials:

| Feature | Standard Tolerance | Precision Tolerance | Common Materials |

|——–|———————|————————|——————|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (1018, 4140), Titanium (Grade 5), Brass (C360), Plastics (PEEK, Delrin, Nylon) |

| Hole Diameter | ±0.025 mm | ±0.01 mm | |

| Flatness | 0.05 mm | 0.01 mm | |

| Positional Accuracy | ±0.05 mm | ±0.01 mm | |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polishing optional) | |

All materials are sourced from certified suppliers and undergo incoming inspection to ensure consistency in mechanical properties and machinability. Our in-house engineering team collaborates with clients during the design phase to optimize parts for manufacturability, minimizing cost and lead time while maintaining performance requirements.

Shenzhen Honyo Prototype adheres to ISO 9001 quality management standards, ensuring every component is produced under controlled conditions with full traceability. Our investment in high-precision CNC equipment, skilled technicians, and rigorous quality control makes us a trusted partner for commercial clients requiring reliable, high-accuracy machined parts.

From CAD to Part: The Process

From CAD to Part: Streamlined CNC Production Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our commercial CNC machining process transforms digital designs into precision components through a rigorously optimized workflow. This integrated sequence—AI Quote, DFM, and Production—ensures manufacturability, cost efficiency, and on-time delivery while minimizing client rework. The process begins when a client uploads a CAD model to our portal. Our proprietary AI quoting engine immediately analyzes geometric complexity, material requirements, tolerances, and feature density. This system cross-references real-time machine availability, tooling costs, and historical production data to generate an accurate quote within hours, not days. Unlike manual methods, the AI identifies potential high-cost elements early, such as deep cavities or thin walls, allowing proactive client consultation before order confirmation.

DFM Optimization: Mitigating Risk Before Machining

Following quote acceptance, every design undergoes mandatory Design for Manufacturability (DFM) review by our engineering team. This phase is critical for eliminating production bottlenecks and ensuring first-pass yield. We collaborate with clients to resolve conflicts between design intent and machining realities, such as non-standard hole depths or unachievable surface finishes. Common DFM issues and our standardized resolutions are summarized below:

| Common DFM Issue | Impact if Unaddressed | Honyo Resolution Strategy |

|————————–|—————————–|—————————————–|

| Tight tolerance clusters | Excessive scrap rates | Redistribute tolerances per GD&T best practices |

| Non-machinable radii | Tool access failures | Recommend minimum 0.5mm internal radii |

| Thin wall sections (<1mm)| Vibration-induced deflection| Suggest ribbing or staged milling |

| Complex multi-axis setups| Extended machine time | Optimize for 3+2 axis where feasible |

Client approval of the DFM report is required before proceeding, ensuring alignment on any necessary design tweaks. This step typically reduces post-CAM revisions by 70% and accelerates time-to-prototype.

CNC Production Execution

With DFM sign-off, the workflow transitions to production. CAM programmers generate optimized toolpaths using Mastercam and Fusion 360, selecting appropriate tooling, feeds, and speeds based on material grade (e.g., 6061-T6 aluminum or 304 stainless steel). Our facility deploys a mix of 3-axis, 4-axis, and 5-axis CNC machining centers—including DMG MORI and Haas systems—calibrated weekly for ±0.005mm accuracy. Raw material inspection precedes machining, with in-process checks at critical stages using coordinate measuring machines (CMMs). Final parts undergo full dimensional validation against the original CAD model, including surface roughness verification (Ra 0.8–3.2μm typical). Throughout production, our MES platform tracks real-time progress, enabling clients to monitor milestones via a secure dashboard. Completed components receive laser-etched traceability codes and are packaged per ESD-sensitive or cosmetic requirements before global shipment.

This closed-loop workflow—from AI-driven quoting to DFM-validated production—ensures Honyo Prototype delivers complex CNC-machined parts with 98.5% on-time completion and <0.5% defect rates, turning design concepts into reliable, high-fidelity prototypes or low-volume production runs.

Start Your Project

Start Your Project with Precision CNC Machining from Shenzhen Honyo Prototype

When it comes to bringing high-performance, precision-engineered parts to life, Shenzhen Honyo Prototype stands at the forefront of CNC machining excellence. Our commercial-grade CNC machining services are designed to meet the rigorous demands of industries ranging from aerospace and automotive to medical devices and industrial equipment. Whether you’re developing a single prototype or scaling up to low-volume production, our advanced manufacturing capabilities ensure accuracy, repeatability, and material integrity—every time.

At Honyo Prototype, we utilize state-of-the-art 3-axis, 4-axis, and 5-axis CNC machines equipped with high-speed spindles and precision tooling systems. Our machining centers are maintained to strict operational standards, enabling us to achieve tolerances as tight as ±0.005 mm. With a versatile material processing range—from aluminum and stainless steel to titanium, brass, and engineering plastics—we support complex geometries and critical surface finishes tailored to your application requirements.

Our end-to-end manufacturing workflow is built for efficiency and transparency. From the moment you submit your CAD file, our engineering team conducts a comprehensive design for manufacturability (DFM) review to identify potential optimizations in geometry, material selection, and cost-effective production strategies. This proactive approach reduces lead times, minimizes post-processing needs, and ensures your part performs exactly as intended.

We understand that every project has unique demands. That’s why we offer customized solutions based on your volume, timeline, and technical specifications. Our in-house quality control lab is equipped with CMM (Coordinate Measuring Machine), optical comparators, and surface roughness testers, ensuring every component meets both your expectations and international quality standards.

Below are key capabilities of our commercial CNC machining services:

| Specification | Detail |

|—————|——–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling and turning centers |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Tolerance | ±0.005 mm (standard), tighter upon request |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin, and more |

| Surface Finishes | As-machined, bead blast, anodizing (Type II & III), passivation, powder coating |

| Lead Time | As fast as 5–7 days for prototypes, 10–15 days for production runs |

| Quality Standards | ISO 9001:2015 compliant, full inspection reporting available |

Starting your project with Honyo Prototype is simple. Just share your 3D CAD model, and our team will provide a rapid quotation along with expert feedback to optimize manufacturability and reduce costs. We support STEP, IGES, SolidWorks, and DWG file formats.

Ready to move forward? Contact Susan Leo today at info@hy-proto.com to discuss your project requirements, request a quote, or schedule a technical consultation. At Shenzhen Honyo Prototype, we’re committed to turning your design concepts into high-precision reality—on time and to specification.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.