Contents

Manufacturing Insight: Motorcycle Customizations

Manufacturing Insight: Precision CNC Machining for Motorcycle Customization

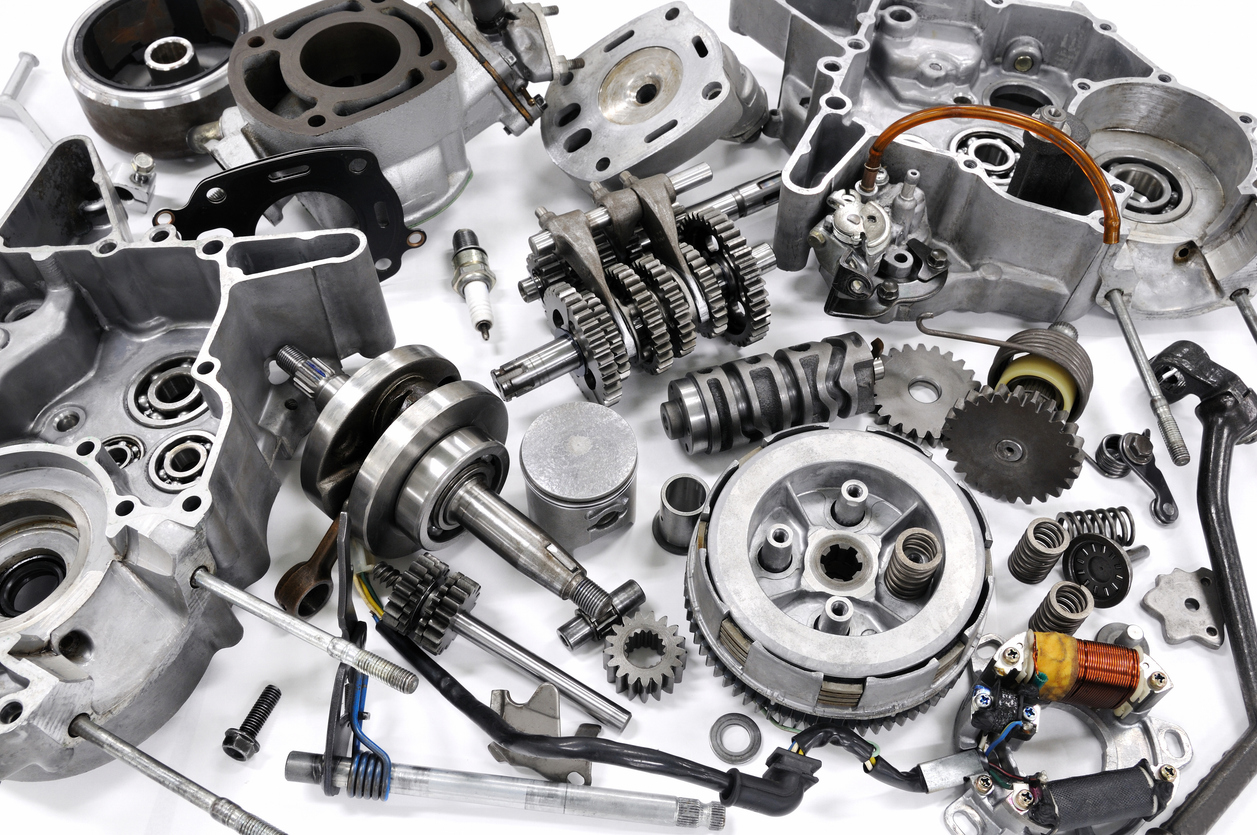

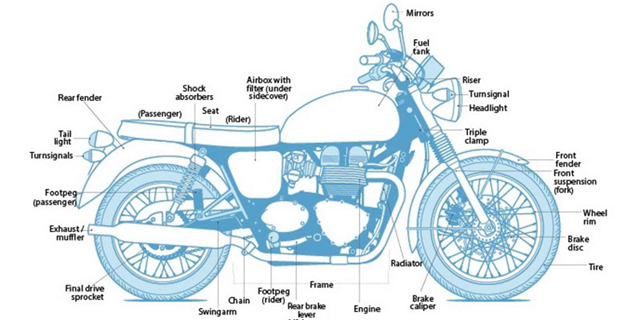

CNC machining represents the cornerstone of high-fidelity motorcycle customization, enabling the transformation of visionary designs into performance-grade components with uncompromising accuracy. At Shenzhen Honyo Prototype, we leverage advanced multi-axis CNC systems to execute complex geometries—such as billet handlebars, engine covers, and frame brackets—that demand micron-level tolerances and structural integrity. Unlike additive methods, CNC subtractive processes ensure optimal material density and fatigue resistance critical for safety-critical motorcycle parts. Our workflow begins with 3D CAD analysis to identify potential machining constraints, followed by strategic fixture planning to minimize vibration and thermal distortion during cutting. This proactive approach guarantees repeatability across production runs, whether prototyping a single showpiece or scaling to limited batches for aftermarket suppliers.

Honyo’s manufacturing ecosystem integrates 5-axis milling centers with real-time tool wear compensation and automated tool changers, eliminating manual repositioning errors. All components undergo in-process inspection via coordinate measuring machines (CMMs) to validate critical dimensions against GD&T callouts, ensuring seamless integration with OEM or third-party assemblies. We specialize in machining challenging materials like aerospace-grade aluminum alloys and titanium, which are increasingly favored in custom builds for weight reduction without sacrificing strength. Below summarizes our core machining specifications for motorcycle applications:

| Parameter | Specification | Application Example |

|——————–|—————————————-|———————————–|

| Materials | 6061-T6, 7075-T6, Ti-6Al-4V, 303/304 SS | Swingarms, triple clamps, footpegs |

| Tolerance Range | ±0.005 mm (standard), ±0.002 mm (tight) | Bearing bores, linkage interfaces |

| Max Work Envelope | 800 x 500 x 400 mm | Full subframes, tank panels |

| Surface Finishes | Bead blast, anodize (Type II/III), polish | Aesthetic & corrosion-resistant parts |

| Lead Time (Prototype) | 7–10 business days | Functional validation builds |

Material selection directly influences both performance and manufacturability. For instance, 7075-T6 aluminum offers superior strength for high-stress components like rearsets but requires slower feed rates to prevent tool chatter compared to 6061-T6. Our engineers collaborate with clients during the design phase to optimize wall thicknesses and avoid undercuts that could necessitate costly secondary operations. Surface treatments are equally strategic: Type III hard anodizing provides 50+ micron wear resistance for control arms, while satin bead blasting delivers consistent texture for visual cohesion across multi-part assemblies.

Honyo’s value extends beyond machining—we provide DFM feedback to eliminate non-value-added features, reducing costs by up to 30% without compromising design intent. By combining technical rigor with deep material science expertise, we empower custom builders to achieve production-ready quality in every component. Partner with us to transform your motorcycle customization concepts into engineered realities that meet both aesthetic and mechanical excellence standards.

Technical Capabilities

Technical Capabilities: Precision CNC Machining for Motorcycle Customizations

At Shenzhen Honyo Prototype, our advanced CNC machining capabilities are engineered to meet the exacting demands of high-performance motorcycle customization. Our integration of 3-axis, 4-axis, and 5-axis milling technologies, combined with precision CNC turning, enables us to produce complex, high-strength components tailored to both aesthetic and functional requirements in the motorcycle aftermarket industry. Whether fabricating custom handlebar mounts, engine housings, foot peg systems, or intricate bracketry, our processes ensure repeatability, durability, and dimensional accuracy.

Our 3-axis milling systems provide reliable performance for straightforward, planar geometries commonly used in base structural components. For parts requiring multi-sided machining or contoured surfaces—such as swingarm fittings or intake manifolds—our 4-axis CNC machines add rotational capability (A-axis), enabling continuous cutting around cylindrical features with minimal manual intervention. The 5-axis machining centers deliver the highest level of versatility, allowing tool access from virtually any angle. This is particularly advantageous for sculpted fairing brackets, exhaust flanges, and bespoke linkage systems where compound angles and tight spatial integration are critical.

All machining operations are supported by high-rigidity machine platforms, dynamic tool monitoring, and real-time in-process inspection using precision probing systems. This ensures that tight tolerances are consistently maintained across production runs. Our standard tolerance capability is ±0.005 mm for critical dimensions, with selective features achievable down to ±0.002 mm under controlled conditions. Surface finishes range from 3.2 µm to 0.8 µm Ra, depending on material and functional requirements.

We specialize in machining aerospace-grade and automotive-qualified materials commonly used in motorcycle applications. Aluminum alloys such as 6061-T6 and 7075-T6 are frequently utilized for lightweight structural components, while stainless steels (303, 304, 316) and alloy steels (4140, 4340) are selected for high-wear or load-bearing parts. Titanium (Grade 5, Ti-6Al-4V) is available for extreme performance applications where strength-to-weight ratio and corrosion resistance are paramount.

The following table outlines our standard machining tolerances and compatible materials for motorcycle customization projects:

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|—————————-|—————-|—————-|—————-|—————–|

| Positional Tolerance | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm | ±0.01 mm | ±0.01 mm | ±0.01 mm |

| Surface Finish (Ra) | 3.2 – 1.6 µm | 3.2 – 1.6 µm | 3.2 – 0.8 µm | 3.2 – 1.6 µm |

| Max Work Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 | 600 × 500 × 400 | Ø300 × 500 L |

| Material Type | Common Grades | Max Tolerance Capability |

|—————————-|———————————–|—————————|

| Aluminum Alloys | 6061-T6, 7075-T6, 2024-T4 | ±0.005 mm |

| Stainless Steel | 303, 304, 316, 17-4 PH | ±0.008 mm |

| Alloy Steel | 4140, 4340, 8620 | ±0.010 mm |

| Titanium | Ti-6Al-4V (Grade 5) | ±0.008 mm |

| Brass & Copper Alloys | C36000, C11000 | ±0.010 mm |

All custom motorcycle components undergo final inspection using coordinate measuring machines (CMM) and optical comparators to verify conformance to engineering drawings. Our technical team collaborates closely with design engineers to optimize part geometry for manufacturability, ensuring performance integrity without compromising creative vision.

From CAD to Part: The Process

From CAD to Custom Motorcycle Part: Honyo Prototype’s CNC Machining Workflow

At Shenzhen Honyo Prototype, our CNC machining process for motorcycle customization projects transforms client CAD models into precision-engineered components through a rigorously defined workflow. This ensures optimal quality, cost efficiency, and adherence to the demanding performance requirements of custom motorcycles. The sequence begins immediately upon receipt of your validated 3D CAD file.

AI-Powered Quoting & Feasibility Assessment

Our proprietary AI engine performs an initial analysis of the submitted CAD geometry against our extensive machining capability database. This rapid assessment evaluates material suitability (focusing on common motorcycle alloys like 6061-T6, 7075-T6 aluminum, and 4140 chromoly steel), identifies potential geometric complexities, and estimates machine time based on feature density and tolerances. Crucially, this step generates a highly accurate preliminary quote within hours, not days, incorporating material costs, machine utilization rates, and necessary secondary operations. The AI flags areas requiring deeper engineering review, setting the stage for formal DFM.

Engineering-Led Design for Manufacturability (DFM)

The core of our value-add occurs in the DFM phase. Our senior manufacturing engineers conduct a meticulous manual review alongside the AI findings. We focus specifically on motorcycle part integrity and function, scrutinizing stress concentrations, weld preparation zones, bearing fits, and thread engagement critical to safety and performance. Key DFM checks include:

| Parameter | Critical Threshold | Common Motorcycle Application |

|———–|——————-|——————————|

| Minimum Wall Thickness | ≥ 1.5mm (Aluminum) | Frame brackets, triple clamp components |

| Undercut Complexity | Avoid internal sharp corners | Engine covers, custom sprockets |

| Critical Feature Tolerance | ±0.025mm (rotating parts) | Axle journals, steering stem interfaces |

| Surface Finish Requirement | Ra 0.8µm (bearing seats) | Swingarm pivot points, fork components |

We provide actionable feedback, suggesting geometric modifications to reduce machining time, eliminate costly secondary operations, or enhance part longevity without compromising the custom design intent. Client collaboration at this stage prevents costly revisions later.

Precision CNC Production & Validation

Upon DFM sign-off and order confirmation, production commences. We select the optimal CNC platform—typically 3-axis for simpler brackets or 5-axis for complex, sculpted components like custom handlebar risers or intricate engine mounts—based on the finalized geometry. High-speed machining centers with in-process probing ensure dimensional accuracy throughout the run. Material is sourced from certified mills with full traceability documentation. Rigorous in-process inspections using calibrated CMMs verify critical features against the approved drawing at defined intervals. Final parts undergo thorough deburring, precision cleaning, and optional surface treatments (anodizing, powder coating, or passivation) as specified. A comprehensive First Article Inspection report, including critical dimension verification against the original CAD model, accompanies every shipment.

This integrated workflow—from AI-assisted quoting through engineering-critical DFM to validated production—eliminates guesswork. It delivers motorcycle customization parts that meet exacting performance standards while providing clients with predictable timelines and transparent cost control, essential for successful custom builds. Honyo Prototype ensures your vision translates flawlessly from digital model to road-ready component.

Start Your Project

Start Your Custom Motorcycle Project with Precision CNC Machining from Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-precision CNC machining solutions tailored to the unique demands of motorcycle customization. Whether you’re developing custom handlebars, engine components, frame modifications, or intricate aesthetic elements, our advanced manufacturing capabilities ensure every part meets exacting performance and design standards. With years of experience in prototyping and low-to-mid volume production, we support innovators, custom builders, and design studios worldwide in transforming concepts into high-functioning, road-ready components.

Our CNC machining process leverages state-of-the-art 3-, 4-, and 5-axis milling and turning centers, enabling us to produce complex geometries with tight tolerances as close as ±0.005 mm. We work with a wide range of materials including aerospace-grade aluminum (6061, 7075), stainless steel (303, 304, 316), titanium, brass, and engineering plastics, ensuring optimal strength, weight, and corrosion resistance for demanding motorcycle applications. Every component undergoes rigorous in-process and final inspection using CMM (Coordinate Measuring Machine) and optical measurement systems, guaranteeing consistency and quality across every batch.

We understand that motorcycle customization is as much about craftsmanship as it is about engineering. That’s why we offer full design for manufacturability (DFM) feedback, material recommendations, and rapid prototyping services to help refine your concept before moving into production. From initial sketches to finished machined parts, we partner with you at every stage to ensure your vision is realized with precision and reliability.

To get started, simply share your CAD files, sketches, or technical specifications with our engineering team. We provide fast turnaround quotes, typically within 12–24 hours, and support both one-off prototypes and scalable production runs. Our facility in Shenzhen is ISO 9001-certified, and we adhere to strict quality control protocols to ensure every component meets international standards.

Below is an overview of our standard CNC machining capabilities for motorcycle customization projects:

| Specification | Detail |

|————–|——–|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Tolerance | ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Plastics (PEEK, Delrin) |

| Max Work Envelope | 1200 x 600 x 500 mm |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder coating, Polishing, Bead blasting |

| Lead Time | 5–15 days (depending on complexity and volume) |

| Certifications | ISO 9001:2015, RoHS compliant |

Ready to bring your custom motorcycle project to life? Contact Susan Leo at Shenzhen Honyo Prototype today. Share your design requirements, and we’ll provide expert guidance, a detailed quote, and a clear path to production. Email us at info@hy-proto.com to start the conversation. Let’s build something exceptional—together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.