Contents

Manufacturing Insight: Nickel Plating Service

Manufacturing Insight: Nickel Plating Service for Precision CNC Components

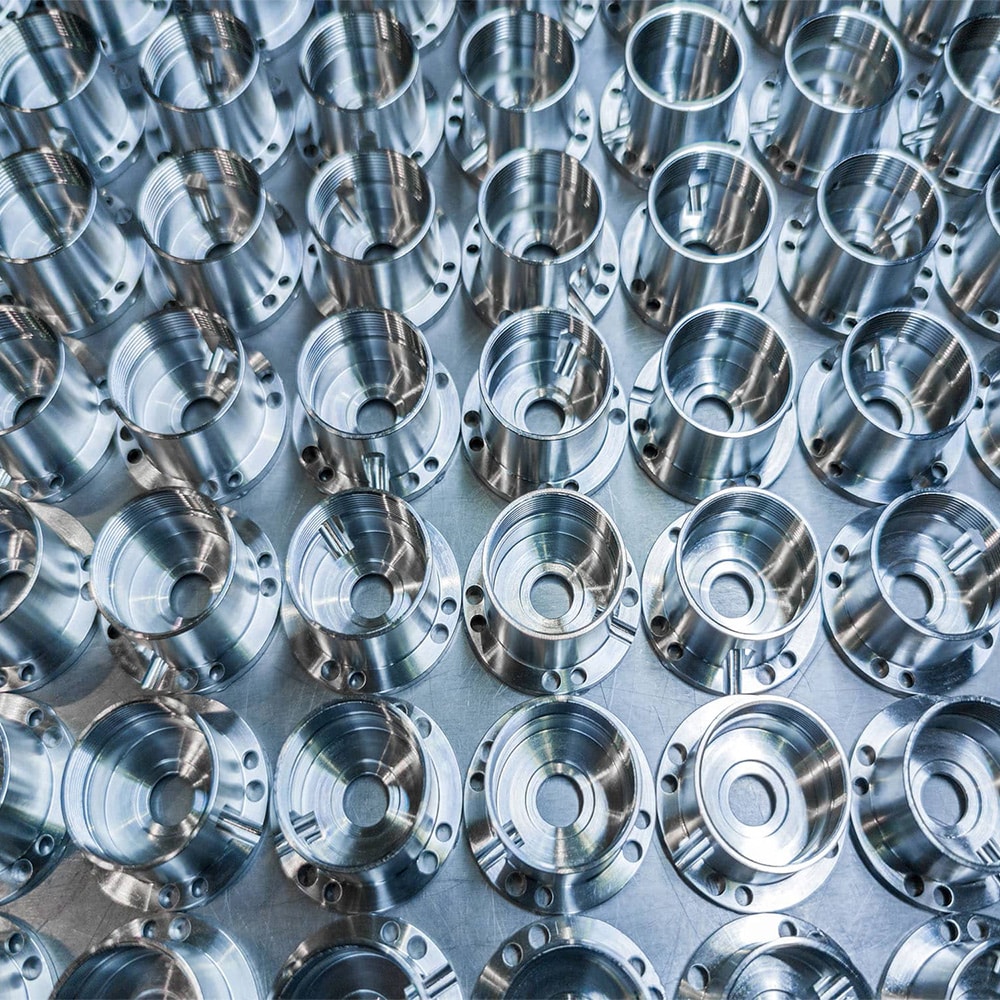

Nickel plating remains a critical surface engineering solution for CNC machined prototypes and low-volume production parts, delivering essential functional and aesthetic properties unattainable with base substrates alone. At Shenzhen Honyo Prototype, we integrate this electrochemical process seamlessly within our end-to-end CNC machining workflow, providing clients with enhanced component durability, corrosion resistance, and electrical conductivity directly from prototype to pilot production. The core technology involves the controlled electrochemical reduction of nickel ions from an aqueous solution onto the conductive workpiece surface, acting as the cathode. This precise deposition forms a uniform, adherent metallic layer that significantly improves wear characteristics and provides an excellent base for subsequent coatings like chromium or gold, or serves as a final finish for demanding applications in aerospace, medical devices, and industrial automation.

Our dedicated nickel plating facility in Shenzhen operates under stringent process controls to ensure consistency and repeatability critical for engineering prototypes. We specialize in both semi-bright and bright nickel plating chemistries, tailored to meet specific functional requirements. Key advantages of utilizing Honyo’s integrated service include rapid turnaround times due to co-located machining and plating operations, eliminating external logistics delays, and direct engineering oversight ensuring plating parameters are optimized for the specific geometry and material of each CNC-machined part. We meticulously manage critical factors such as bath composition, temperature, current density, and filtration to prevent defects like pitting, roughness, or poor adhesion, common pitfalls in substandard plating operations. Material compatibility spans aluminum alloys, stainless steels, copper alloys, and carbon steels commonly processed through our CNC centers, with pre- and post-plate treatments rigorously applied to maximize bonding and performance.

Honyo adheres strictly to international quality standards, including ASTM B656 and ISO 4520, with in-process thickness verification using X-ray fluorescence (XRF) and adhesion testing per ASTM D3359. Our commitment to quality is embedded in every step, from initial material verification to final dimensional inspection post-plating, ensuring the coating meets both functional specifications and the tight tolerances inherent in precision CNC work. Below are the core technical specifications for our standard nickel plating service:

| Parameter | Specification Range | Standard Control Method | Key Benefit |

| :—————– | :———————– | :—————————- | :———————————– |

| Thickness | 5 – 25 µm (0.2 – 1.0 mil) | XRF Spectroscopy | Tailored corrosion/wear resistance |

| Hardness (HV) | 450 – 600 | Microhardness Tester | Enhanced abrasion resistance |

| Ductility | > 15% Elongation | Mandrel Bend Test | Resists cracking under stress |

| Corrosion (NSS) | 96 – 500+ hours | ASTM B117 Salt Spray Testing | Reliable environmental protection |

| Surface Roughness | Ra 0.1 – 0.4 µm | Profilometer | Smooth finish for sealing/coating |

Choosing Honyo for nickel plating on CNC machined components guarantees more than just a surface finish; it provides a validated engineering solution. Our process expertise, integrated manufacturing environment, and rigorous quality assurance protocols ensure your plated prototypes perform reliably in validation testing and transition smoothly into production. We partner with clients to select the optimal plating type and parameters, transforming raw machined parts into high-performance components ready for the most demanding applications. Trust Honyo Prototype to deliver nickel-plated excellence from concept to functional reality.

Technical Capabilities

Nickel Plating Service – Technical Capabilities

Shenzhen Honyo Prototype offers precision nickel plating services tailored for high-performance components produced through advanced CNC machining processes. Our integrated plating solutions enhance wear resistance, corrosion protection, and surface hardness while maintaining the dimensional accuracy and functional integrity of machined parts. Designed for applications in aerospace, automotive, medical, and industrial equipment sectors, our nickel plating is optimized for components manufactured via 3-, 4-, and 5-axis milling, as well as precision turning operations.

Our nickel plating process is applied post-machining to ensure compatibility with tight tolerance requirements and complex geometries. We utilize electroless and electrolytic nickel plating techniques, allowing for uniform deposition even on intricate features and internal surfaces. Electroless nickel (Ni-P) provides excellent thickness consistency and superior hardness (up to 70 HRC after heat treatment), making it ideal for components requiring dimensional stability and durability. Electrolytic nickel plating is employed when additional ductility or specific finish characteristics are needed.

All plating operations are conducted under strict process control, with pre-treatment stages including precision cleaning, acid activation, and surface conditioning to ensure optimal adhesion. Post-plating inspection includes thickness verification via X-ray fluorescence (XRF) and cross-sectional analysis, as well as adhesion and porosity testing per ASTM B734 and ASTM B117 standards.

The following table outlines the key technical specifications for our nickel plating service, including compatible materials, achievable tolerances, and plating thickness ranges:

| Parameter | Specification |

|———|—————|

| Plating Type | Electroless Nickel (Ni-P), Electrolytic Nickel |

| Phosphorus Content (Electroless) | 6–9% (medium phosphorus), 10–12% (high phosphorus) |

| Plating Thickness Range | 5–75 µm (standard), up to 100 µm (build-up applications) |

| Surface Hardness (As-Plated) | 500–600 HV (electroless), 150–200 HV (electrolytic) |

| Hardness After Heat Treatment | Up to 1000 HV (electroless, 400°C for 1 hour) |

| Corrosion Resistance | >500 hours salt spray (ASTM B117) for 25 µm coating |

| Compatible Substrates | Aluminum (6061, 7075), Stainless Steel (303, 304, 17-4 PH), Steel Alloys (4140, 1018), Brass, Copper |

| Dimensional Impact | ±2–3 µm variation per surface (controlled process) |

| Typical Tolerance Maintenance | ±0.005 mm for features post-plating |

| Finishing Options | As-plated (semi-bright), Matte, or Post-Plate Polishing |

Our 5-axis milling and turning capabilities ensure that parts are machined to within ±0.002 mm before plating, allowing the final plated component to meet tight assembly and functional requirements. We routinely support IT Grade 6–7 tolerances on critical dimensions, with plating processes calibrated to minimize buildup on datum features and sealing surfaces.

Shenzhen Honyo Prototype combines precision CNC manufacturing with controlled surface finishing to deliver nickel-plated components that meet rigorous performance standards. Each project is supported by in-house engineering review to optimize plating sequence, fixturing, and masking of critical areas, ensuring functional reliability and repeatable quality.

From CAD to Part: The Process

Nickel Plating Service: Integrated CNC Machining Workflow

Shenzhen Honyo Prototype delivers precision nickel plating services engineered specifically for low-volume, high-integrity CNC machined components. Our process ensures optimal adhesion, uniform thickness, and superior corrosion/wear resistance critical for functional prototypes and bridge production parts. The workflow seamlessly integrates plating within the CNC machining lifecycle, starting from your CAD file through to final inspection.

AI-Powered Quoting & Feasibility Assessment

Upon receiving your CAD model (STEP, IGES, or native formats), our proprietary AI quoting engine performs an initial technical review. This system analyzes geometric features pertinent to successful plating, flagging potential issues such as sharp internal corners prone to burning, blind holes risking solution entrapment, or excessively thin walls susceptible to hydrogen embrittlement during plating. The AI cross-references your material specification (e.g., 303SS, 6061-T6, 1018 Steel) against known plating compatibility matrices. You receive a detailed quote within hours, including explicit notes on any geometry or material concerns requiring attention before proceeding, ensuring realistic expectations and avoiding downstream delays.

Engineering-Driven Design for Manufacturability (DFM)

Following quote acceptance, our manufacturing engineering team conducts a rigorous DFM review focused on plating integration. This is not a generic checklist but a material- and process-specific analysis. Engineers evaluate:

Critical dimensions requiring plating thickness allowance (typically +0.0002″ to +0.001″ per side)

Necessary masking requirements for non-plated features or tight tolerance zones

Risk assessment for hydrogen embrittlement on high-strength steels, mandating specified baking parameters

Optimal racking points to ensure electrical contact and minimize fixture marks

Surface finish requirements pre-plating (e.g., 32 Ra minimum) for adhesion

Client collaboration is essential at this stage; we provide specific, actionable recommendations to refine the design for plating success without compromising functional intent.

Controlled Production Execution

Approved designs move to production. CNC machining achieves the base geometry to tight tolerances, followed by meticulous pre-plate preparation:

1. Alkaline soak cleaning to remove oils and contaminants

2. Electrocleaning for active surface activation

3. Acid activation to ensure metallurgical readiness

The nickel plating process employs automated rectifiers for precise current density control within optimized Watts nickel baths. Real-time monitoring maintains bath chemistry (Ni²⁺ concentration, pH, temperature) within strict parameters. Post-plating, parts undergo thorough rinsing, optional passivation for stainless substrates, and mandatory hydrogen embrittlement relief baking for susceptible alloys per ASTM B850. Final inspection verifies all critical attributes against the agreed specification.

Critical Plating Specifications & Verification

| Parameter | Standard Range | Test Method | Acceptance Criteria |

| :—————– | :——————- | :—————- | :————————– |

| Nickel Thickness | 5 – 25 μm (0.0002″ – 0.001″) | XRF / Coulometric | Per print; Min 80% of spec |

| Adhesion | N/A | ASTM B571 Chisel | No peeling or blistering |

| Porosity | N/A | ASTM B735 Nitric | ≤ 5 pores/cm² (25μm min) |

| Salt Spray (Cu/Ni) | 96 – 500+ hours | ASTM B117 | White corrosion <5% area |

| Hydrogen Bake | 190 – 220°C | ASTM B850 | 3 – 24 hours per spec |

This integrated workflow, from AI-driven quoting through engineering-centric DFM to rigorously controlled plating execution, ensures Shenzhen Honyo Prototype delivers nickel-plated CNC components meeting the demanding performance requirements of advanced prototyping and low-volume production. Every step is documented and audited for traceability and consistent quality.

Start Your Project

Start Your Project with Precision Nickel Plating Services at Shenzhen Honyo Prototype

When it comes to high-performance, durable, and corrosion-resistant surface finishes in CNC machining, nickel plating stands out as a critical process for enhancing both the functional and aesthetic qualities of metal components. At Shenzhen Honyo Prototype, we specialize in providing precision nickel plating services tailored to meet the rigorous demands of industries such as aerospace, automotive, medical devices, and industrial equipment manufacturing. Whether you’re developing functional prototypes or scaling into low-volume production, our advanced plating solutions ensure your parts perform reliably under extreme conditions.

Nickel plating offers exceptional benefits including improved wear resistance, reduced friction, enhanced hardness, and superior protection against oxidation and chemical exposure. Our electroless and electrolytic nickel plating processes are engineered for uniform coating thickness, even on complex geometries produced through CNC machining. This ensures dimensional stability and consistent performance across every component in your assembly.

We understand that every project has unique requirements. That’s why our team evaluates substrate materials, part geometry, operating environments, and performance expectations to recommend the optimal nickel plating solution. From initial design consultation to final inspection, we maintain strict process controls and adhere to international quality standards to deliver repeatable, high-integrity finishes.

Our facility in Shenzhen is equipped with automated plating lines, environmental control systems, and in-house quality testing equipment, enabling us to maintain tight tolerances and rapid turnaround times. With decades of experience in precision manufacturing and surface engineering, we are committed to helping engineers and product designers achieve their technical goals without compromise.

To ensure your project starts on the right foot, we offer free technical consultations with our plating specialists. We review your CAD models, material selections, and functional requirements to provide actionable feedback and processing recommendations before production begins.

Below are the key specifications for our nickel plating services:

| Parameter | Specification |

|——————————|———————————————–|

| Plating Type | Electroless Nickel, Electrolytic Nickel |

| Nickel Thickness Range | 5–75 µm (standard), up to 100 µm (custom) |

| Substrate Materials | Steel, Stainless Steel, Aluminum, Copper Alloys |

| Phosphorus Content (EN) | 6–9% (medium phosphorus) |

| Hardness (as-plated) | 500–600 HV |

| Post-Plate Heat Treatment | Available (up to 700 HV) |

| Corrosion Resistance | ASTM B117 Salt Spray Tested (500+ hours) |

| Surface Finish (Ra) | As-machined to 0.1 µm (polished options) |

| Lead Time | 3–7 days (depending on volume and complexity) |

Starting your project with Honyo Prototype means partnering with a team that values precision, reliability, and technical excellence. If you’re ready to move forward or have questions about how nickel plating can enhance your CNC-machined components, contact Susan Leo directly at info@hy-proto.com. We respond to all inquiries within 12 hours and provide detailed quotes with process recommendations tailored to your application. Let us help you transform your designs into high-performance, production-ready parts—efficiently and with confidence.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.